Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

A technology for desulfurization wastewater and agglomeration agent, which is applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of complex desulfurization wastewater treatment technology system and high cost, and achieves reduction of secondary dust, economical price, and reduced water consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

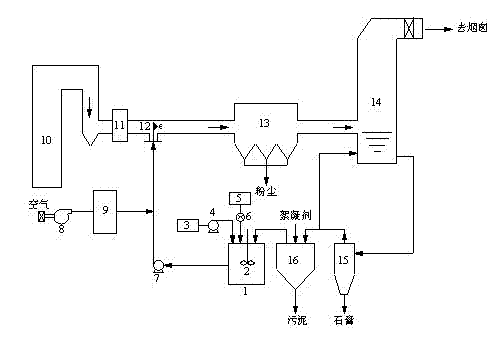

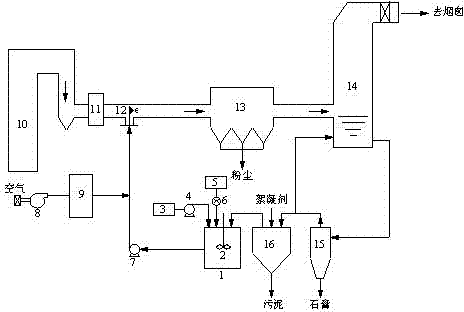

Image

Examples

Embodiment 1

[0034] The flue gas is produced by a fully automatic coal-fired boiler with a flue gas volume of 150Nm 3 / h, using limestone / gypsum wet flue gas desulfurization process; the mass percentage of agglomerating agent solution is composed of: 0.05% polyferric sulfate, 0.005% polyether modified silicone, and the rest is from the temperature of the desulfurization test system at about 45 °C Desulfurization wastewater. Spray agglomerating agent droplets with a temperature of 45°C and a particle size of about 40-50 microns into the flue between the coal-fired boiler and the wet desulfurization tower through a two-fluid atomizing nozzle, and the injection volume is 0.01kg / Nm 3 For the flue gas, the agglomerating agent accounts for about 0.25% of the dust mass, the temperature of the flue gas at the injection point is about 131°C, and the residence time is about 1.0s. Under the action of high-temperature flue gas, the droplets of agglomerating agent evaporate rapidly and interact with f...

Embodiment 2

[0036] The composition of the agglomerating agent solution is: 0.025% sodium carboxymethyl cellulose, 0.005% ethoxylated polydimethylsiloxane, and the rest is desulfurization wastewater; the injection amount of the agglomerating agent solution is 0.01kg / Nm 3 For the flue gas, the agglomerating agent accounts for about 0.125% of the dust mass, and the temperature of the flue gas at the injection point is about 128°C; the rest are the same as in Example 1. As measured by the Vaisala-HMT337 temperature and humidity transmitter, the moisture content of the flue gas at the entrance of the desulfurization tower increased from 6.90% to 10.45%, the temperature of the flue gas dropped to 116°C, and the desulfurization wastewater could be completely evaporated before entering the desulfurization tower. After the online test of the electric low-pressure impactor ELPI, after adding the agglomerating agent, the PM at the inlet of the desulfurization tower 2.5 The number concentration was r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com