Method for regulating and controlling temperature of outlet of evaporator of ORC system

An evaporator outlet and evaporator technology, which is applied in the field of ORC systems, can solve problems such as unstable low-temperature waste heat resources, power generation efficiency needs to be improved, and system operation is unstable, so as to improve energy utilization rate, small order, and small amount of calculation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

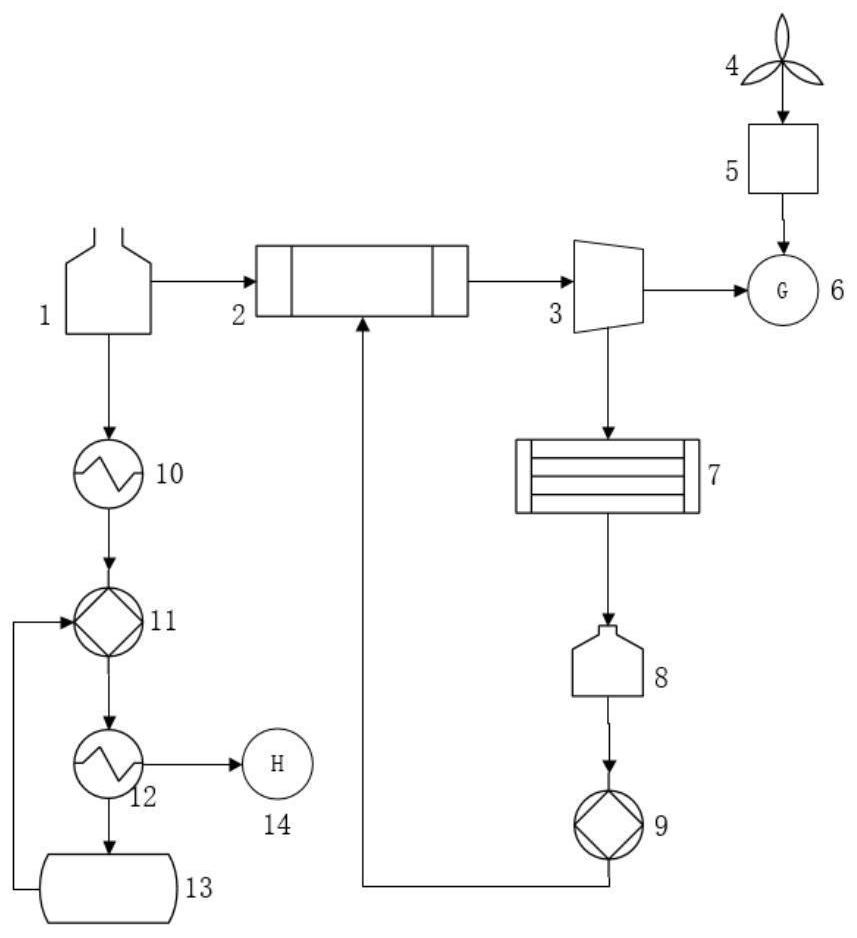

[0047] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

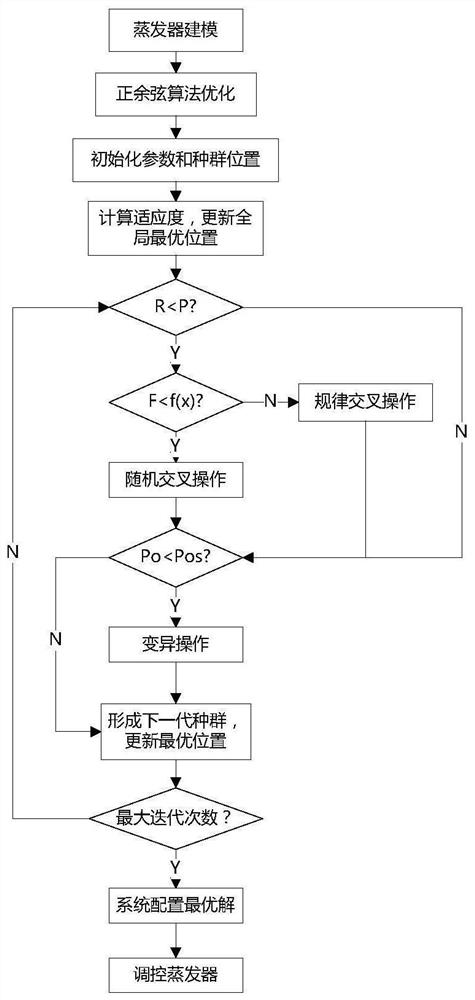

[0048] Such as figure 1 Shown, the regulation and control method of ORC system evaporator outlet temperature of the present invention comprises the following steps:

[0049] 1) The evaporator in the ORC system is modeled using the moving boundary method;

[0050] 2) according to the evaporator model obtained in step 1, utilize the sine-cosine algorithm to optimize the system configuration;

[0051] 3) Control the outlet temperature of the evaporator according to the optimized configuration results obtained in step 2.

[0052] Wherein, the process of evaporator modeling in step 1 includes the following steps:

[0053] 11) Divide the evaporator into a subcooling zone, a two-phase zone and a superheating zone, and use a nonlinear partial differential equation to describe the model according to the energy conservation and mass conservation theo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com