Separator used for separating product flow, and separating method

A separation device and product flow technology, applied in the application and manufacture of cigars, tobacco, etc., can solve the problems of unstable supply, difficult separation device, difficult to obtain satisfactory separation results, etc., and achieve the effect of uniform and continuous feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

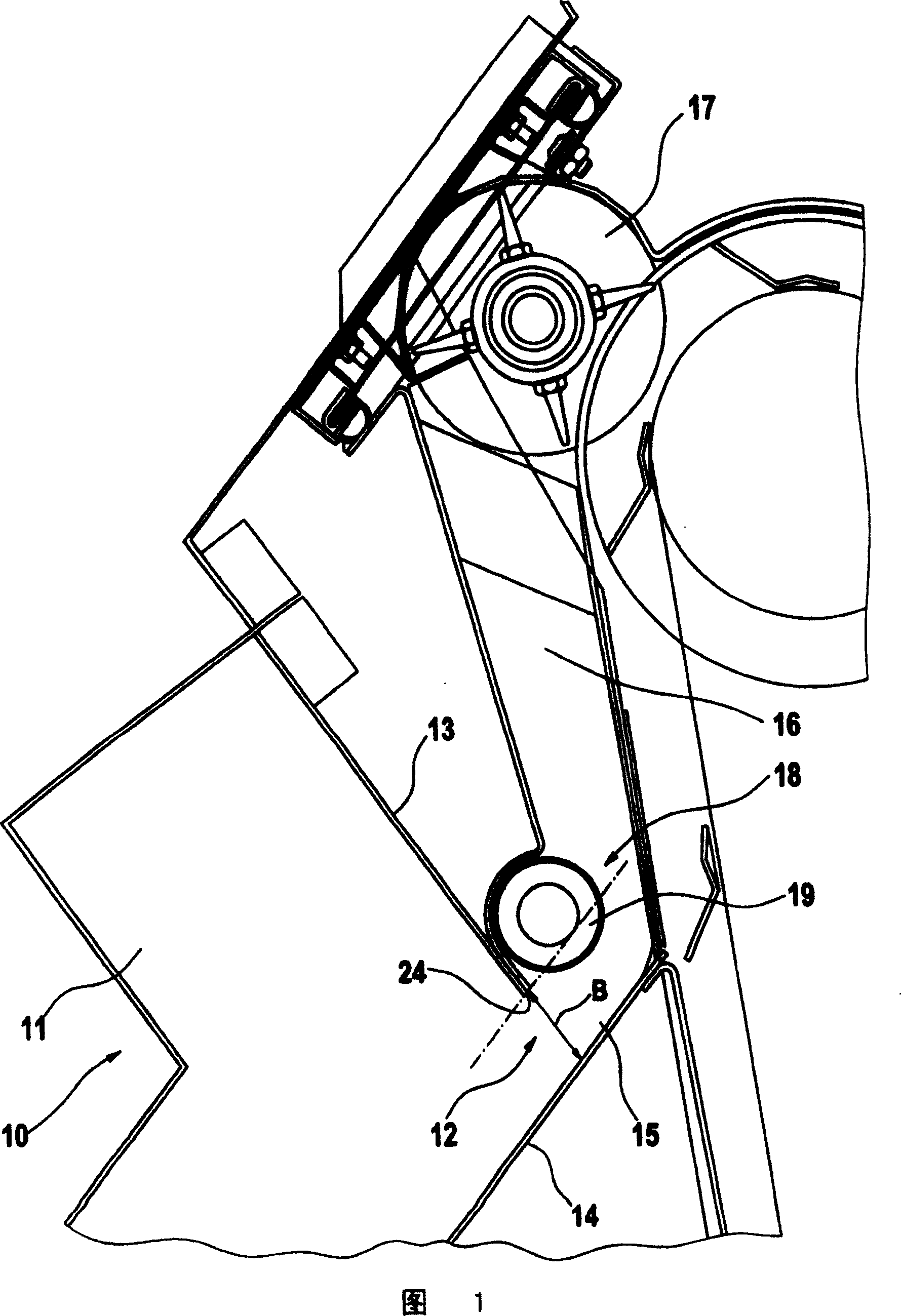

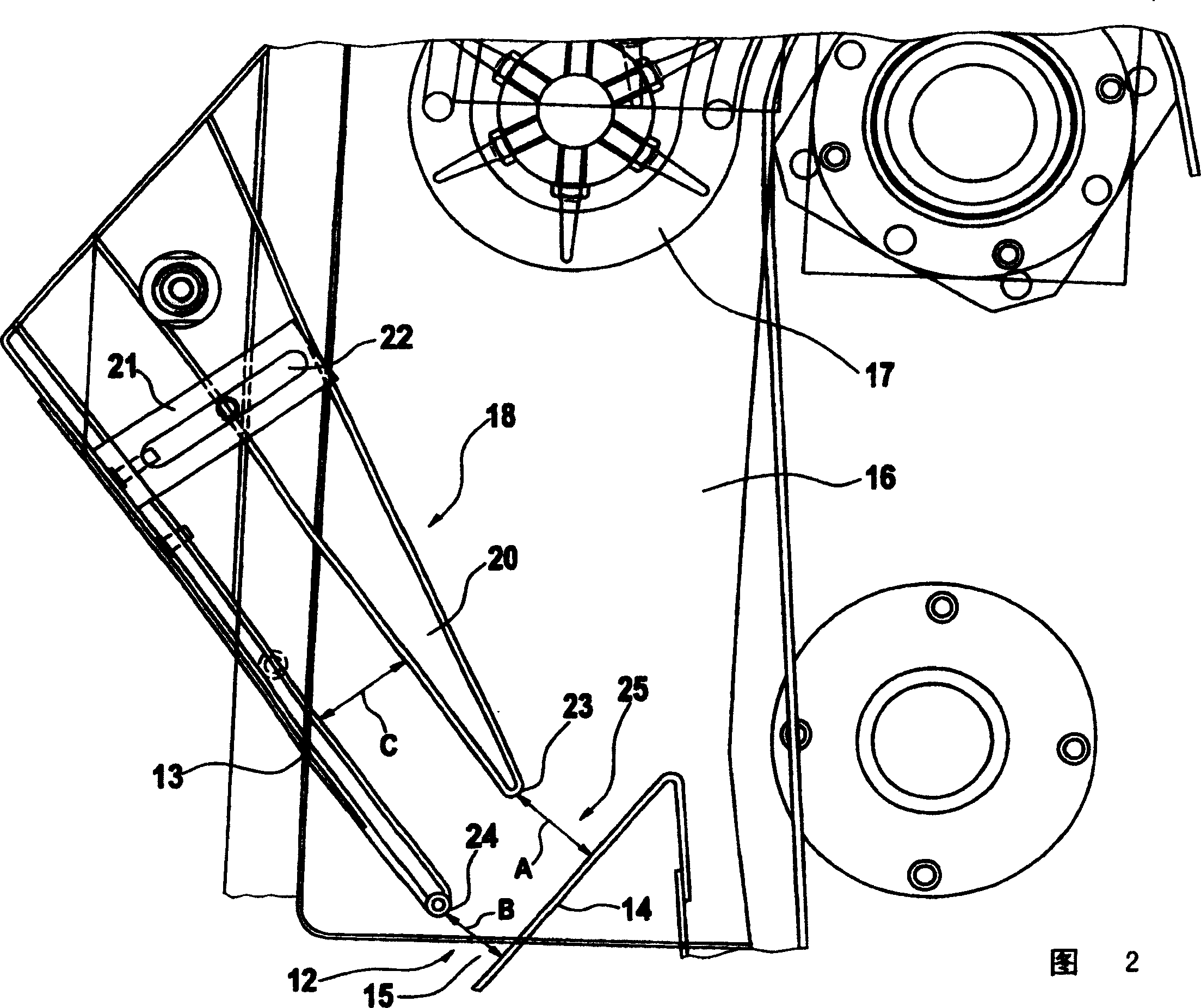

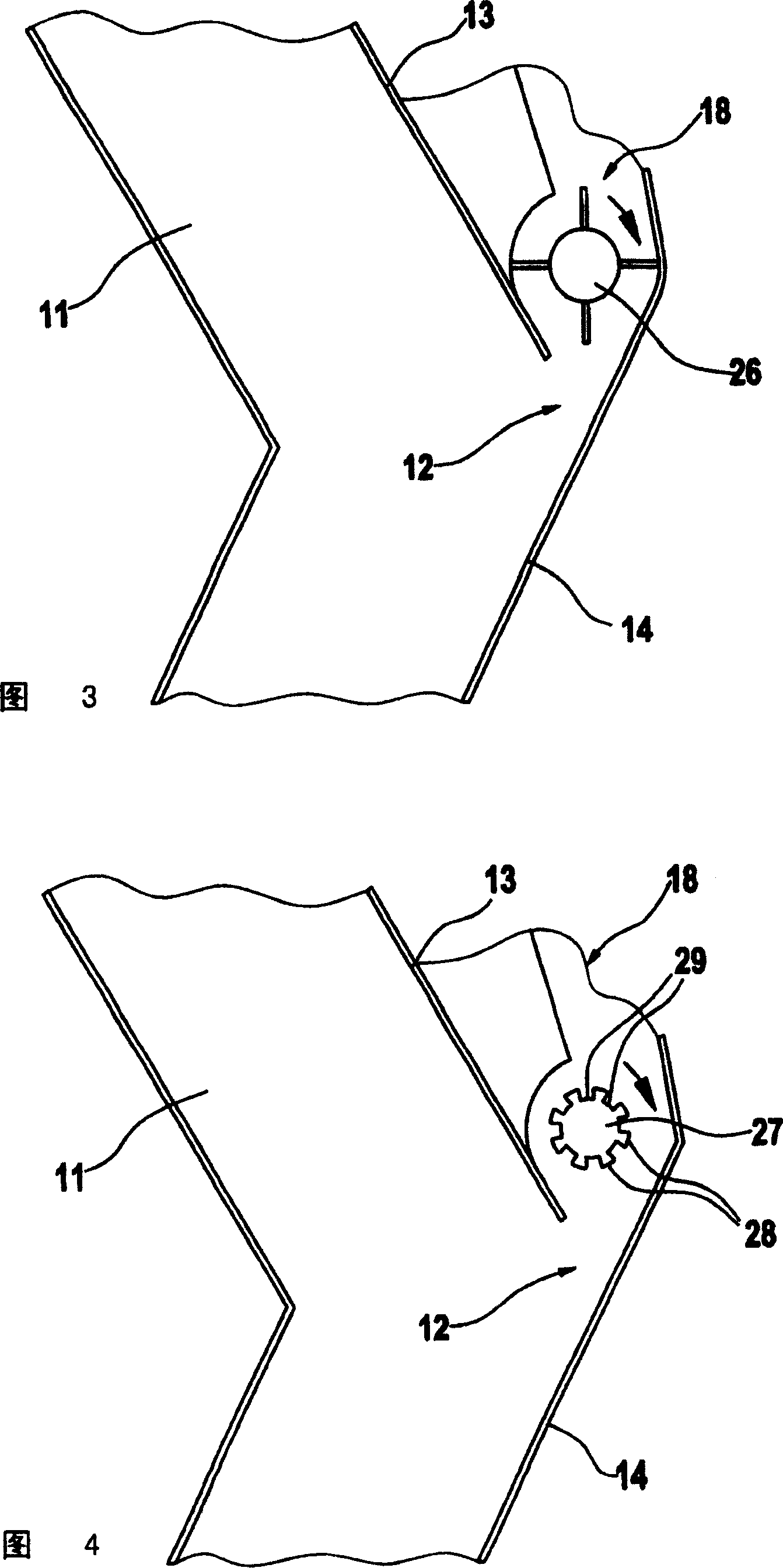

[0024] The zigzag separator shown in the figure is used to separate a product stream, preferably a product stream substantially consisting of tobacco constituents, in a distributor device for feeding a cigarette plying machine.

[0025] The separating device 10 according to the exemplary embodiment shown in FIG. 1 is designed as a so-called zigzag separator 11 and is part of a distributor device which is only partially shown. The zigzag separator 11 is arranged approximately vertically within the distributor device. The zigzag separator 11 has an inlet 12 for feeding the product flow. Alternatively, multiple inlets are also conceivable. The inlet 12 is formed by side walls, namely an upper side wall 13 and a lower side wall 14 , which in turn form an opening 15 . To this end, the upper side wall 13 stands approximately perpendicularly on the lower side wall 14 at a distance B, so that the product flow is guided into the zigzag separator 11 .

[0026] A feed channel 16 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com