Patents

Literature

33results about How to "Continuous and even feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

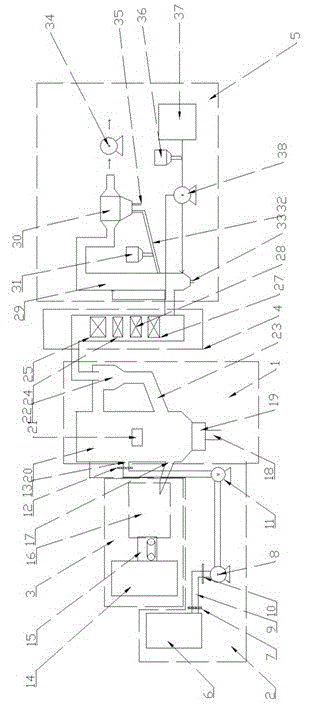

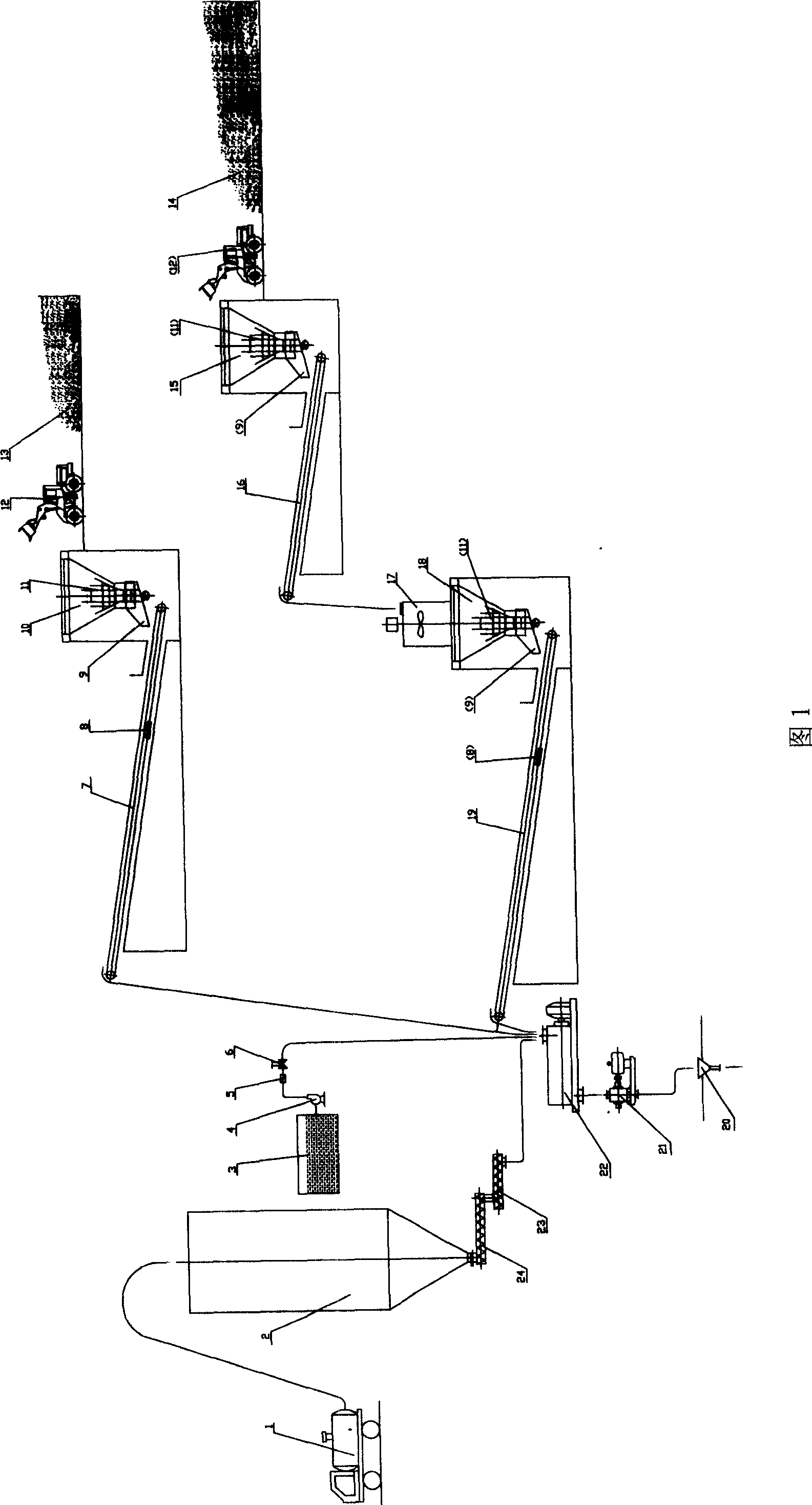

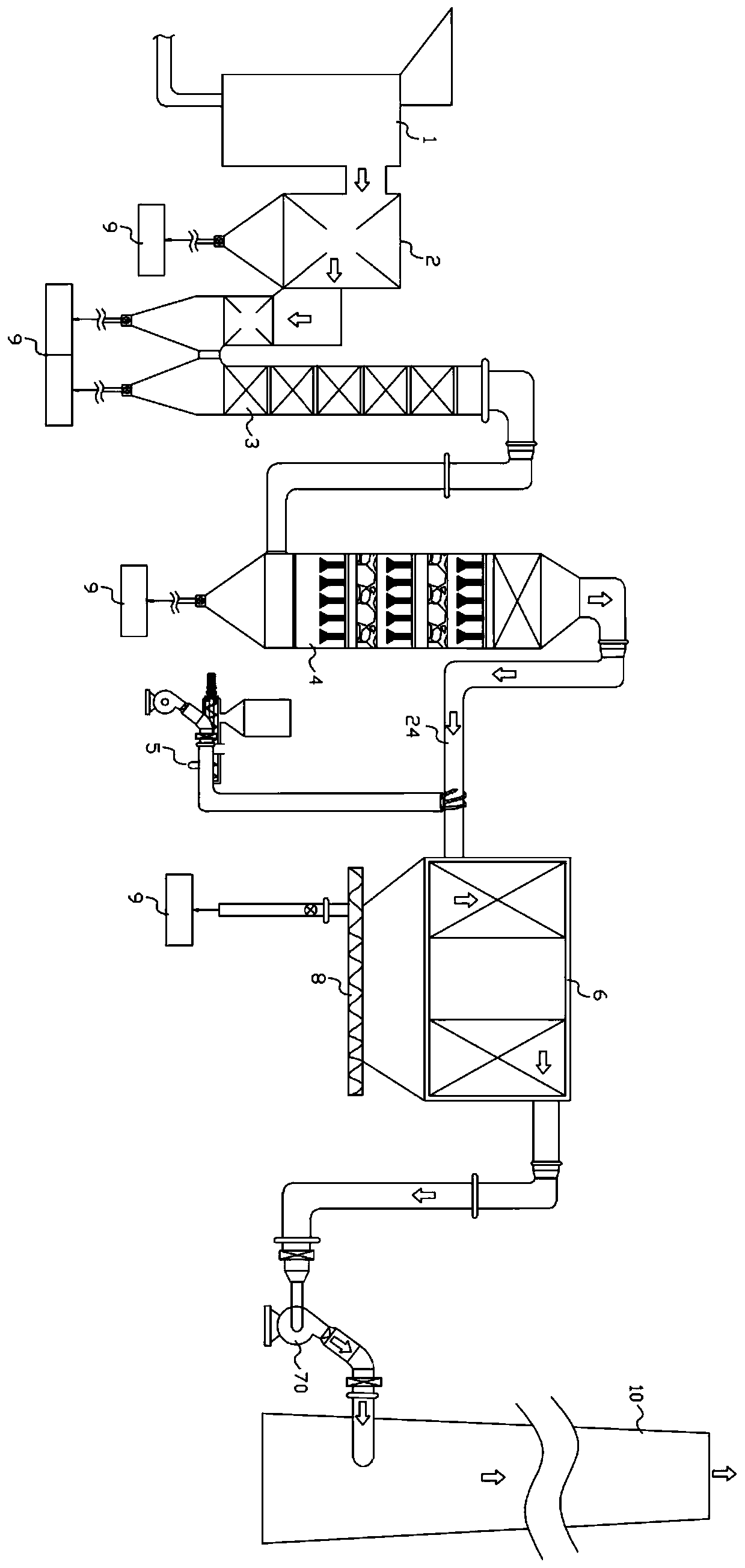

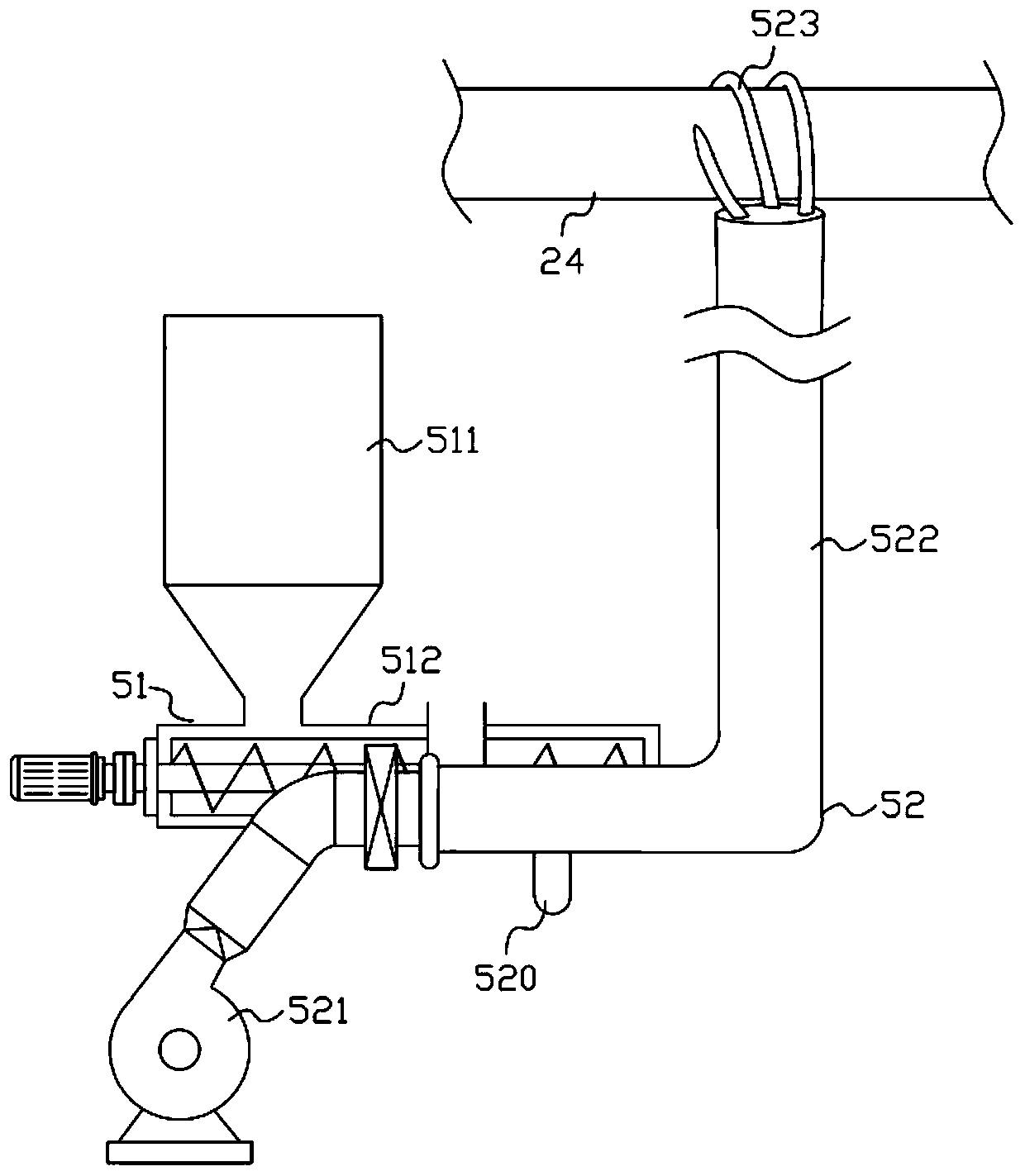

Incinerating system and method of disposing solid-liquid multi-phase hazardous waste mutually for fluidized bed

ActiveCN103175208AGuaranteed immediate incineration disposalEasy to adjust controlIncinerator apparatusFluidized bedResource utilization

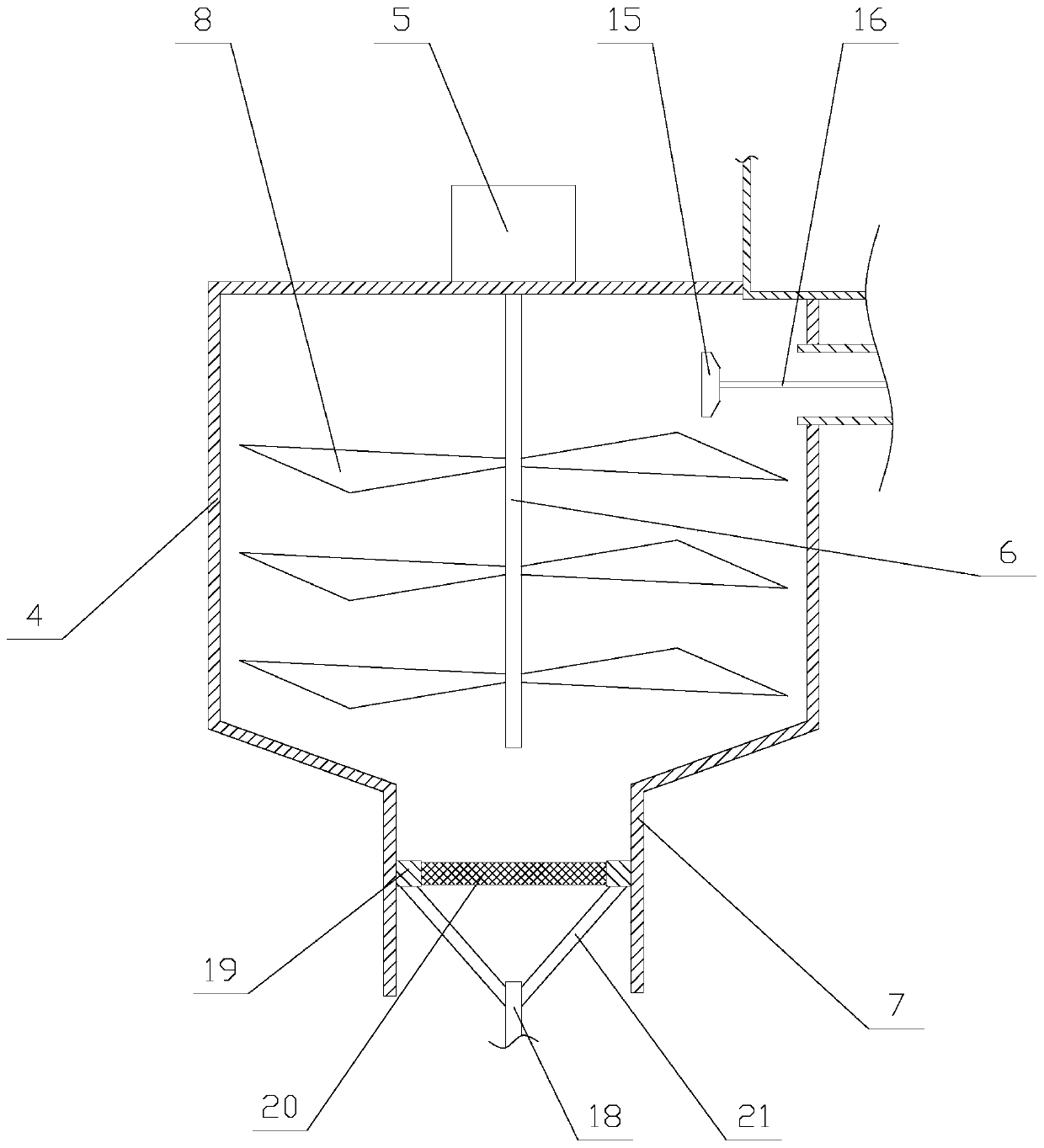

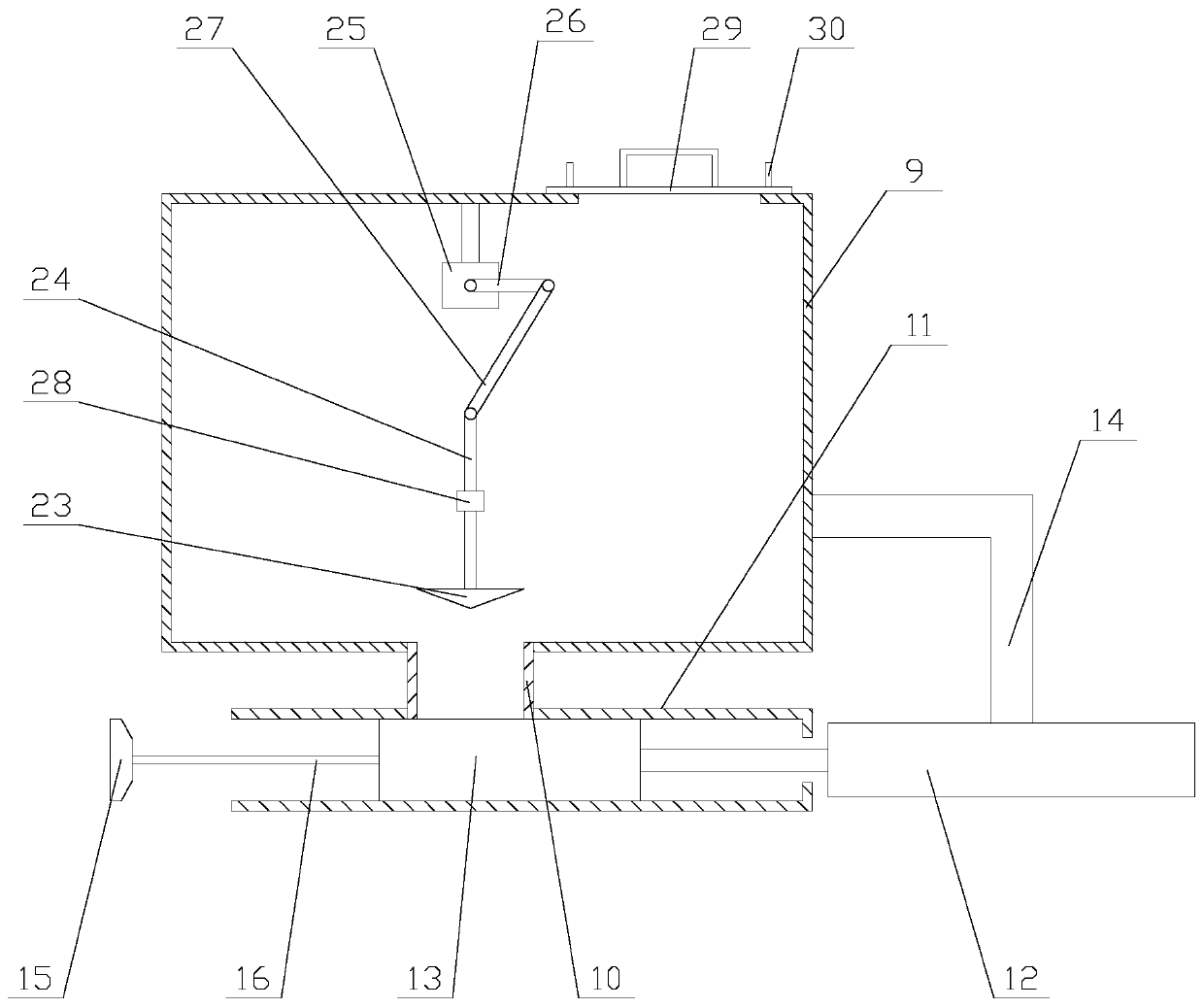

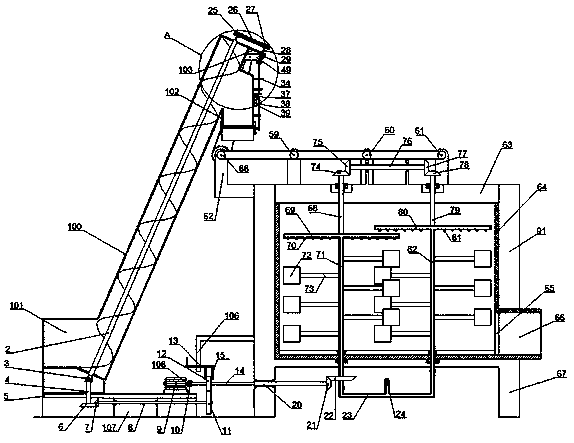

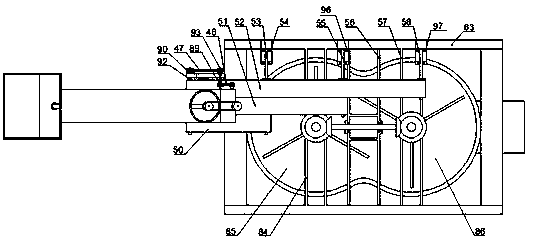

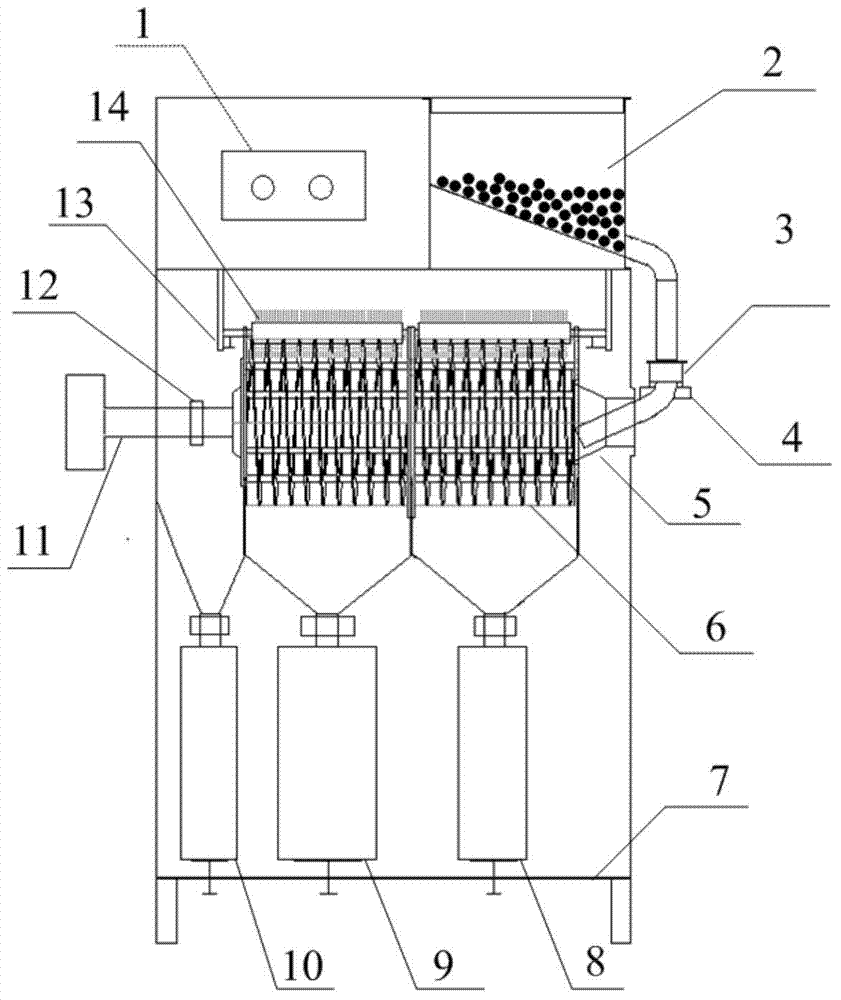

The invention discloses an incinerating system and method of disposing solid-liquid multi-phase hazardous waste mutually for a fluidized bed. The incinerating system comprises a fluidized bed incinerating device body, a liquid hazardous waste feeding system, a solid hazardous waste feeding system, a waste heat utilizing system and a tail gas treatment system. According to the incinerating system and method, solid-liquid multi-phase waste enters the fluidized bed incinerating device body respectively through the liquid hazardous waste feeding system and the solid hazardous waste feeding system to be incinerated, and waste heat utilization and clean gas clean-up processing are carried out on smoke through the waste heat utilizing system and the tail gas treatment system. The incinerating system and method are a whole system which composed of an incinerating device, waste heat utilization and tail gas processing, and are suitable to the reduction of multi-phase hazardous waste and resource utilization. Therefore, fluidized bed device incineration of different feed materials aiming at hazardous waste of different physical states is achieved, the technical problem that one feeding device carries out hazardous waste feeding material limitation of different states is solved, and meanwhile the resource reusing and the detoxifying treatment of the hazardous waste are achieved.

Owner:ZHEJIANG UNIV

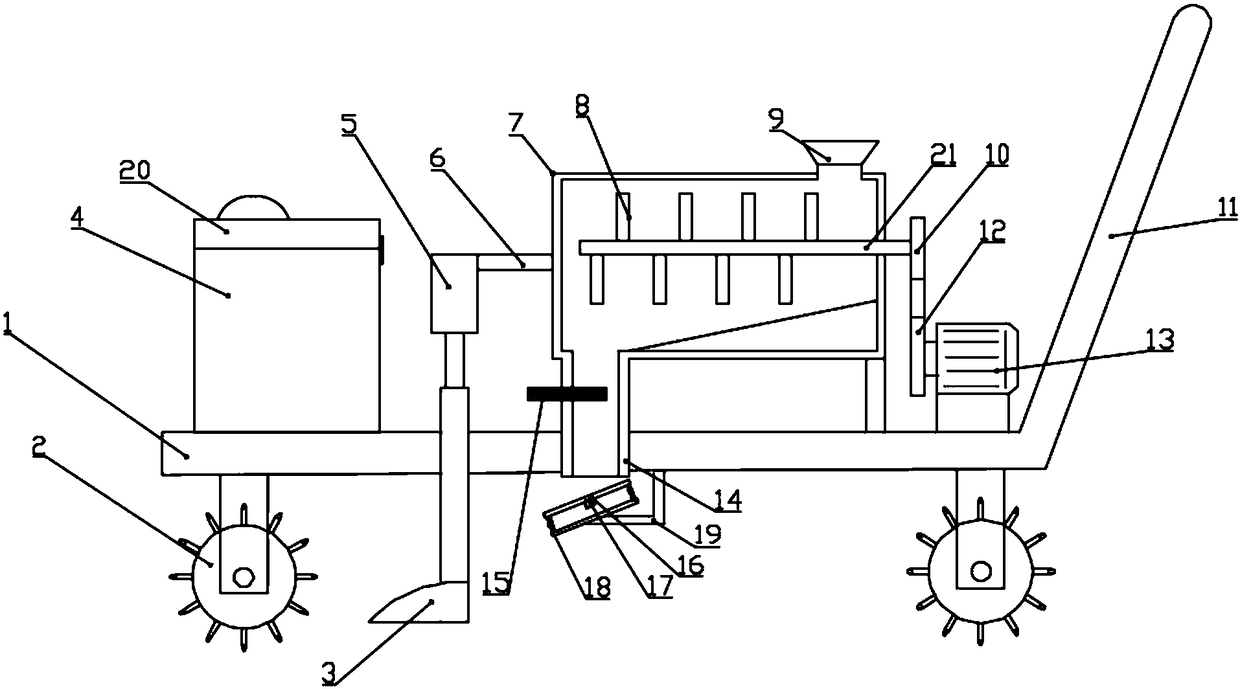

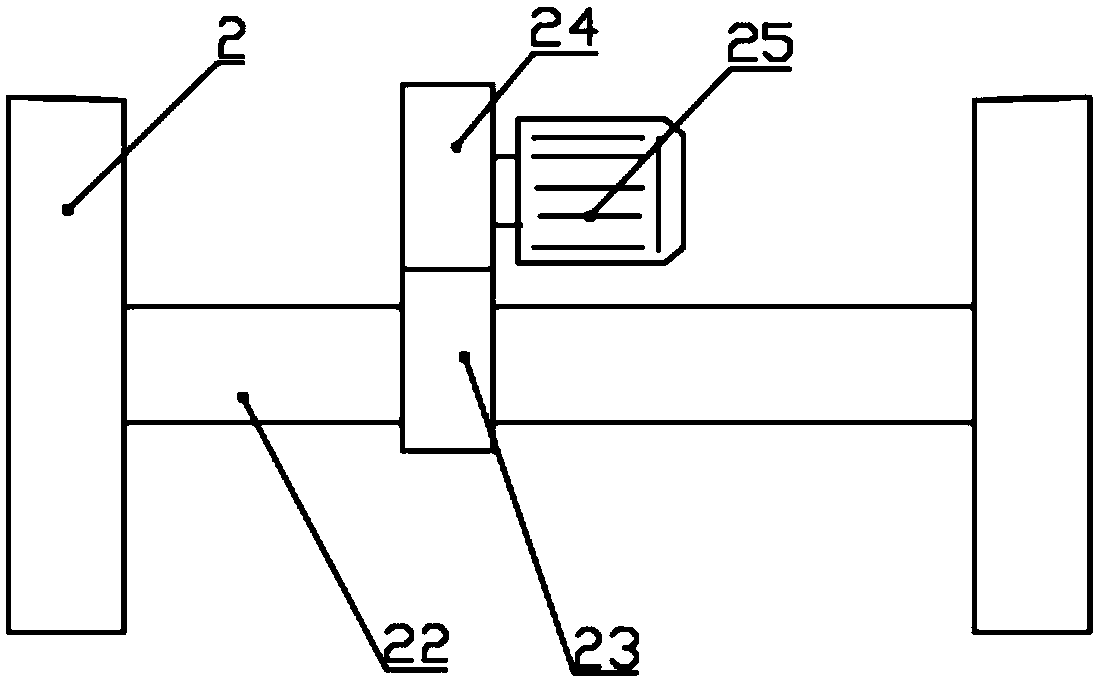

Uniform-feeding agricultural fertilizing apparatus

InactiveCN108307757AStir wellConvenient and even fertilizationPlantingFertiliser distributersAgricultural engineeringShovel

The invention discloses a uniform-feeding agricultural fertilizing apparatus. The apparatus comprises a mounting plate, road wheels are arranged at the bottom of the mounting plate, a tool box is arranged at the left side of the mounting plate, a soil turning shovel is arranged at the right end of the tool box, an adjusting device is arranged at the upper end of the soil turning shovel, the adjusting device is fixed to a stirring main body by a connecting rod, the stirring main body is arranged on the mounting plate, a first rotating shaft is arranged in the stirring main body, a first belt pulley is arranged at the right end of the first rotating shaft, the first belt pulley is connected with a second belt pulley through a belt, the second belt pulley is arranged at the output end of a rotating motor, the rotating motor is arranged on the mounting plate, the first rotating shaft is provided with stirring vanes, a discharge port is arranged at the left end of the bottom of the stirringmain body, and the vibration plate is arranged at the bottom of the discharge port. The uniform-feeding agricultural fertilizing apparatus has the advantages of simple structure, low labor intensity,simplicity in operation, good applicability, good fertilization effect and easiness in promotion.

Owner:鲁忠华

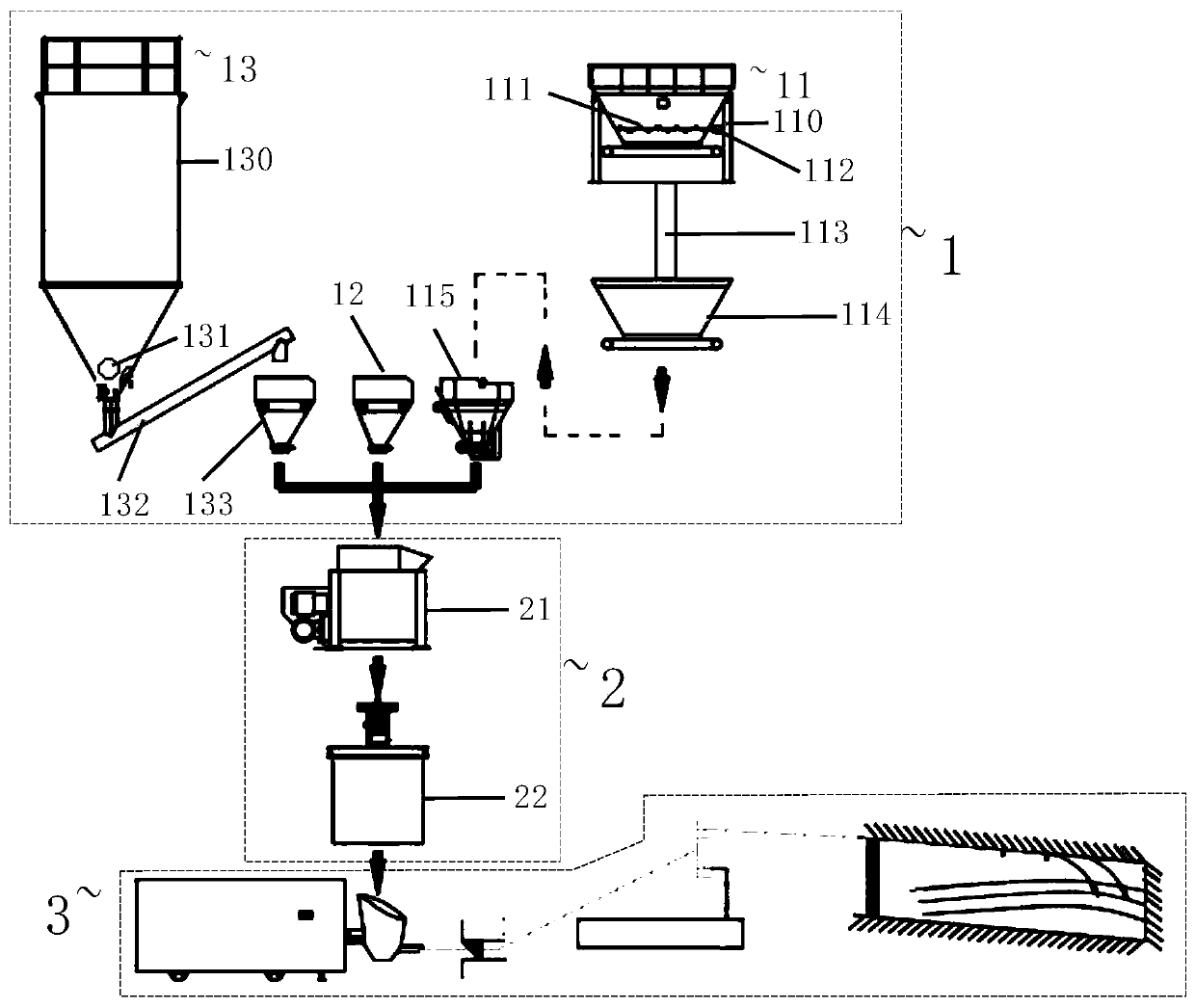

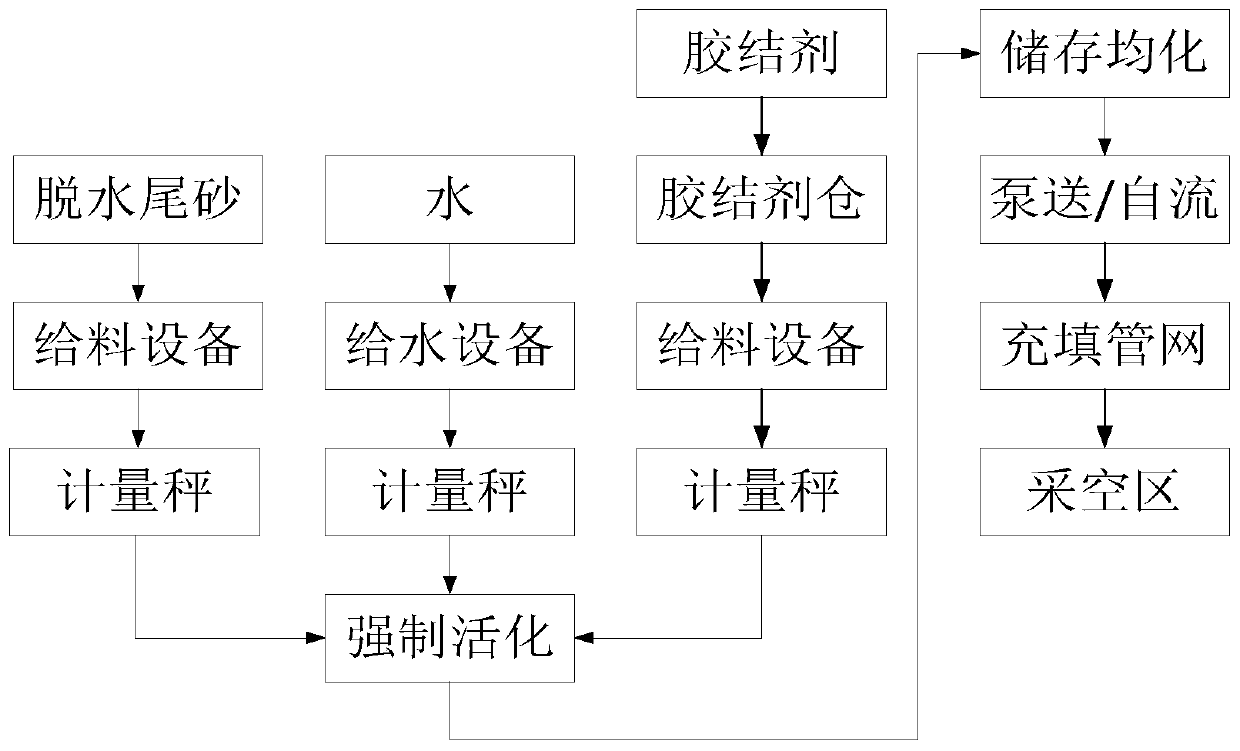

Dehydrated tailing precise blending and forced homogenizing preparation structural flow filling technology and filling system

PendingCN111322108AAccurately control the mix ratioControl quality costMaterial fill-upAutomatic controlControl system

The invention provides a dehydrated tailing precise blending and forced homogenizing preparation structural flow filling technology and filling system. The filling system is composed of a feeding andmetering subsystem, a stirring and preparing subsystem, a slurry conveying and filling subsystem and an automatic control system. The feeding and metering subsystem comprises a dehydrated tailing feeding and metering system, a concentrated water feeding and metering system and a cementing agent feeding and metering system. The filling technology realizes advanced material preparation, precise metering and forced activation cycle preparation and storing offset adjustment two-section stirring. The filling material ratio and filling slurry mass concentration can be accurately controlled, high-concentration homogeneous steady-state structural flow filling slurry is prepared, and the filling slurry preparation quality and filling cost are controlled. The technology and the system have strong adaptability to mining of unbalanced mines and can be used for mines with mechanically dehydrated tailing, tailing pond sand and the like as aggregates, the construction investment is saved, the periodis short, and the technology and the system are applicable to filling and station establishment of mines in various scales.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

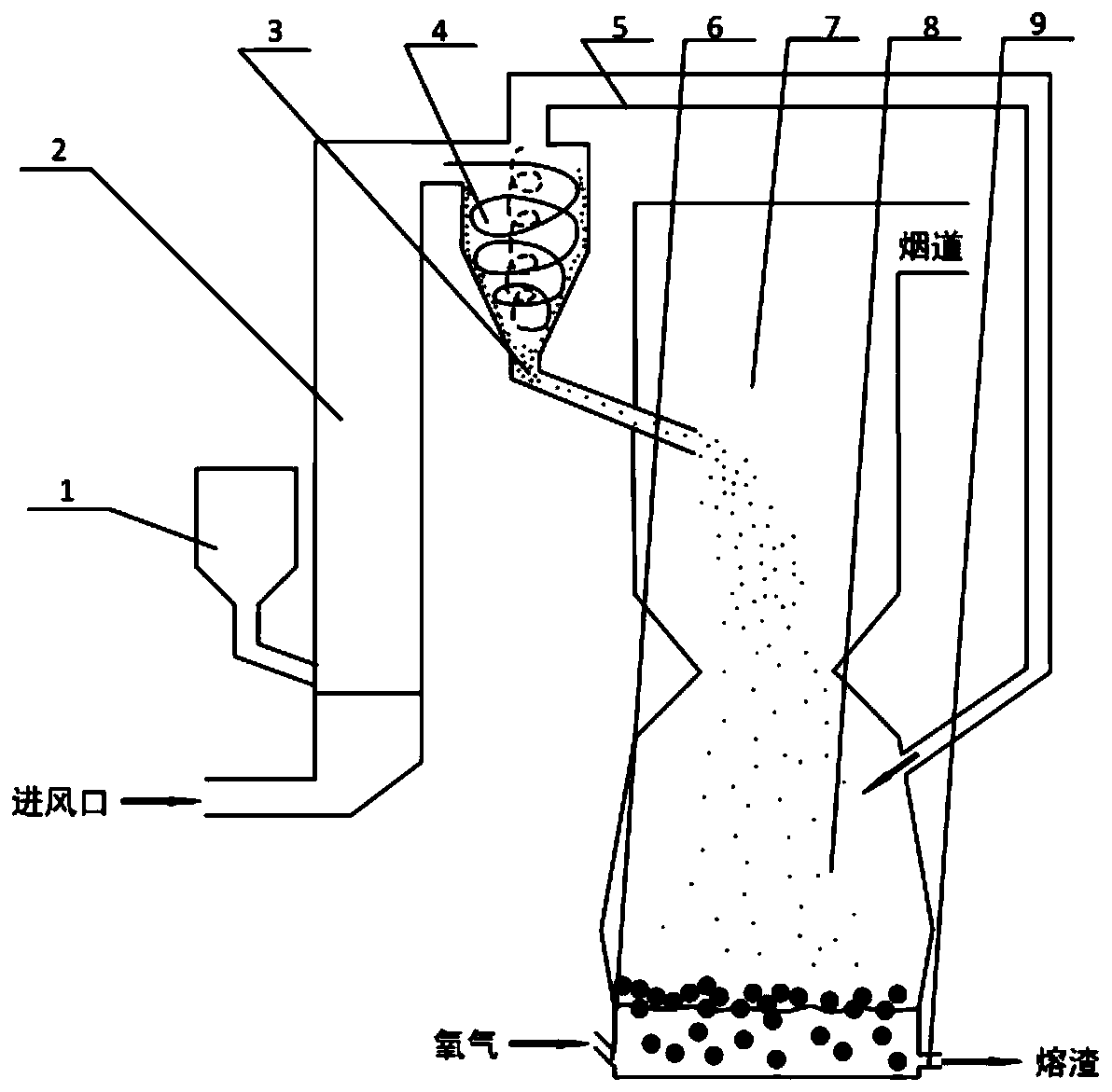

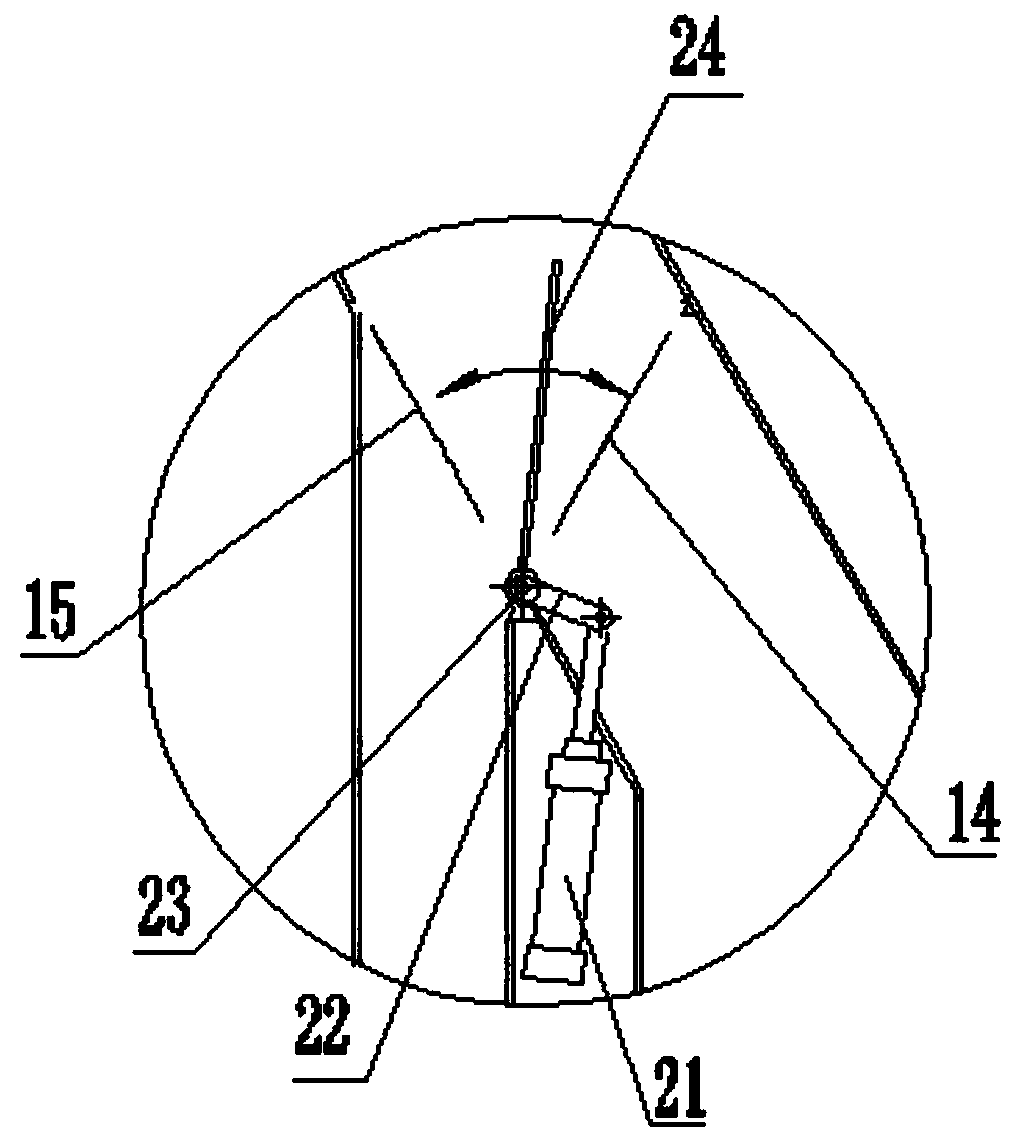

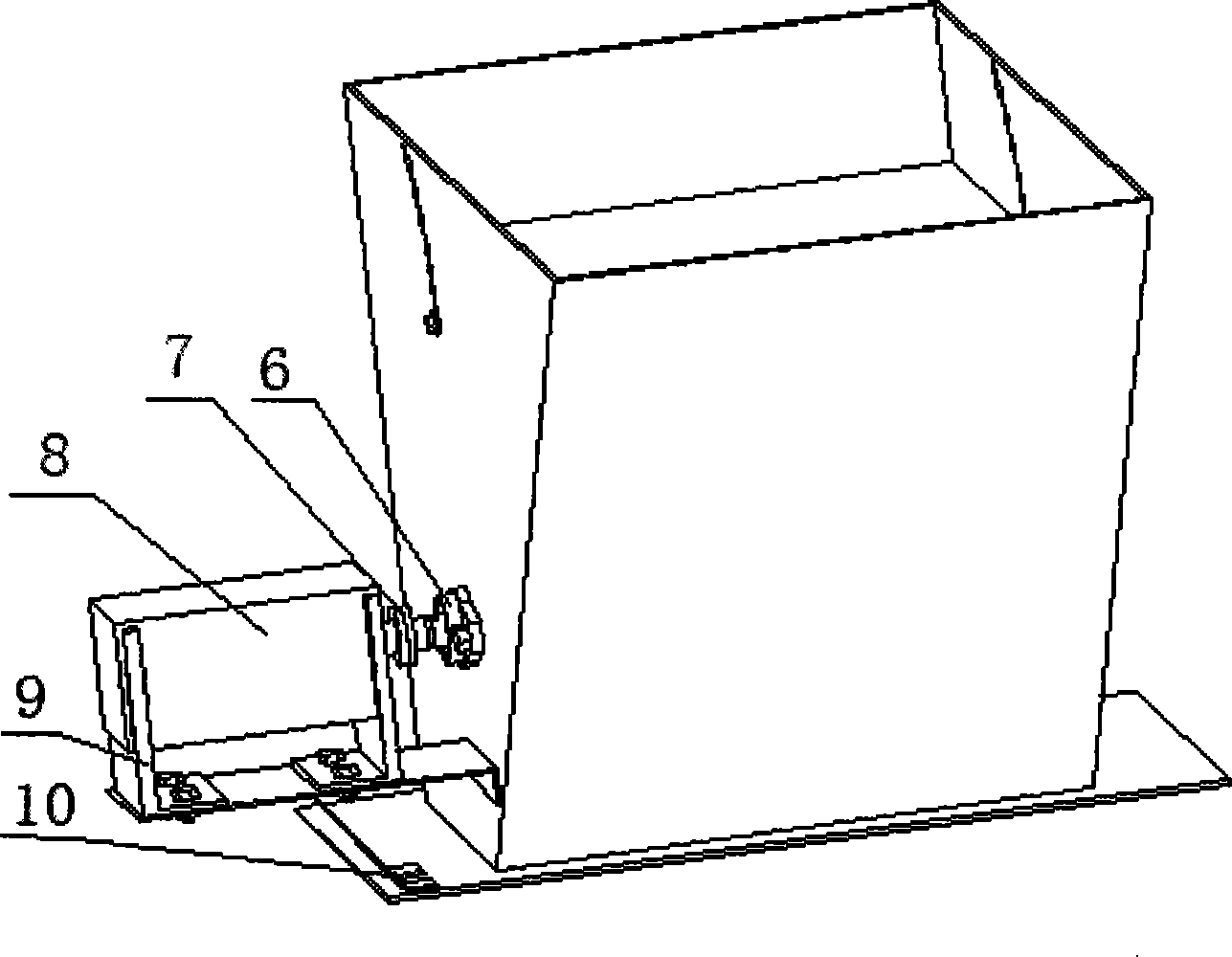

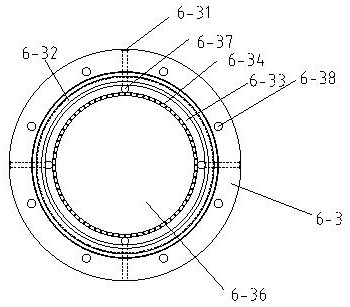

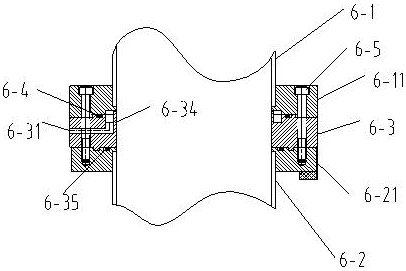

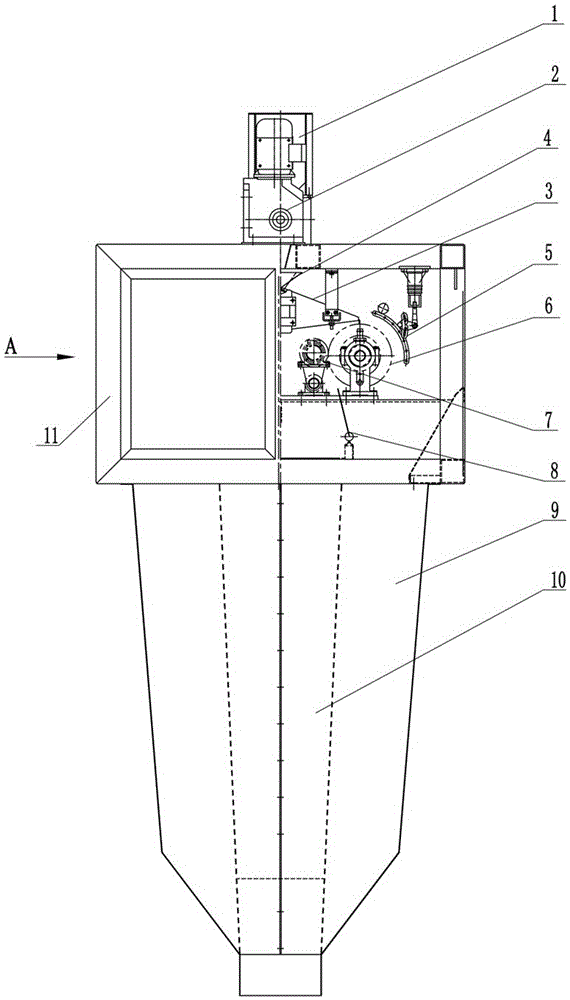

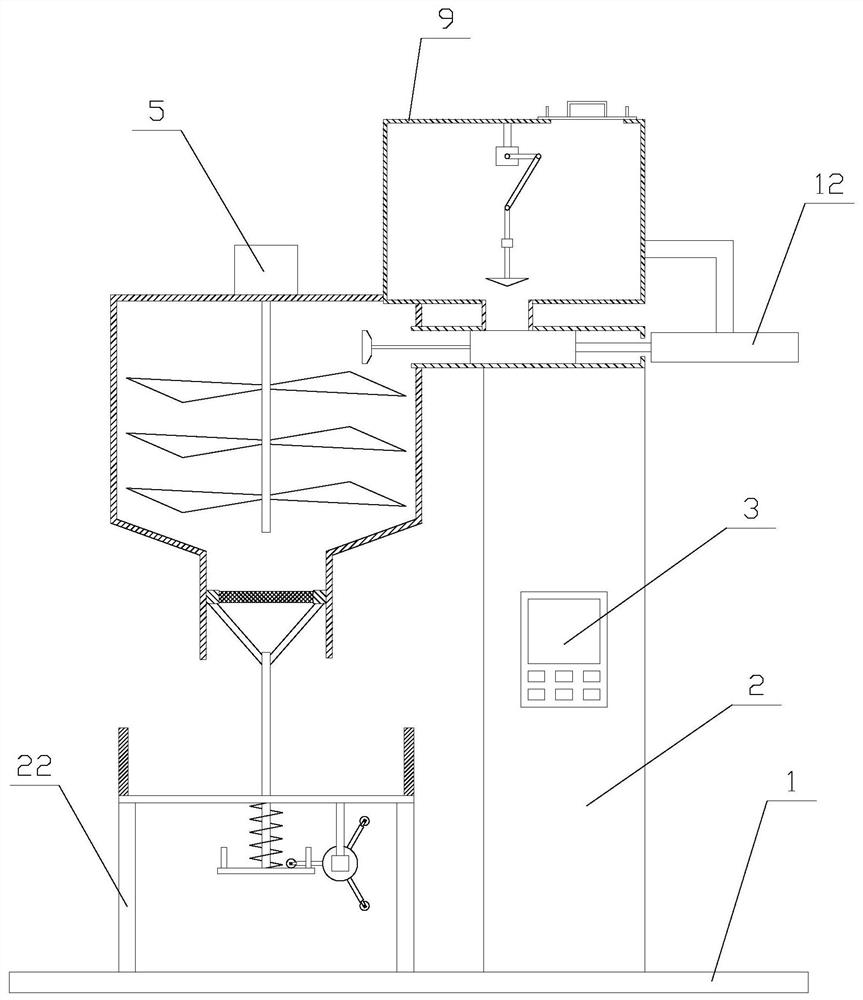

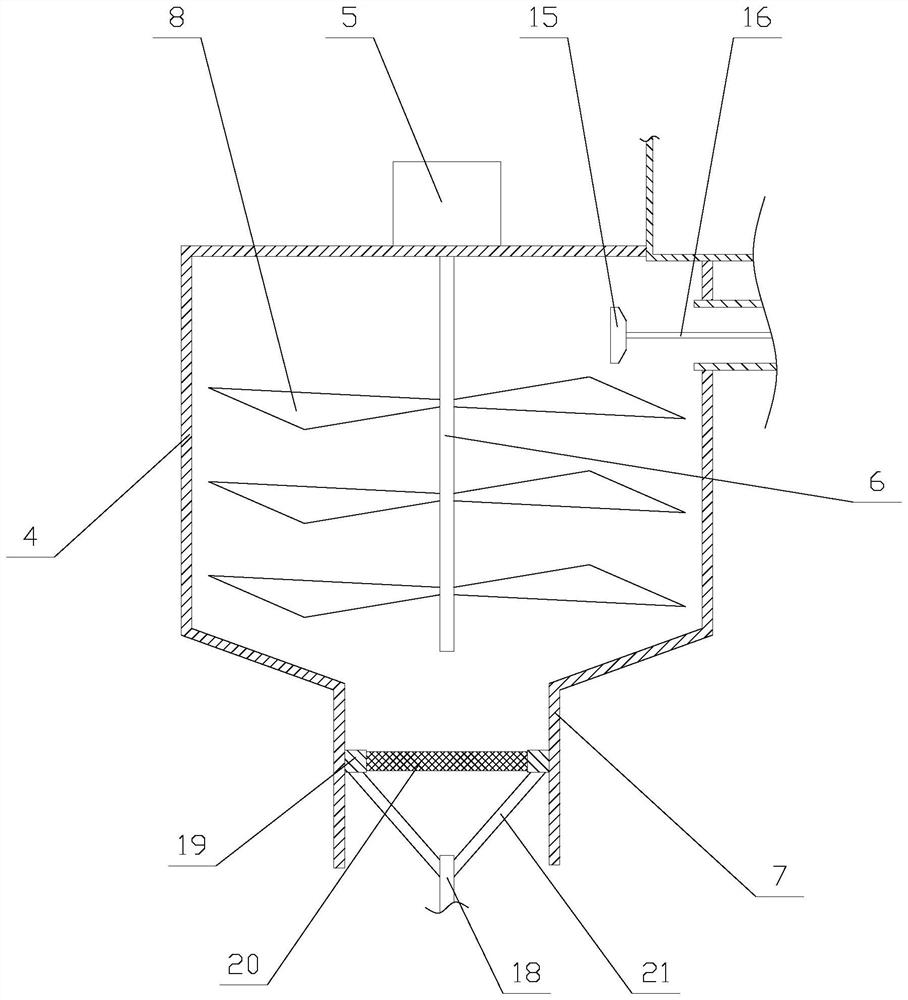

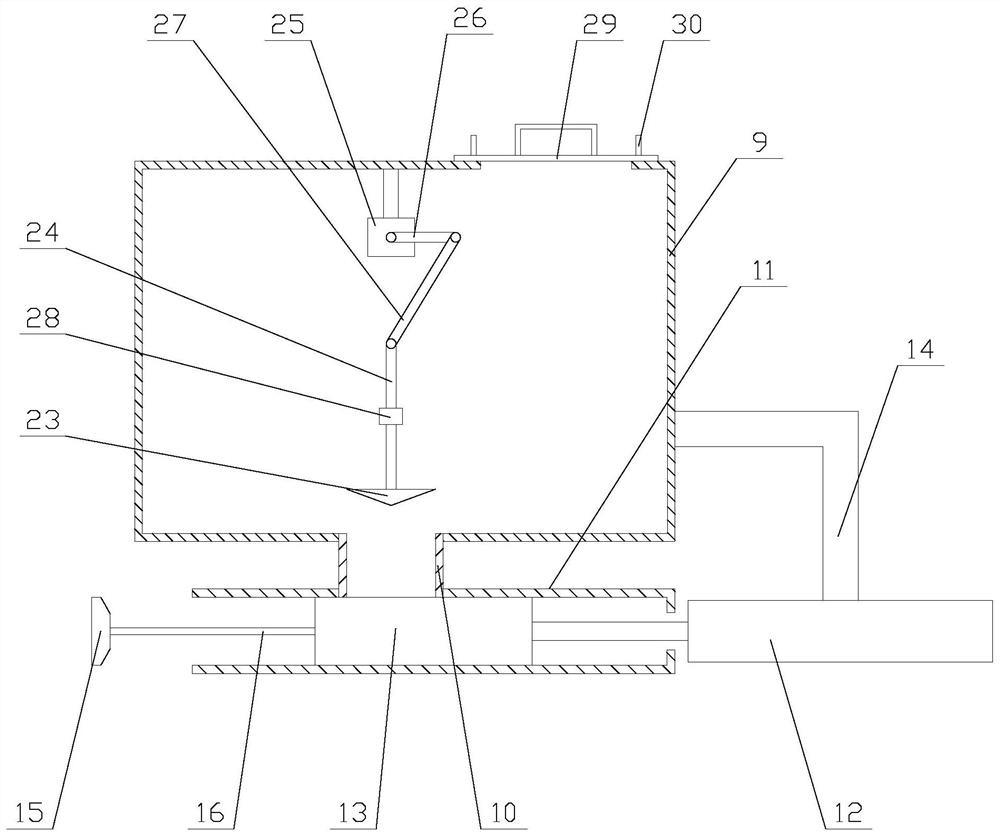

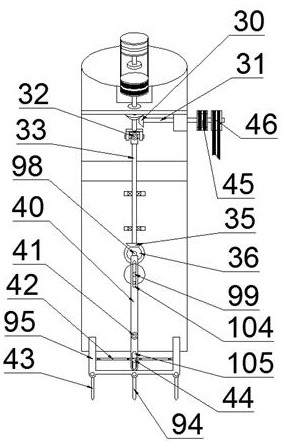

Uniform continuous feeding device for garbage incineration fly ash particles

ActiveCN110566977AFully burntConducive to stable operation at high temperatureIncinerator apparatusLitterFluidized bed

The invention provides a uniform continuous feeding device for garbage incineration fly ash particles. The uniform continuous feeding device comprises a fluidized bed feeder. The fluidized bed feederis provided with a wind inlet and a material storing bin. A tail outlet of the fluidized bed feeder is connected with an inlet of a cyclone material separator. The upper portion of the cyclone material separator is connected to the upper portion of a high-temperature melting furnace through a wind pipe. A solid particle collector is arranged on the bottom of the cyclone material separator. The solid particle collector is connected with a preheating furnace. The connecting position is arranged on the upper portion of the preheating furnace. The preheating furnace is located above the high-temperature melting furnace and communicates with the high-temperature melting furnace. An oxygen inlet and a molten slag outlet are formed in the bottom of the high-temperature melting furnace. Accordingto the uniform continuous feeding device, by means of the coordinative effect of the fluidized bed feeder and the cyclone material separator, continuous uniform feeding of materials is achieved.

Owner:XI AN JIAOTONG UNIV

Chopper mixer with uniform feeding for processing meat products

he invention relates to a chopper mixer with uniform feeding for processing meat products, which comprises a base, a controller, a feeding mechanism, a chopped mixing mechanism and a collecting mechanism, the chopped mixing mechanism comprises a chopped mixing box, a first motor, a rotating shaft, a discharging tube and a plurality of chopped mixing knives, and the feeding mechanism comprises a material box, a connecting tube, a feeding tube and a feeding assembly, the feeding assembly comprises a cylinder, a sealing block, a sealing plate and a connecting rod, and the collecting mechanism comprises a collecting table, a driving assembly, a vertical rod, a frame, a sieve mesh, a plurality of side bars and a plurality of legs. The chopper mixer realizes continuous and uniform feeding of theequipment through the feeding mechanism, and avoids over-loading operation due to excessive loading of the raw materials at one time. The collecting mechanism can drive the sieve mesh to move upwards, so that the sieve mesh pushes the larger-sized meat piece above the sieve mesh into the chopped mixing box and cuts the meat again until the meat is pulverized into pieces of meat that can pass through the sieve mesh, so that the chopped mixing effect is ensured, and the usability of the device is increased.

Owner:LIAOCHENG DONGDA FOOD

Concrete mixing device

ActiveCN110757649AContinuous and even deliveryServe evenlyRotary stirring mixersTransportation and packagingEngineeringStructural engineering

The invention discloses a concrete mixing device. The concrete mixing device includes a support casing, a mixing barrel arranged in the support casing, and a spiral feeding mechanism located on the left side of the support casing, a power mechanism is arranged between the support casing and the spiral feeding mechanisms, and the power mechanism controls the conveying work of the spiral feeding mechanism and the stirring work of a left hollow stirring shaft and a right hollow stirring shaft. According to the concrete mixing device, the left hollow stirring shaft and the right hollow stirring shaft are utilized to convey water, then the water is added through a water spraying method with the layout of a first water outlet and a second water outlet, and thus stirring is more uniform.

Owner:宜昌力华新型建材有限公司

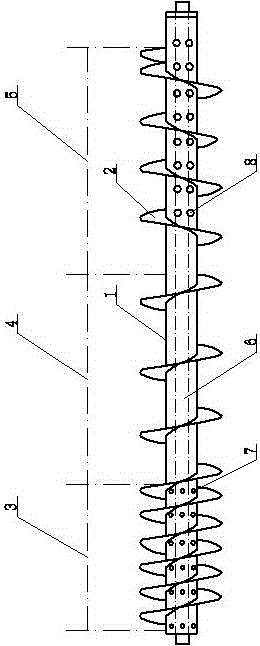

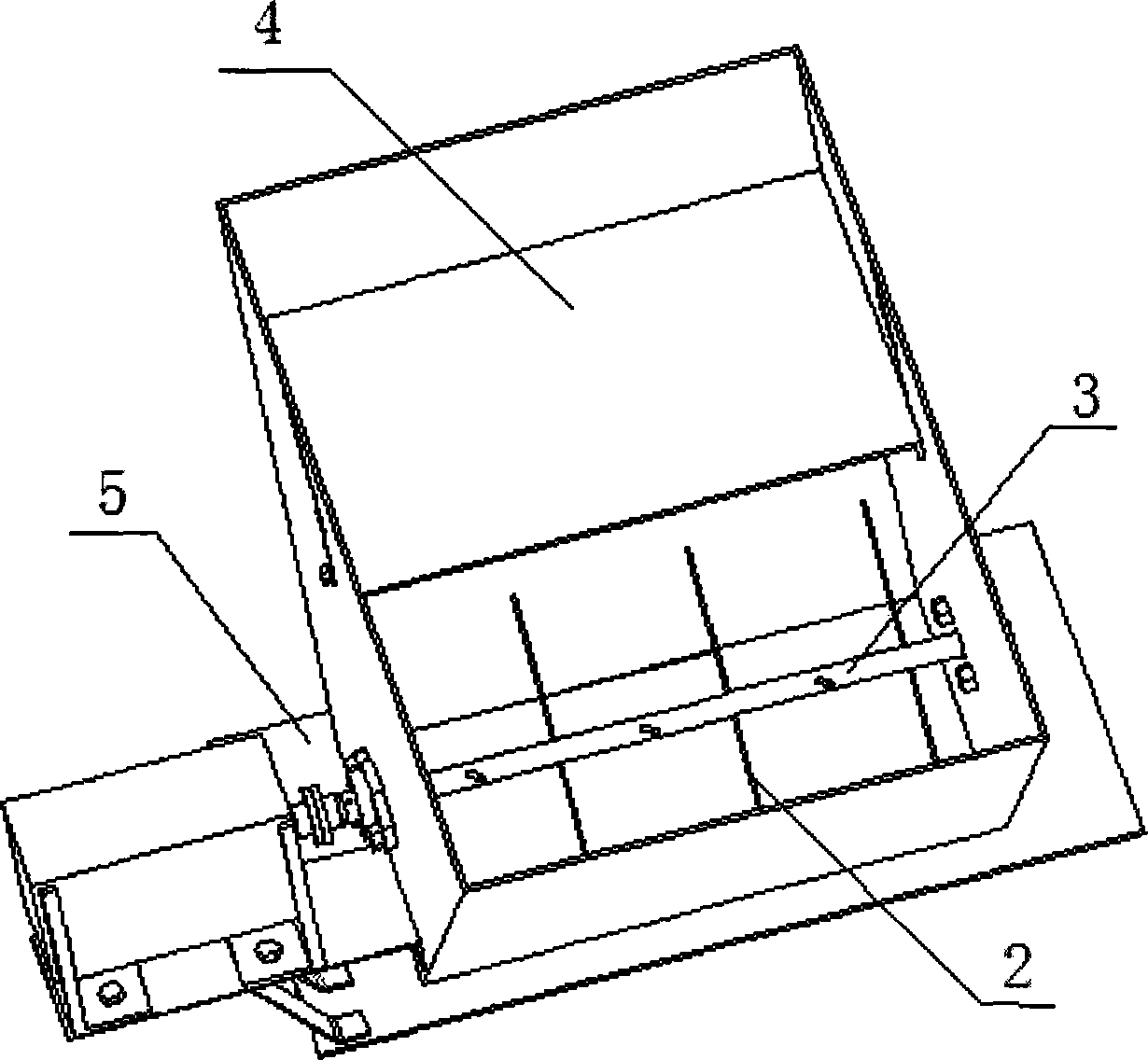

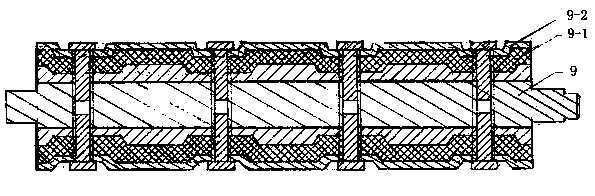

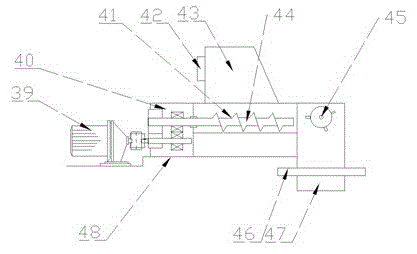

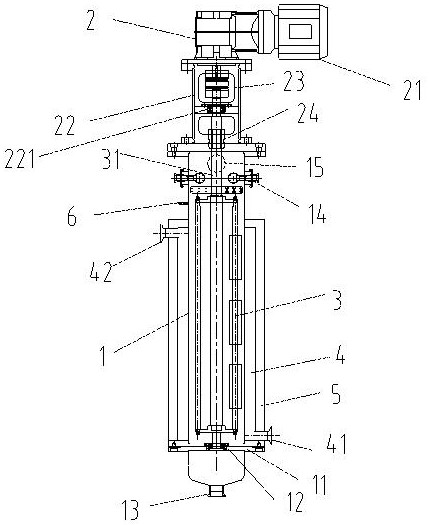

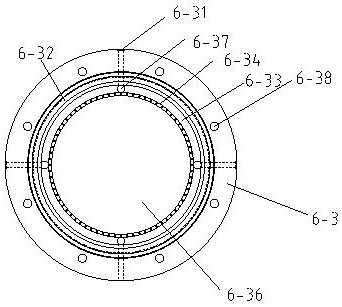

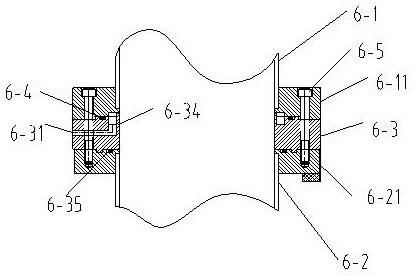

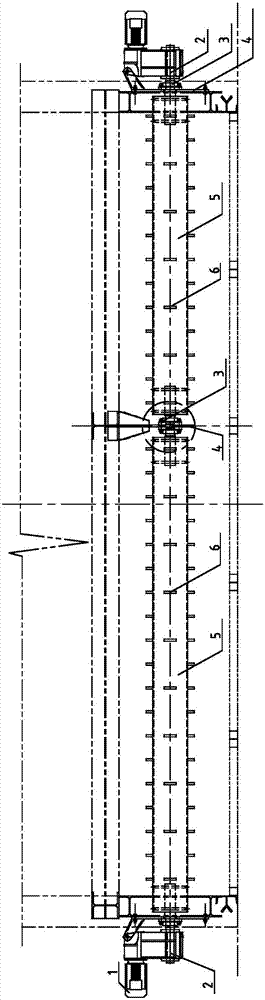

Hollow tube type variable-pitch spiral conveyor for potato pulp dewatering device

InactiveCN105115288AContinuous and even feedingImprove sealingDrying gas arrangementsDrying solid materialsHelical bladeEngineering

The invention belongs to the technical field of potato pulp dewatering devices, and particularly relates to a hollow tube type variable-pitch spiral conveyor for a potato pulp dewatering device. The spiral conveyor comprises a screw (1) and screw blades (2) arranged on the screw (1) and is mainly composed of a dense spiral section (3) located at the front end of the screw (1), a wide spiral section (4) located in the middle of the screw (1) and a reverse acting spiral section (5) located at the tail end of the screw (1). The spiral conveyor is characterized in that a hollow pipeline (6) is arranged in the screw (1), and the hollow pipeline (6) penetrates through the whole screw (1) and is connected with external equipment. The spiral conveyor has the advantages that bearing blocking is prevented, long-time stable and continuous spiral conveyance is guaranteed, and potato pulp is pressurized and heated to be dried through external hot air.

Owner:郑世奇

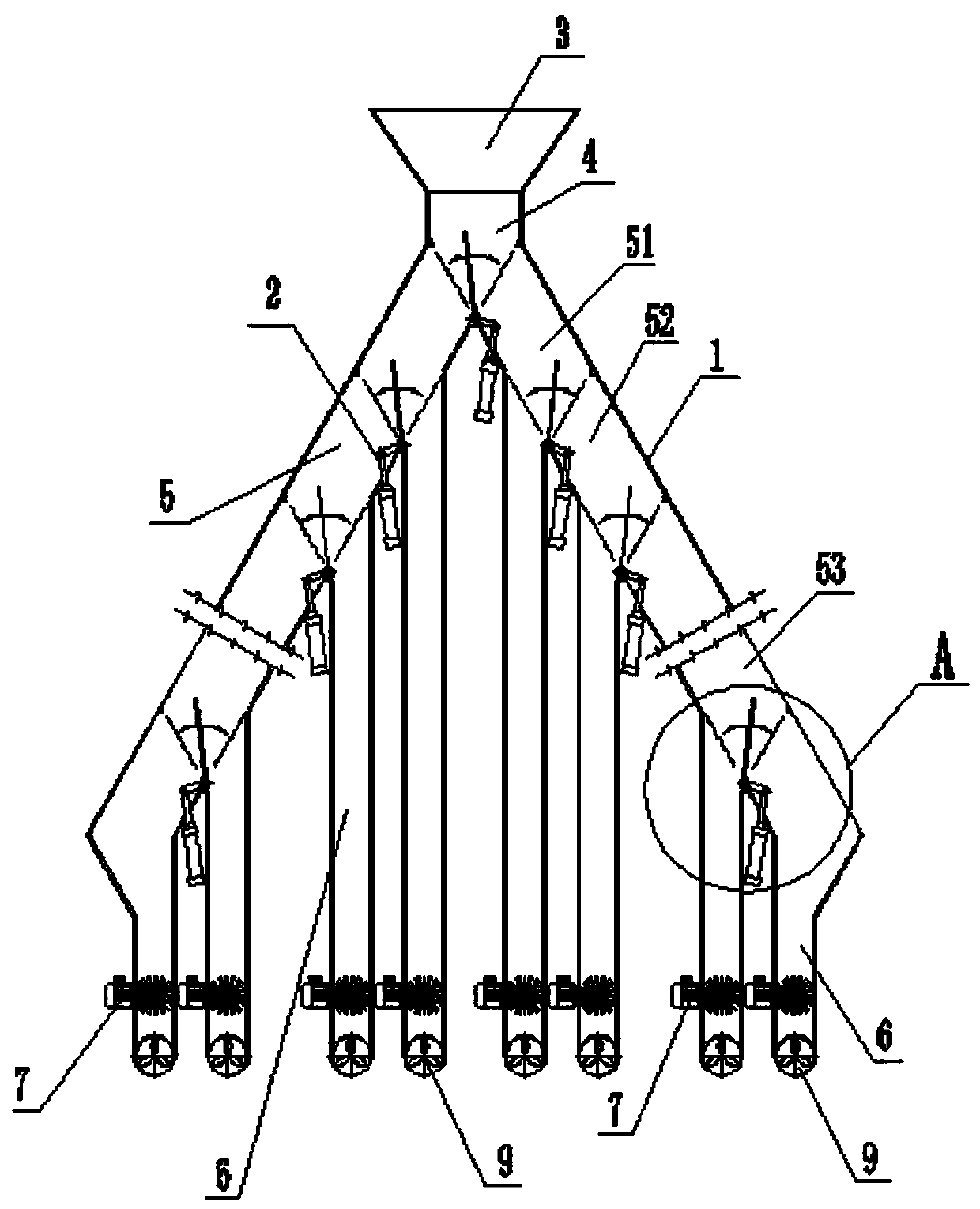

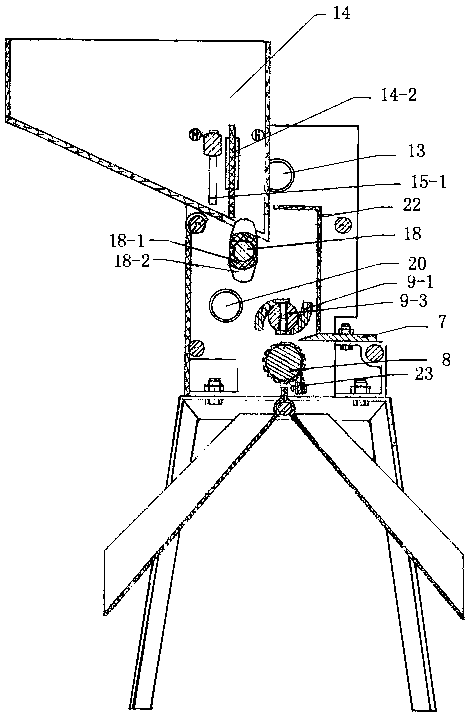

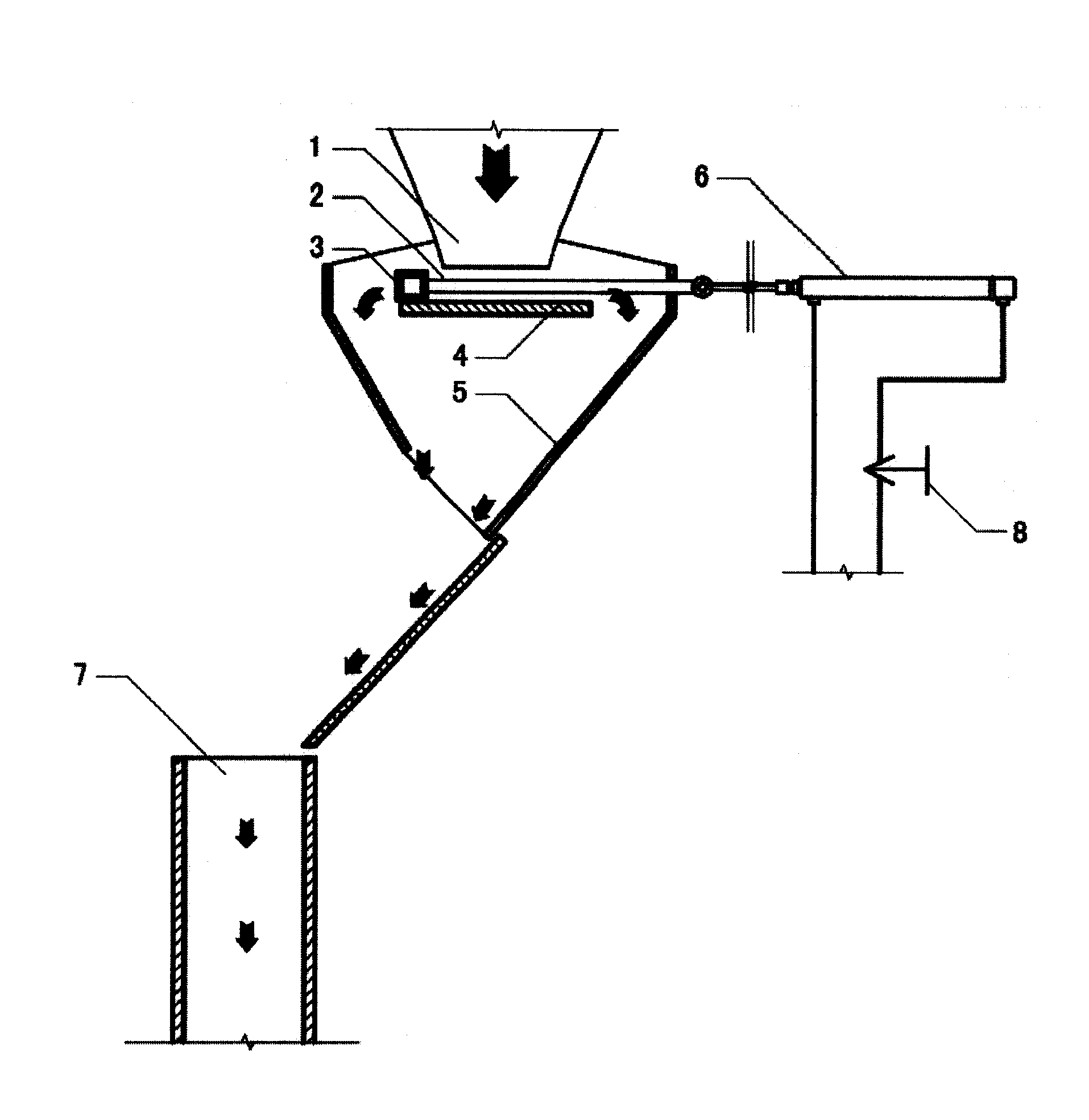

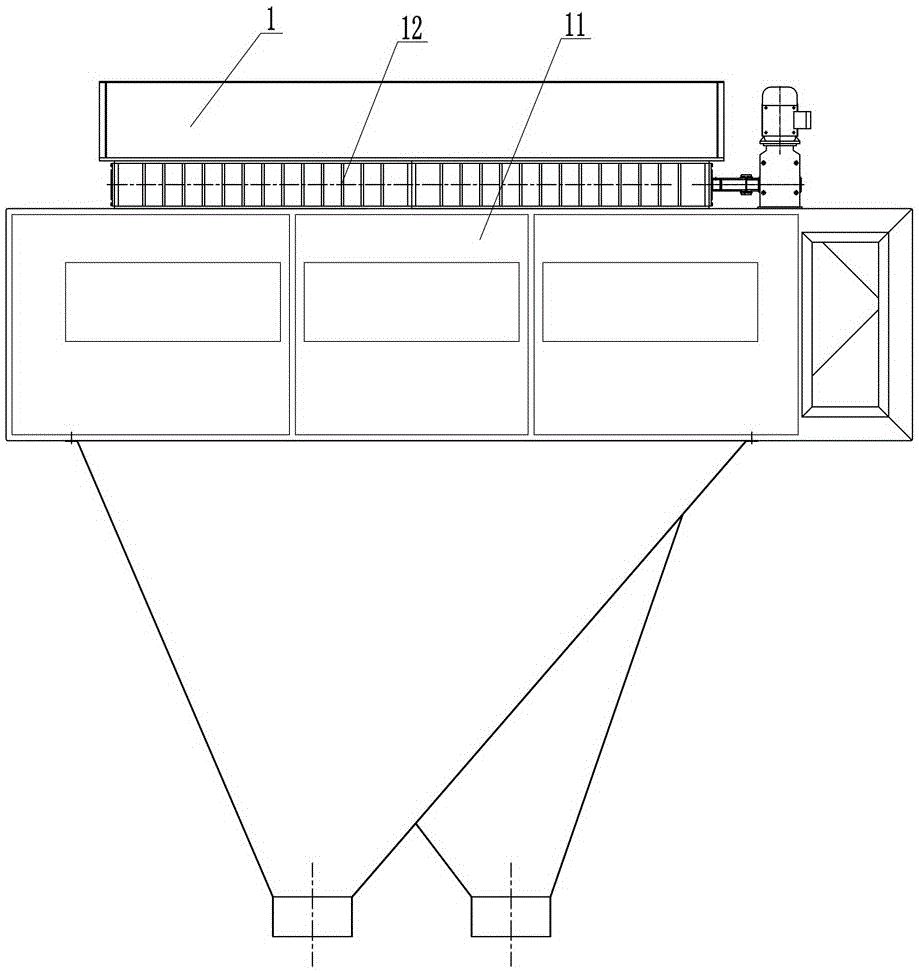

Separate warehouse type shred feeder and working method thereof

PendingCN110395580AHigh working reliabilityContinuous and even feedingBulk conveyorsEngineeringWind speed

The invention discloses a separate warehouse type shred feeder and a working method thereof and relates to the technical field of tobacco shred feeding. The separate warehouse type shred feeder comprises a shell and a feeding opening. A feeding cavity is formed in the top of an inner cavity of the shell. The feeding opening is formed in the top of the feeding cavity. The longitudinal section of the inner cavity of the shell is of an inverted-V shape. Multiple levels of separate warehouses are symmetrically arranged on the two sides of the inverted-V-shaped inner cavity from top to bottom. A material storing chamber vertically arranged is connected into the bottom of the inner wall of each level separate warehouse correspondingly. Mutual interference of feeding of the multiple separate warehouses is avoided, and uniform and continuous feeding of all shred feeding pipes is ensured. In the working process, the distributing and shred feeding process is completed by means of a pneumatic turning-over plate door mechanism, a quantitative discharging mechanism, a material sucking pipe and the shred feeding pipes, the wind speed required by the shred feeding pipes is low, and the breaking rate of the tobacco shreds is reduced. The tobacco shreds are conveyed into a tobacco rolling machine from the shred sucking pipe through negative pressure in the shred feeding pipe and a wind supplementing fan, the shred feeding amount is large, and the shred feeding wind speed is reduced substantially.

Owner:阜阳丰达机电设备有限公司

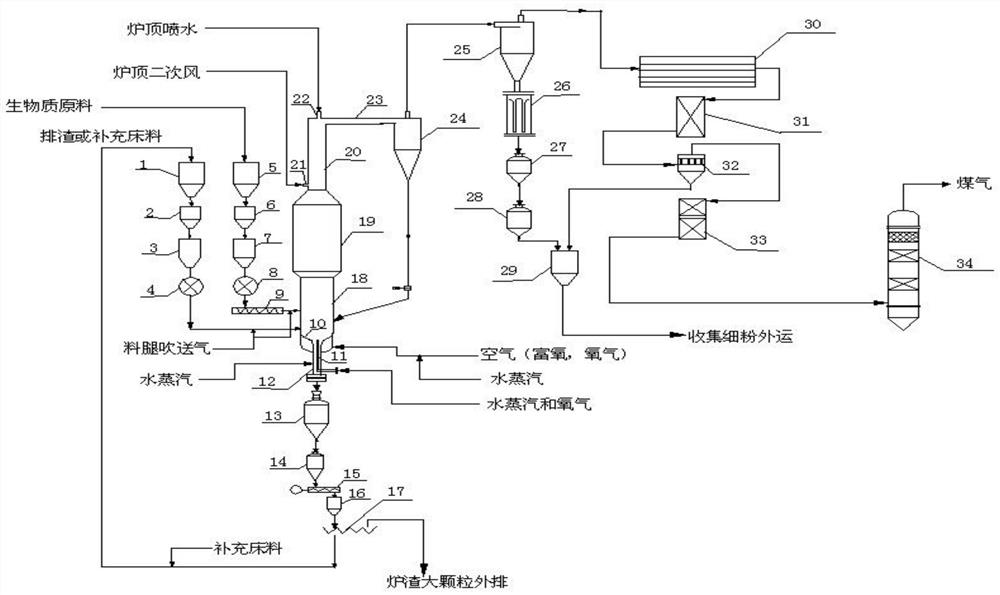

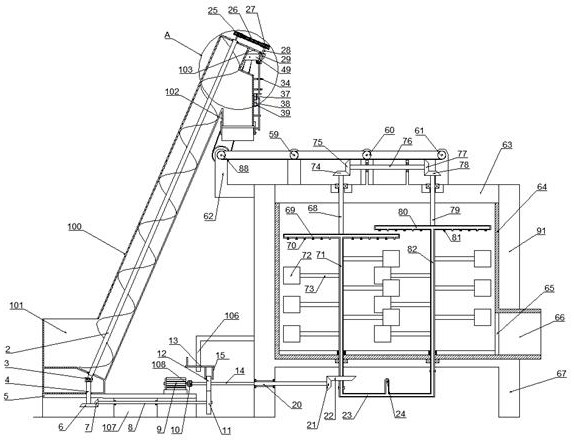

Method and apparatus for preparing fuel gas or synthetic gas through biomass fluidized bed gasification

The invention belongs to the technical field of preparation of fuel gas or synthetic gas, and particularly relates to a method and an apparatus for preparing fuel gas or synthetic gas through biomassfluidized bed gasification. The apparatus comprises a feeding device, a fluidized bed, a dust removal device, a waste heat recovery device and a water washing tower, wherein a bed material star-shapedfeeder and a biomass spiral feeder are connected with the lower section of a gasification furnace through a feeding pipe, a vibrating screen is connected with a bed material receiving hopper througha conveying system, the upper section of the gasification furnace is connected with an inlet of a first-stage cyclone separator through a high-temperature pipe section, and a powder outlet of the first-stage cyclone separator is connected with the lower section of the gasification furnace. A bed material and a biomass raw material are respectively metered and respectively blown to the lower section of the gasification furnace, so that the problem that the bed material and the biomass raw material are automatically layered in the stock bin after being mixed due to different particle sizes and different densities of the bed material and the biomass raw material is solved, and stable metering and stable conveying of the bed material and the biomass raw material can be realized.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

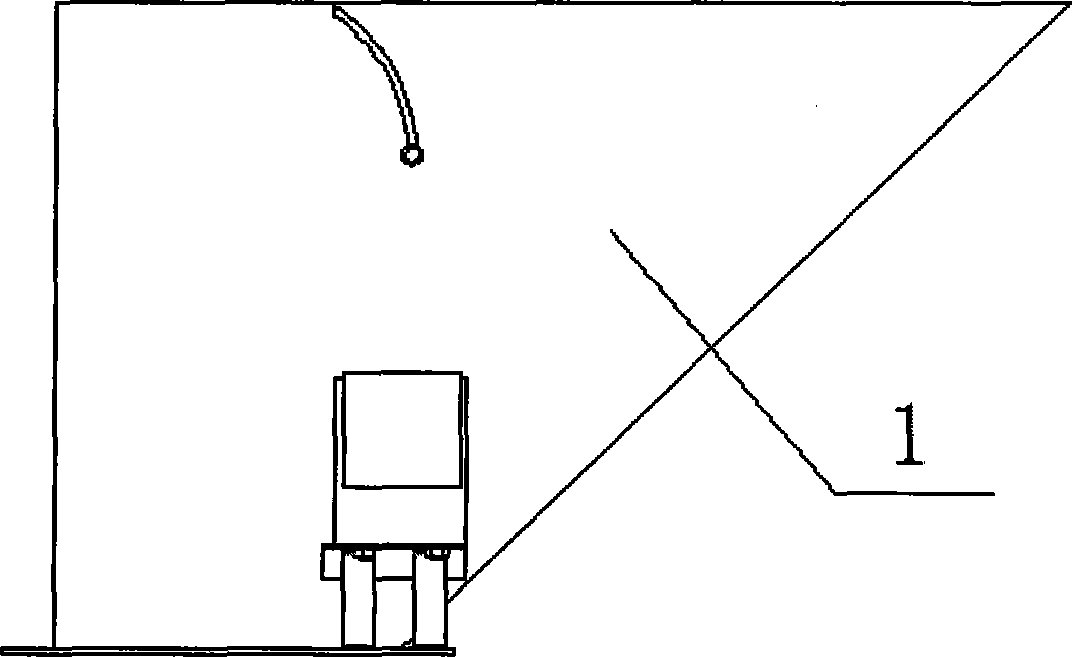

Feeder for crushing of crop straw material

InactiveCN104221899AContinuous and even feedingImprove delivery capacityAnimal feeding devicesCouplingEngineering

The invention discloses a feeder for crushing of crop straw material. The feeder comprises a feeding hopper, wherein the bottom part of the feeding hopper is provided with a rotary shaft, one end of the rotary shaft is fixedly arranged on the outer wall of the feeding hopper by a bearing, the other end of the rotary shaft penetrates through the bearing and is connected with an output shaft of a motor through an elastic coupling, the bottom part of the motor is welded with a motor frame, the bottom part of the motor frame is fixedly arranged on a support plate by a connecting rod, one side of the motor frame is fixedly arranged on the outside surface of the feeding hopper by a connecting rod, the rotary shaft is welded with a plurality of elastic teeth, and a 90-degree staggering structure is formed between the axially arranged elastic teeth. The feeder has the advantages that by controlling the rotation speed of the motor and the lifting angle of a retaining plate, the feeding amount can be controlled, the material is continuously and uniformly fed into a spiral conveying device, and the conveying property of the crop straw in the spiral conveying device is improved; the structure is simple, the installation is convenient, and the operation and use are very rapid.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

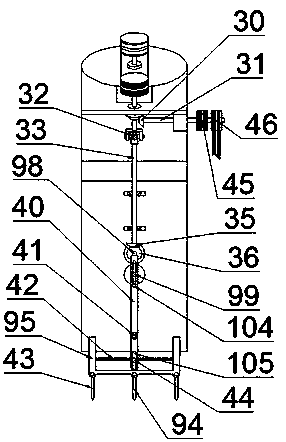

A kind of cornus officinale fully automatic meat core peeling machine

ActiveCN105962386BAchieve strippingAvoid shed blockageFruit stoningEngineeringUltimate tensile strength

The invention discloses a fully-automatic dogwood meat-nuclear stripping machine which comprises a rack, a feeding mechanism, a meat-nuclear stripping mechanism, a transmission mechanism and a motor are arranged on the rack, the feeding mechanism comprises a hopper and a discharging regulating shaft, the lower portion of the hopper is provided with discharging openings which are formed at intervals in the axial direction, and a discharging regulating shaft is located on the lower portions of the discharging openings; the meat-nuclear stripping mechanism is located on the lower portion of the discharging regulating shaft and comprises a poking piece shaft, a stripping knife, a striker plate and a stripping tooth roller shaft, the poking piece shaft is symmetrically provided with two flexible poking pieces in the axial direction, the lower portion of the poking shaft is provided with the stripping tooth roller shaft, the stripping knife is mounted on the rack, the cutting edge of the stripping knife faces the position between the poking piece shaft and the stripping tooth roller shaft, the distance between the cutting edge of the stripping knife and the poking piece shaft is matched with the size of the dogwood, and the stripping knife is provided with the striker plate. By means of the fully-automatic dogwood meat-nuclear stripping machine, fully automatic discharging can be achieved, manually-assisted discharging of operation staff is not needed, labor intensity is greatly relieved, meanwhile even discharging is guaranteed, and stripping efficiency is improved.

Owner:王东贵 +1

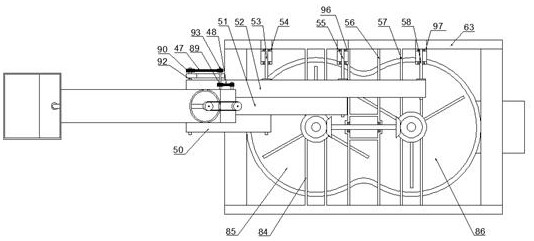

Ultra-broad width full-wire type non-polar speed governing feeder

InactiveCN101220281AContinuous and even feedingIncrease the lengthCharging devicesElectricityHigh density

The invention provides a super-wide full-line type nonpolar speed regulating feeder which is composed of a hopper, a material-receiving board, a distributing guide slot, a distributing push plate, a connecting rod and a hydraulic device. The working principle is that the coal material in the hopper falls down on the material-receiving board under the effect of the gravity, the distributing push plate is driven to do reciprocating motion on the material-receiving board by the hydraulic device, the coal material is pushed out from the two sides of the material-receiving board, falls down to the distributing guide slot and slides from the distributing guide slot to a coal chute of a side-mounted coal truck. The super-wide full-line type nonpolar speed regulating feeder is characterized by continuous and uniform feeding, cloth with the uniform width, fast pastry-forming, high density, random adjustable speed, saving water and electricity, etc. The invention mainly aims at realizing the tamping process in the technique of tamping and coking, realizing continuous uniform feeding and distributing material in a thin layer and improving the tamping quality.

Owner:程相魁

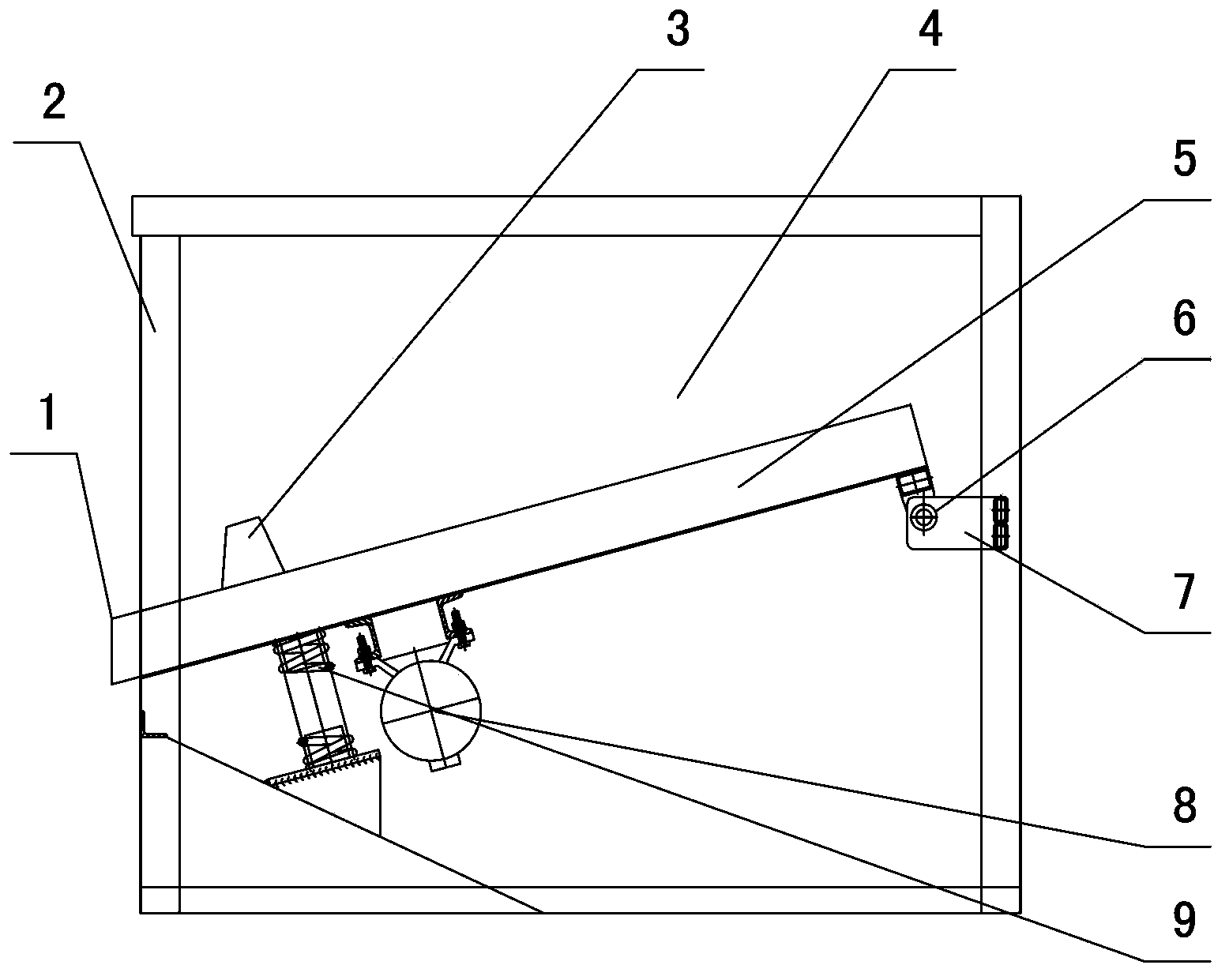

Vibratory feeding mechanism of grain selection separator

InactiveCN103506322AContinuous and even feedingRealize Regulatory ControlGas current separationVoltageEngineering

The invention relates to a vibratory feeding mechanism of a grain selection separator, and belongs to the technical field of cleaning and grading of grain. The vibratory feeding mechanism comprises a machine frame of a frame structure. The vibratory feeding mechanism is characterized in that a vibrating board is arranged on the machine frame in an inclined mode, the upper right portion of the vibrating board is the grain entering end, the lower left end of the vibrating board is the grain feeding end, the upper right end of the vibrating board is hinged to the right side of the machine frame, the lower left end of the vibrating board is connected to the left side of the machine frame through an elastic part, and a vibrating motor is arranged at the bottom of the vibrating board. By means of the vibratory feeding mechanism, under the action of the vibrating motor, a vibration rotating shaft, an anti-impact check block and a spring, the purpose that the grain is controlled in a stable zero-degree feeding state is achieved. When the vibratory feeding mechanism is applied, by adjusting the input voltage of input frequency of the vibrating motor, the amplitude or vibrating frequency can be adjusted correspondingly, and adjustment and control of feeding quantity can be achieved.

Owner:SHANDONG YIKAI STORAGE ENG

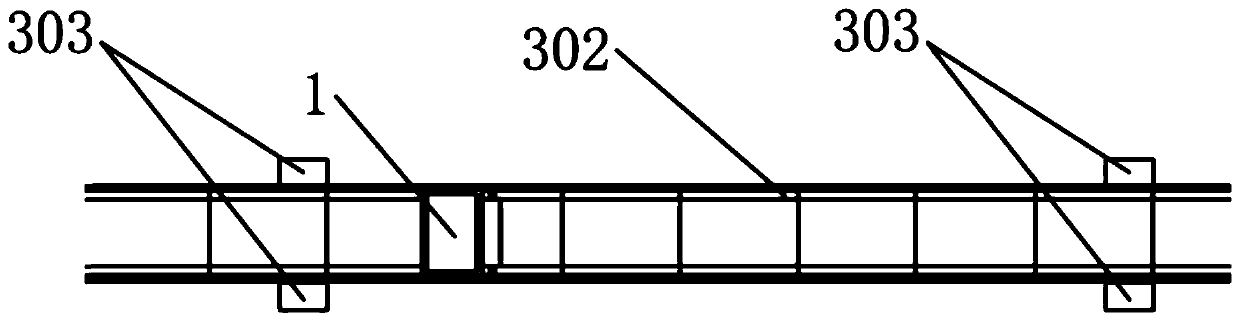

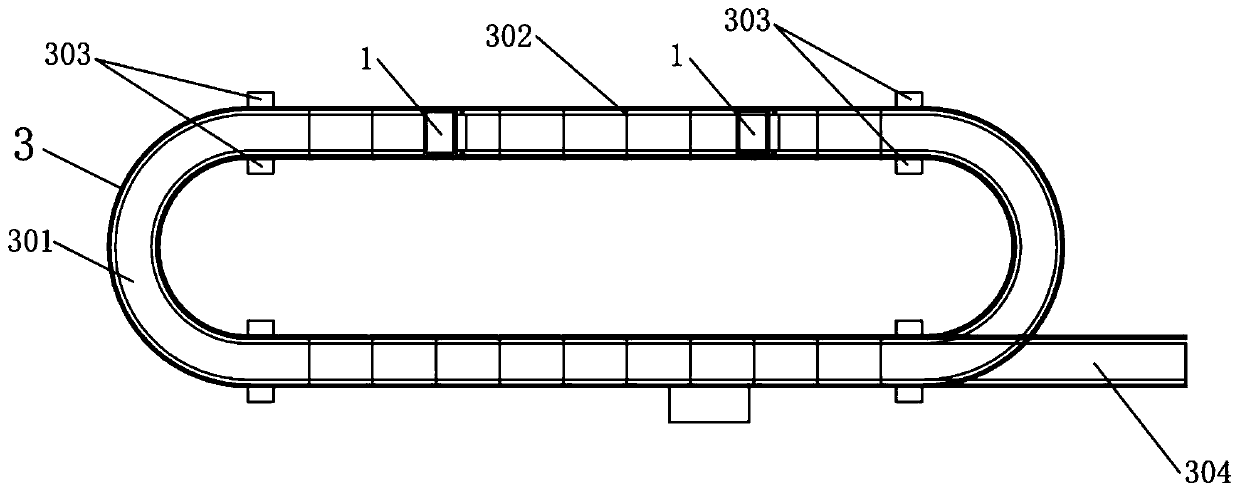

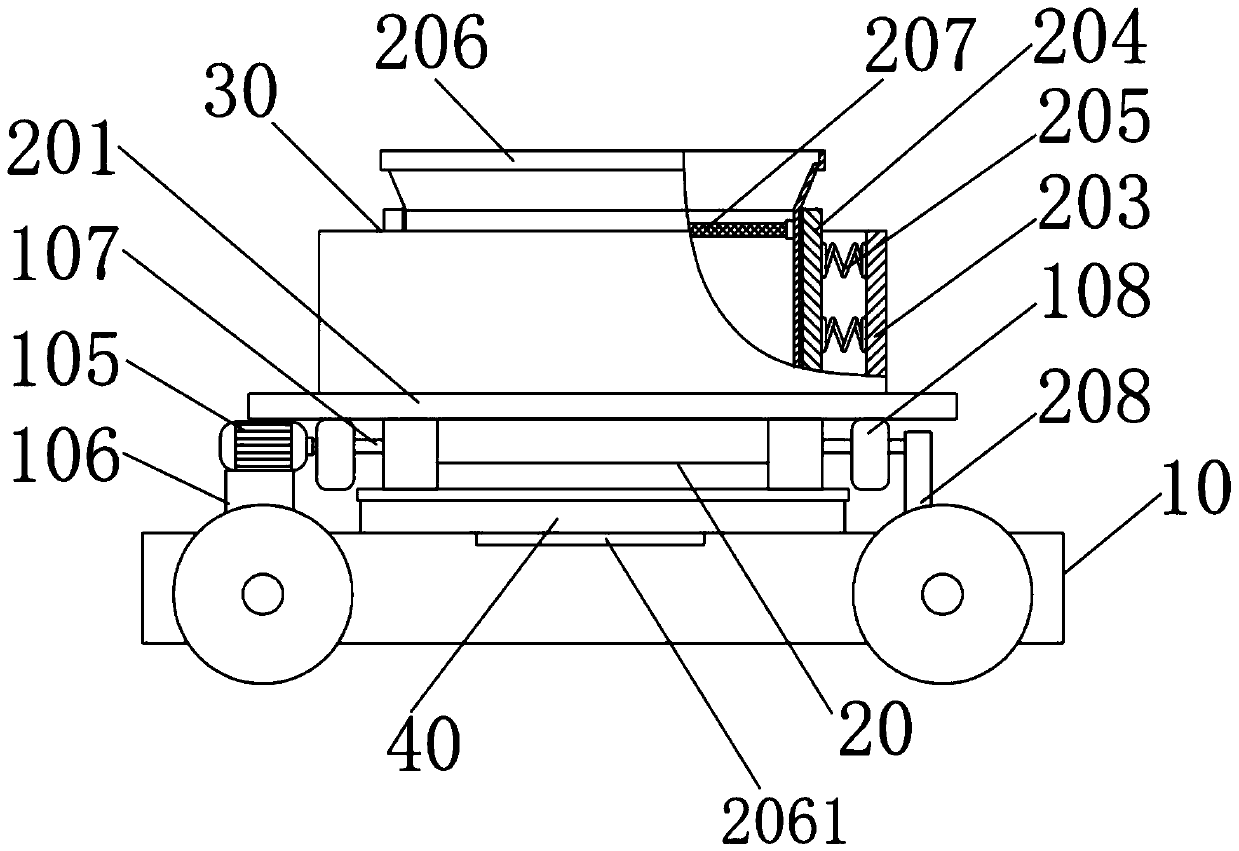

Tea feeding and conveying device

InactiveCN109733820AContinuous and even feedingImprove uniformityPre-extraction tea treatmentMechanical conveyorsAutomation

The invention provides a tea feeding and conveying device. At least one conveying trolley, an annular track or a linear track used for guiding the conveying trolleys to convey tea to a kneading and twisting machine, and a feeding device used for loading tea into the conveying trolleys are included; the conveying trolleys are arranged on the annular track or the linear track, are used for transferring the tea loaded by the conveying trolleys to the corresponding position along the annular track or the linear track, and complete charging on the kneading and twisting machine close to the position; and after unloading is completed, the conveying trolleys move to preset positions along the annular guide rail, and tea loading on the conveying trolleys is completed through the feeding device. Thetea feeding and conveying device achieves continuous and uniform conveying and feeding on the tea, the uniformity and stability of conveying of the tea are improved, the automation degree is high, and the manpower cost is effectively lowered; and the tea feeding and conveying device is adjustable in conveying and feeding speed, controllable in conveying amount, and applicable to automatic conveying and feeding of various tea processing equipment with different feeding requirements.

Owner:宁波市姚江源机械有限公司

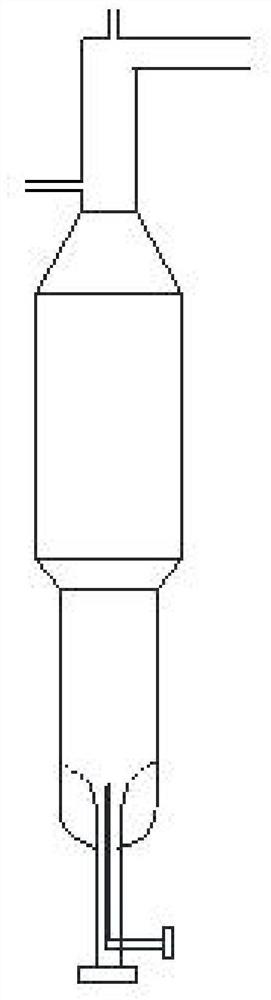

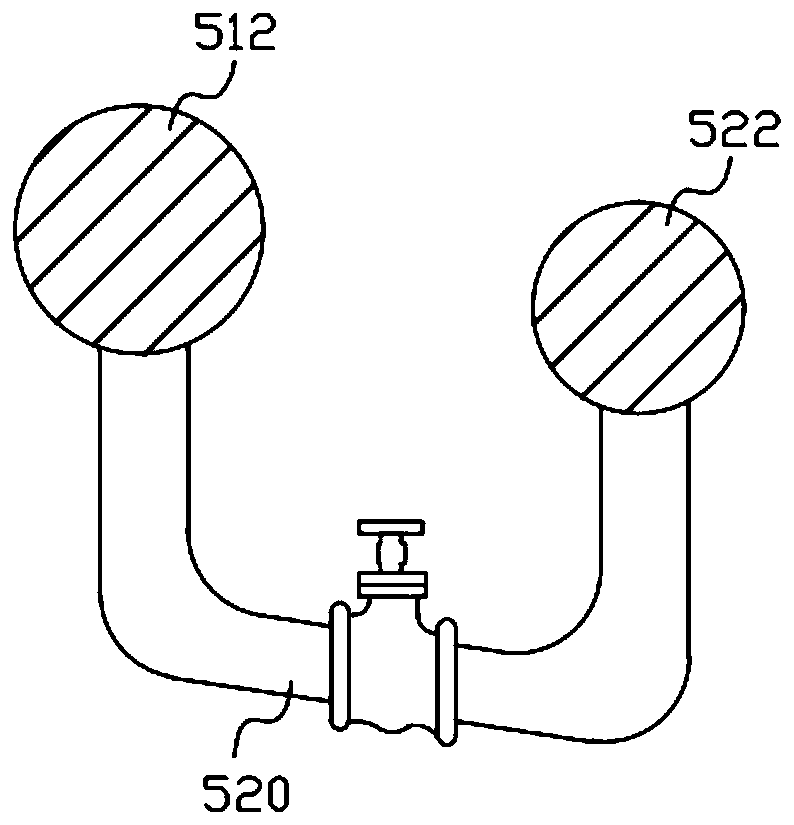

Emulsifying bacteria evaporation system

PendingCN111803976AOvercoming the problem of large particle sizeGuaranteed evaporation effectEvaporator accessoriesEvaporators with vertical tubesThermodynamicsOrganosolv

The invention discloses an emulsifying bacteria evaporation system which comprises an emulsifying section, a bacteria preparation section, an evaporation section, a quantitative transfer filtering section and a storage section which are connected through a pipeline, the emulsifying section comprises a water phase tank and an organic solvent tank, and the two tanks are mixed into an emulsifying tank in proportion; the homogenizing section is a circulating bacteria preparation section and comprises a first bacteria preparation tank and a second bacteria preparation tank which are connected in parallel, the homogenizing section further comprises a bacteria preparation machine, and a buffer tank and a coil preheating structure are sequentially arranged between the bacteria preparation sectionand the evaporation section; the evaporation section comprises at least two scraper type film evaporators, and the scraper type film evaporators are connected in series and / or in parallel under the action of pipelines and valves. According to the invention, a circulating bacteria preparation mechanism is adopted, the problem that the particle size is increased due to insufficient bacteria preparation is solved, novel evaporation is adopted, buffer preheating is matched, the evaporation effect is ensured, and meanwhile, a plurality of filtering processes are performed before finished products so that the product safety is high.

Owner:苏州岑途智能装备科技股份有限公司

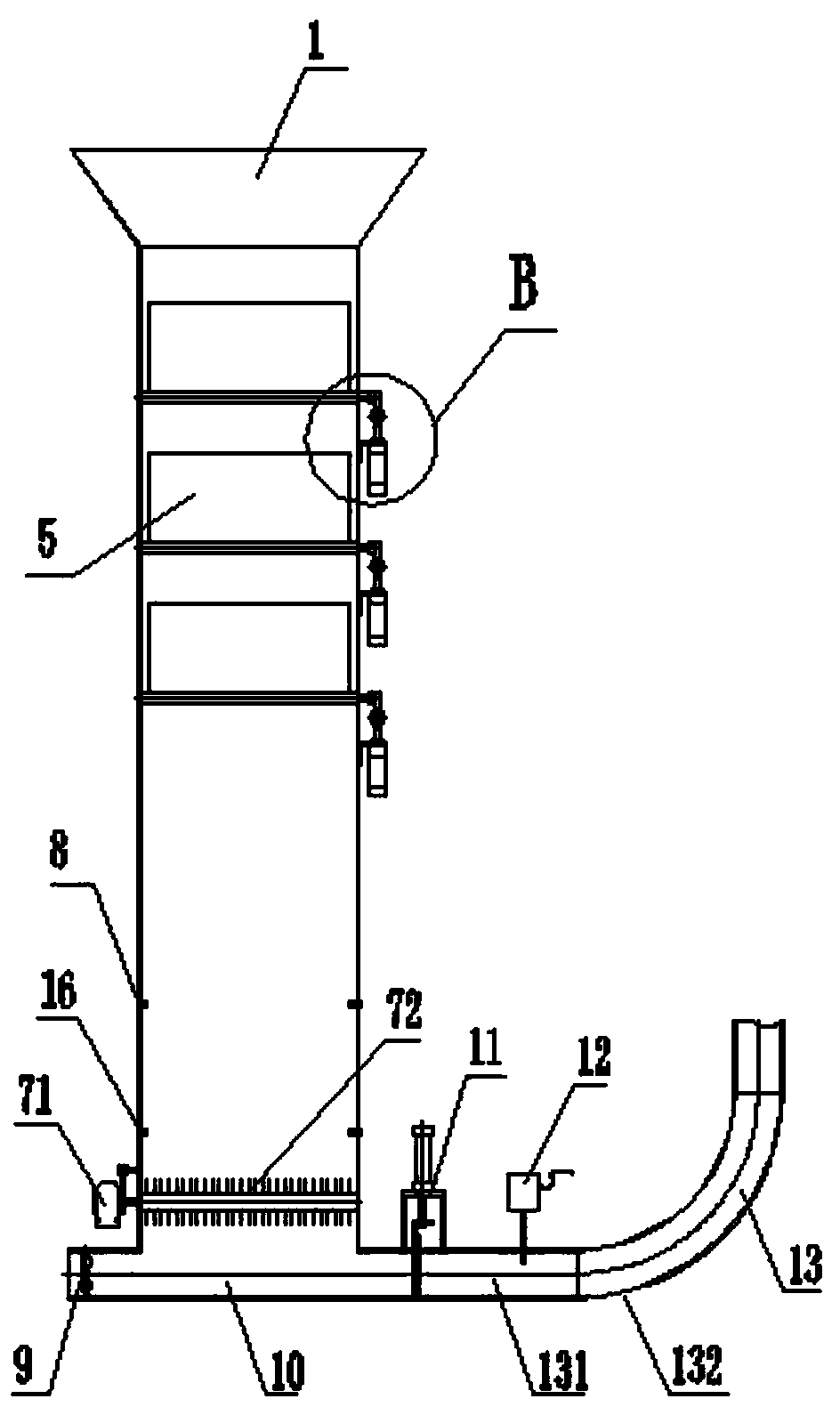

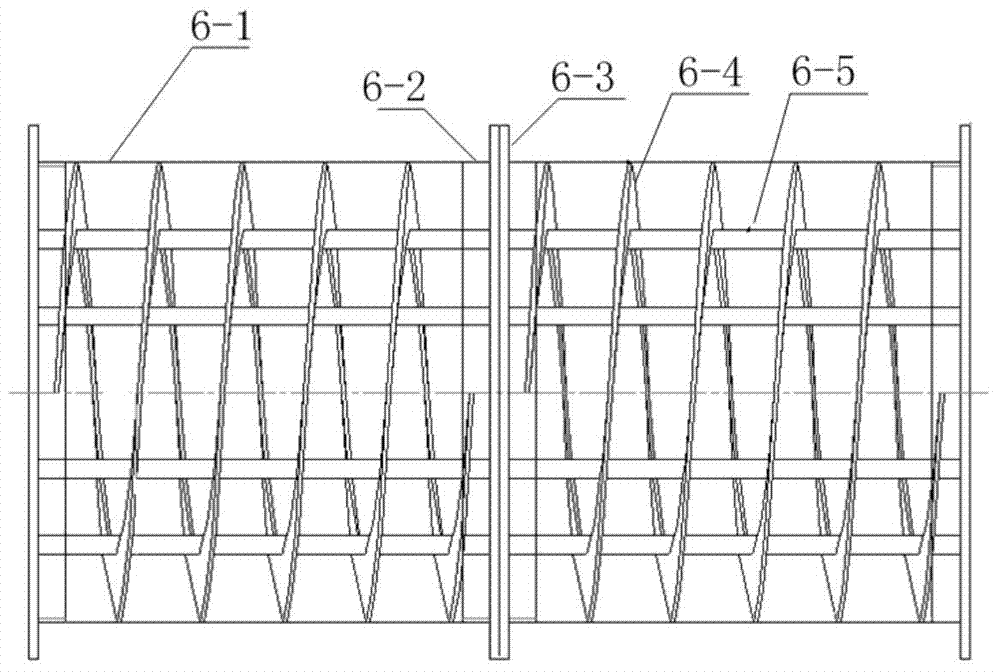

Fluidized bed co-processing solid-liquid polymorphic hazardous waste incineration system and method thereof

ActiveCN103175208BGuaranteed immediate incineration disposalEasy to adjust controlIncinerator apparatusResource utilizationFluidized bed

The invention discloses an incinerating system and method of disposing solid-liquid multi-phase hazardous waste mutually for a fluidized bed. The incinerating system comprises a fluidized bed incinerating device body, a liquid hazardous waste feeding system, a solid hazardous waste feeding system, a waste heat utilizing system and a tail gas treatment system. According to the incinerating system and method, solid-liquid multi-phase waste enters the fluidized bed incinerating device body respectively through the liquid hazardous waste feeding system and the solid hazardous waste feeding system to be incinerated, and waste heat utilization and clean gas clean-up processing are carried out on smoke through the waste heat utilizing system and the tail gas treatment system. The incinerating system and method are a whole system which composed of an incinerating device, waste heat utilization and tail gas processing, and are suitable to the reduction of multi-phase hazardous waste and resource utilization. Therefore, fluidized bed device incineration of different feed materials aiming at hazardous waste of different physical states is achieved, the technical problem that one feeding device carries out hazardous waste feeding material limitation of different states is solved, and meanwhile the resource reusing and the detoxifying treatment of the hazardous waste are achieved.

Owner:ZHEJIANG UNIV

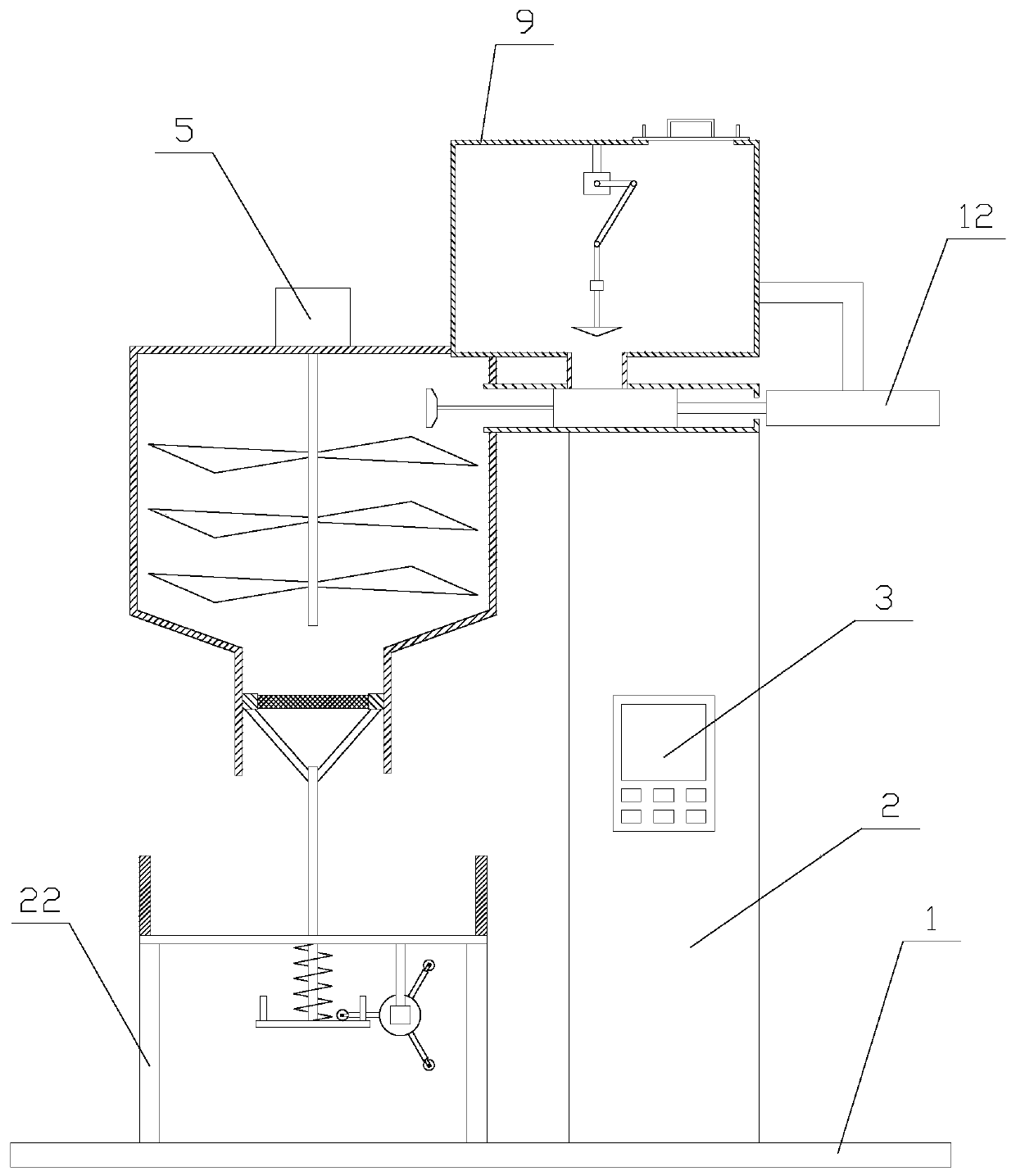

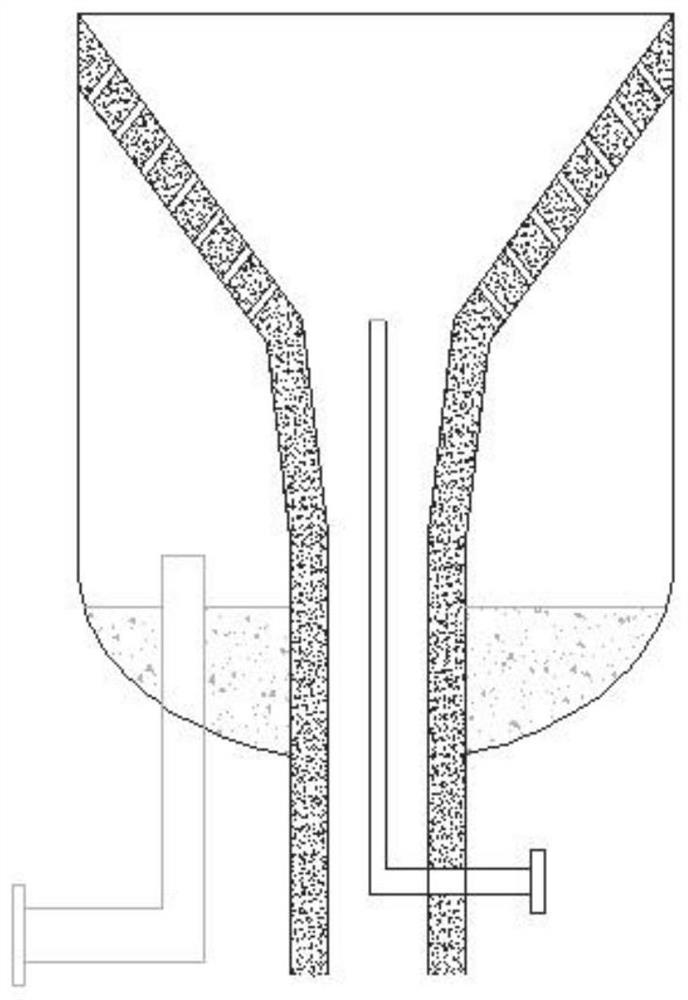

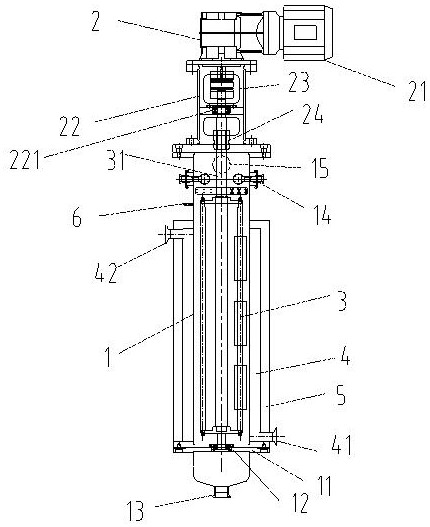

Scraper type film evaporator

PendingCN111773751AUniform feedingEasy to diluteEvaporator accessoriesEvaporators with vertical tubesThin membraneEngineering

The invention discloses a scraper type film evaporator. The evaporator comprises an evaporator cylinder and a driving structure arranged on the upper side of the evaporator cylinder. The scraper cagestructure is arranged in the evaporator cylinder; the upper side is connected to the driving structure; the lower side is limited by a bearing on a lower seal head at the bottom of the evaporator cylinder; a discharge port is arranged in the lower side of the lower seal head. A water cavity is formed in the side wall of the evaporator cylinder, a water inlet and a water outlet are formed in the lower portion of the water cavity in an up-down mode, a heat preservation layer is arranged on the outer side of the water cavity, a cleaning opening and a vacuum connector are sequentially formed in the cylinder wall, on the upper side of the scraper cage structure, of the evaporator cylinder upwards, and a feeding structure is arranged on the cylinder wall of the evaporator cylinder adjacent to the scraper cage structure. Through the arrangement of the distributing device, materials are evenly fed into the whole cylinder wall in an overflowing mode, discharging is continuous and even, subsequent scraper blade thinning is facilitated, and it is guaranteed that the separation effect of the evaporator is stable and efficient.

Owner:苏州岑途智能装备科技股份有限公司

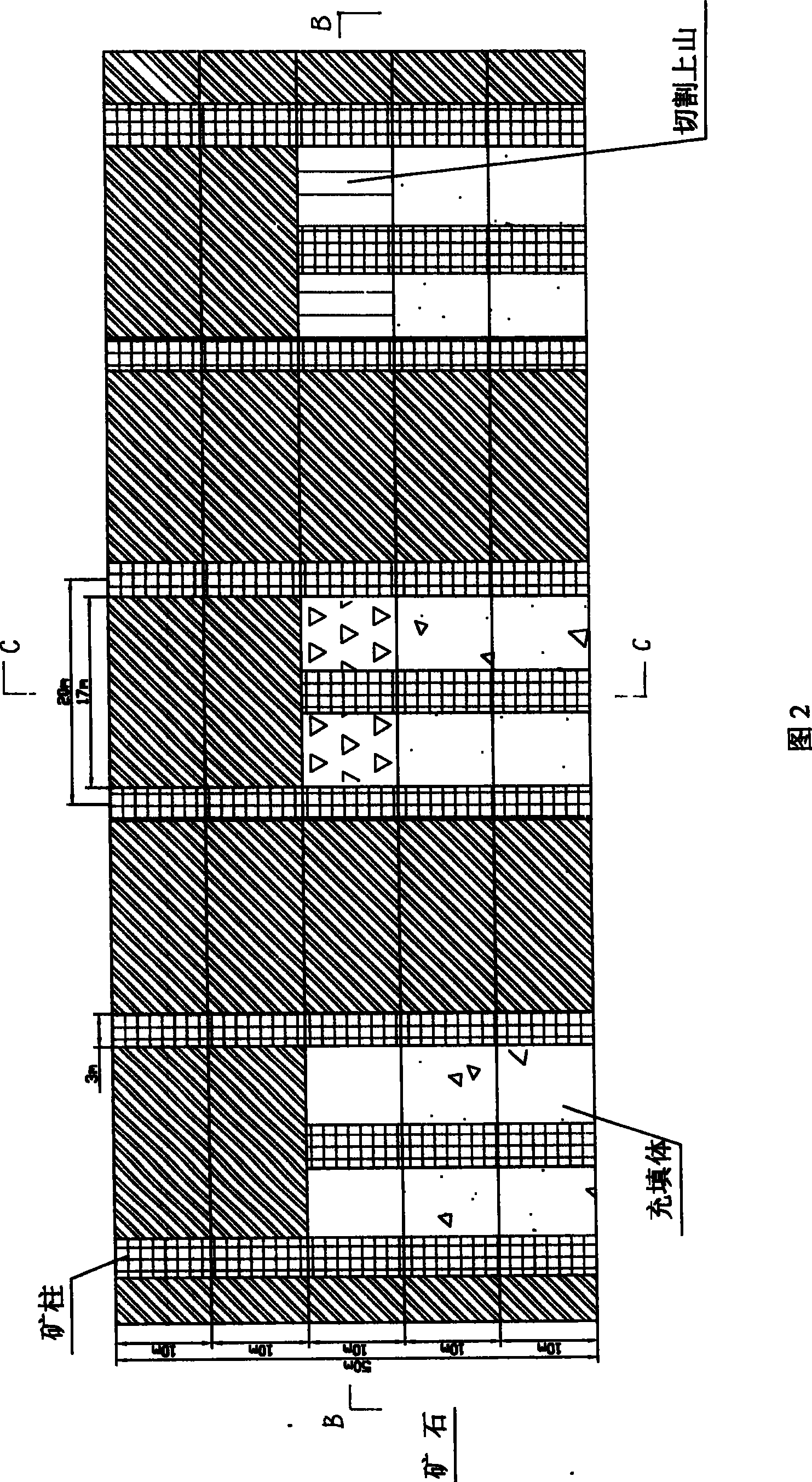

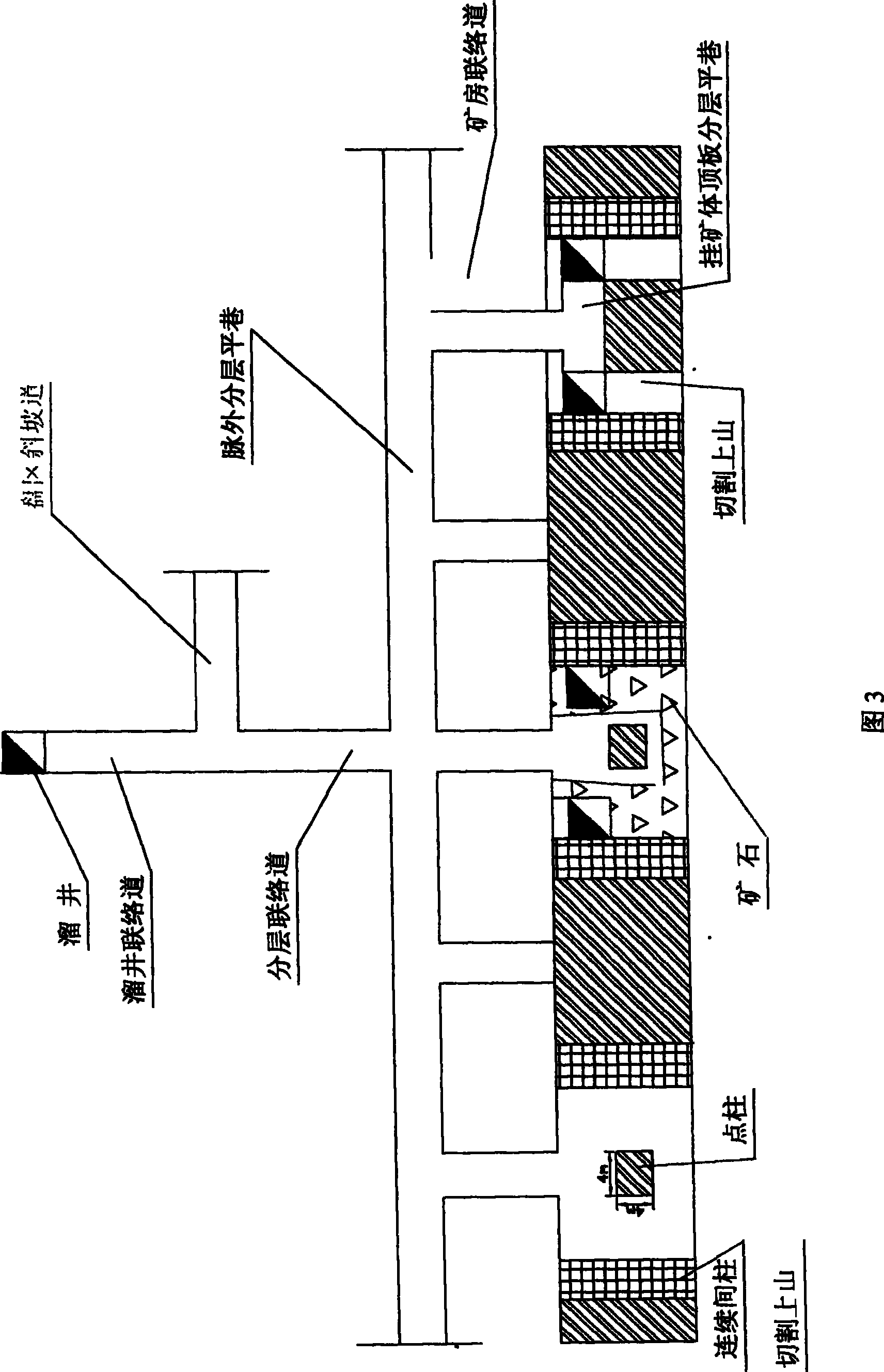

Phosphogypsum cementing and post-filling mining method and pulping technology thereof

ActiveCN101008316BSolve problems that are difficult to handle in large blocksIncrease profitMaterial fill-upDolostoneAdhesive

The invention discloses a stuff mining method when the ardealite adhesive is solidified and relative pulp production. The stuff mining method comprises that preparing mine house, stuffing preparation, preparing pulp, and stuffing. The pulp preparation comprises that using ardealite, coal powder / dolostone and cement as the stuff material to be added into water and mixed into stuff pulp; the stuff pulp via the stuff drill hole or the pump station is input to the upper outer flat channel of the mining field via the stuff tube, to be fed into the mining field. The inventive stuff mining method can confirm the yield and stability of mine, to improve the recycle rate of mineral and protect the environment.

Owner:贵州开磷设计研究院有限责任公司

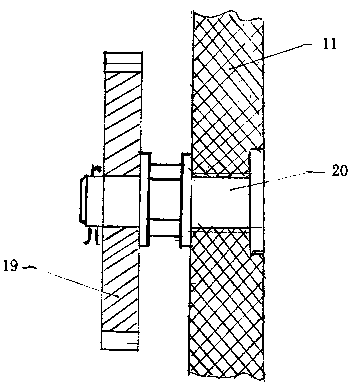

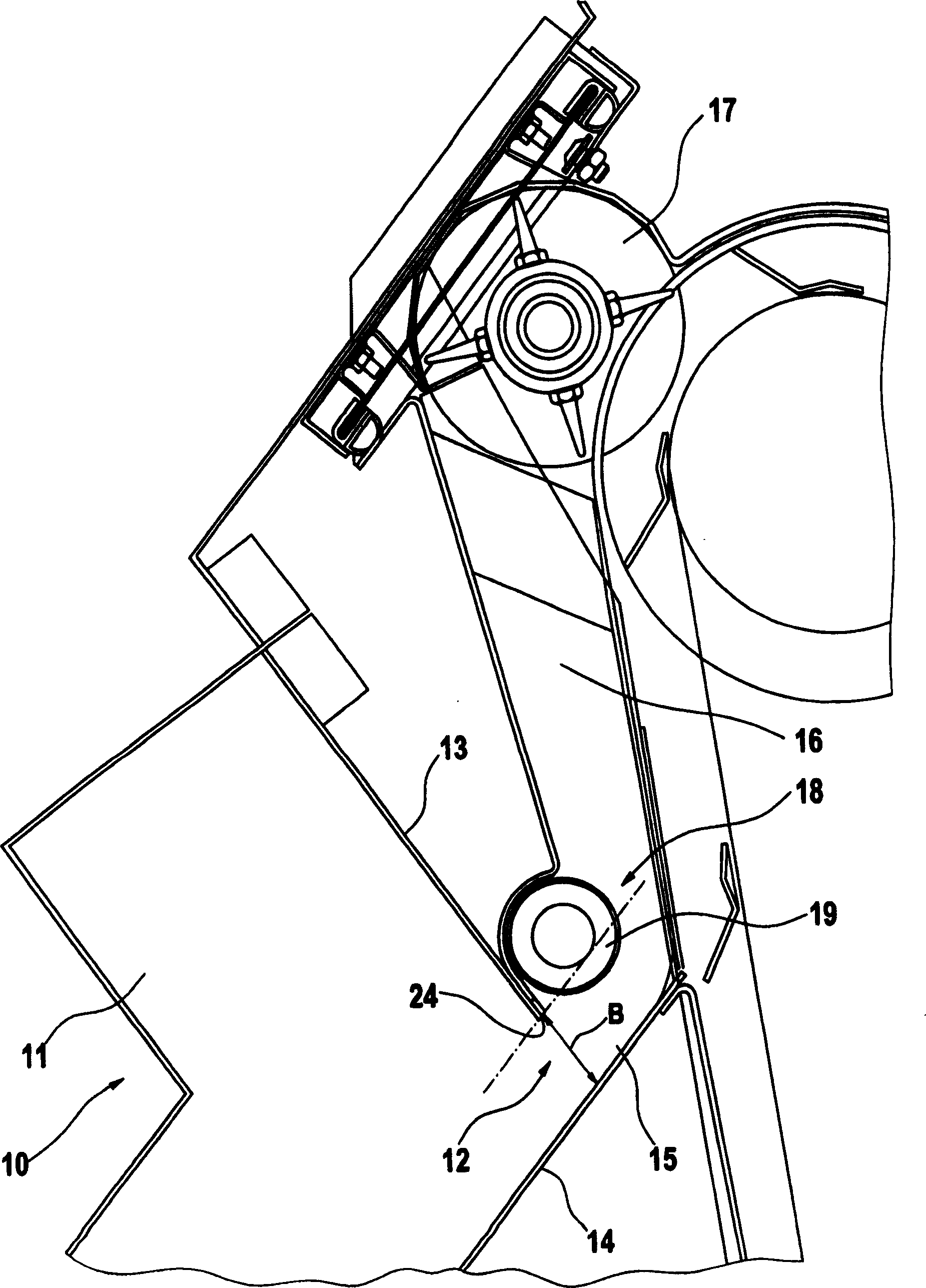

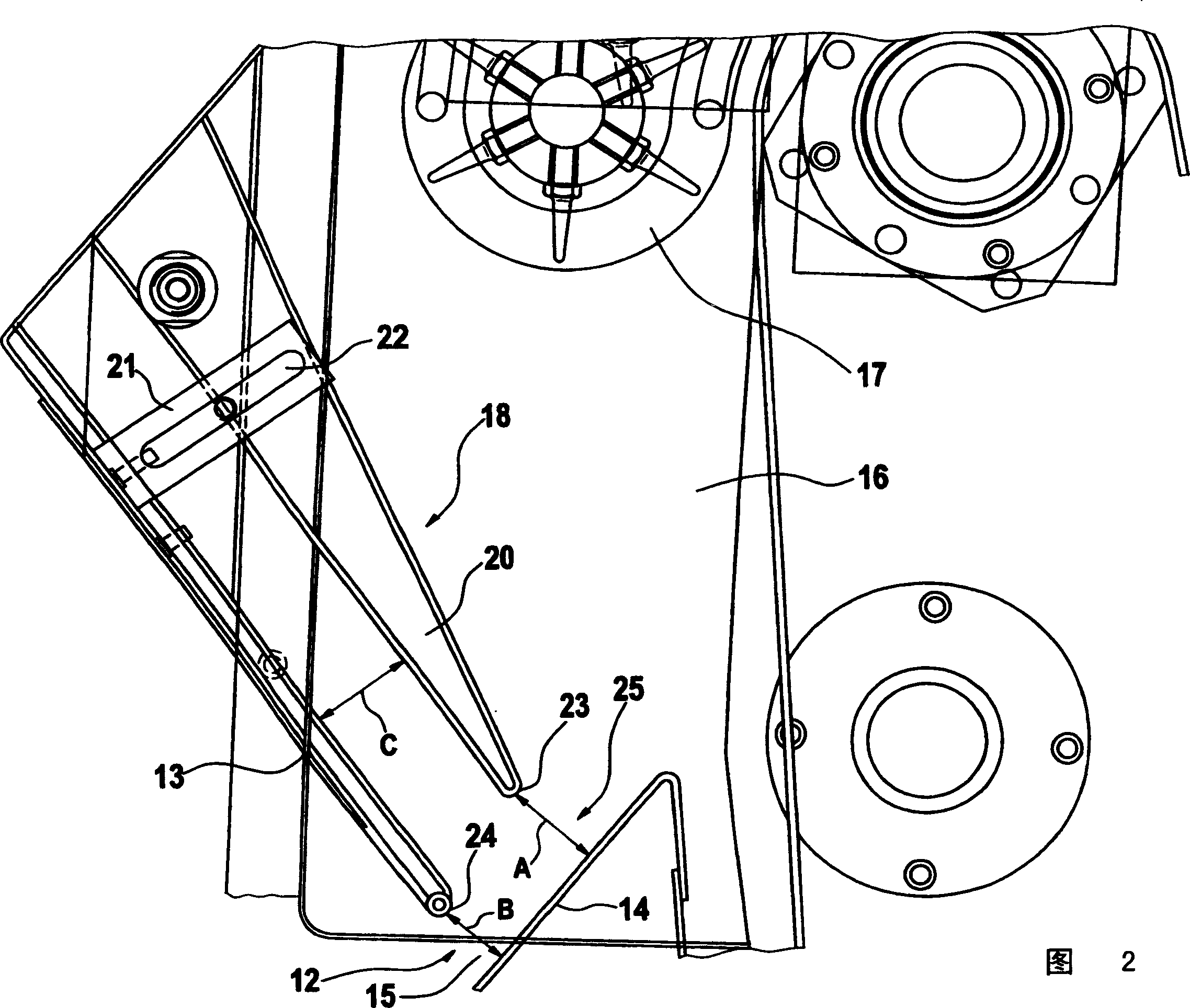

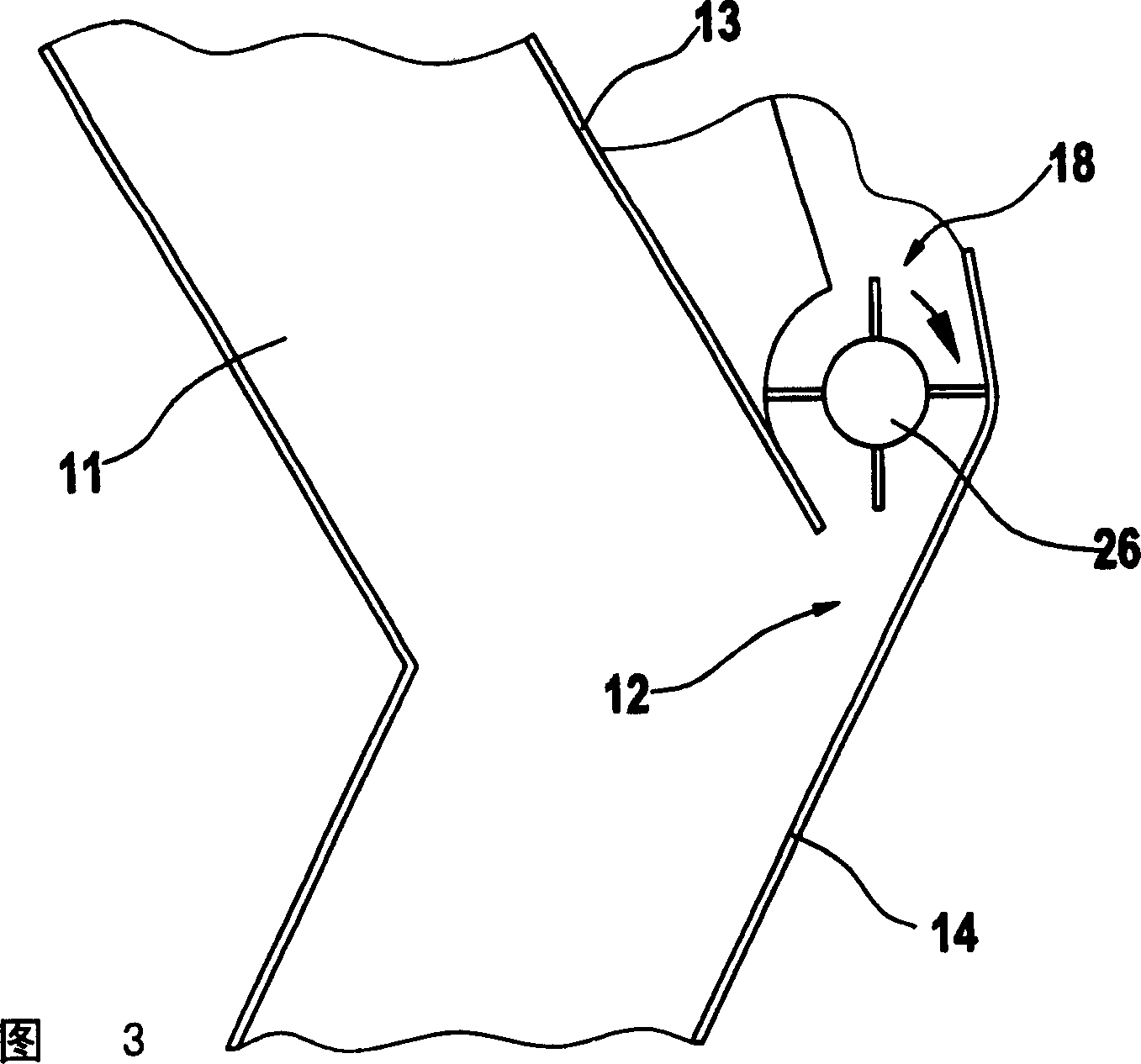

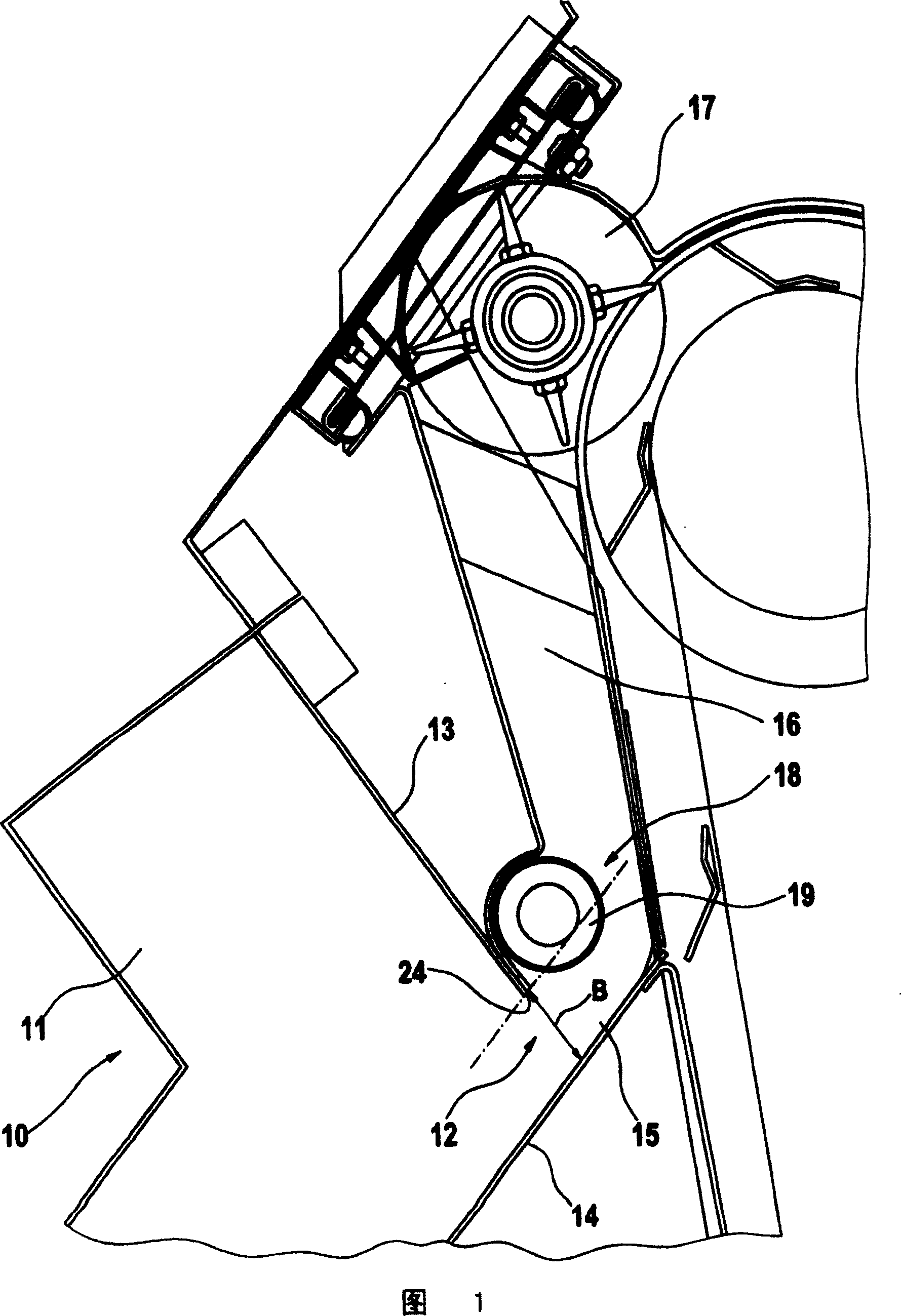

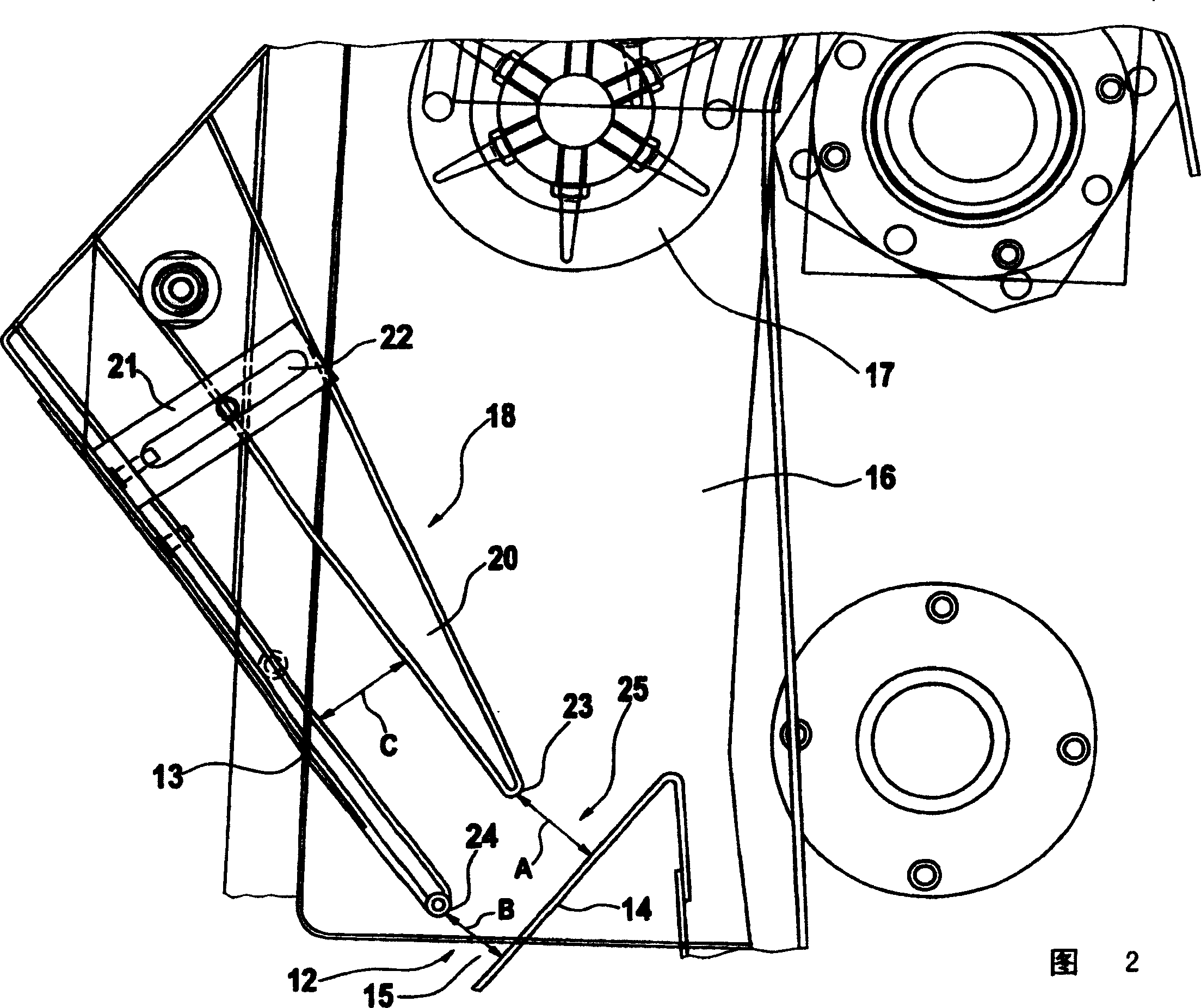

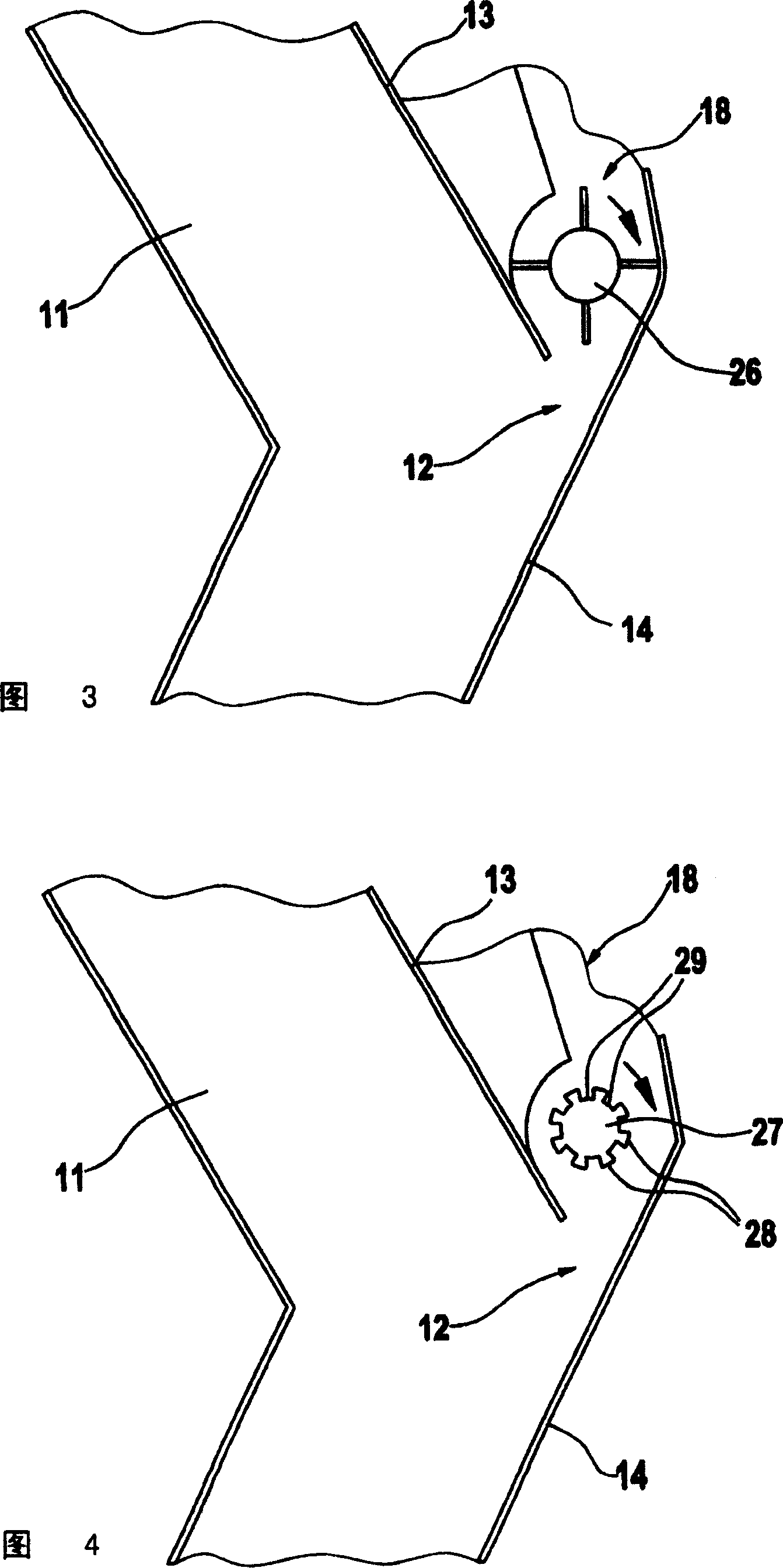

Z shaped separator used for separating product flow

ActiveCN1533718AUniform and continuous feedingActive and even deliveryCigar manufactureCigarette manufactureEngineering

Separating device (10) for separating a product flow, especially for separating parts of a product flow that are to be processed or not to be processed within a distribution device for loading a cigarette-making machine, comprises a vertical zigzag separator (11) and at least one inlet (12) for the product flow to be separated. An insertion aid (18) for the product flow is arranged in the zigzag separator in the region of the inlet. An Independent claim is also included for a process for separating a product flow. Preferred Features: The insertion aid is a rotating roller (19). The inlet is formed by two side walls (13, 14) of the zigzag separator. The roller is arranged in the region of a free end (24) of the upper side wall.

Owner:柯尔柏技术有限责任公司

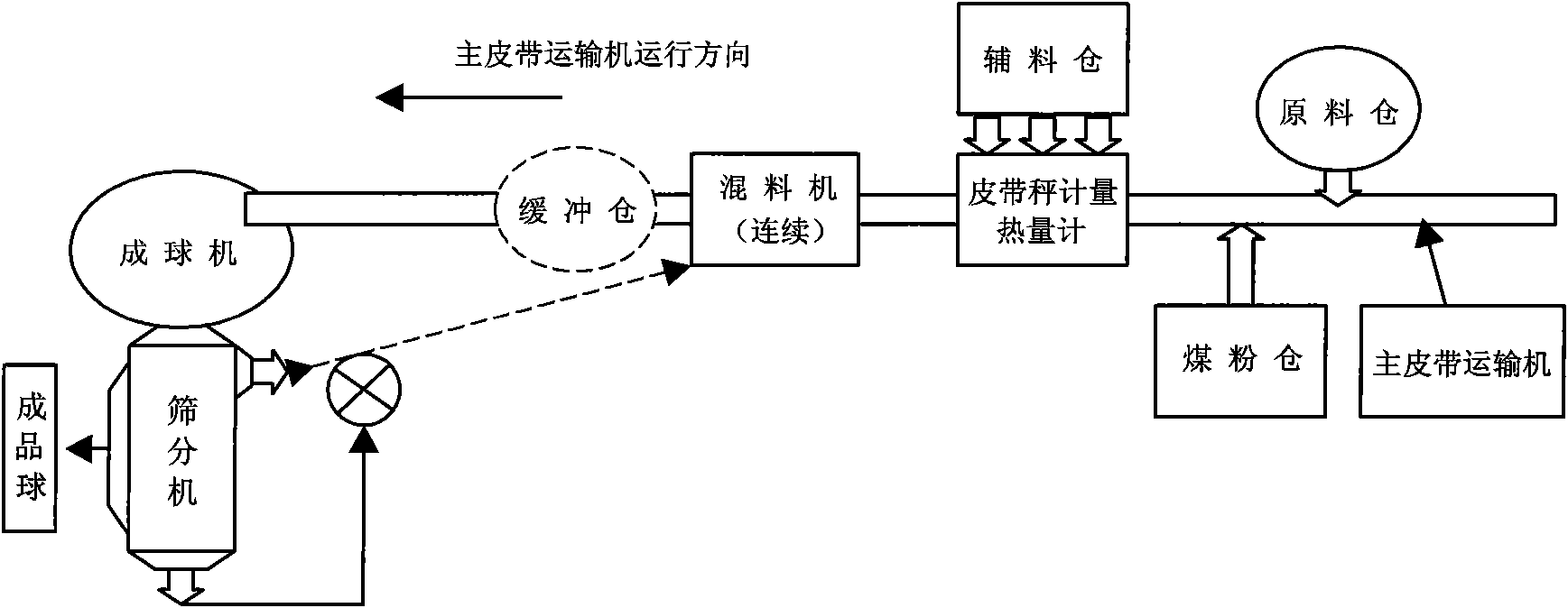

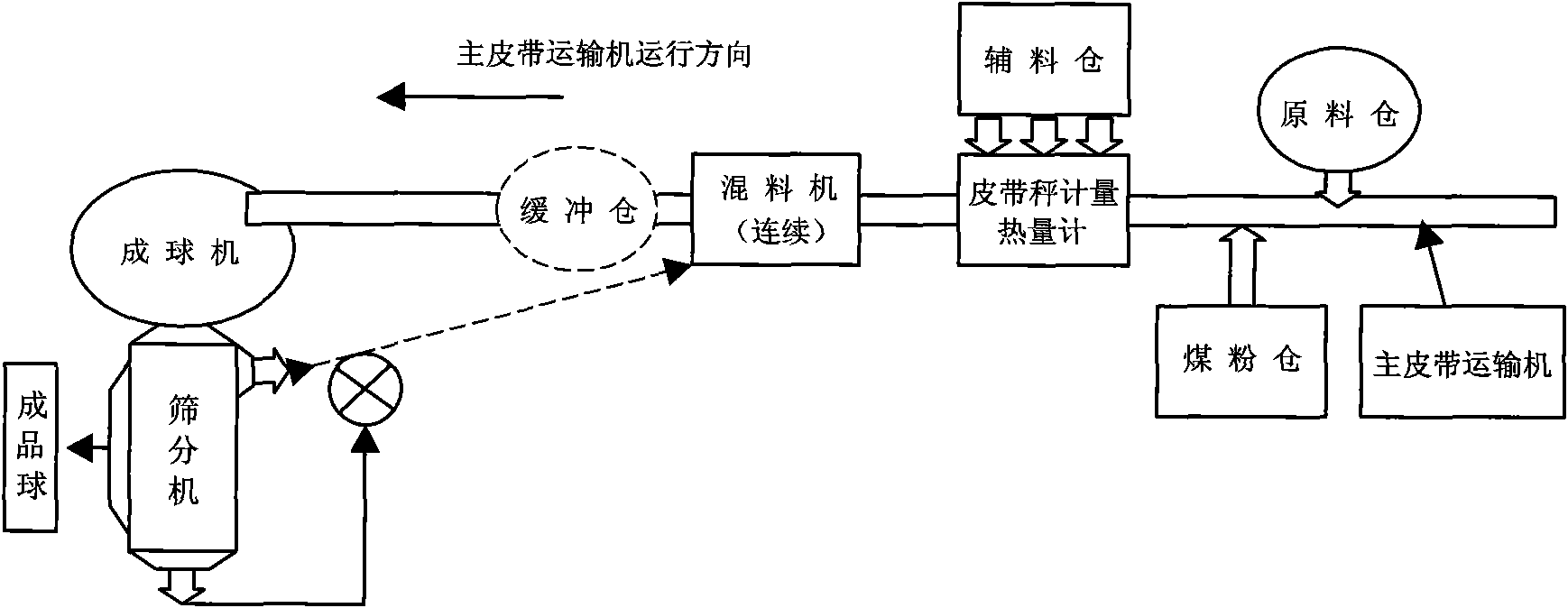

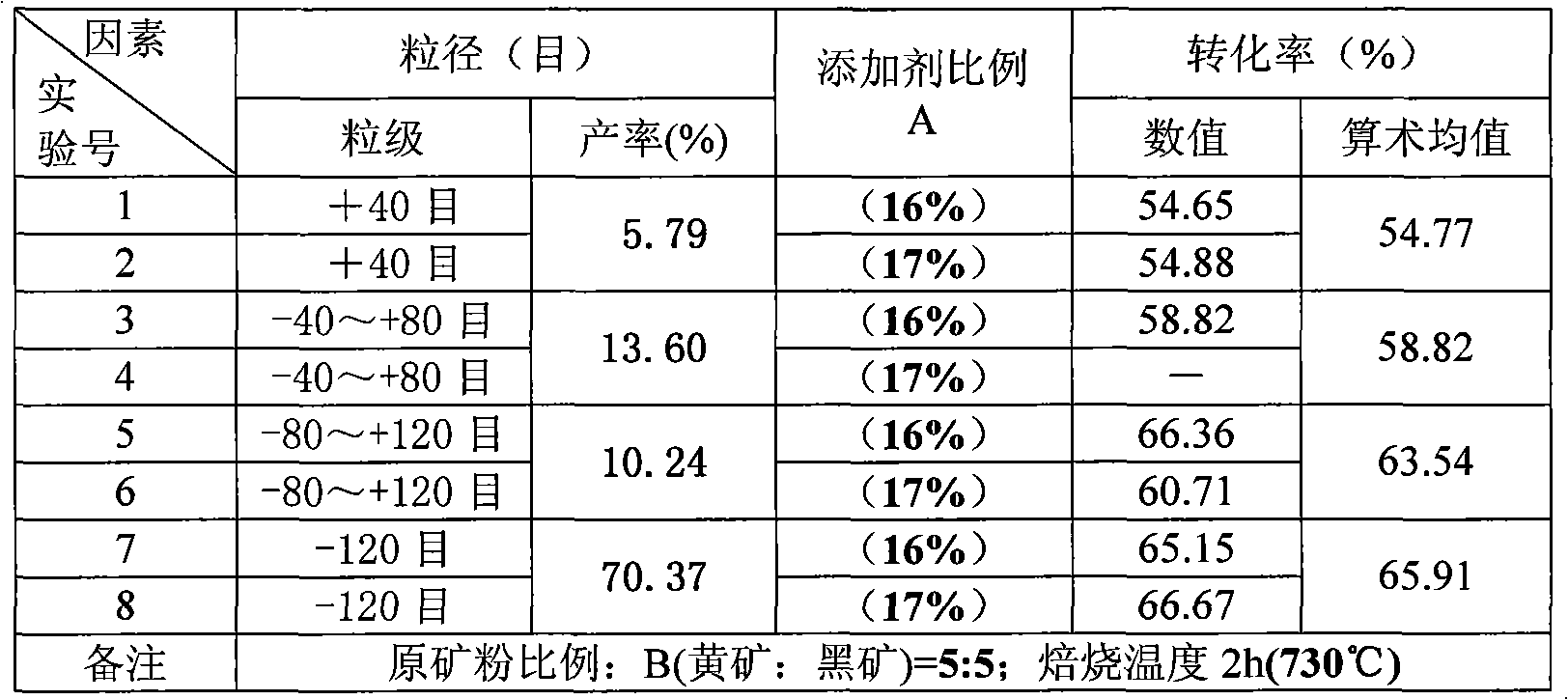

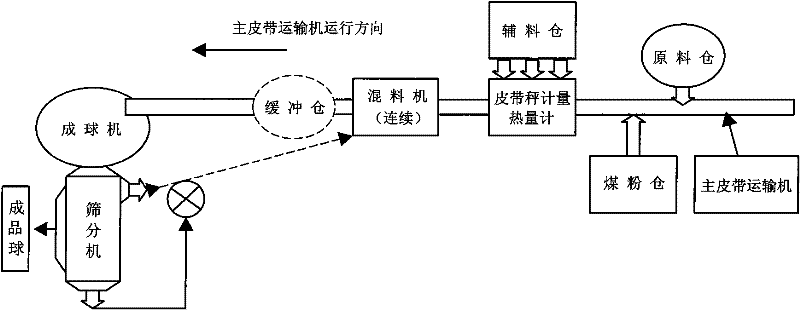

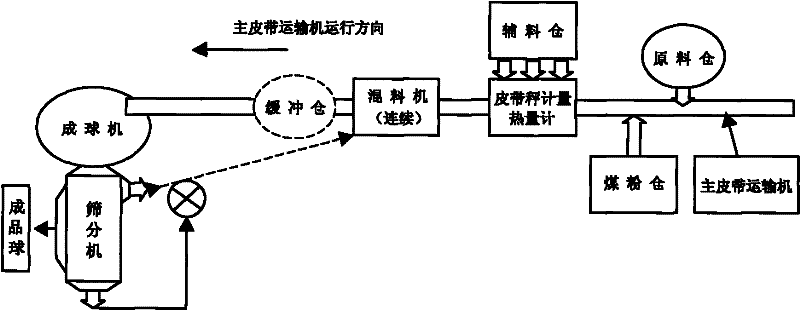

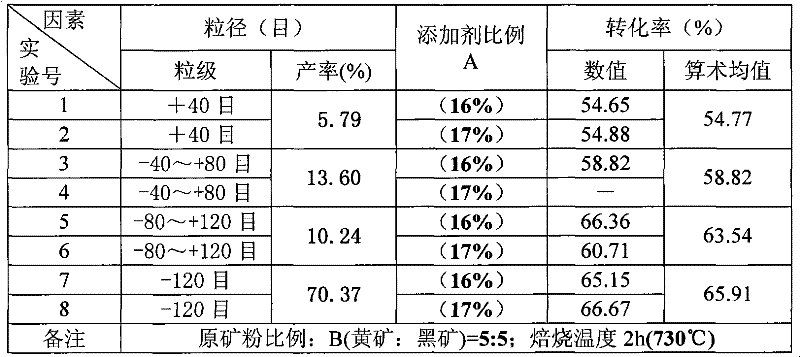

Method for increasing leaching rate of navajoite under navajoite kiln roasting condition

The invention discloses a method for increasing the leaching rate of navajoite under the navajoite kiln roasting condition, which is characterized in that NaCl and Na2CO3 are used as the auxiliary material, vanadium powder is used as the raw material, wherein the vanadium powder with the particle size less than 0.074mm accounts for 70-80 percent of the vanadium powder weight; 8-10 portions of NaCl, 3-4 portions of NaCO3, and 100 portions of vanadium powder are sent by weight portion to a material mixer for mixing, the carbon content of the vanadium powder is of 8-10 portions; green balls are generated by a ball forming mill; after being sieved, the green balls with diameter of 8-13 mm are conveyed to the kiln, the green balls with diameter smaller than 8 mm and larger than 13 mm are sent back to the material mixer; the green balls entering the kiln are roasted at the temperature of 650-750 DEG C. and maintained at the temperature for 2-3 hours, then, the finished balls are produced. The invention has the advantages that through the improvement of the process condition, the roasting temperature can be increased to 700 DEG C. more or less, the carbon content in the mixed material and the Na2CO3 content in the auxiliary material are controlled, the particle size of the vanadium powder (table 4) and the particle diameter of the green ball (table 2) are controlled; the experiment proves that the leaching rate of the vanadium can be increased to over 75 percent, even to the highest rate of 82 percent.

Owner:LIAONING CHENGUANG FERRO ALLOYS GROUP

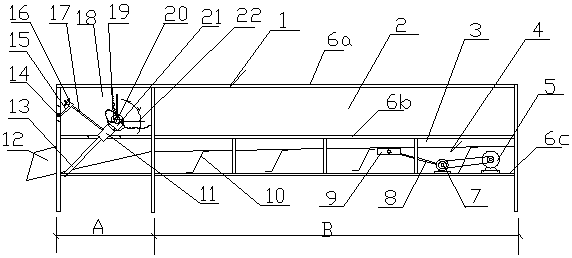

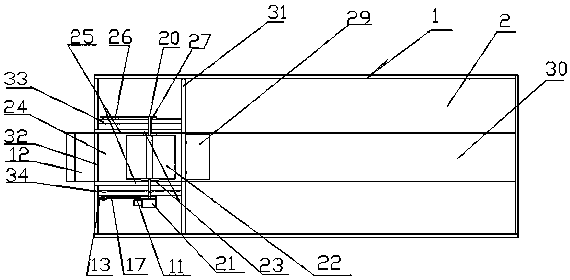

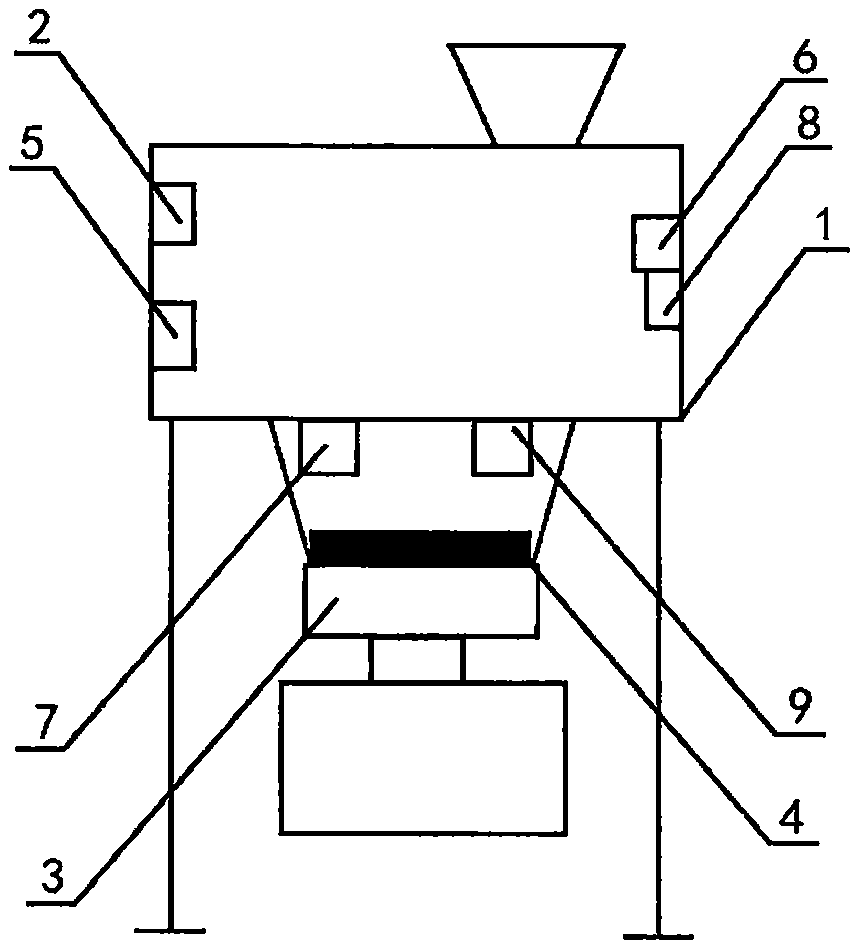

High voltage electric separator for fly ash separation

ActiveCN103861739BCompact and reasonable structureNo secondary pollutionElectrostatic separationEngineeringPulverized fuel ash

The invention discloses a high-voltage electric separator applicable to separation of pulverized fuel ash. The high-voltage electric separator comprises a rack, wherein the rack is dived into a feeding zone, separation zones and a material receiving zone in sequence in a material separation direction; a vibration cloth hopper and a riffle are arranged in the feeding zone; the vibration cloth hopper and the riffle are mounted at the top of the rack; the riffle is fixed on the vibration cloth hopper; two separation zones are arranged in parallel and located under the vibration cloth hopper. The high-voltage electric separator applicable to separation of the pulverized fuel ash has the advantages of compact structure, little pollution and capability of continuously and uniformly feeding.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

A method and system for reducing dioxins in flue gas produced by waste incineration

ActiveCN110864297BReduce penetrationReduce impactDispersed particle filtrationEmission preventionActivated carbonFlue gas

The invention provides a method and system for reducing the dioxin in the flue gas produced by waste incineration. By adopting a PTFE cloth bag and increasing the quantity of the PTFE cloth bag and adjusting the operation parameters of cloth bag dust removal, the method specifically comprises the following steps that the flue gas flow rate and the differential pressure value on both sides of the cloth bag are reduced, the penetrability of the dust on the cloth bag is reduced accordingly, meanwhile, by arranging a spiral spraying pipe and an inner pipe assembly, the flue gas makes contact withthe activated carbon under the state that the flow direction and rotation direction are both opposite, the contacting area of the flue gas and the activated carbon is greatly increased, third-time adsorption using of the activated carbon is achieved, the full utilization of the activated carbon is achieved, the adsorption effect is greatly improved, and the problems of the penetration of the dustthrough the cloth bag and substandard emission of the dioxin due to the large differential pressure on both sides of the cloth bag and the high reverse vibration effect and the flow rate of the clothbag flue gas in the prior art are solved.

Owner:CHANGXING XINCHENG ENVIRONMENTAL PROTECTION

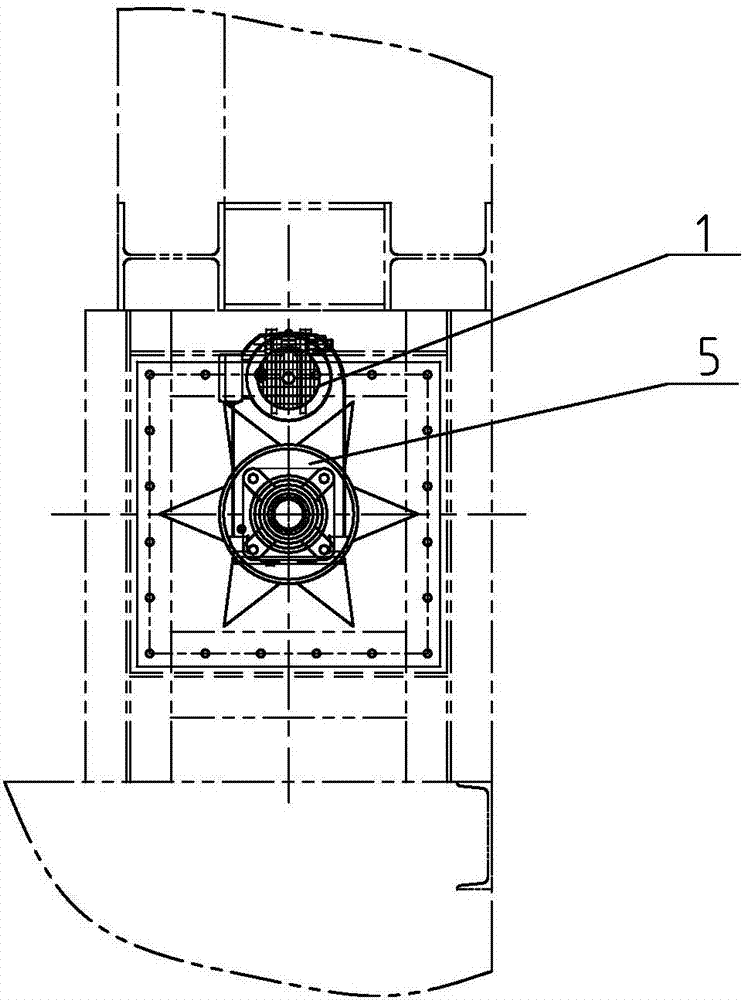

Stirring roller

InactiveCN106956872AContinuous and even feedingAvoid getting in the wayLarge containersReducerPulp and paper industry

Owner:常州联合锅炉容器有限公司

Method for increasing leaching rate of navajoite under navajoite kiln roasting condition

The invention discloses a method for increasing the leaching rate of navajoite under the navajoite kiln roasting condition, which is characterized in that NaCl and Na2CO3 are used as the auxiliary material, vanadium powder is used as the raw material, wherein the vanadium powder with the particle size less than 0.074mm accounts for 70-80 percent of the vanadium powder weight; 8-10 portions of NaCl, 3-4 portions of NaCO3, and 100 portions of vanadium powder are sent by weight portion to a material mixer for mixing, the carbon content of the vanadium powder is of 8-10 portions; green balls are generated by a ball forming mill; after being sieved, the green balls with diameter of 8-13 mm are conveyed to the kiln, the green balls with diameter smaller than 8 mm and larger than 13 mm are sent back to the material mixer; the green balls entering the kiln are roasted at the temperature of 650-750 DEG C. and maintained at the temperature for 2-3 hours, then, the finished balls are produced. The invention has the advantages that through the improvement of the process condition, the roasting temperature can be increased to 700 DEG C. more or less, the carbon content in the mixed material and the Na2CO3 content in the auxiliary material are controlled, the particle size of the vanadium powder (table 4) and the particle diameter of the green ball (table 2) are controlled; the experiment proves that the leaching rate of the vanadium can be increased to over 75 percent, even to the highest rate of 82 percent.

Owner:LIAONING CHENGUANG FERRO ALLOYS GROUP

Continuous automatic feeding machine

ActiveCN105852181BContinuous and even feedingIncrease the feeding speedTeaFood shapingBlack teaEngineering

The invention provides a continuous automatic feeding machine and relates to a root and leaf type agricultural product processing and feeding equipment, in particular to black tea production and feeding equipment. The continuous automatic feeding machine comprises a machine frame and a material bin and is characterized in that an opening is formed in the bottom of the material bin, a material vibration groove is formed in a position under the opening, a vibrator is arranged under the material vibration groove, a material homogenizing bin is arranged in front of the material bin, and a tea homogenizing wheel rotating anticlockwise is arranged in the material homogenizing bin. The continuous automatic feeding machine can realize continuous uniform feeding in the root and leaf type agricultural product processing process, is free from interrupt feeding or blocking, high in feeding speed and high in efficiency, requires no artificial feeding, can adapt to root and leaf type agricultural product processing and especially meets the black tea mechanization and automation production requirements.

Owner:HUNAN JIANLING IND

Separator used for separating product flow, and separating method

ActiveCN100376180CActive and even deliveryContinuous and trouble-free operationCigar manufactureCigarette manufactureEngineering

Separating device (10) for separating a product flow, especially for separating parts of a product flow that are to be processed or not to be processed within a distribution device for loading a cigarette-making machine, comprises a vertical zigzag separator (11) and at least one inlet (12) for the product flow to be separated. An insertion aid (18) for the product flow is arranged in the zigzag separator in the region of the inlet. An Independent claim is also included for a process for separating a product flow. Preferred Features: The insertion aid is a rotating roller (19). The inlet is formed by two side walls (13, 14) of the zigzag separator. The roller is arranged in the region of a free end (24) of the upper side wall.

Owner:KOERBER TECH GMBH

Drum-type particle sorting device

ActiveCN103433200BAvoid damageContinuous and even feedingSievingScreeningParticle sortingEngineering

Owner:TSINGHUA UNIV

A cutting and mixing machine for uniform feeding of meat products

The invention relates to a chopping and mixing machine for uniform feeding of meat products, which includes a base, a controller, a feeding mechanism, a chopping and mixing mechanism and a collecting mechanism. The chopping and mixing mechanism includes a chopping and mixing box, a first motor, a rotating shaft, The discharge pipe and several chopping knives, the feeding mechanism includes the material box, the connecting pipe, the feeding pipe and the feeding assembly, the feeding assembly includes the cylinder, the sealing block, the sealing plate and the connecting rod, and the collecting mechanism includes the collecting platform and the driving assembly , vertical bar, frame, filter screen, several side bars and several legs, the cutting and mixing machine for uniform feeding of processed meat products realizes continuous and uniform feeding of the equipment through the feeding mechanism, avoiding excessive addition of raw meat at one time Not only that, the filter screen can be driven upward by the collection mechanism, so that the filter screen can push the larger meat pieces above it to the chopping box and cut again until it is crushed into pieces that can pass through the filter screen. The minced meat of the net ensures the chopping effect and improves the practicability of the equipment.

Owner:LIAOCHENG DONGDA FOOD

Intelligent sensing selecting assembly of jigging machine

InactiveCN107913791AIngenious structural designContinuous and even feedingWet separationPoor qualityEngineering

An intelligent induction selection component of a jig, comprising a body (1), on which a setting module (2), a humidity control module (3), a filter module (4), and a transmission module (5) are arranged , the management module (6), during operation, the setting module (2) sets the flow rate required for the operation and the feeding amount within a certain period of time, and the humidity control module (3) can adjust the humidity of the operation in the jig machine, filter The module (4) can further remove materials with poor quality in the materials, and the transmission module (5) transmits various sensed information to the management module (6) for comprehensive processing; the wind speed sensor (7) is installed to detect the wind speed in the air duct conditions and keep the wind speed in balance; a flow sensing module (9) is provided, and the flow rate during the sensing operation can be adjusted in real time.

Owner:XINCHANG LINYU MACHINERY TECH CO LTD

A kind of concrete mixing equipment

ActiveCN110757649BContinuous and even deliveryServe evenlyRotary stirring mixersTransportation and packagingArchitectural engineeringStructural engineering

The invention discloses a concrete mixing equipment, which comprises a supporting shell, a mixing barrel arranged in the supporting shell, and a screw feeding mechanism located on the left side of the supporting shell, the supporting shell and the screw upper A power mechanism is arranged between the feeding mechanisms, and the power mechanism controls the conveying work of the screw feeding mechanism and the stirring work of the left hollow stirring shaft and the right hollow stirring shaft; the present invention carries out conveying through the left hollow stirring shaft and the right hollow stirring shaft Water, and then add water through the water spraying method of the layout of the first water outlet and the second water outlet, so that the stirring is more uniform.

Owner:宜昌力华新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com