Emulsifying bacteria evaporation system

A technology of evaporation system and evaporation section, which is applied in the direction of evaporation, standpipe evaporator, evaporator accessories, etc., which can solve the problems of large particle size and insufficient bacterial control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

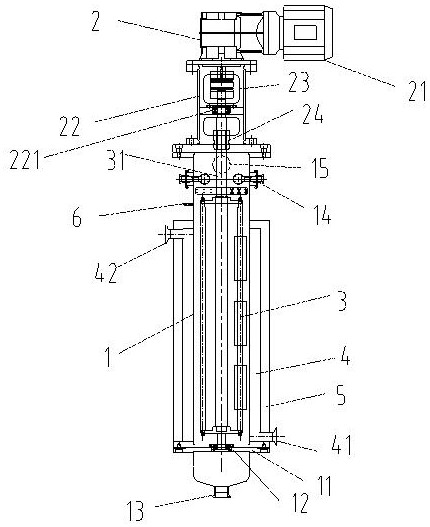

[0043] An emulsifying bacteria evaporation system, such as Figure 1-6 As shown, it includes the emulsification section, bacterial preparation section, evaporation section, quantitative transfer filtration section and storage section connected by pipelines.

[0044] Wherein, the emulsification section includes an aqueous phase tank 100 and an organic solvent tank 200, and the two are mixed in proportion to the emulsification tank 300; referring to a specific case, in this embodiment, the water phase and the organic phase can be mixed at a rate of 10:1.

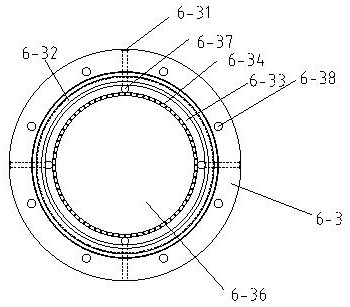

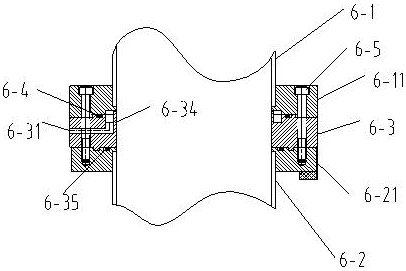

[0045] The homogeneous section is a cycle bacteria production section, including the parallel first bacteria tank 400 and the second bacteria tank 500, bacteria machine 600, bacteria machine 600 high-pressure micro-jet bacteria machine, bacteria process, emulsification tank The output of the bacteria enters the first bacteria tank, and then the bacteria machine reverses into the second bacteria tank and the first bacteria tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com