Vibratory feeding mechanism of grain selection separator

A technology of vibrating feeding and separators, applied in the direction of solid separation, separating solids from solids with air flow, chemical instruments and methods, etc., can solve grain control, affect impurity removal, grain grading, increase the amount of feeding or Minimize and other problems, to achieve the effect of continuous and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

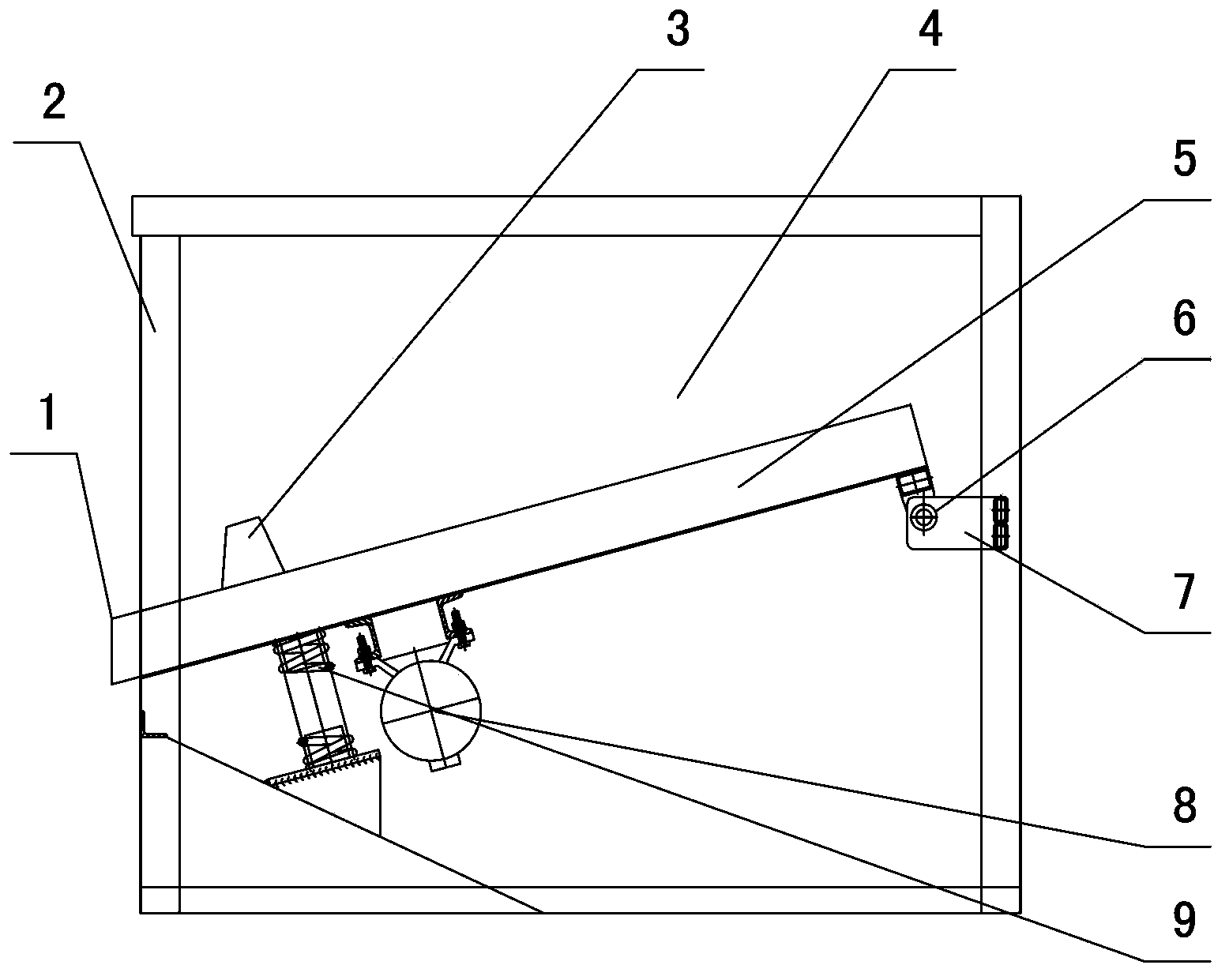

[0013] Such as figure 1 As shown, the vibrating feeding mechanism of the grain selection separator includes a frame structure 2, on which a vibrating plate 5 is obliquely installed, the upper right part of the vibrating plate 5 is the grain entry end 4, and the left lower end of the vibrating plate 5 is It is the grain feeding end 1, the upper right end of the vibrating plate 5 is hinged on the right side of the frame 2, the lower left end of the vibrating plate 5 is connected to the left side of the frame 2 through an elastic member, and a vibrating motor 8 is installed at the bottom of the vibrating plate 5, and the vibrating plate 5 The upper surface of the left lower end is provided with an anti-shock block 3, and the anti-shock block 3 is arranged parallel to the grain feeding end 1. The upper right end of the vibrating plate 5 is connected with the rotary shaft suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com