Wastewater zero discharge treatment device

A treatment device and zero-discharge technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dispersed particle separation, etc. Low transportation rate and other issues, to achieve the effect of controlling pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

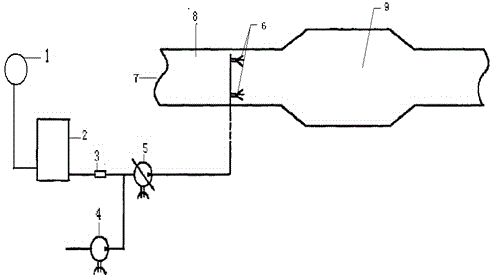

[0010] A waste water zero-discharge treatment device is characterized in that it includes a logic control system, a desulfurization tower 1, a pre-sedimentation tank 2, a filter 3, a clean water pump 4, a high-pressure pump 5, an air preheater 7, a flue 8, a nozzle 6 and Dust collector 9; the logic control system includes a waste water pipeline system, an air pipeline system and a clear water pipeline system; the nozzle 6 adopts a two-fluid nozzle to achieve a fine atomization effect, and the maximum particle diameter is below 100un, while The average particle size of atomized particles is only 42um.

[0011] The present invention is further described below in conjunction with specific embodiment, but not as limiting the present invention:

[0012] The technological process of the desulfurization wastewater integrated treatment system (such as figure 1 )as follows:

[0013] ①. After the desulfurization wastewater passes through the pre-sedimentation tank 2 for preliminary so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com