Roller device comprising temperature sensor for sensing temperature of packaging material

一种传感器装置、温度传感器的技术,应用在包装材料进料装置、测量装置、感测移动物体的辐射等方向,能够解决直接接触不总是适当、损坏传感器、短寿命等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

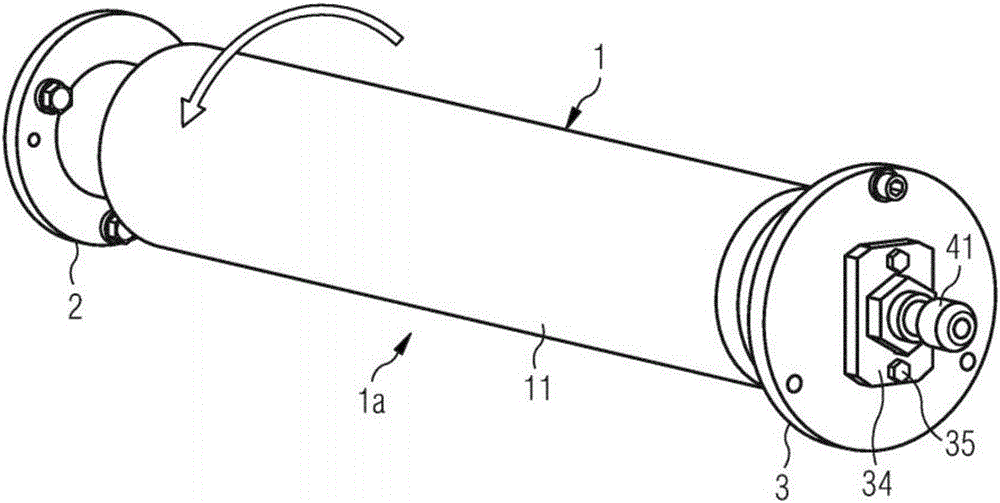

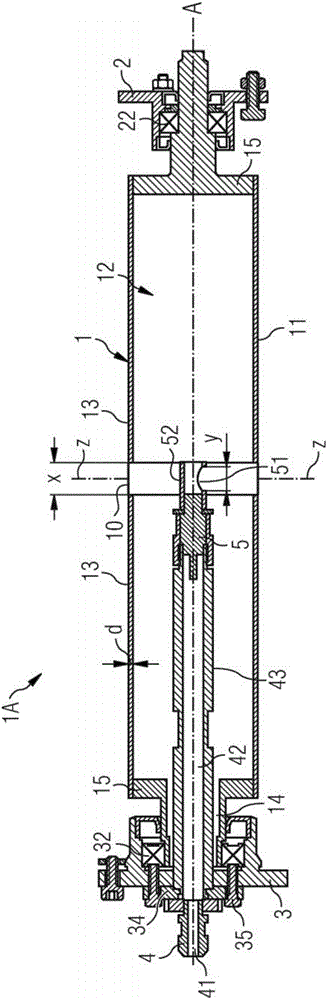

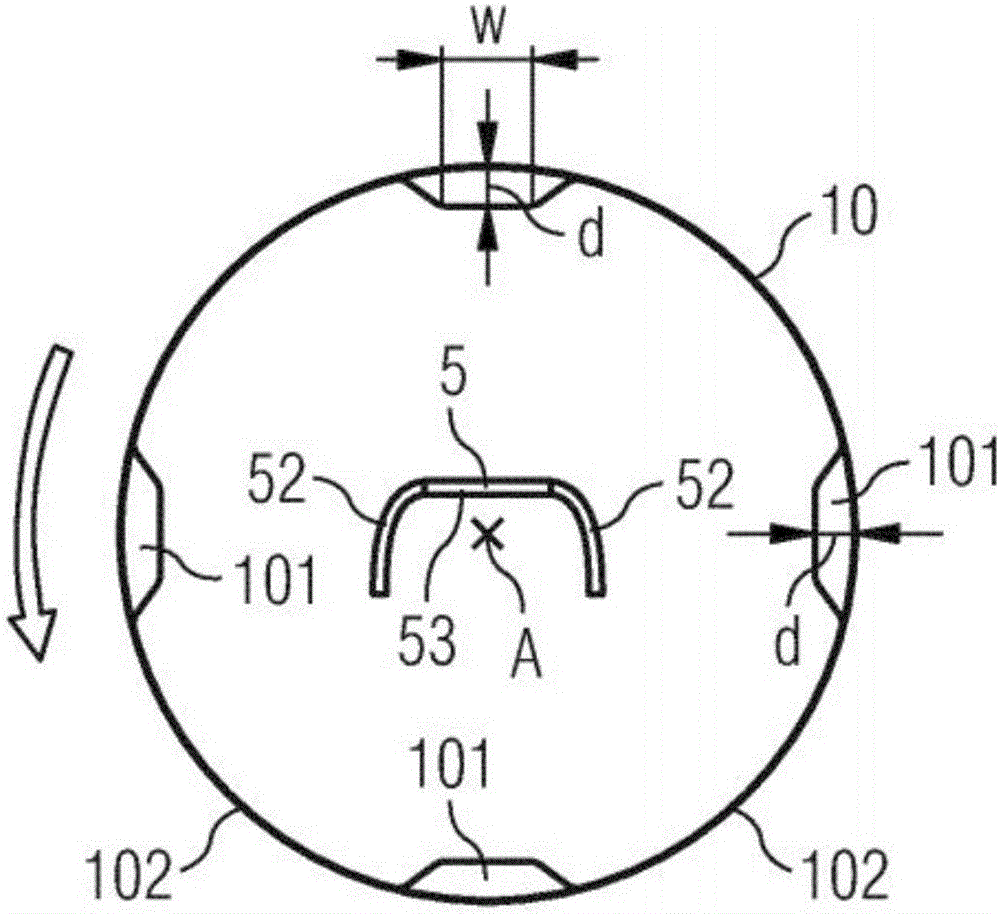

[0035] Figure 4 A filling machine for filling consumable liquids into cardboard based packages is schematically shown. The term paperboard based package includes packages of any shape and size having at least one fiber, pulp, paper or cardboard layer arranged between laminated layers. Packaging material can be supplied in rolls or in blank form.

[0036] The filling machine comprises a packaging material cassette 6 for feeding packaging material 6A to a filling station 8 in the filling machine. A filling station 8 is arranged after the sterilization device 7 to sterilize the packaging material before it is filled with liquid.

[0037] Exemplary sterilization devices contain a bath of hydrogen peroxide solution or a gas-filled space of hydrogen peroxide. The packaging material to be sterilized is conveyed / moved through the bath or the gas-filled space within the device 7, respectively. The hydrogen peroxide kills all microorganisms and bacteria on the material, thereby ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com