Intelligent sensing selecting assembly of jigging machine

A jig and intelligent technology, applied in the field of jigs, can solve the problems of selection and adjustment of coal volume, insufficient stability of air volume and water volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

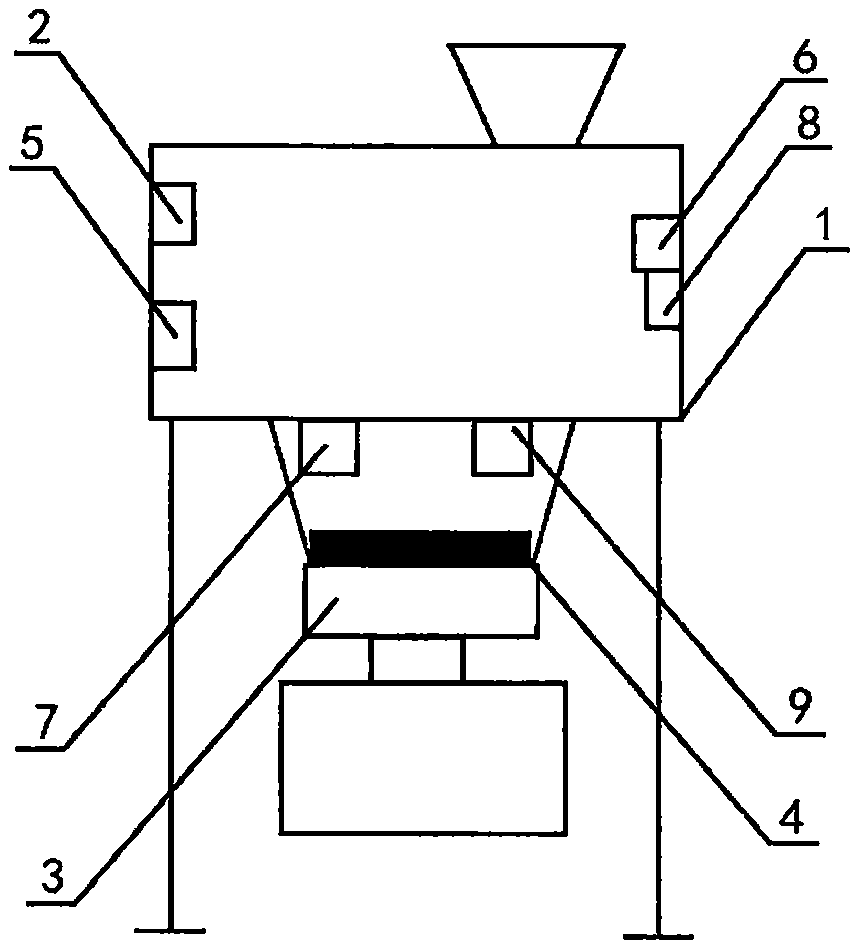

[0012] Embodiment: as shown in the accompanying drawing. An intelligent induction selection component of a jig, comprising a body (1), on which a setting module (2), a humidity control module (3), a filter module (4), and a transmission module (5) are arranged , the management module (6), during operation, the setting module (2) sets the flow rate required for the operation and the feeding amount within a certain period of time, and the humidity control module (3) can adjust the humidity of the operation in the jig machine, filter The module (4) can further remove materials with poor quality in the materials, and the transmission module (5) transmits various sensed information to the management module (6) for comprehensive processing.

[0013] An intelligent induction selection component of a jig machine, in which a wind speed sensor (7) is arranged on a machine body (1) to detect the wind speed in an air duct and keep the wind speed in balance.

[0014] An intelligent induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com