Top rolling stopping support structure for B-type independent liquid cargo tank

A liquid cargo tank and support structure technology, applied in the field of ship construction, can solve the problems of large force on the anti-roll support structure, hidden danger of ship safety, LNG leakage, etc., and achieve the effect of ensuring thermal insulation effect, reducing installation difficulty and avoiding cold leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below in conjunction with specific embodiments:

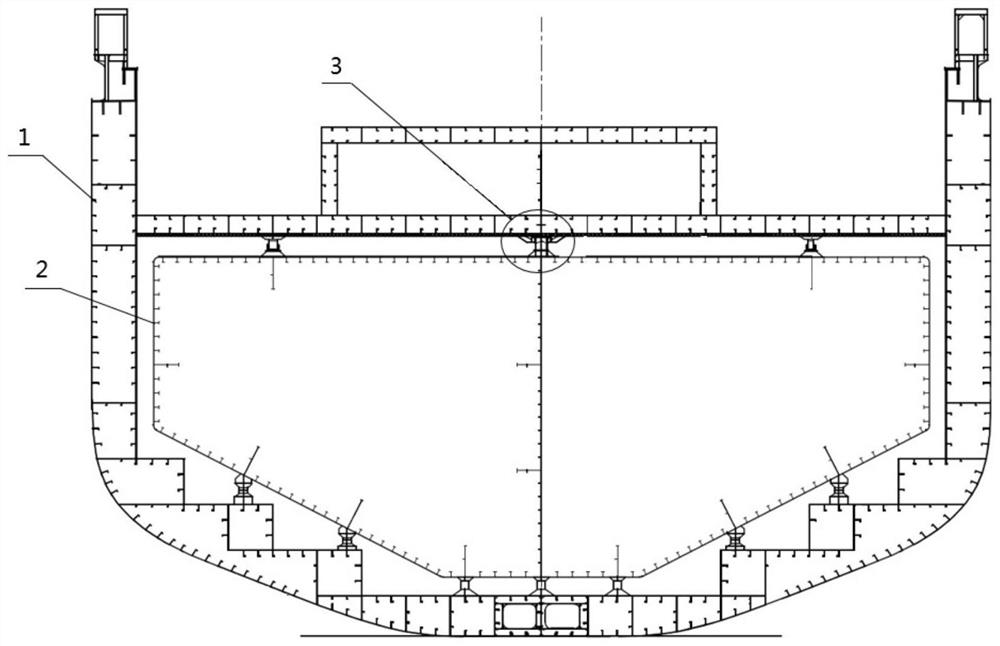

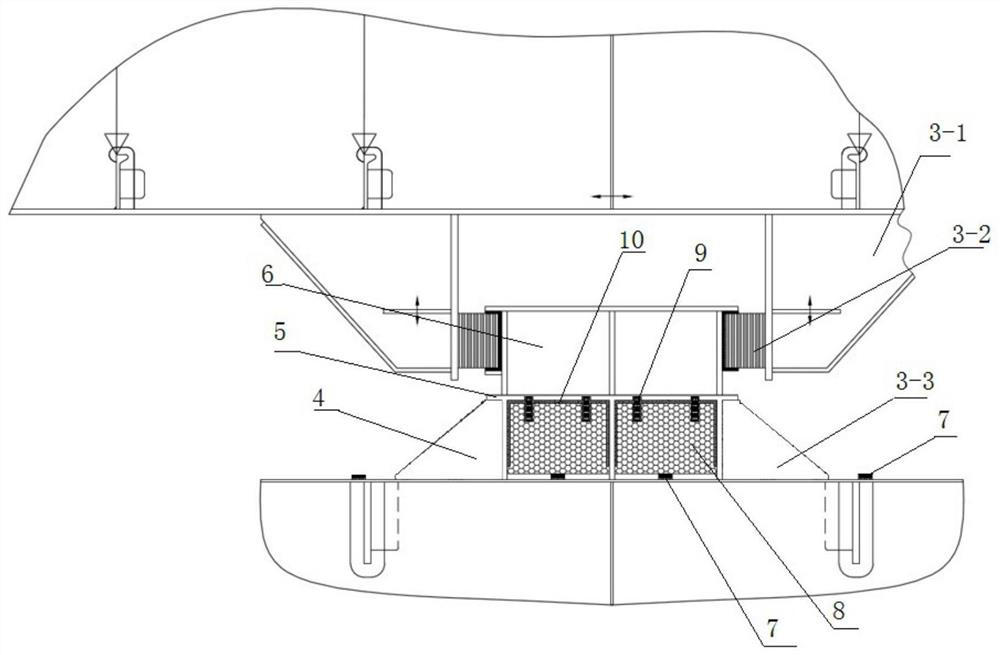

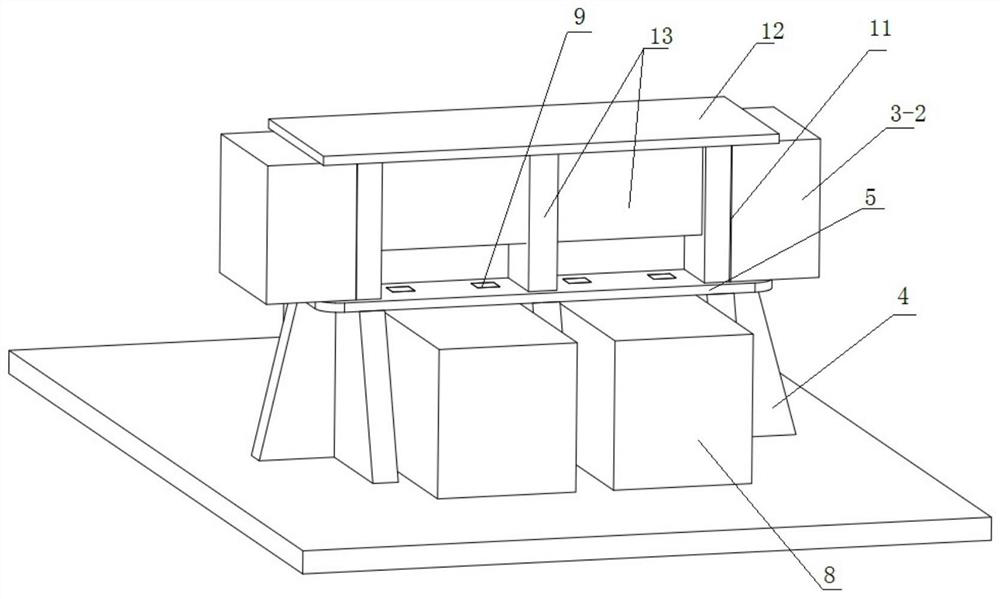

[0024] A top anti-roll support structure for Type B independent liquid cargo tanks, such as Figure 1-4 As shown, on a container ship, the anti-roll support 3 at the top of the Type B tank is installed at the middle position on the top of the Type B independent liquid cargo tank 2 to limit the lateral displacement of the Type B independent liquid cargo tank 2 . The anti-rolling support 3 on the top of the B-type tank includes the upper hull anti-rolling support 3-1, laminated wood 3-2, the lower liquid cargo tank anti-rolling support 3-3, and the lower liquid cargo tank anti-rolling support 3 -3 is installed on the top of Type B independent liquid cargo tank 2, laminated wood 3-2 is fixed on both sides of the anti-rolling support 3-3 of the lower liquid cargo tank near the upper end, and the upper hull anti-rolling support 3-1 is clamped The two sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com