Energy-saving and environmental-protecting type air suction tube assembly of split type refrigeration evaporator

A refrigeration evaporator, energy saving and environmental protection technology, applied in refrigeration components, evaporators/condensers, coolers, etc., can solve the problem of low refrigeration heat exchange efficiency of refrigerators, reduced compressor work efficiency, increased compressor work load, etc. problems, to achieve excellent anti-hygroscopicity, reduce noise, improve the effect of cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

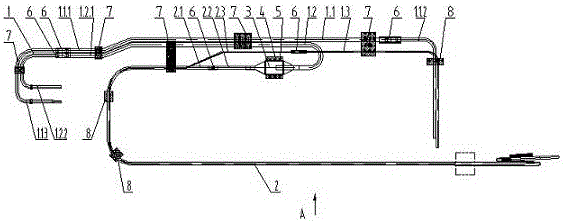

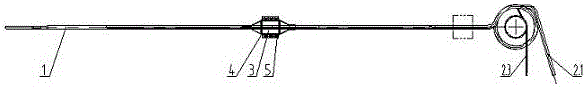

[0019] The suction pipe assembly of the energy-saving and environment-friendly split refrigerated evaporator shown in the attached figure includes suction pipe part 1, return air pipe part 2, liquid reservoir 3, damping block I4, polypropylene plate 5, damping block II6, double-hole partition Block 7, sponge 8; suction pipe part 1 includes suction pipe Ⅰ1.1, suction pipe Ⅱ1.2, transition pipe 1.3; suction pipe Ⅰ1.1 includes aluminum connection pipe Ⅰ1.1.1, respectively fixed and sealed connection aluminum connection pipe Ⅰ1 .1.1 Copper joints I1.1.2 and copper joints II1.1.3 at both ends; suction pipe II1.2 includes aluminum joint II1.2.1, copper joint III1.2.2 fixed and sealed with one end of aluminum joint II1.2.1; aluminum joint II1. The other end of 2.1 is connected to the liquid accumulation device 3; the air return pipe part 2 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com