Patents

Literature

34results about How to "Fully burnt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

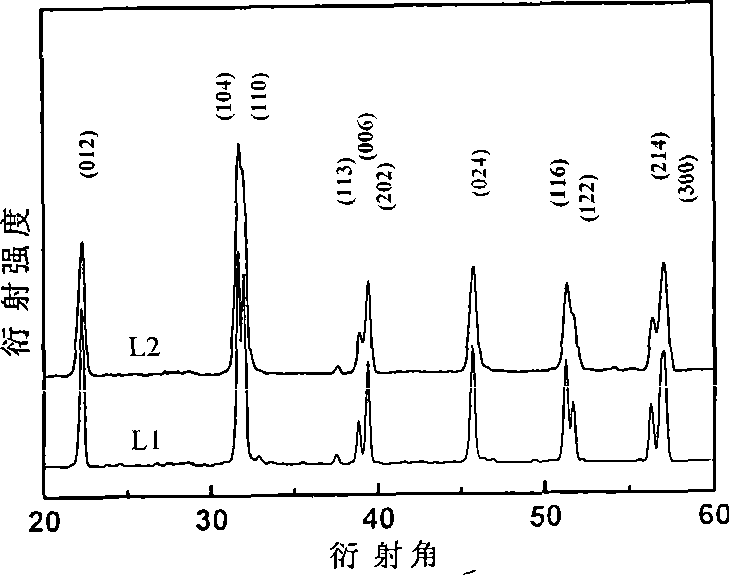

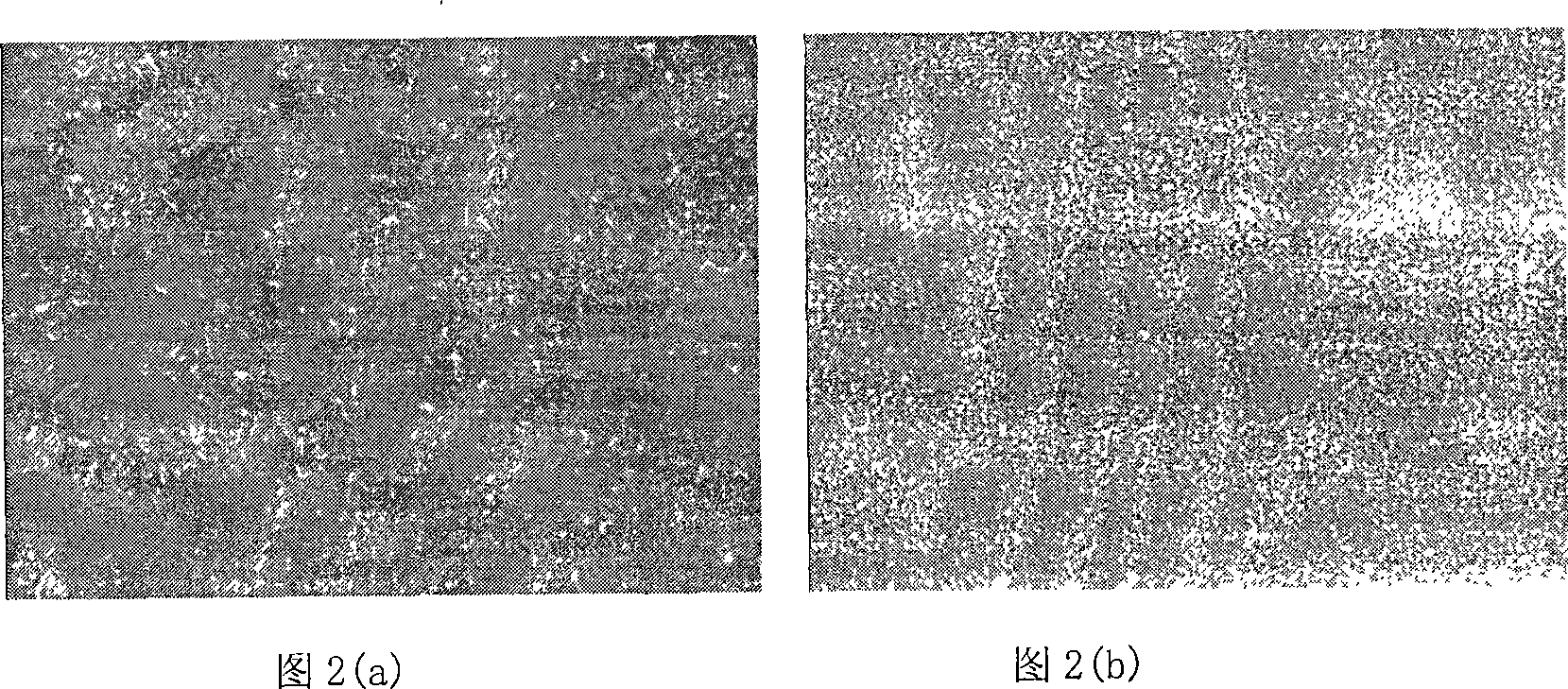

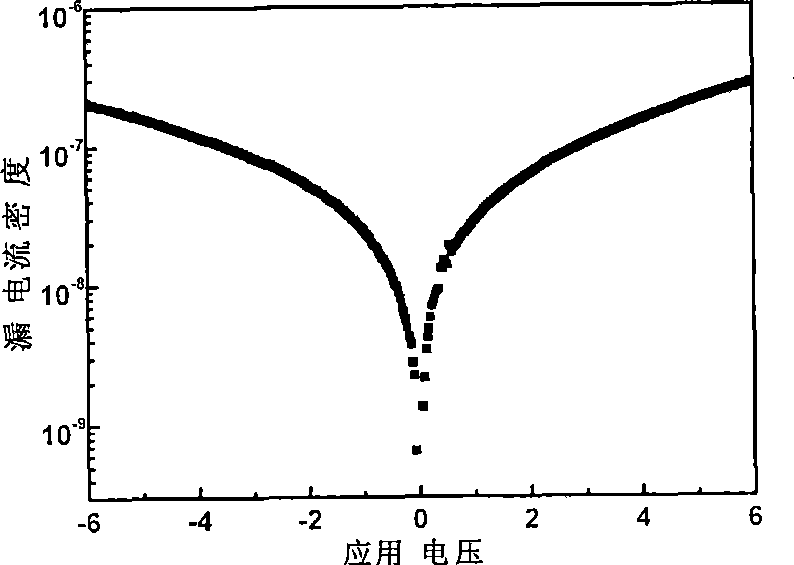

BiFeO3 target and film production method

InactiveCN101429642ALow costFine and uniform powderVacuum evaporation coatingSputtering coatingDrain currentOxide

The invention provides a preparation method for a BiFeO3 target material. The preparation method for the BiFeO3 target material comprises the following steps: carrying out grinding, ball milling, preburning, re-ball milling, granulation and screening for the mixture of bismuth oxide Bi2O3 and ferric oxide Fe2O3 to obtain the target material; and then carrying out batch dropping, baking, heating with pressure, heat insulation and cooling for the target material. The invention also provides a method for preparing a film through the BiFeO3 target material. The method comprises the following steps: selecting a Pt / TiO2 / SiO2 / p-Si substrate; preparing the BiFeO3 film through a radio frequency magnetron sputtering method; and finally carrying out the annealing treatment of the prepared BiFeO3 film. The target material has the advantages of no impurity phase, levelness and compactness. The film prepared through the target material has a compact and even surface, better crystallinity, no impurity phase, low drain current, saturated electric hysteresis loop, good fatigue characteristic, and good repeatability.

Owner:HUAZHONG UNIV OF SCI & TECH

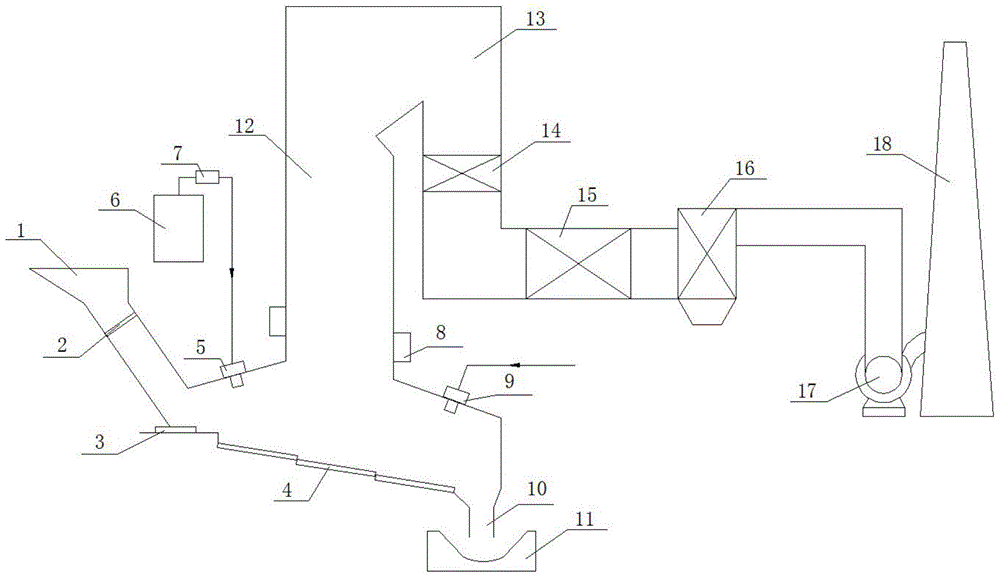

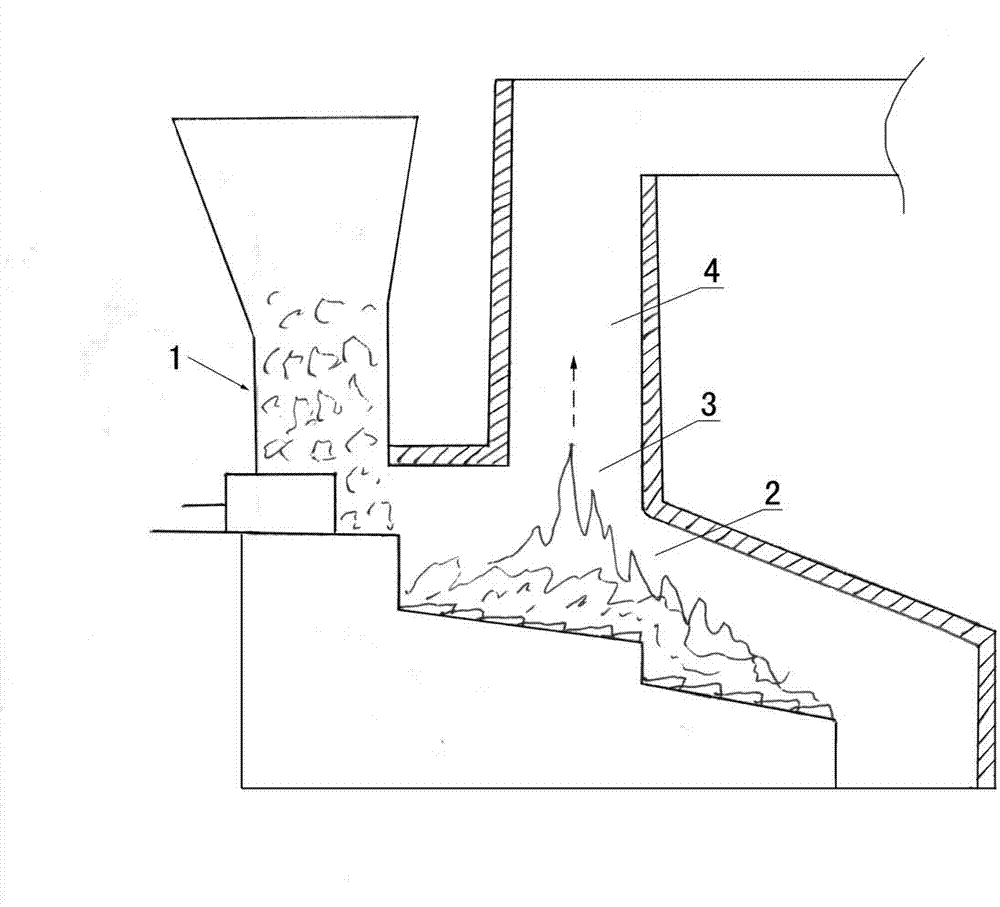

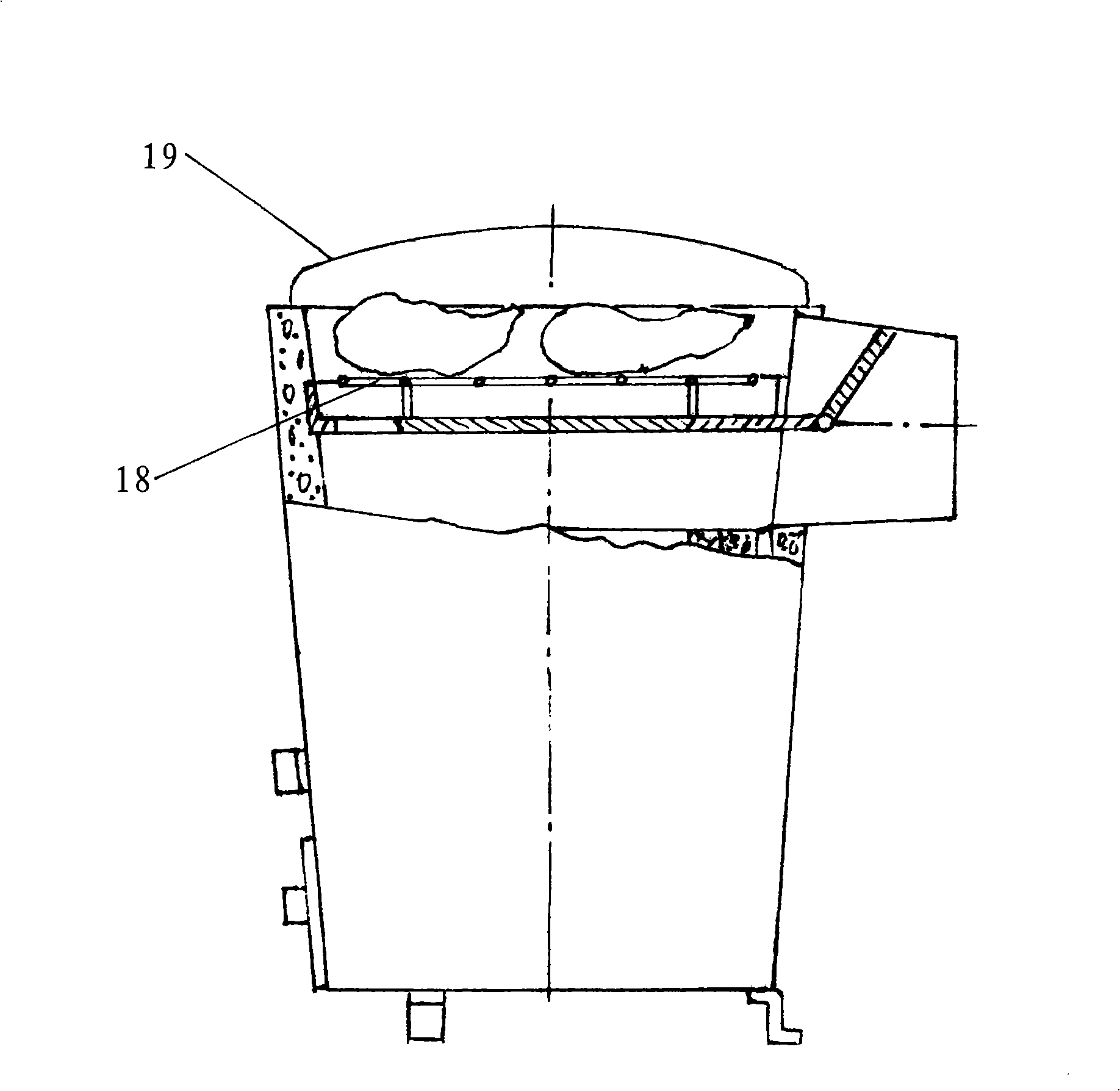

Low-corrosion and high-efficiency city garbage combusting system and method

InactiveCN105570898AIncrease moisture contentAvoid the phenomenon of lowering the combustion temperatureIncinerator apparatusCombined combustion mitigationCombustion chamberSlag

The invention discloses a low-corrosion and high-efficiency city garbage combusting system and method. The low-corrosion and high-efficiency city garbage combusting system comprises a boiler system and a marsh gas auxiliary combusting system. The boiler system comprises a combusting room with a cavity. The combusting room is provided with a feeding port, a slag discharging port, an air inlet and an exhaust opening. The marsh gas auxiliary combusting system comprises a combusting device, a dehumidifying device and a fermenting device used for fermenting kitchen garbage. The combusting device is connected to the combusting room, and the combusting device, the dehumidifying device and the fermenting device are communicated in sequence and in series. By means of the low-corrosion and high-efficiency city garbage combusting system, the difference of the water content of garbage is small, the combustion heat value and the water content are uniform, and corrosivity is low.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

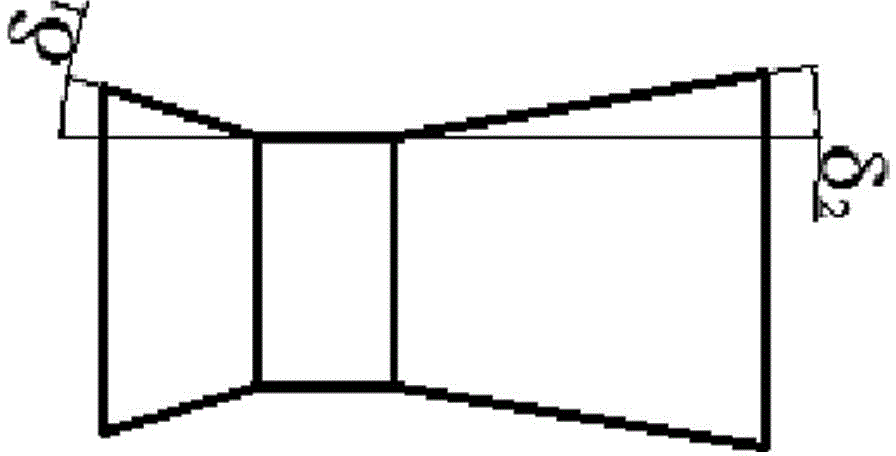

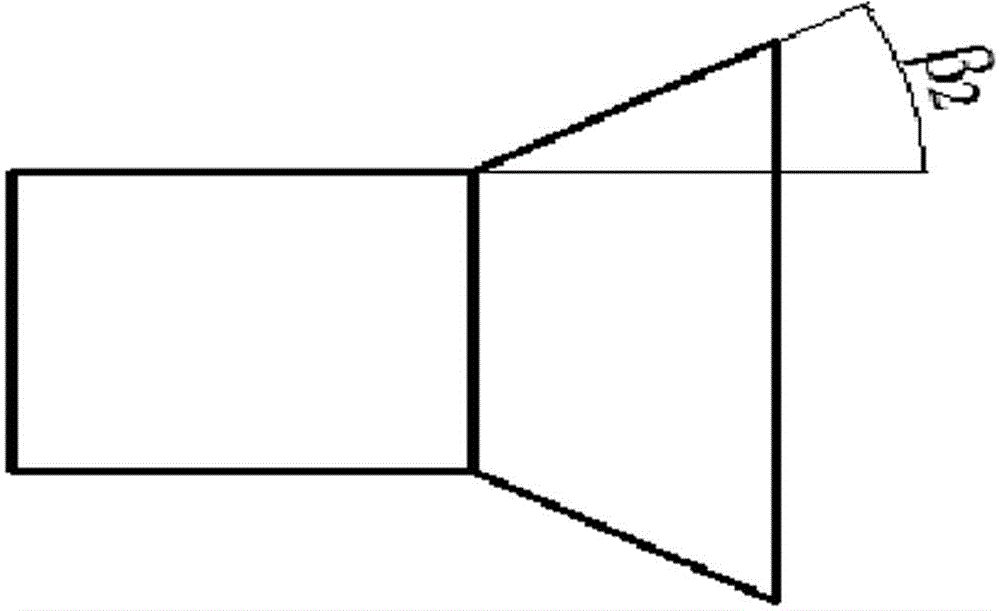

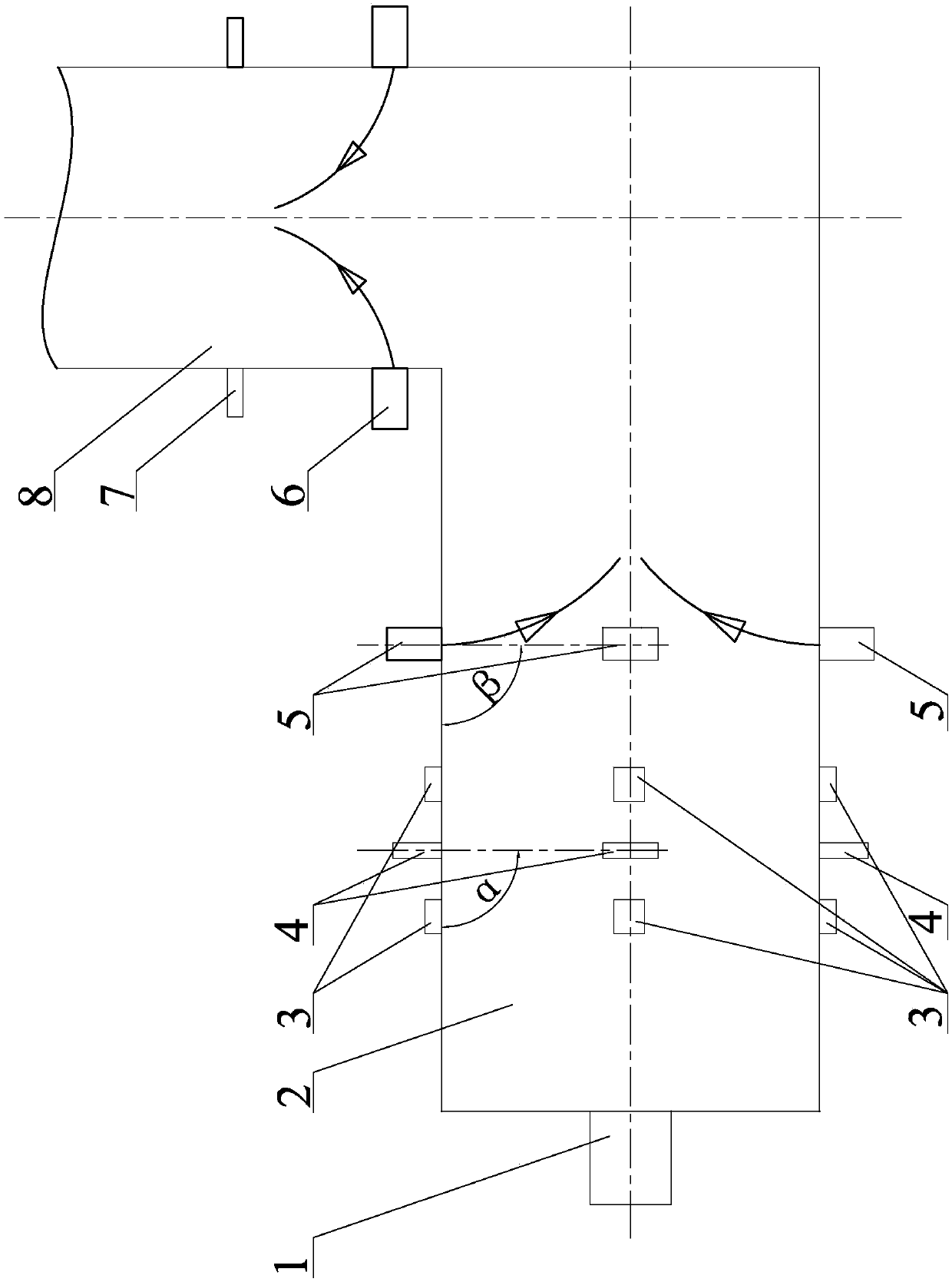

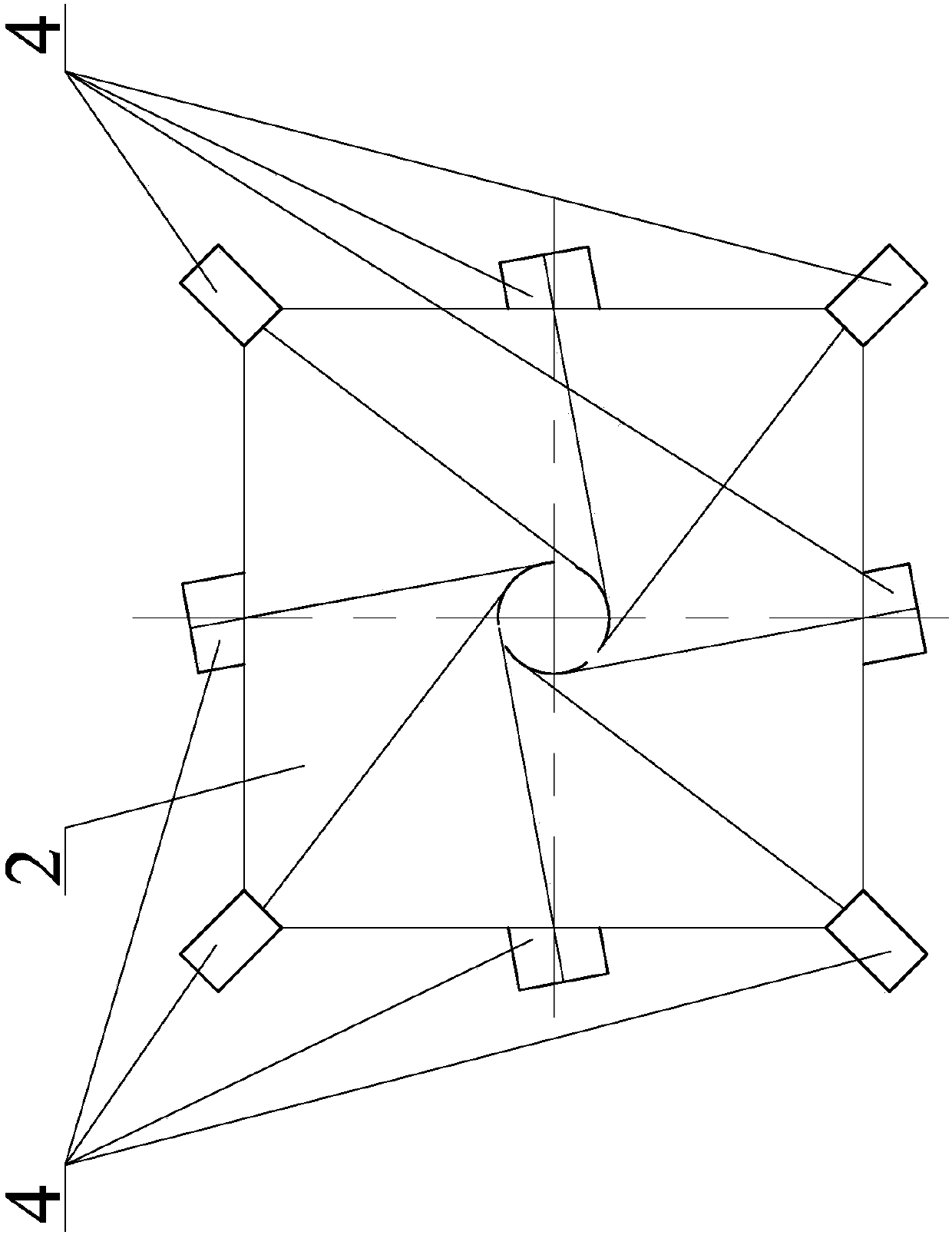

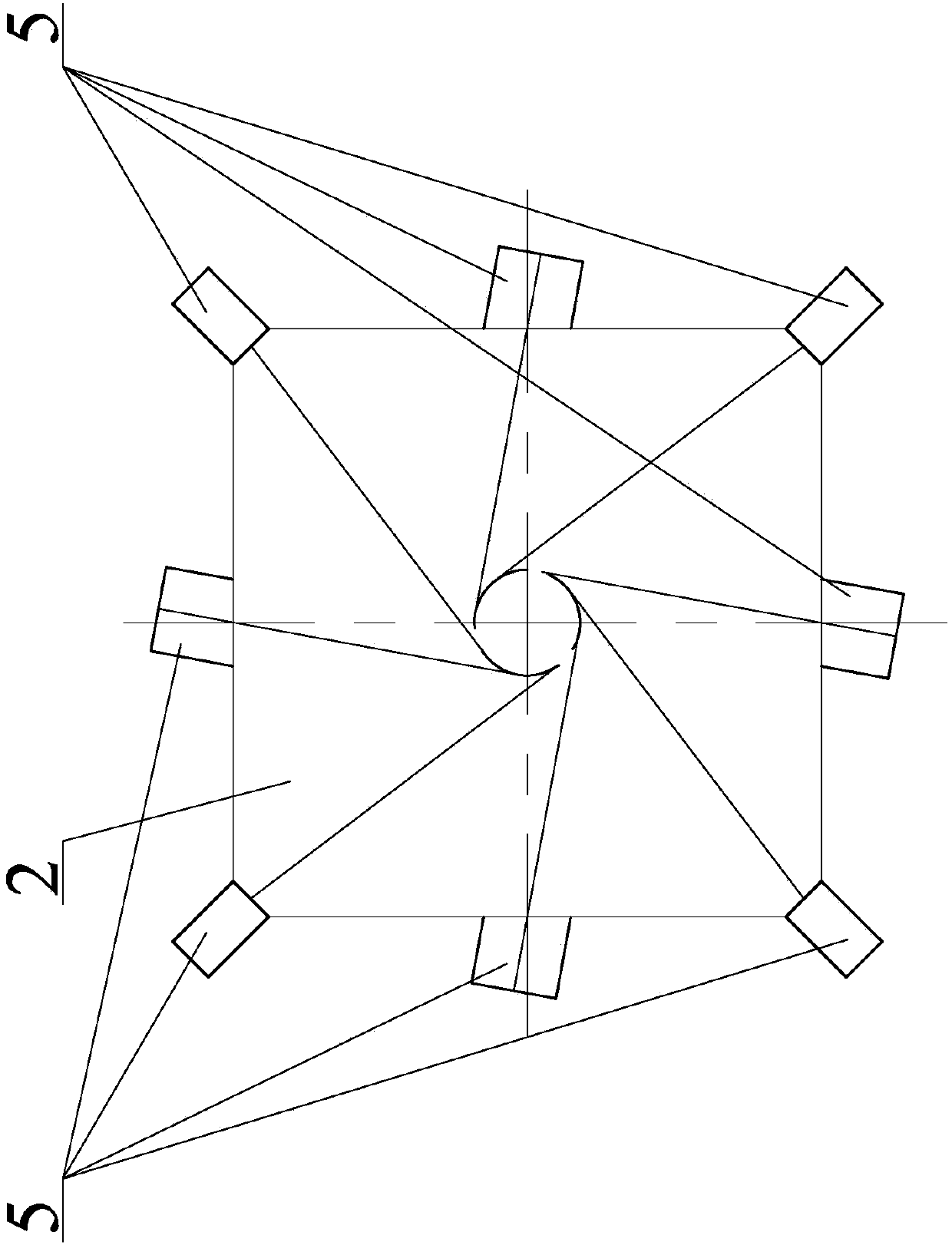

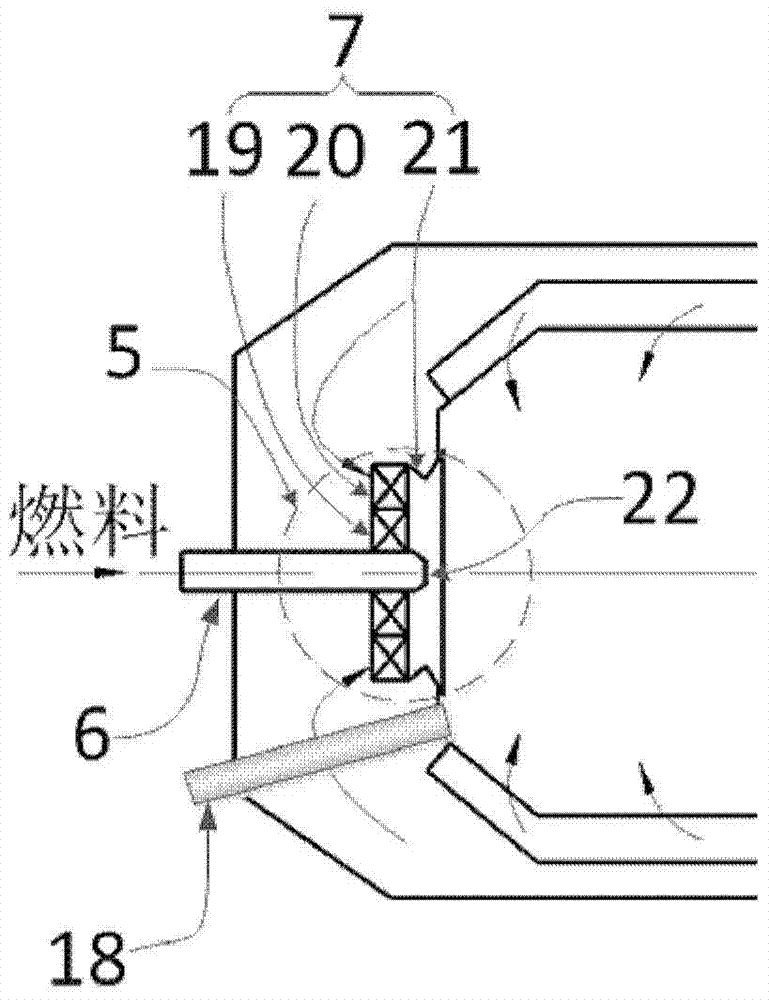

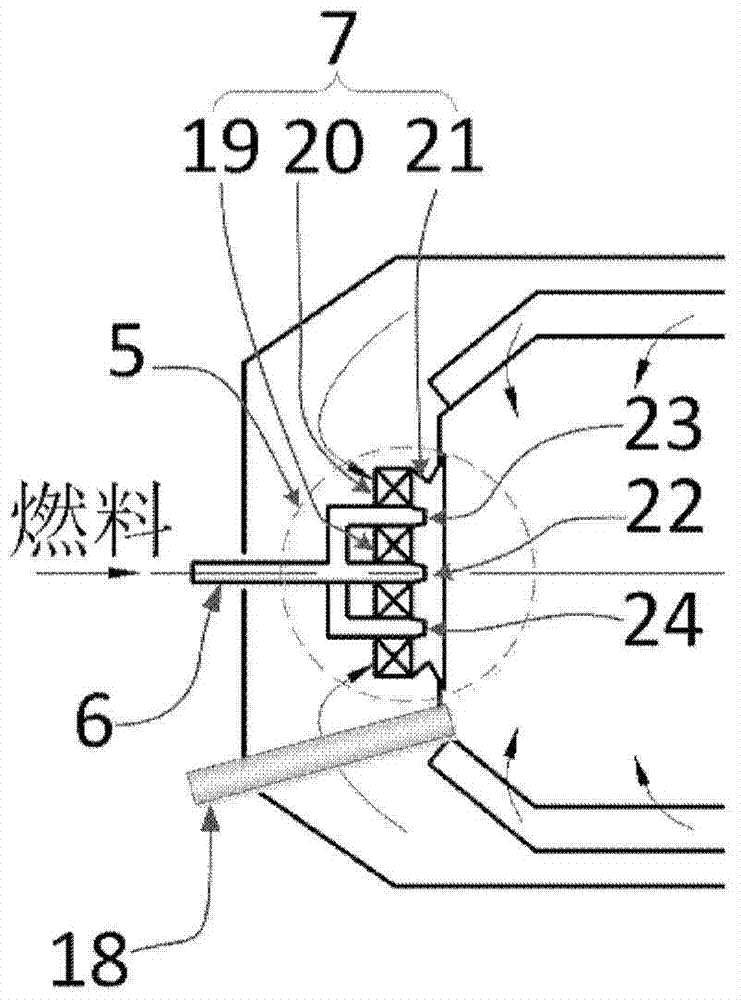

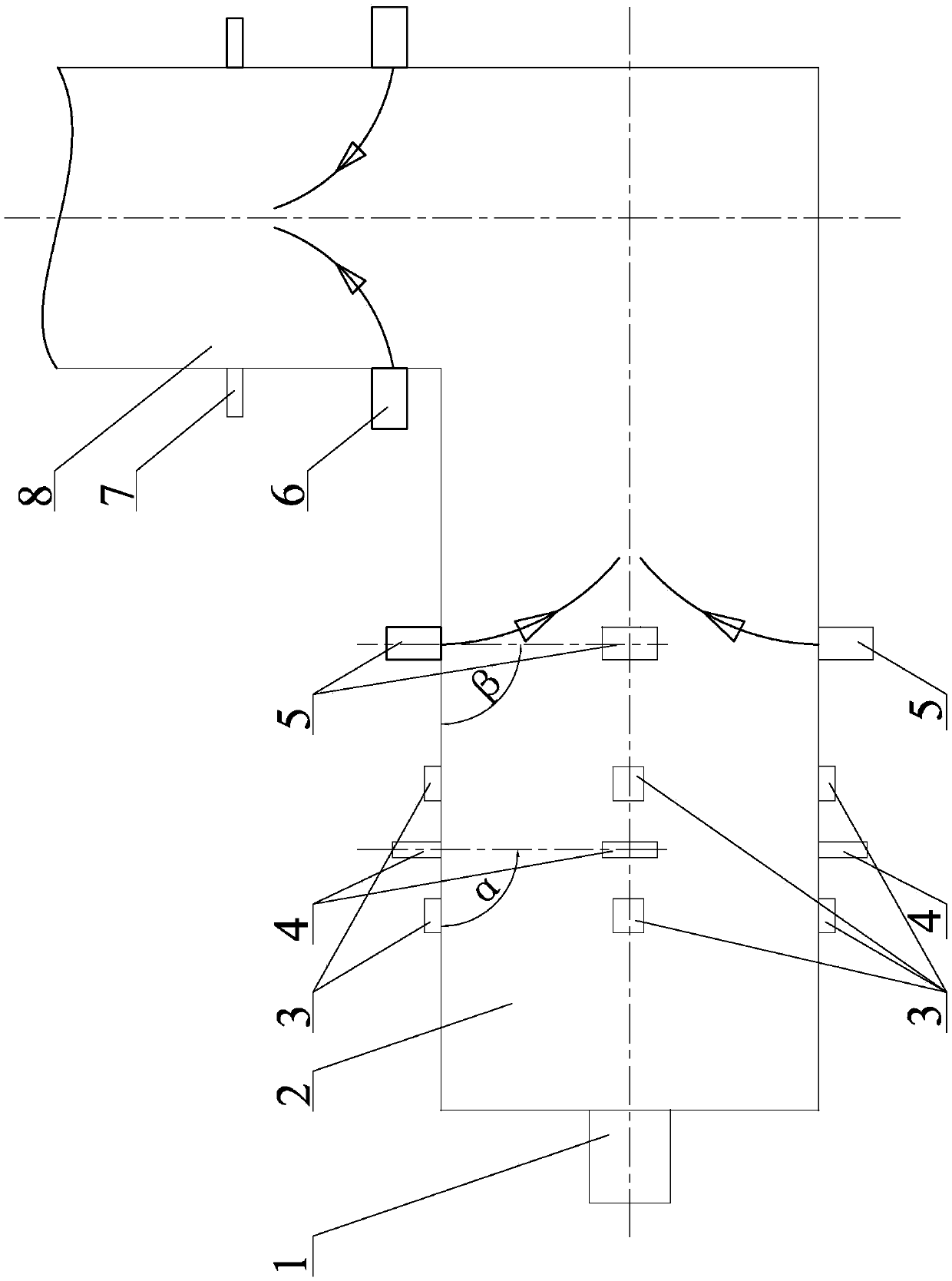

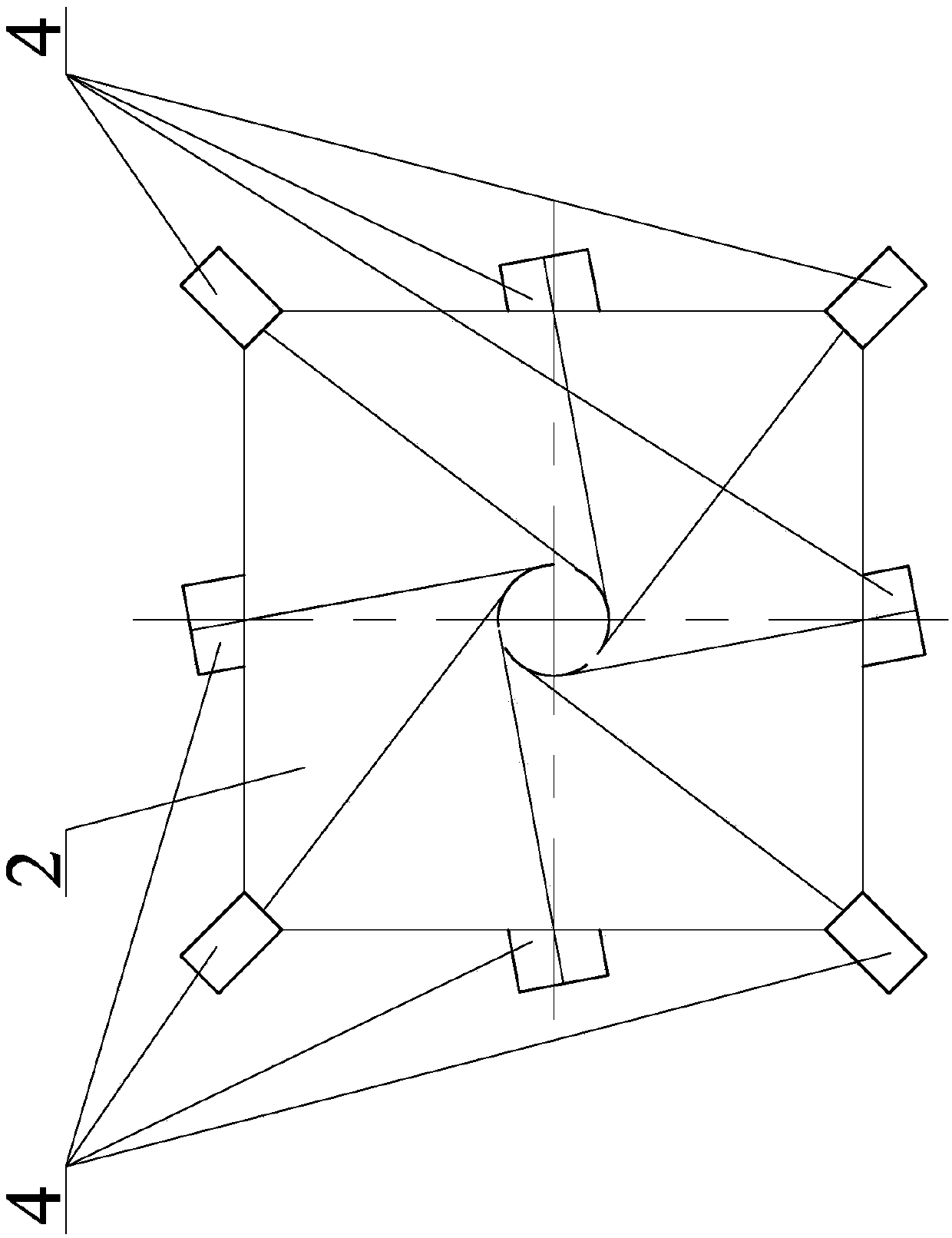

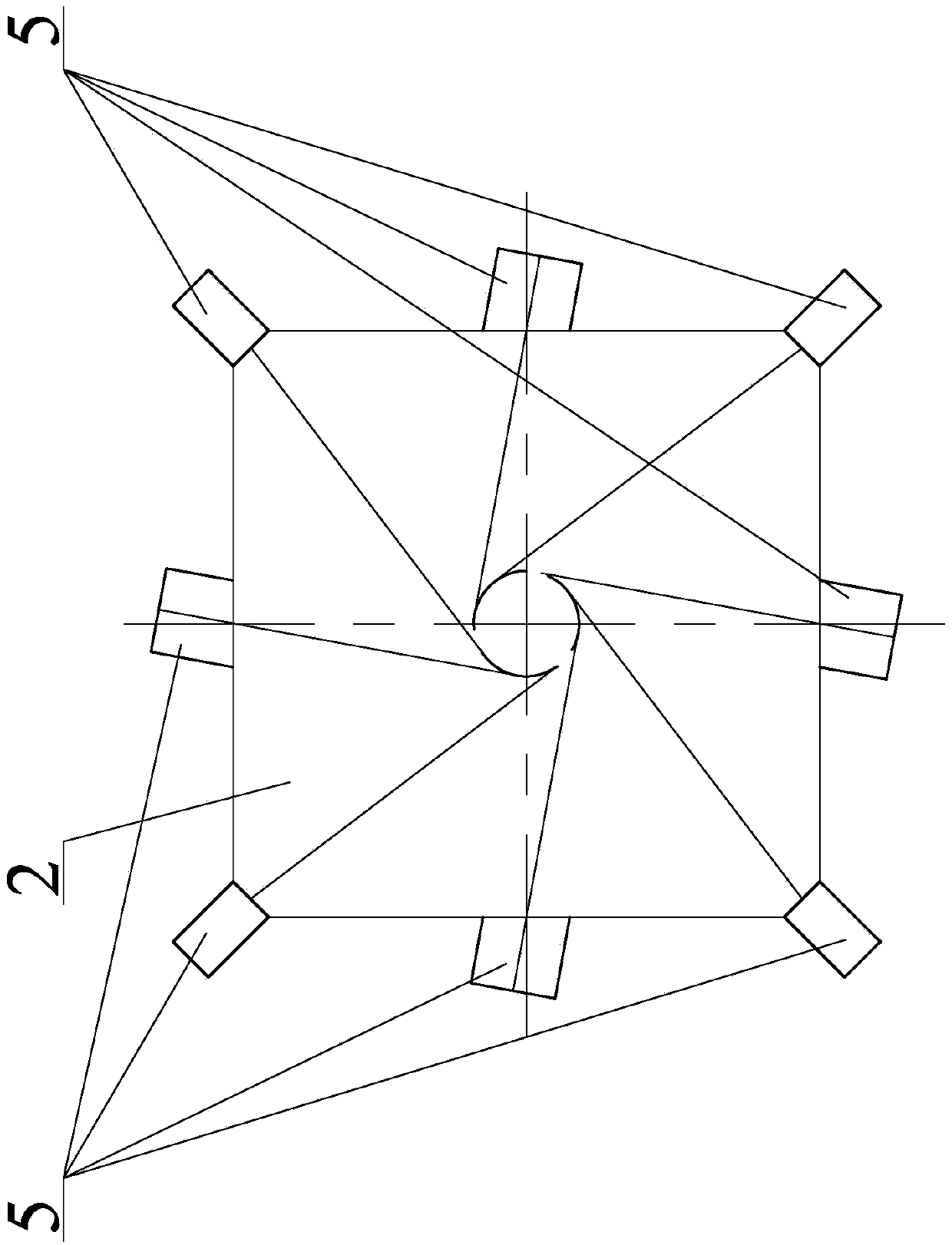

Novel cyclone bias pulverized coal burner

InactiveCN104832918AImprove stabilityEfficient combustionPulverulent fuel combustion burnersAir channelCyclone

The invention discloses a novel cyclone bias pulverized coal burner. The novel cyclone bias pulverized coal burner is characterized by comprising a central pipe, a pulverized coal concentration device, a primary air channel, a pulverized coal bias separating cylinder, a central pipe flaring, a primary air pipe flaring, a secondary air channel, a cyclone, a tertiary air channel and a tertiary air pipe flaring from inside to outside. According to the novel cyclone bias pulverized coal burner, the ignition and the burning of anthracite are supported in a mode of supplementing high-quality bituminous coal, the effect of increasing volatile matters of pulverized coal in a disguised form is achieved in the preliminary burning stage of the pulverized coal, and the timely ignition, the stable burning and the efficient burnout of low-volatile-matter pulverized coal are guaranteed. The novel cyclone bias pulverized coal burner is simple in structure, convenient to transform, and capable of efficiently burning the low-volatile-matter coal and particularly suitable for the structural transformation of burners of medium and small-sized industrial boilers, and can be widely applied to burning of low-volatile-matter anthracite duff for the industrial boilers.

Owner:JIMEI UNIV

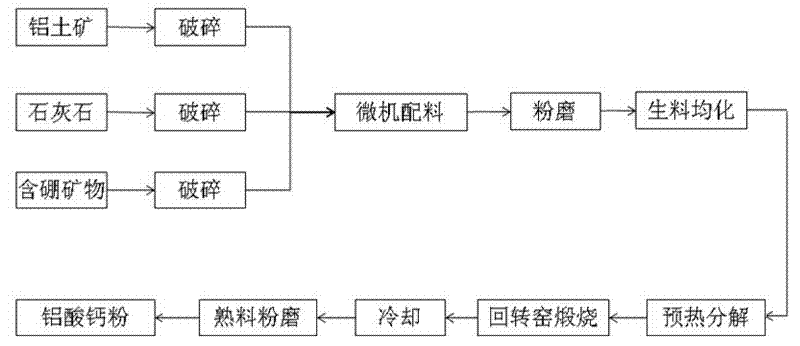

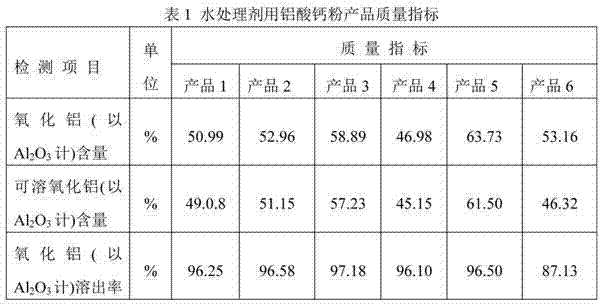

Calcium aluminate powder for water treatment agent and preparation method thereof

InactiveCN102363529AHigh dissolution rateIncrease profitEnergy inputWater/sewage treatmentClinker (waste)Boron containing

The invention discloses calcium aluminate powder for a water treatment agent and a preparation method thereof. The calcium aluminate powder is prepared from raw materials of bauxite, limestone and boracic mineral according to a weigh ratio of 60-80:30-45:0.5-2. The preparation method is characterized in that the high activity calcium aluminate powder is produced through treating the boracic mineral as a mineralizer, and adopting a calcining tail gas waste heat preheating pre-decomposition-calcining technology. The method which treats the boracic mineral as the mineralizer in the invention allows a case that the high activity calcium aluminate powder is produced from low grade bauxite to be possible, so the utilization rate of bauxite resources is improved, thereby the method has substantial economic, social and environmental benefits; and the clinker calcining temperature is reduced, the clinker sintering reaction speed is accelerated, and the alumina leaching rate is improved, so purposes of energy consumption reduction, and product quality and output improvement are reached.

Owner:广东慧信环保有限公司

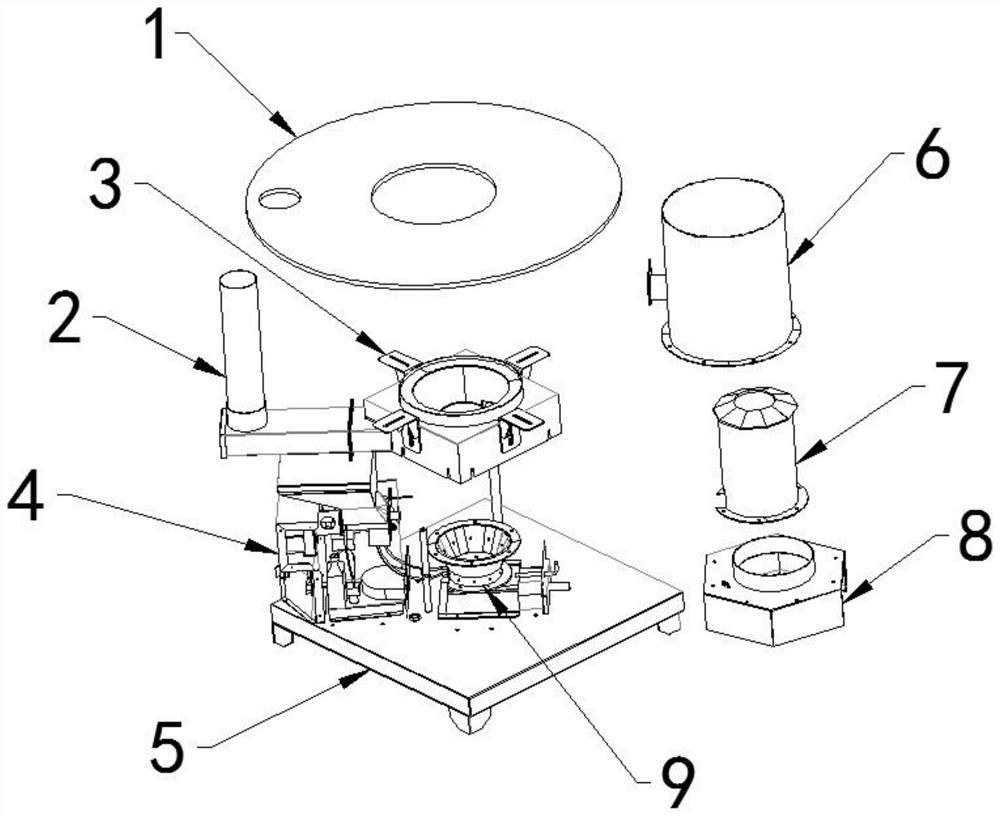

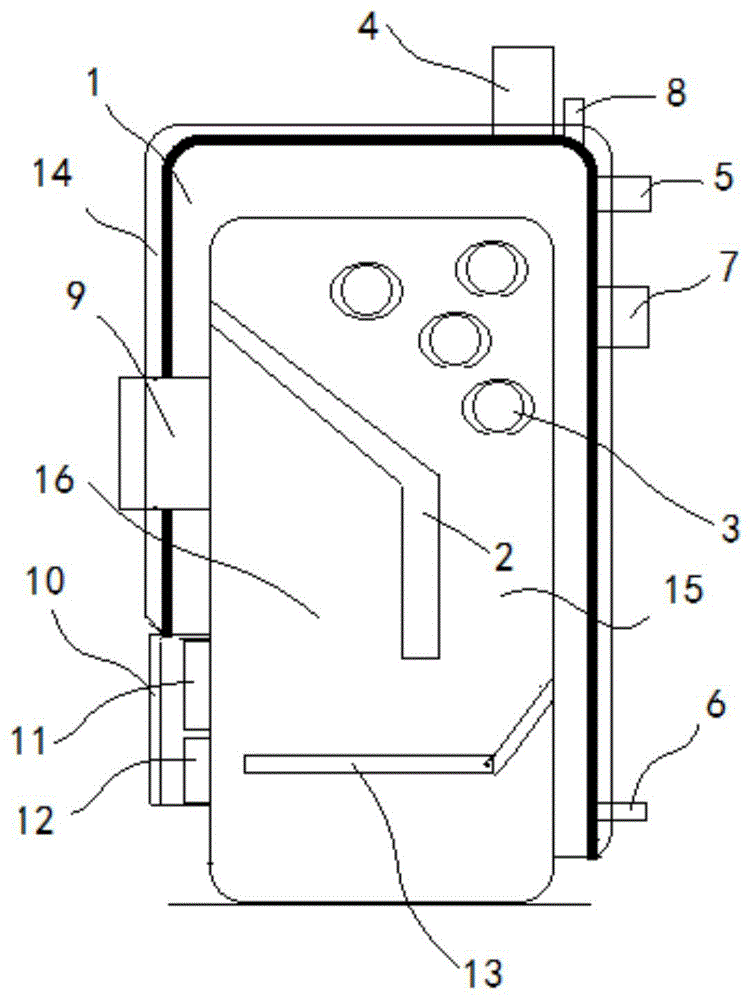

Medical waste pollution-free combustion treatment device

ActiveCN111174217AFully burntCombustion treatment is effectiveCombination devicesGas treatmentMedical wasteProcess engineering

The invention relates to a medical waste pollution-free combustion treatment device, and relates to the technical field of medical waste disposal. The device comprises a feeding and combustion device,a liquid medicine separation assembly, an automatic discharging mechanism, a compression crushing mechanism, a stirring mechanism and a waste gas treatment mechanism. The device has the beneficial technical effects that waste can be subjected to crushing, medicine separation, compression and preheating drying treatment in batches before waste incineration, batch treatment can ensure that the eachbatch of waste can be sufficiently crushed, compressed and subjected to medicine separation treatment, the waste gas treatment mechanism is arranged at the lower end of the feeding and combustion device, the liquid medicine separation assembly is arranged in the middle of the feeding and combustion device, the liquid medicine separation assembly communicates with the upper end of the feeding andcombustion device, the automatic discharging mechanism is arranged on the liquid medicine separation assembly, the compression crushing mechanism is arranged on the liquid medicine separation assembly, the left end of the compression crushing mechanism corresponds to the left end of the automatic discharging mechanism, and the stirring mechanism is arranged on the liquid medicine separation assembly and the compression crushing mechanism.

Owner:GENERAL HOSPITAL OF THE NORTHERN WAR ZONE OF THE CHINESE PEOPLES LIBERATION ARMY

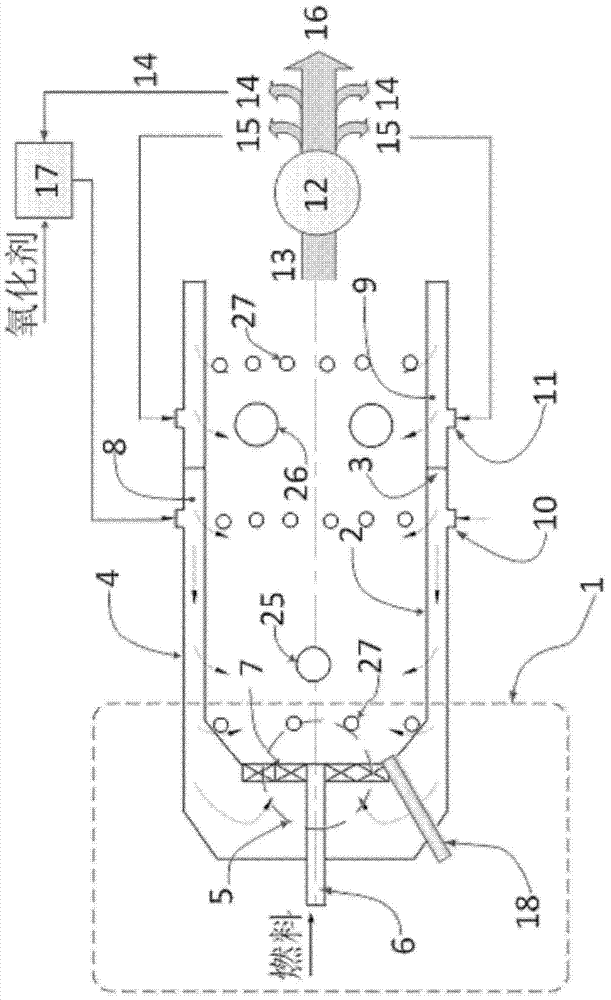

Incinerator for processing pulping foul gas in paper mills

The invention relates to an incinerator for processing pulping foul gas in paper mills, belonging to machinery. The incinerator is composed of a cylinder burning system, a support structure, a fan, an air duct, a pipeline and a valve, wherein the cylinder is composed of an inner cylinder and an outer cylinder; an interlayer is formed between the inner cylinder and the outer cylinder; a flow guide plate is arranged in the interlayer and connected with the inner cylinder and the outer cylinder; the burning system is composed of a main burner and a foul gas burner; the main burner and the foul gas burner are connected to the bottom of the cylinder through flanges; the main burner is positioned at the center of the bottom of the cylinder; the spouts of the main burner are perpendicular to the foul gas burner and annularly arranged around the main burner; and the cylinder is perpendicularly fixed above an alkali recovery boiler by the support structure. The incinerator for processing foul gas has the advantages of reasonable structure, convenient use and operation, can be matched with the alkali recovery boiler, and can also be independently used for long-time service when the alkali recovery boiler stops working. The incinerator is suitable for processing pulping foul gas in paper mills by incineration, and can also be widely used for processing other similar harmful waste gases.

Owner:湖北盘古环保工程技术有限公司

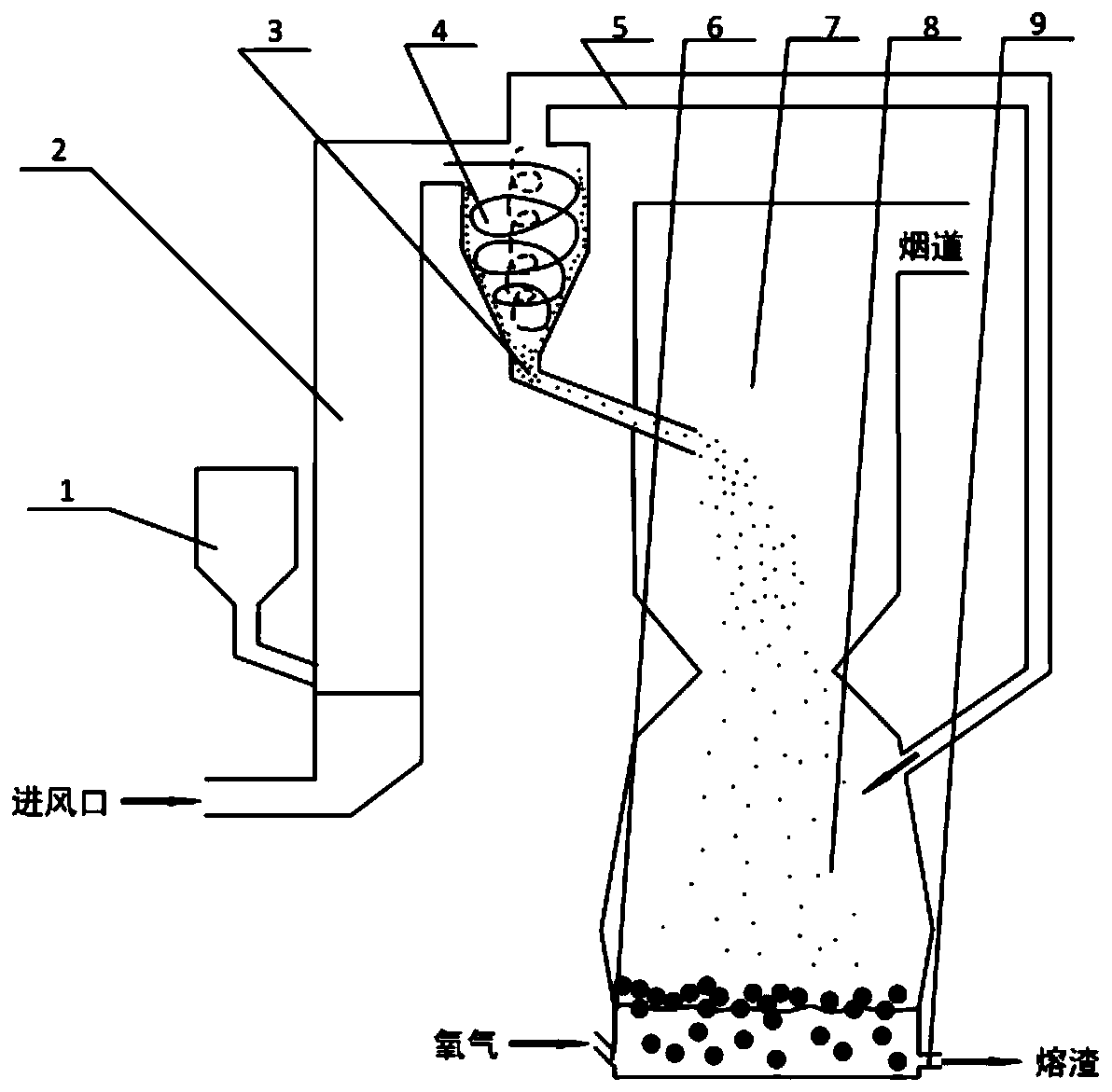

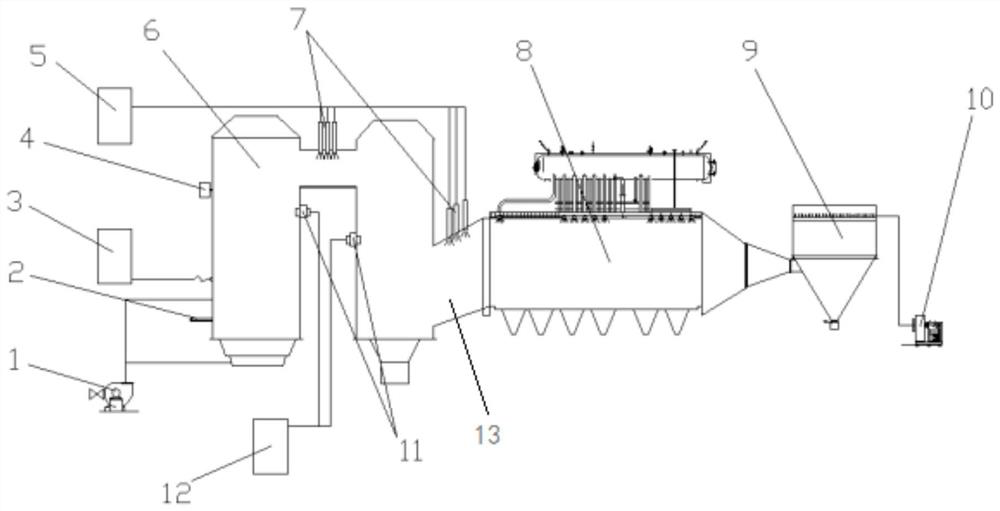

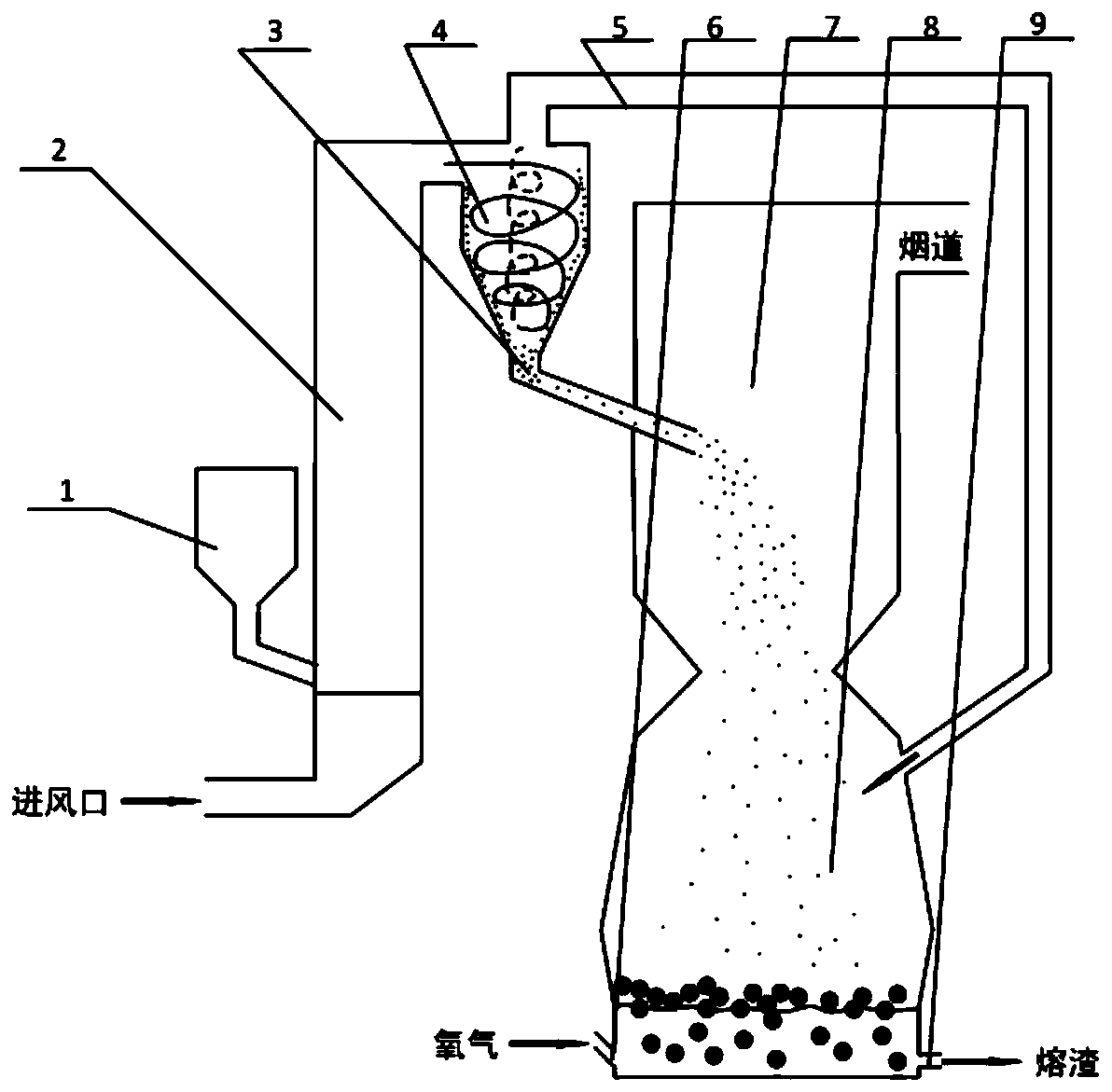

Uniform continuous feeding device for garbage incineration fly ash particles

ActiveCN110566977AFully burntConducive to stable operation at high temperatureIncinerator apparatusLitterFluidized bed

The invention provides a uniform continuous feeding device for garbage incineration fly ash particles. The uniform continuous feeding device comprises a fluidized bed feeder. The fluidized bed feederis provided with a wind inlet and a material storing bin. A tail outlet of the fluidized bed feeder is connected with an inlet of a cyclone material separator. The upper portion of the cyclone material separator is connected to the upper portion of a high-temperature melting furnace through a wind pipe. A solid particle collector is arranged on the bottom of the cyclone material separator. The solid particle collector is connected with a preheating furnace. The connecting position is arranged on the upper portion of the preheating furnace. The preheating furnace is located above the high-temperature melting furnace and communicates with the high-temperature melting furnace. An oxygen inlet and a molten slag outlet are formed in the bottom of the high-temperature melting furnace. Accordingto the uniform continuous feeding device, by means of the coordinative effect of the fluidized bed feeder and the cyclone material separator, continuous uniform feeding of materials is achieved.

Owner:XI AN JIAOTONG UNIV

Ferrite magnetic material for heat-sensitive sensor

InactiveCN104446414AFine and uniform grainHigh initial permeabilityTemperature controlSpray Granulation

The invention discloses a ferrite magnetic material for a heat-sensitive sensor. The ferrite magnetic material mainly contains the ingredients in percentage by weight: 34-45% of Fe2O3, 10-15% of ZnO, 5-10% of CuO, 1-3% of NiO, 0.01-0.03% of CaCO3, 0.002-0.012% of Bi2O3 and the balance of Mn3O4. The ferrite magnetic material for the heat-sensitive sensor is prepared through the steps of weighing and mixing, carrying out first-time pulping, carrying out first-time spraying granulation, prefiring, sanding, carrying out second-time spraying granulation and the like. By adopting the ingredients and the preparation method, the crystal grain of the ferrite magnetic material for the heat-sensitive sensor can be uniform, the initial magnetic permeability can be improved, the magnetic core sintered density can be improved, and the range of Curie temperature can be narrowed; the volatilization of zinc oxide can be inhibited, the specific temperature coefficient is increased, the maximum slope of magnetic permeability temperature change is high, and the temperature control accuracy is high; due to first-time pulping, namely wet mixing, all main ingredients can be mixed more uniformly, and gluing is more uniform.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

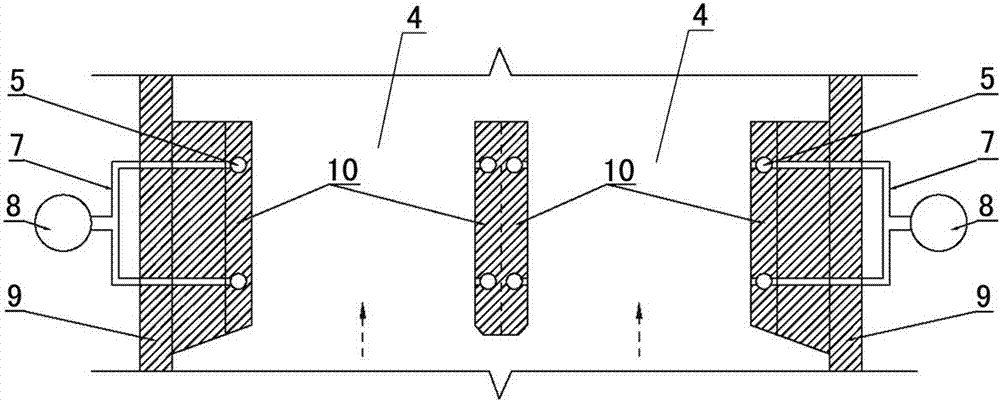

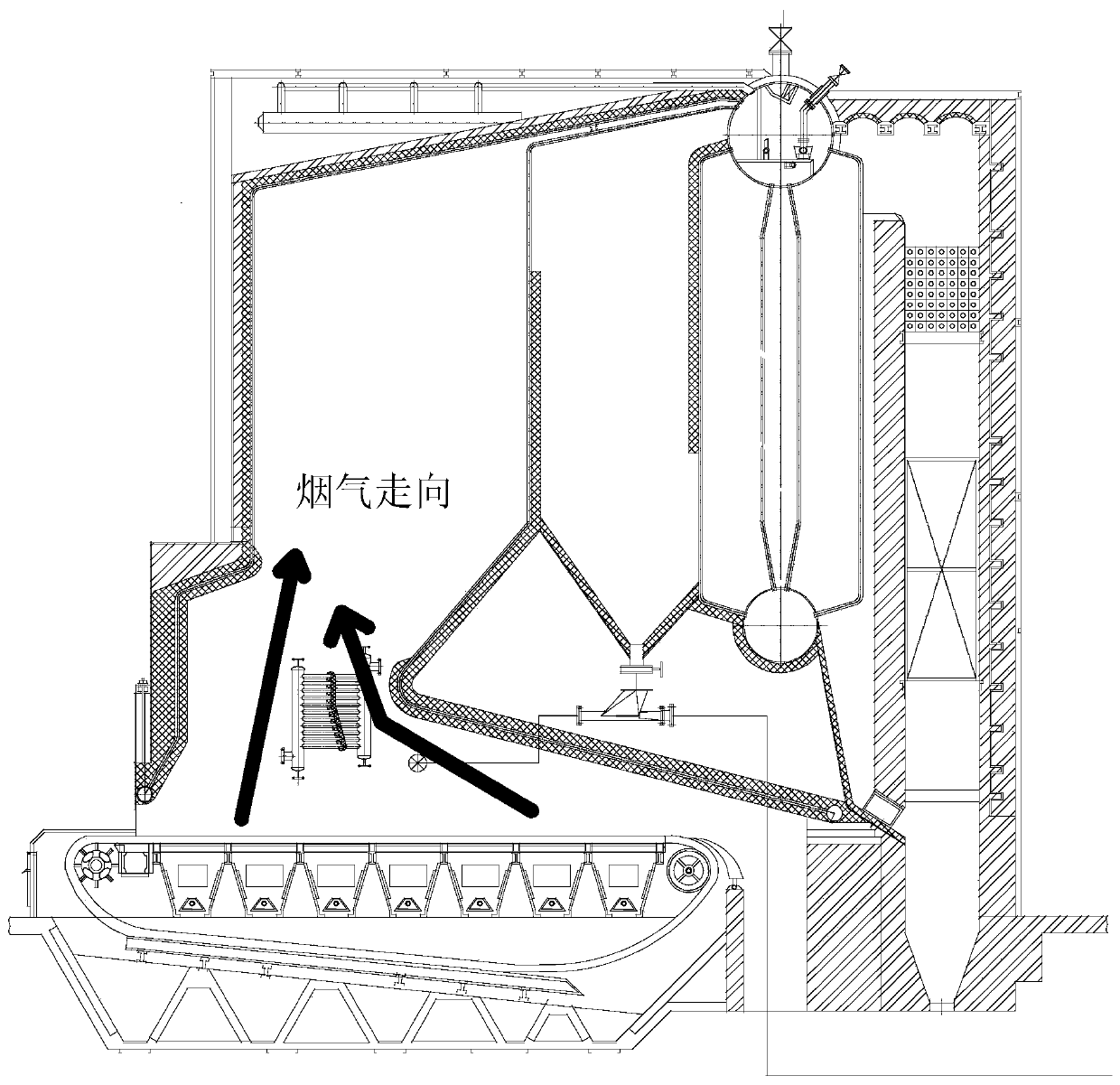

Horizontal boiler with SNCR and OFA arranged in staggered manner

ActiveCN107606602AEmission reductionComplete restorationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorPoor adaptive skills

The invention provides a horizontal boiler with SNCR and OFA arranged in a staggered manner and relates to an industrial boiler. The horizontal boiler with the SNCR and the OFA arranged in the staggered manner aims at solving the problems that a horizontal industrial coal powder boiler in the prior art is high in denitration cost, consequently, the NOx emission amount of an industrial coal powderboiler is high, the coal powder over-fire effect is poor, the adaptive capacity on load changes is poor, and the heat efficiency is low. The horizontal boiler with the SNCR and the OFA arranged in thestaggered manner comprises a combustor, a hearth, an upstream flue, a set of primary amino reducing agent spraying ports, a set of primary over-fire air spraying ports, a set of secondary over-fire air spraying ports, a set of secondary amino reducing agent spraying ports and two sets of temperature sensors; the combustor is installed at the front end of the hearth; the upstream flue is communicated with the top of the rear end of the hearth; the primary amino reducing agent spraying port and the primary over-fire air spraying port are fixedly installed on the side wall, from the front end tothe back end, of the hearth; and the secondary over-fire air spraying port and the secondary amino reducing agent spraying port are sequentially installed on the side wall of the upstream flue from bottom to top. The invention is used in the industrial boiler coal powder combustion field.

Owner:HARBIN INST OF TECH

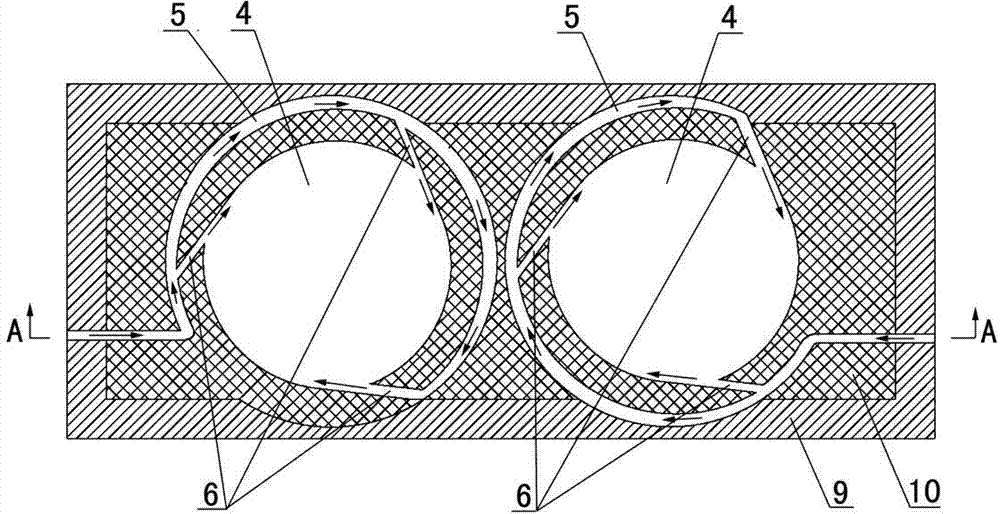

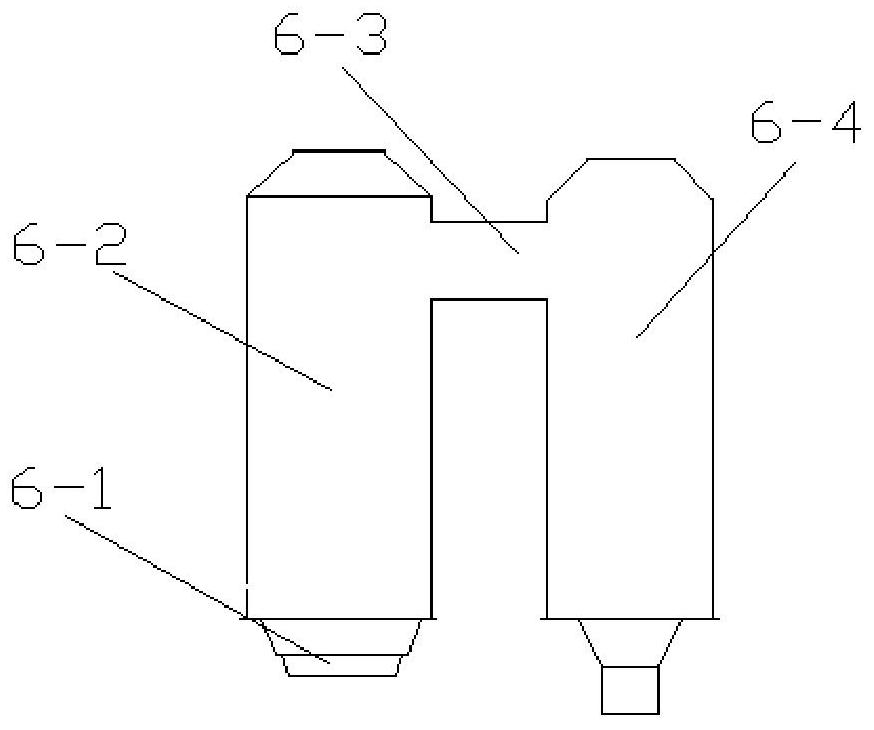

Combustion intensifying device in furnace

ActiveCN103939917AResolve Insufficient CombustionSolve the problem of black smokeIncinerator apparatusNon-combustible gases/liquids supplyCombustion chamberEngineering

A combustion intensifying device in a furnace comprises two combustion chamber walls, two combustion chambers on the inner sides of the two combustion chamber walls, and oxygen supply fans located on the outer sides of the two combustion chamber walls. Each combustion chamber is composed of at least two cylindrical combustion intensifying chambers, the bottoms of the combustion intensifying chambers are communicated with one combustion chamber through fire outlets, and the tops of the combustion intensifying chambers are communicated with a waste heat boiler; turbulence oxygen supply channels are formed in the two combustion chamber walls, each turbulence oxygen supply channel comprises an annular oxygen conveying channel and a tangential oxygen spray channel, air outlets of the tangential oxygen spray channels are communicated with the combustion intensifying chambers, and air inlets of the tangential oxygen spray channels are communicated with oxygen supply fans on the outer sides of the two combustion chamber walls through the annular oxygen conveying channels. According to the device, a traditional combustion intensifying chamber with a rectangular section is replaced by multiple cylindrical combustion intensifying chambers, meanwhile, oxygen is supplied to the combustion intensifying chambers tangentially through the tangential oxygen spray channels so that the defects that two combustion chambers of a mechanical fire grate type domestic garbage incinerator is insufficient in combustion and black smoke is prone to being generated can be overcome, the aim of treatment from sources is achieved, and environment is protected.

Owner:山东威澳环保科技有限公司

Ferrite material for heat-sensitive sensor

The invention discloses a ferrite material for a heat-sensitive sensor. The ferrite material mainly contains the ingredients in percentage by weight: 16-25% of ZnO, 5-8% of MgO, 3-7% of CuO, 1-3% of NiO, 0.008-0.01% of Al2O3, 0.008-0.02% of Nb2O5, 0.003-0.01% of Bi2O3 and the balance of Fe2O3. The ferrite material for the heat-sensitive sensor is prepared mainly through the steps of weighing and mixing, carrying out vibrated-grinding, pelletizing, prefiring, sanding, carrying out spraying granulation and the like. By adopting the ingredients and the preparation method, the crystal grain of the ferrite material for the heat-sensitive sensor can be fine and uniform, the initial magnetic permeability can be improved, the sintering temperature can be lowered, the magnetic core sintered density can be improved, and the range of Curie temperature can be narrowed; the volatilization of zinc oxide can be inhibited, the specific temperature coefficient is increased, the maximum slope of magnetic permeability temperature change is high, and the temperature control accuracy is high; due to vibrated-grinding, large granules and agglomerated powdery materials in mixed powder can be crushed, so that the gluing and mixing are uniform.

Owner:东莞时富电子有限公司

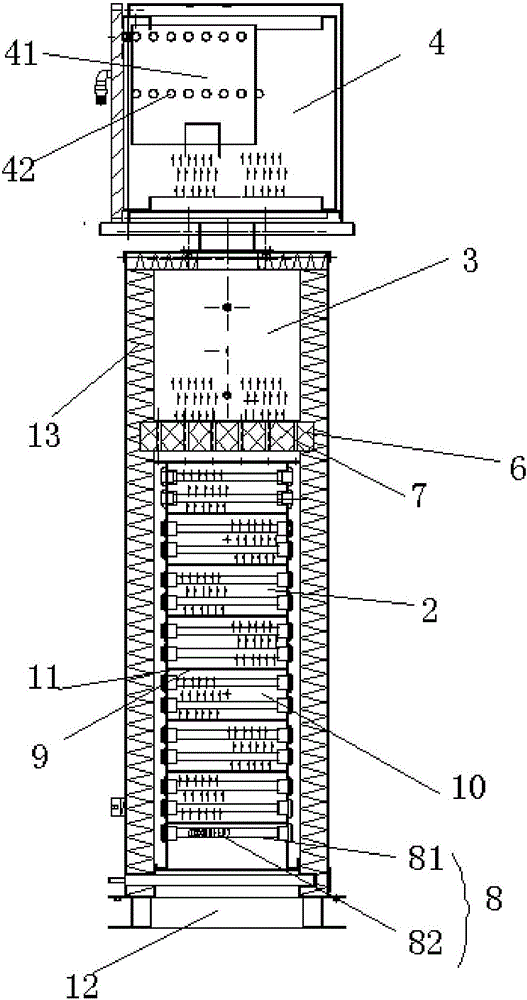

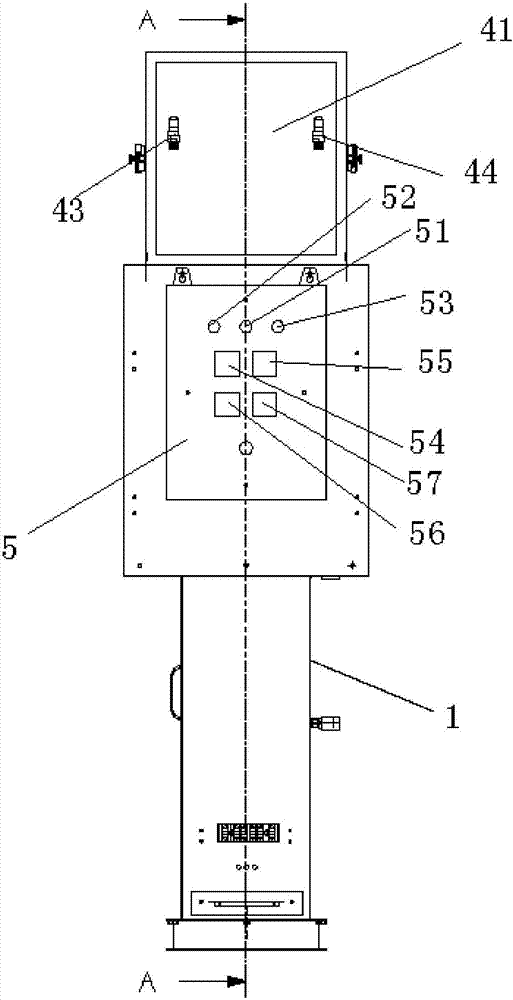

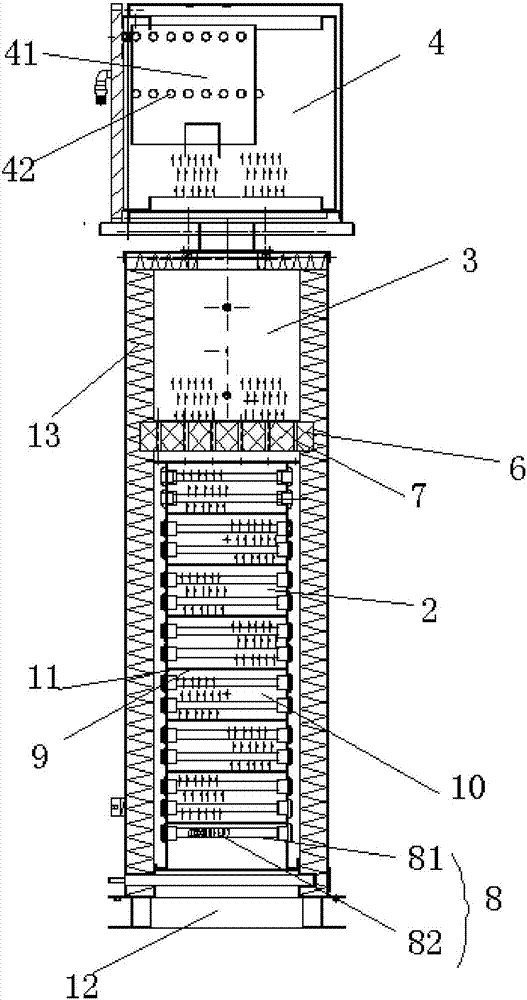

Double-wire drying combustion tower and combustion method thereof

The invention discloses a double-wire drying combustion tower which comprises a combustion box body. A combustion cavity capable of prolonging the combustion time, a combustion gas gathering cavity used for gathering combustion gas and a cooling cavity used for cooling combusted gas are formed in a combusting cavity of the combustion box body in sequence from bottom to top. A control box used for controlling the temperature of the combustion box body is arranged on the front side or the rear side of the combustion box body. By means of the double-wire drying combustion tower and the combustion method thereof, a bottom-to-top layer-by-layer combustion manner is adopted, ventilation partition plates are arranged in a staggered manner, so that the time for waste gas particles to pass through each combustion area is prolonged, the waste gas particles can be combusted more sufficiently in each combustion area, and gas discharged afterwards reaches the marked discharging grade. By means of the combustion manner of the combustion tower, discharging of the waste gas particles can be greatly reduced, discharged gas can be more environment-friendly, all dust generated after combustion of the particles can be thoroughly removed through a dust collector, and collecting and cleaning of the combustion tower are facilitated.

Owner:FOLUNGWIN AUTOMATIC EQUIP CO LTD

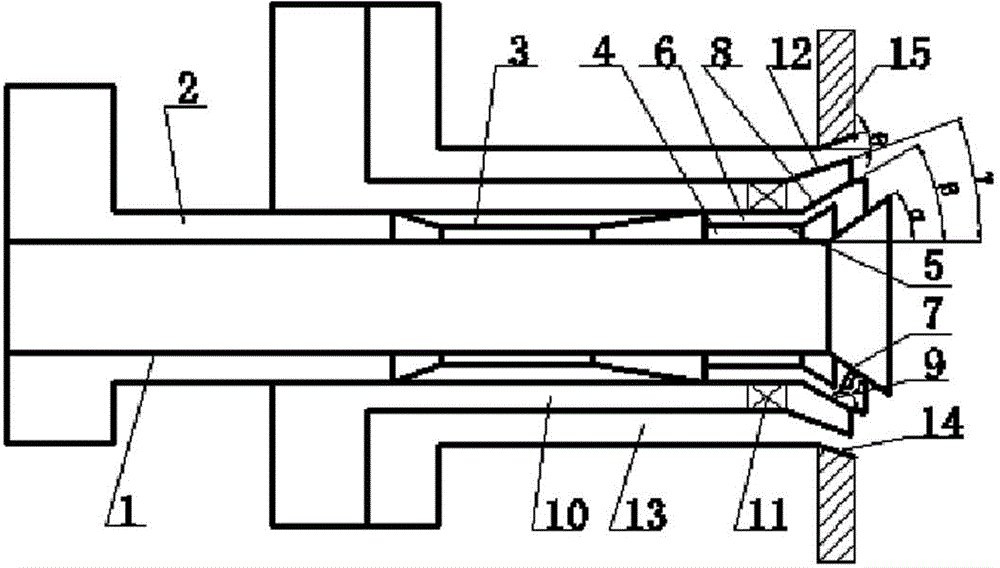

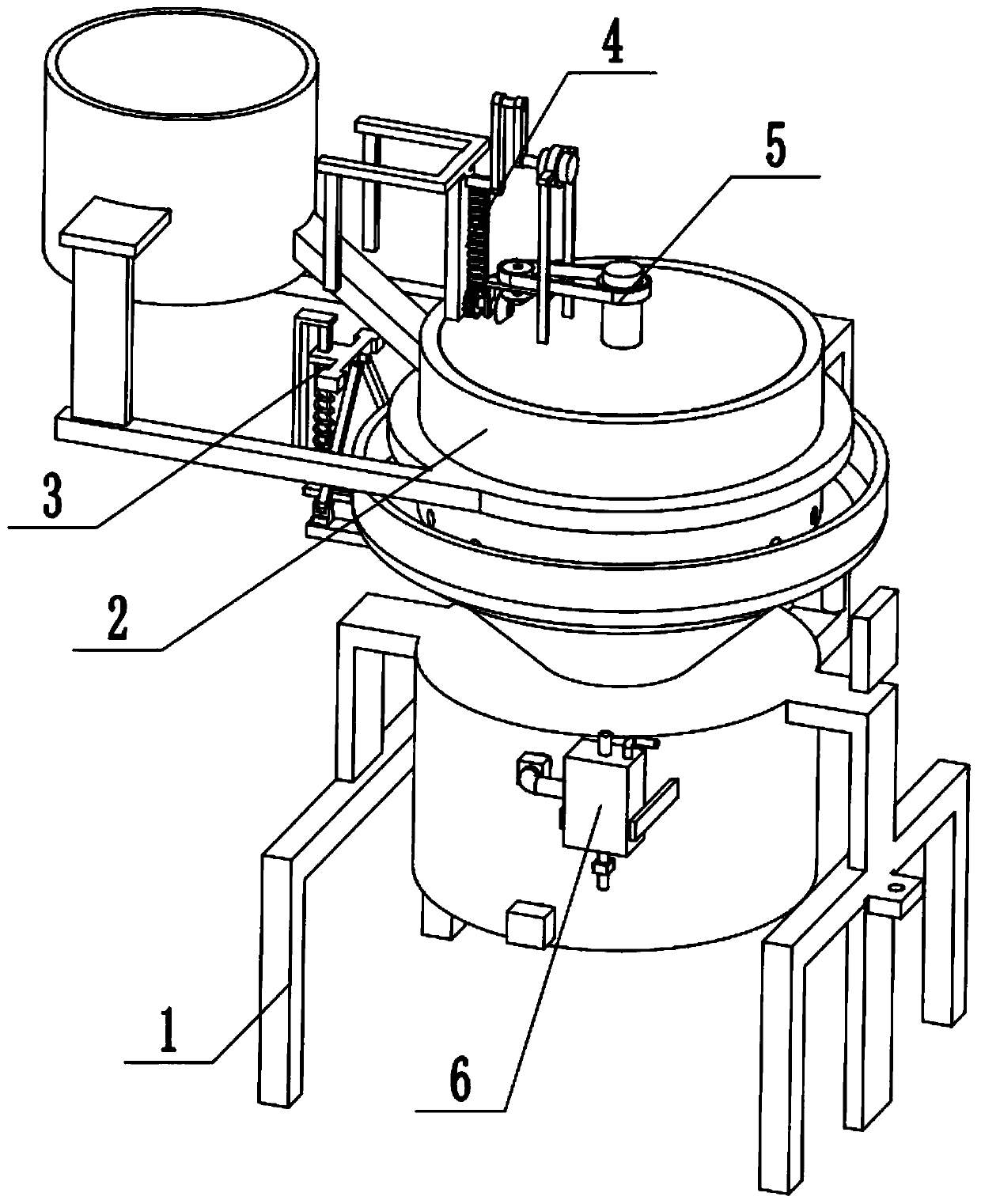

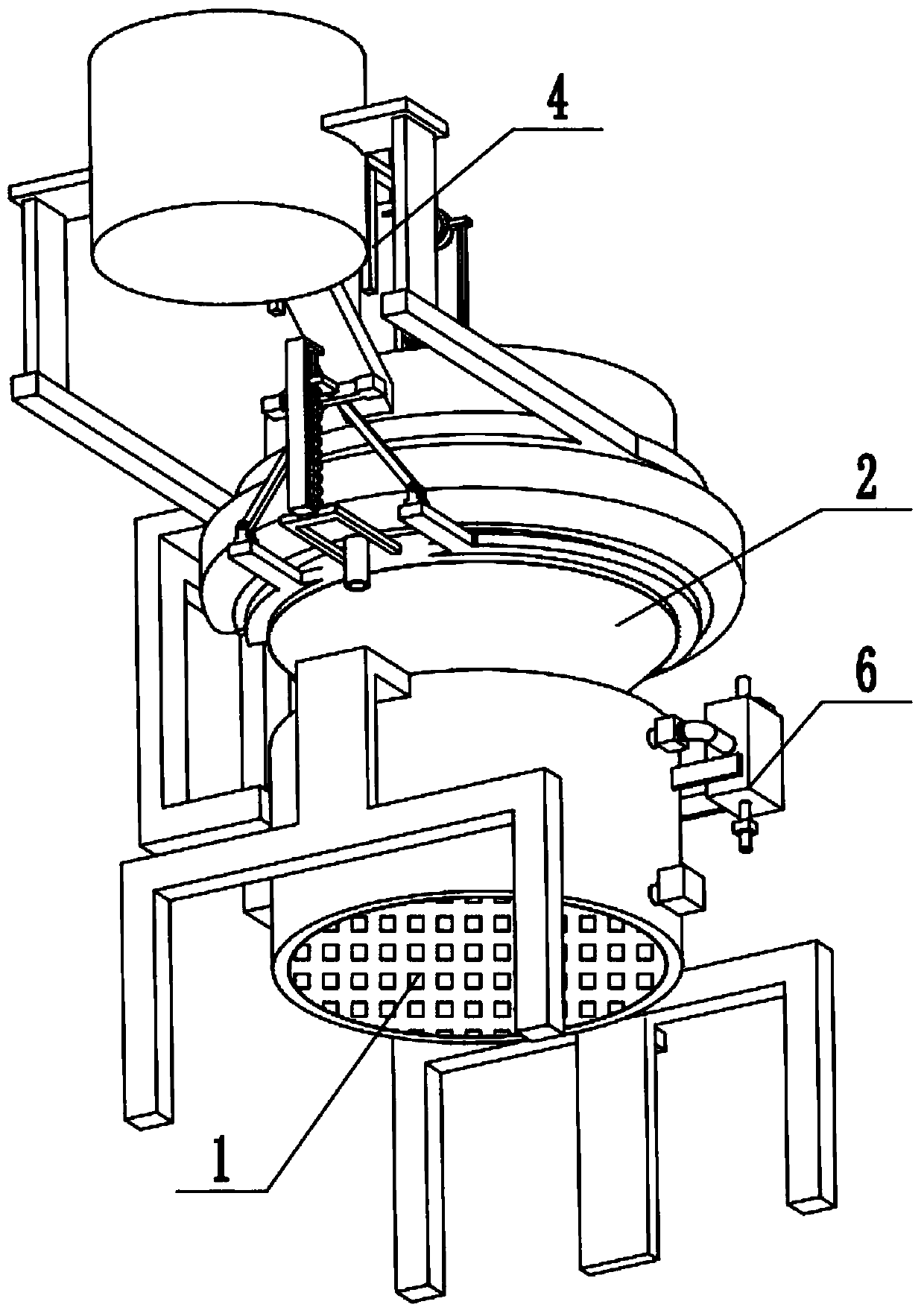

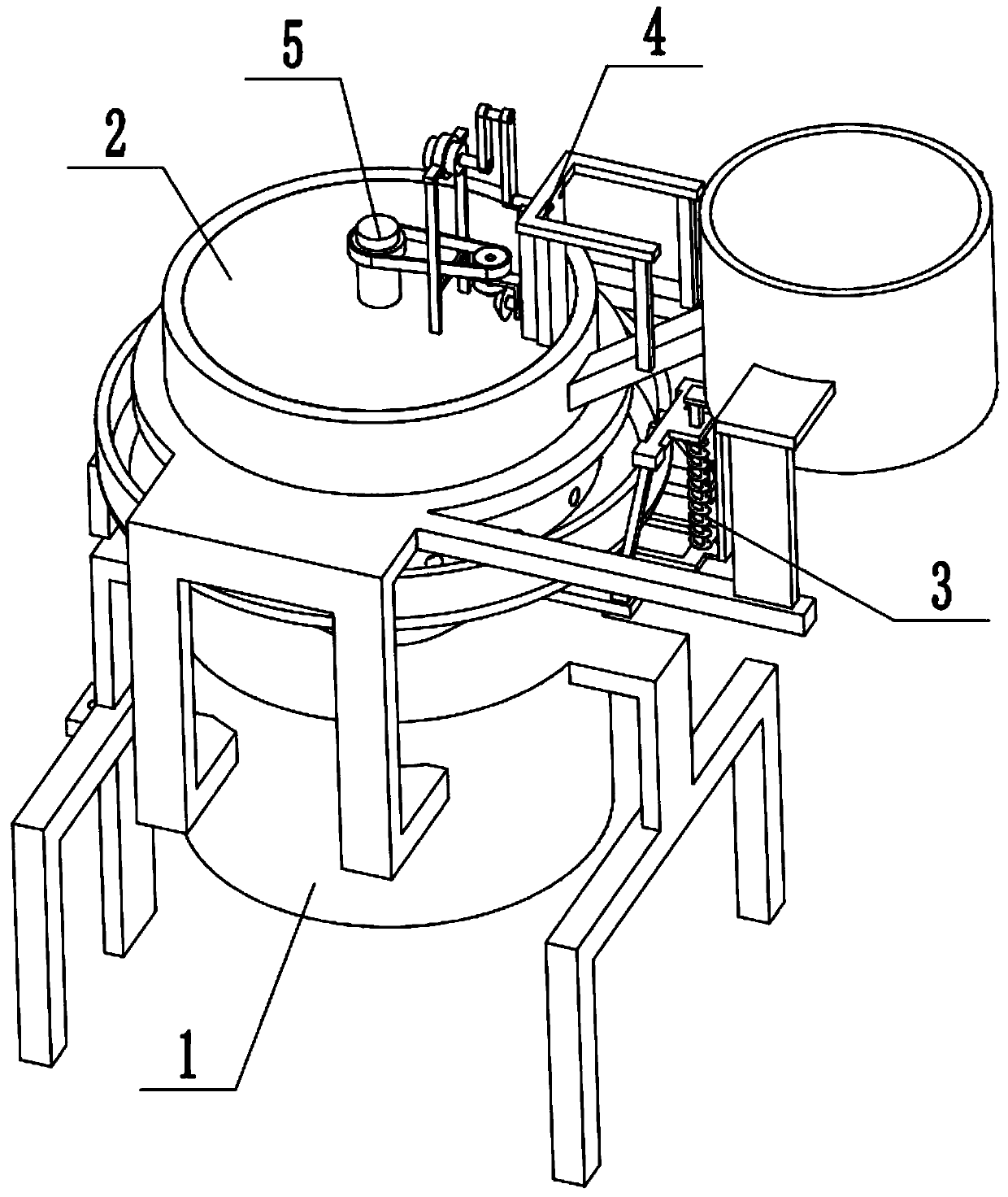

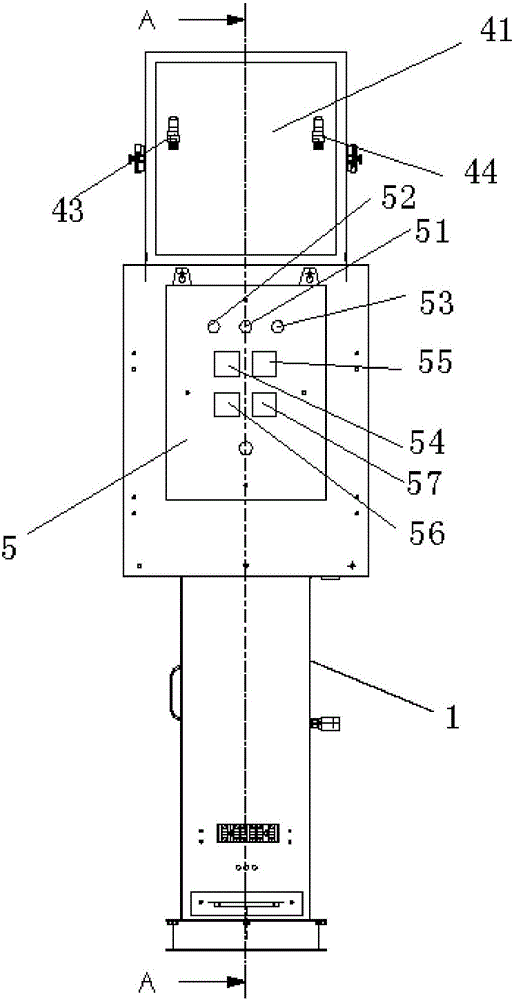

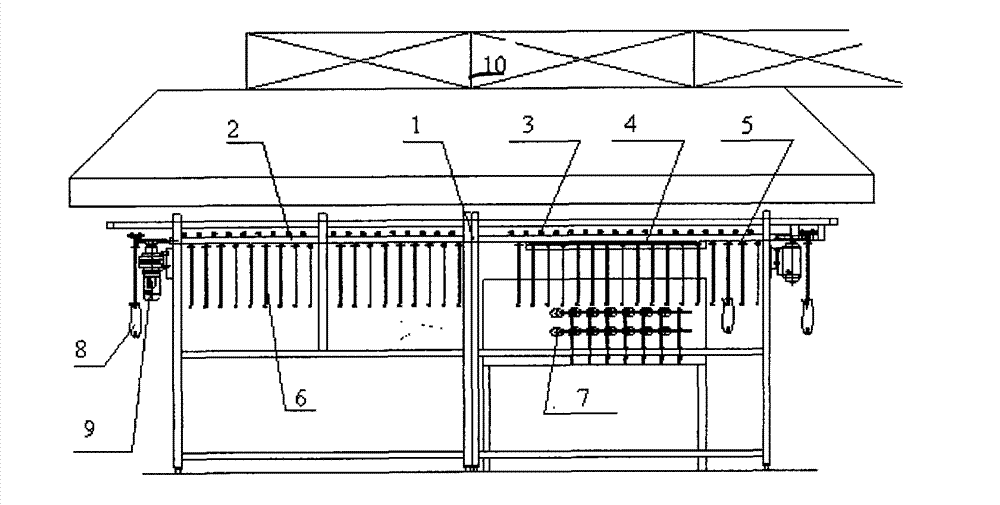

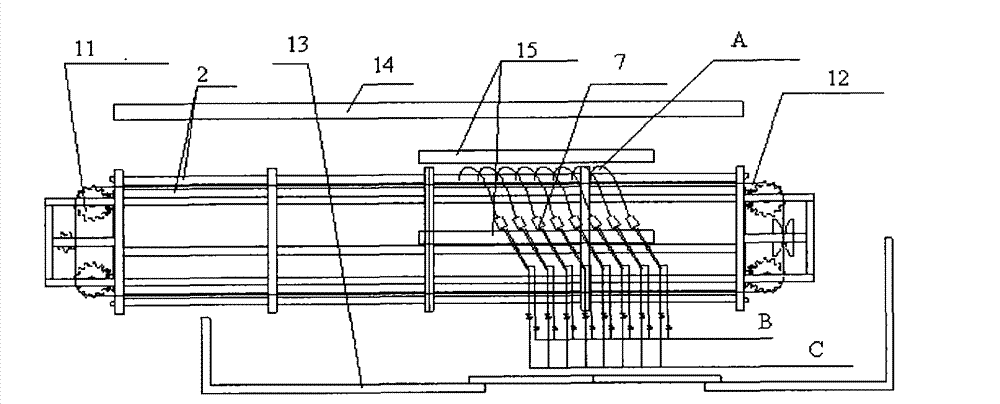

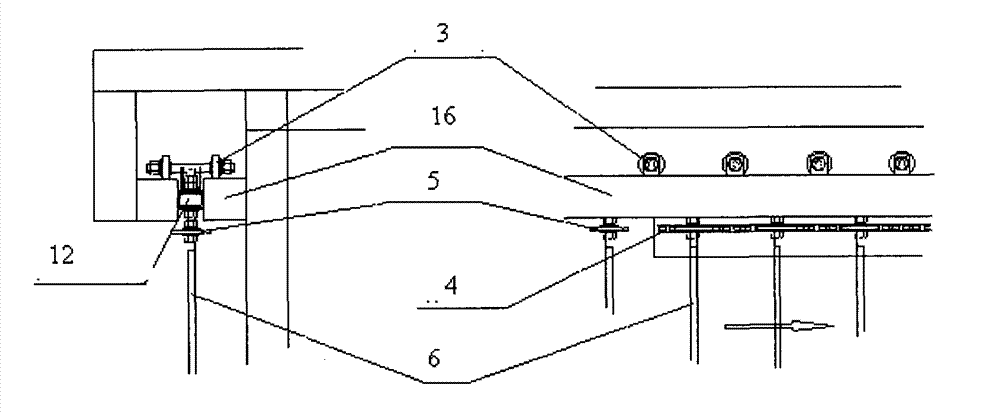

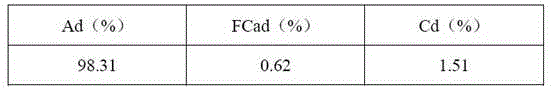

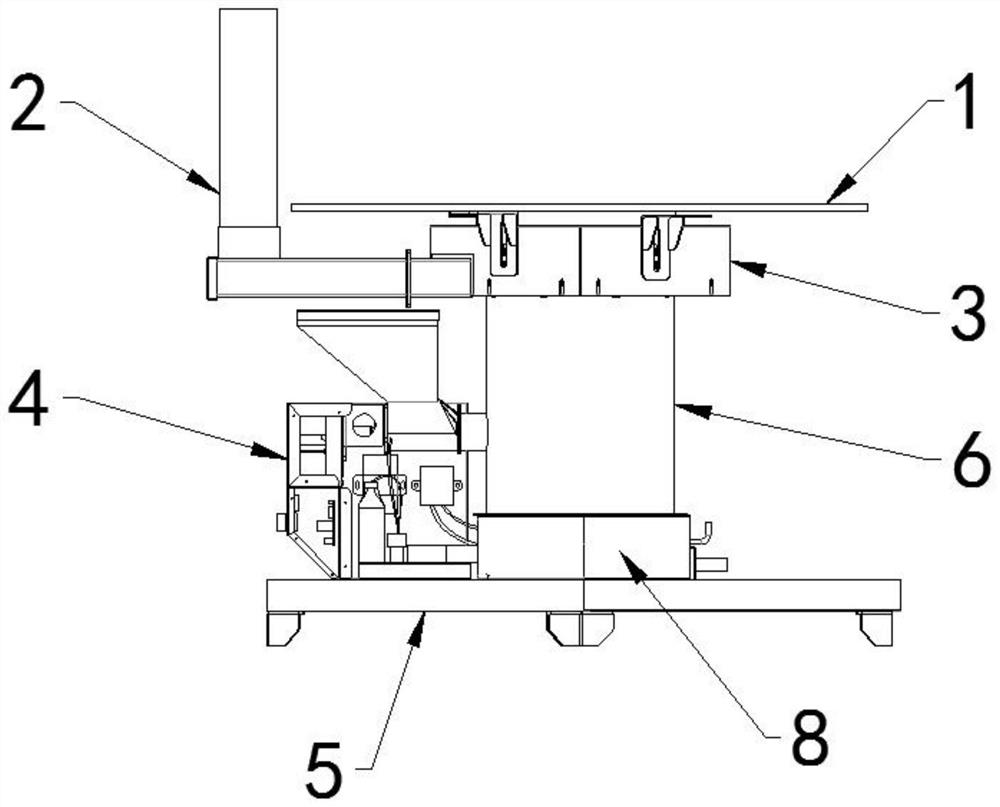

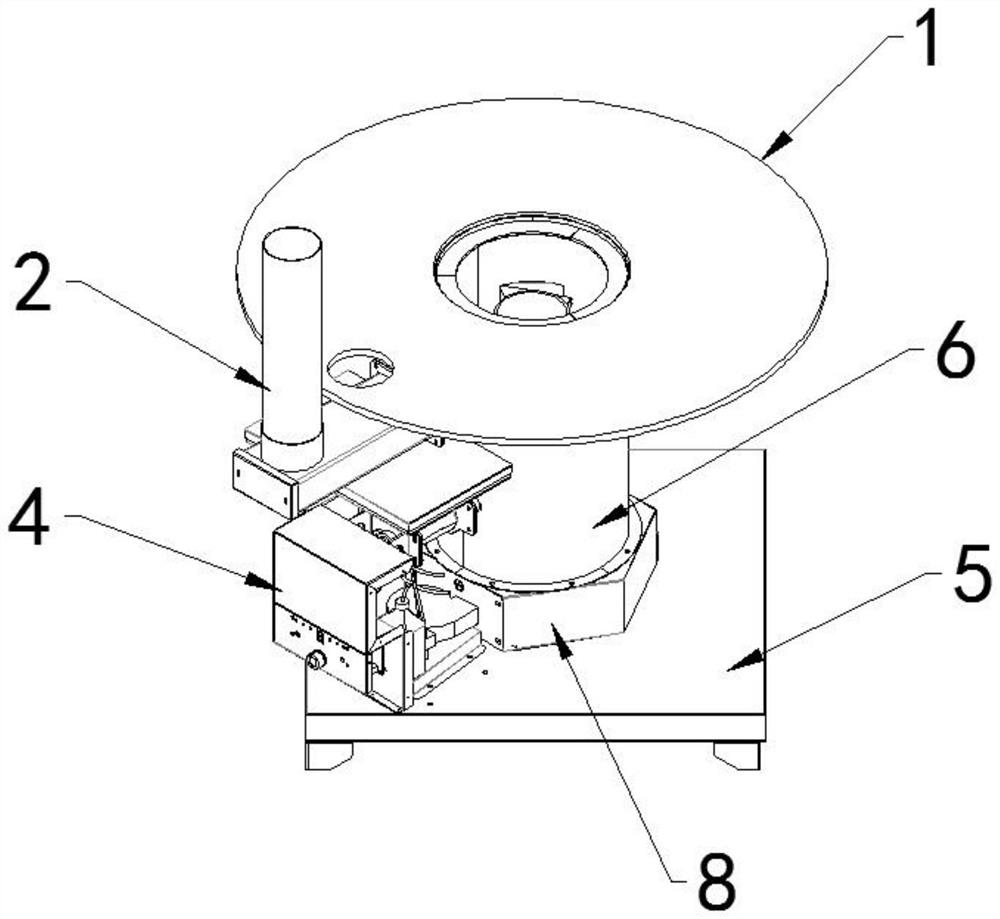

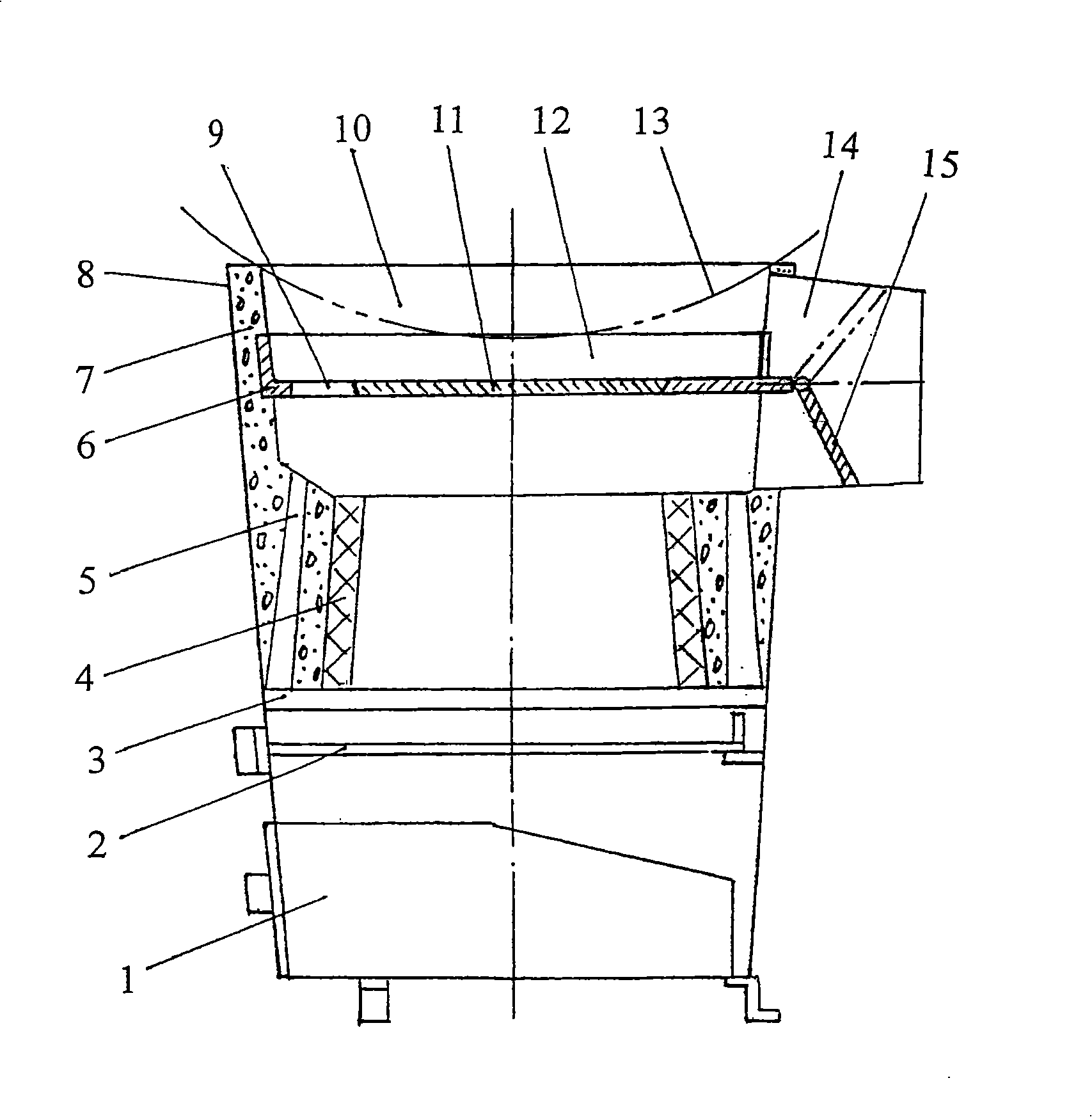

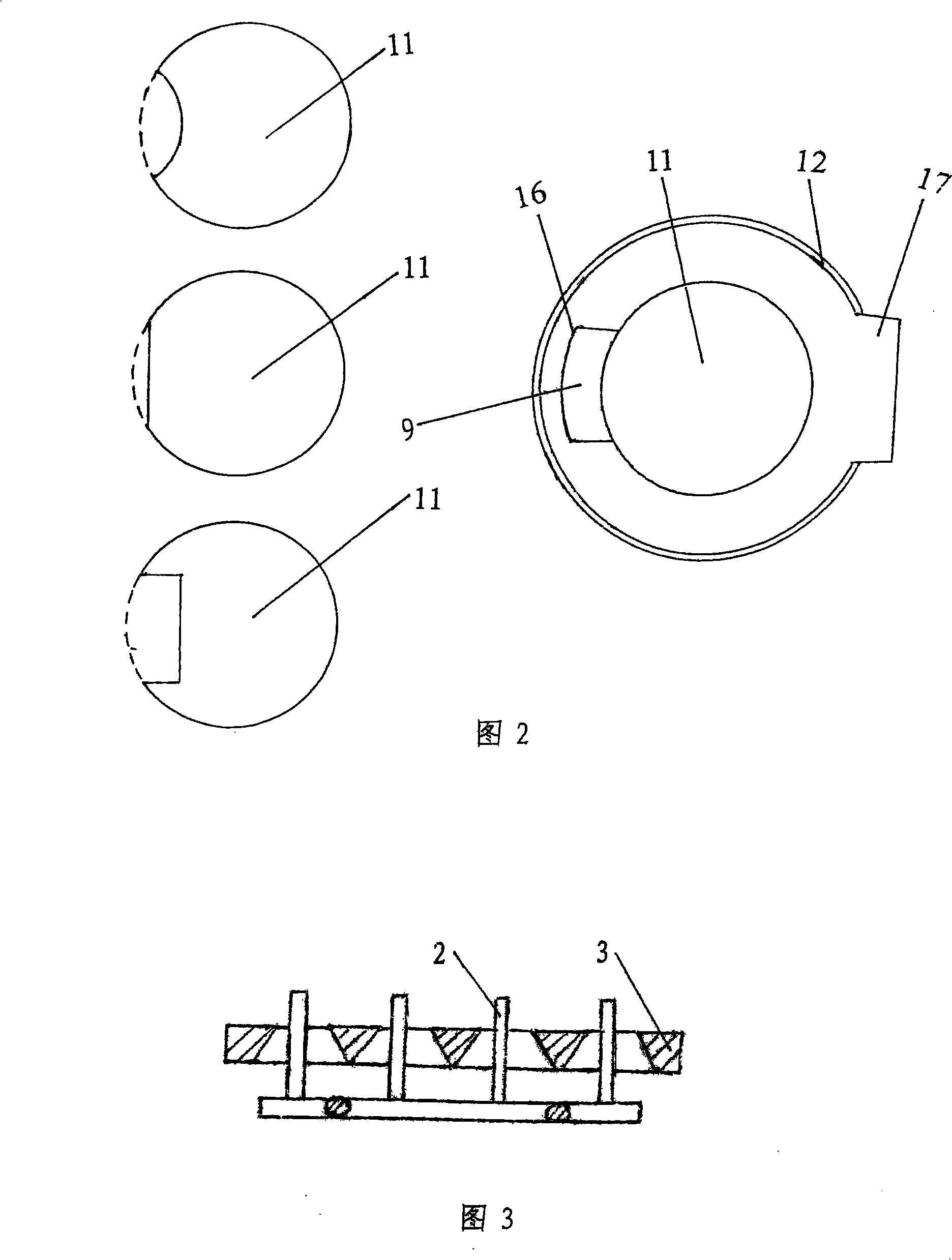

Pettitoes surface treatment method

InactiveCN102823634AFully burntAvoid distributingSlaughtering accessoriesWorking environmentElectrical control

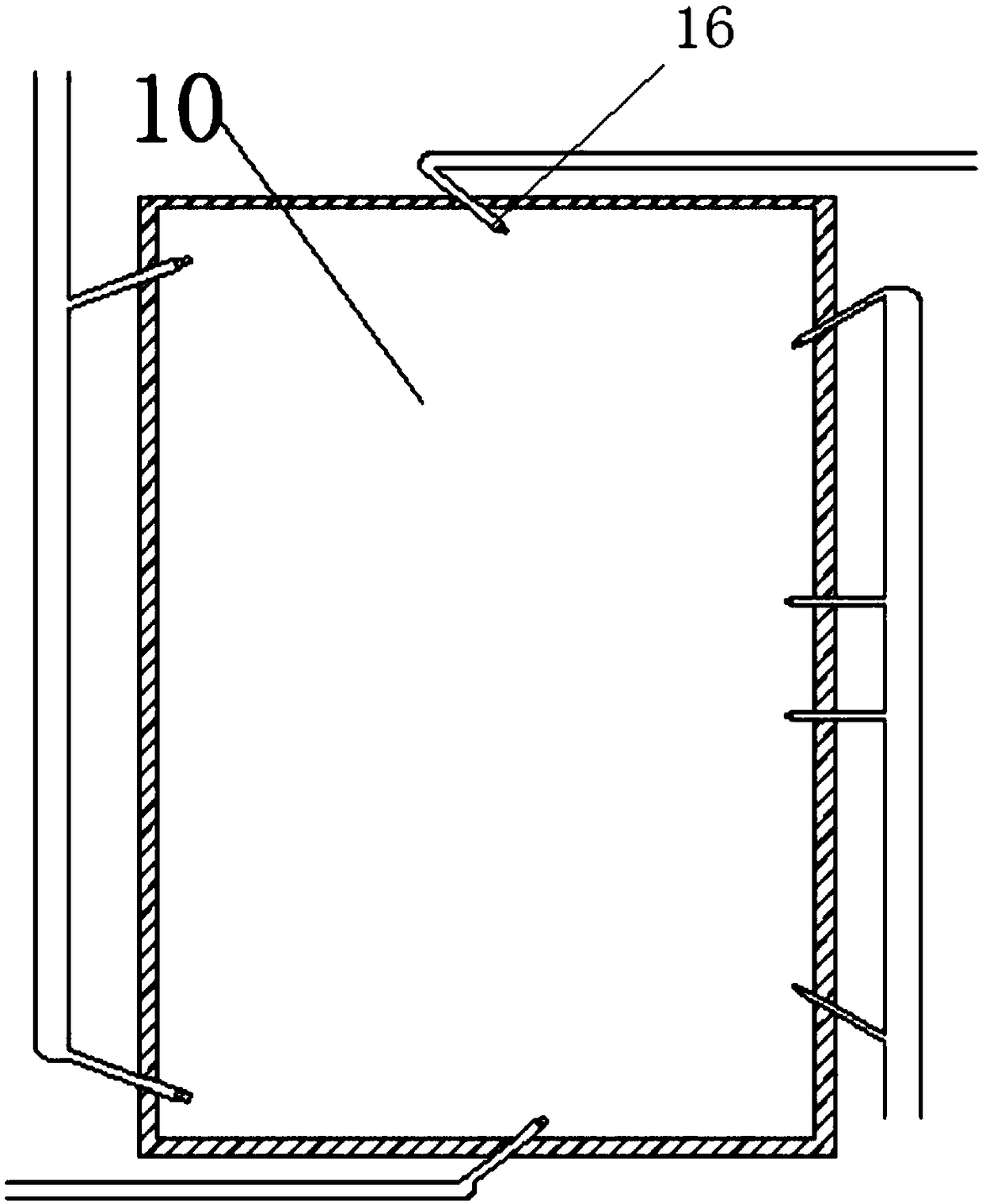

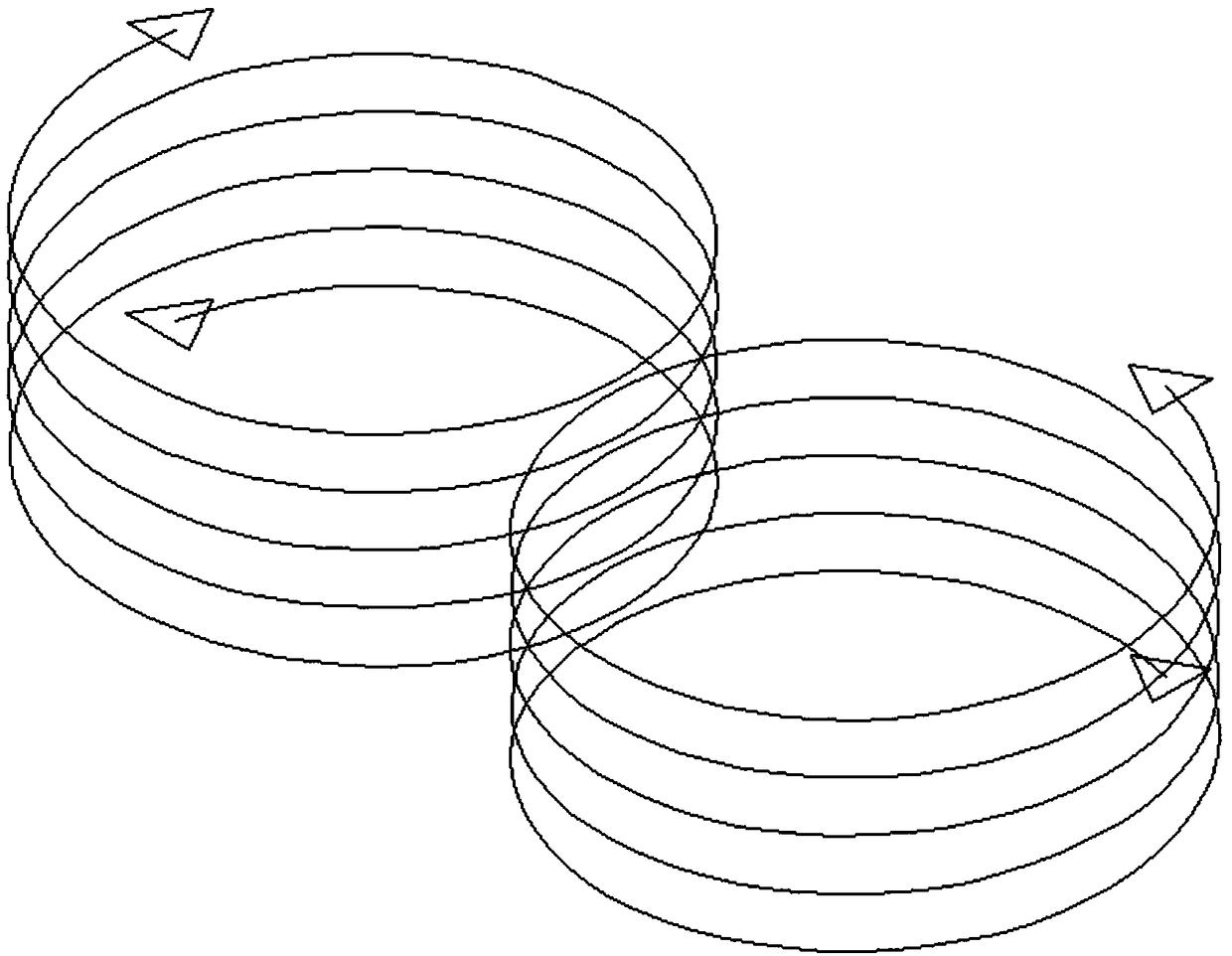

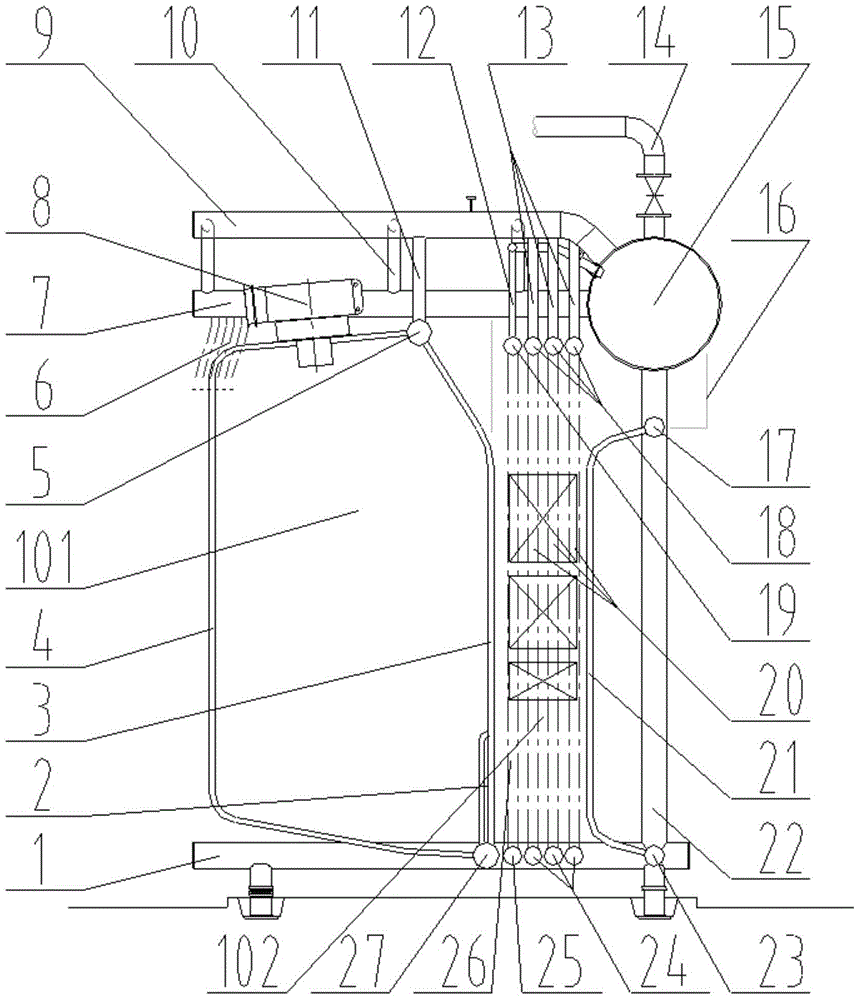

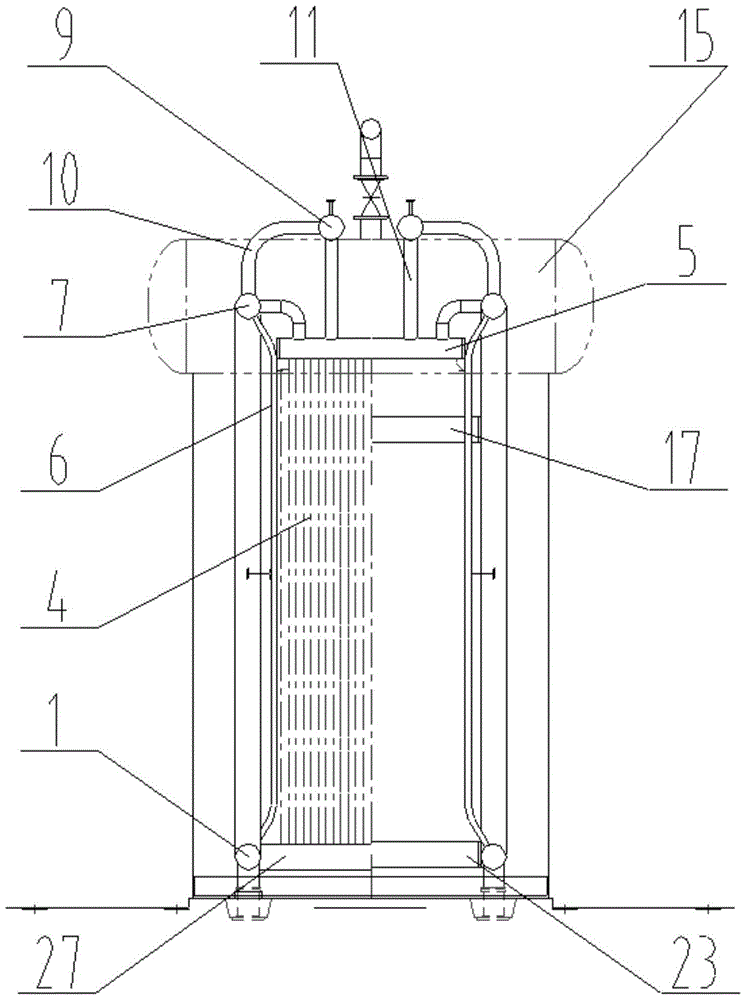

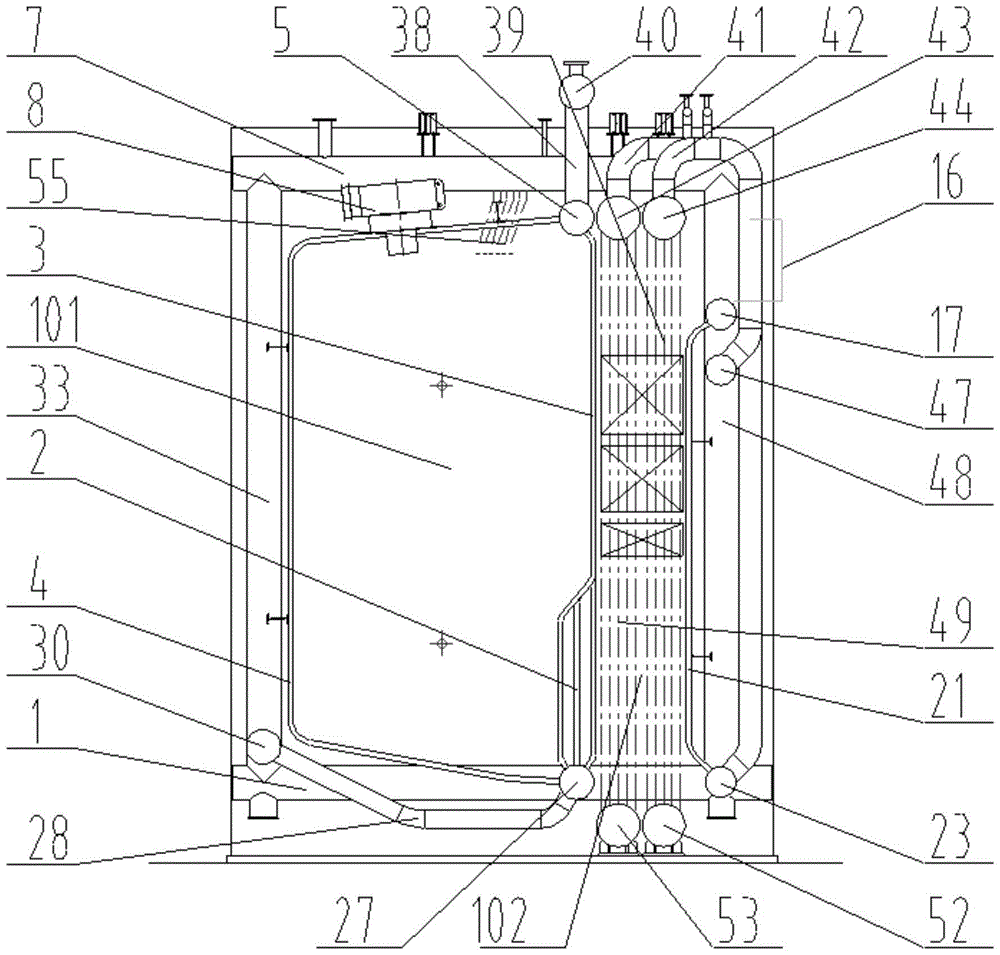

The invention relates to a pettitoes surface treatment method, which belongs to the field of cooking in kitchens. According to the pettitoes surface treatment method, a pettitoes surface treatment machine with a frame (1), a transmission mechanism, a flame spray torch (7), an automatic hanging hook rotating mechanism, a fuel gas distribution system, an electric control system and a heat insulation device (15) is utilized for treatment, and the method mainly comprises the following specific steps of: hanging a pettitoes (8) on hanging hooks (6); adopting the transmission mechanism to support a hanging hook trolley on the frame to perform oriented planar circulating uniform-speed motion; uniformly singing and burning the surfaces of the pettitoes by adopting the flame spray torch, the fuel gas distribution system and the automatic hanging hook rotating mechanism; and washing the pettitoes which are well burned by utilizing circulating water heated by the heat insulation device; and the whole operation of the method is controlled by the electric control system. According to the pettitoes surface treatment method disclosed by the invention, the automated pettitoes surface treatment can be realized, the singing and burning quality and the working efficiency are improved, energy is fully utilized, the operation of the whole machine only needs one person, and a working environment of staff is further improved.

Owner:BEIJING KAILONGWANBANG KITCHENWARE IND&TRADING

Rural garbage harmless, reduction and recycling incinerator and method

PendingCN108224429ABurn fullyIncrease temperatureIndirect carbon-dioxide mitigationIncinerator apparatusAir preheaterCombustion

The invention discloses a rural garbage harmless, reduction and recycling incinerator and method. A smoke outlet in the top of a hearth is sequentially connected with an air preheater, a water coolingheat exchanger, a cyclone separator, a tail gas treatment device and a chimney through a pipeline, the incinerator further comprises a motor, a primary fan, a secondary air assembly and a nozzle array composed of multiple nozzles, the motor is used for driving the secondary air assembly and the primary fan to work, the nozzles are distributed in an inclined manner in the circumferential directionof the inner wall of a flue outlet in the top of the hearth, a spiral air flow is formed in a flue, and smoke is driven to be entrained and spirally ascend, the secondary air assembly sucks gas emitted by garbage from a material bin, meanwhile, negative pressure is formed in the material bin, and the gas is emitted to the flue outlet in the top of the hearth through a nozzle; the incinerator andmethod have the beneficial effects of being high in combustion efficiency, nearly zero in emission, low in running cost, wide in fuel application and the like, and are suitable for rural garbage harmless, reduction and recycling incinerating treatment of the China.

Owner:SOUTH CHINA UNIV OF TECH

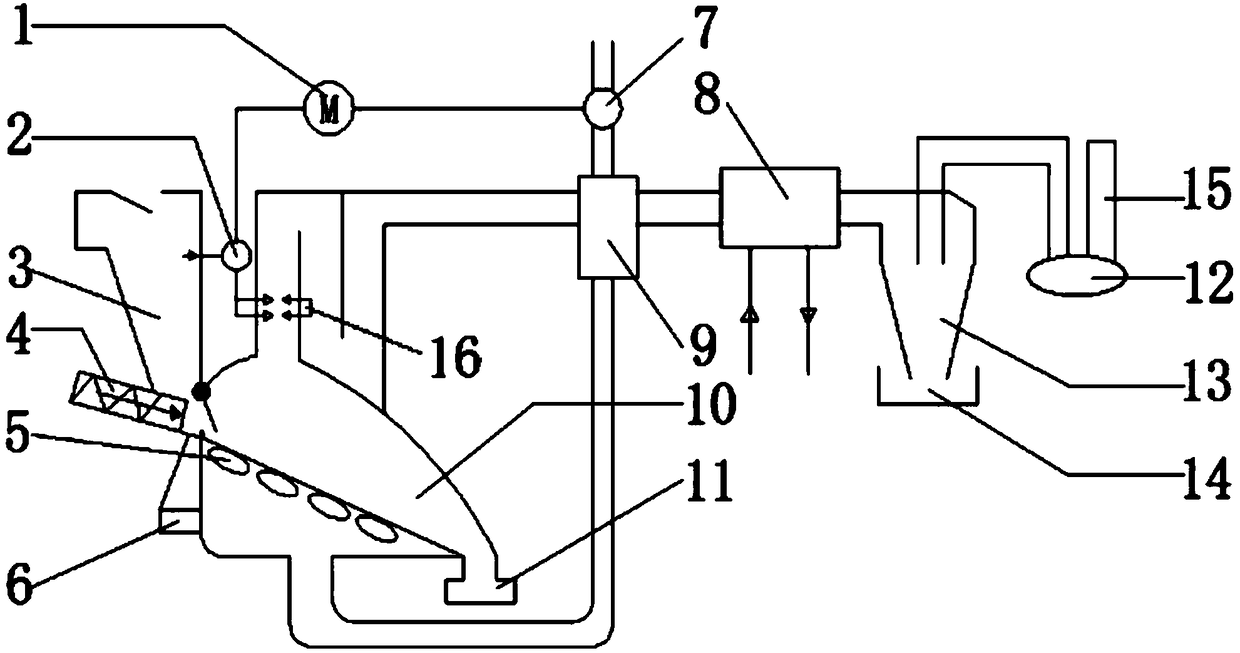

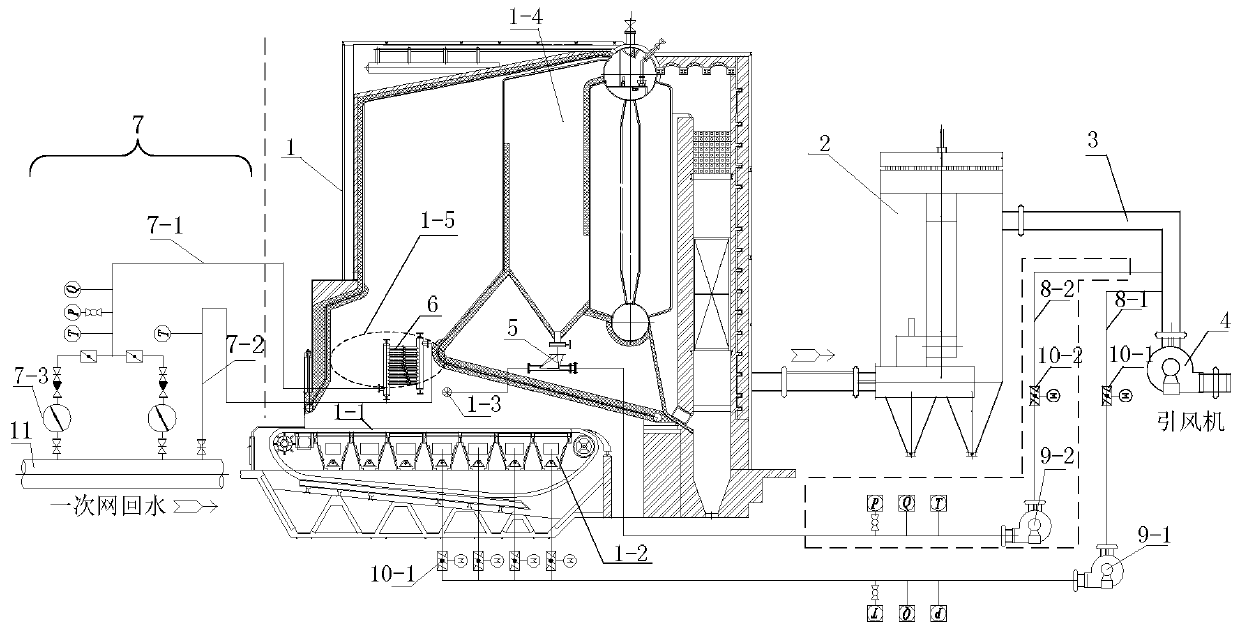

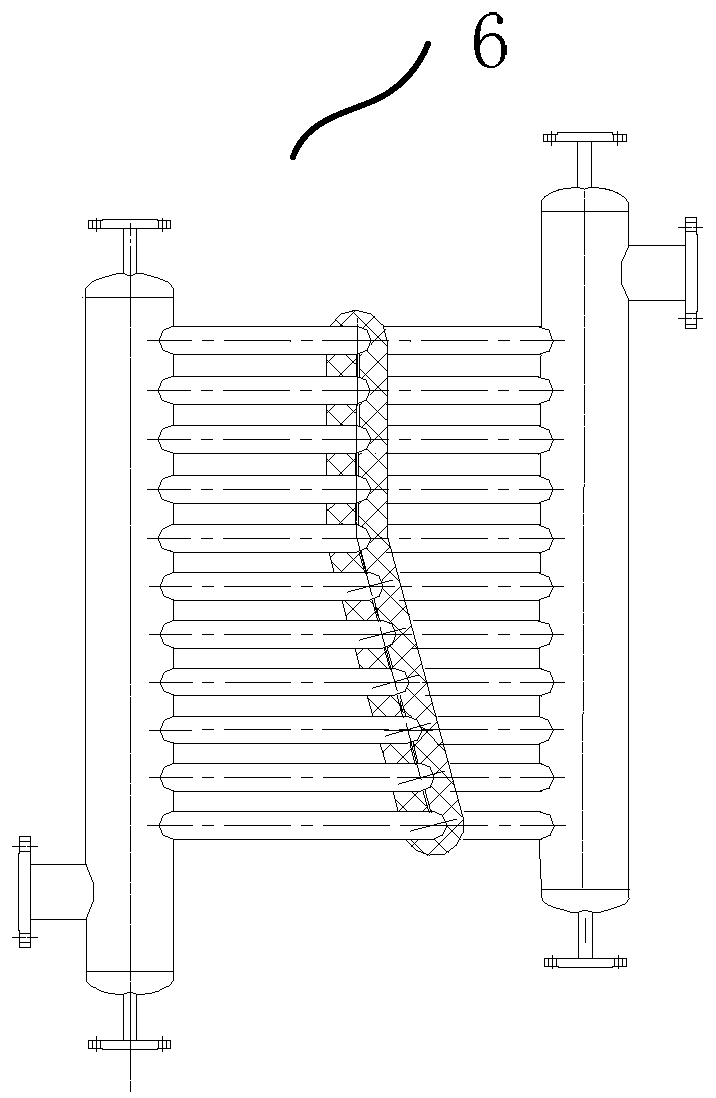

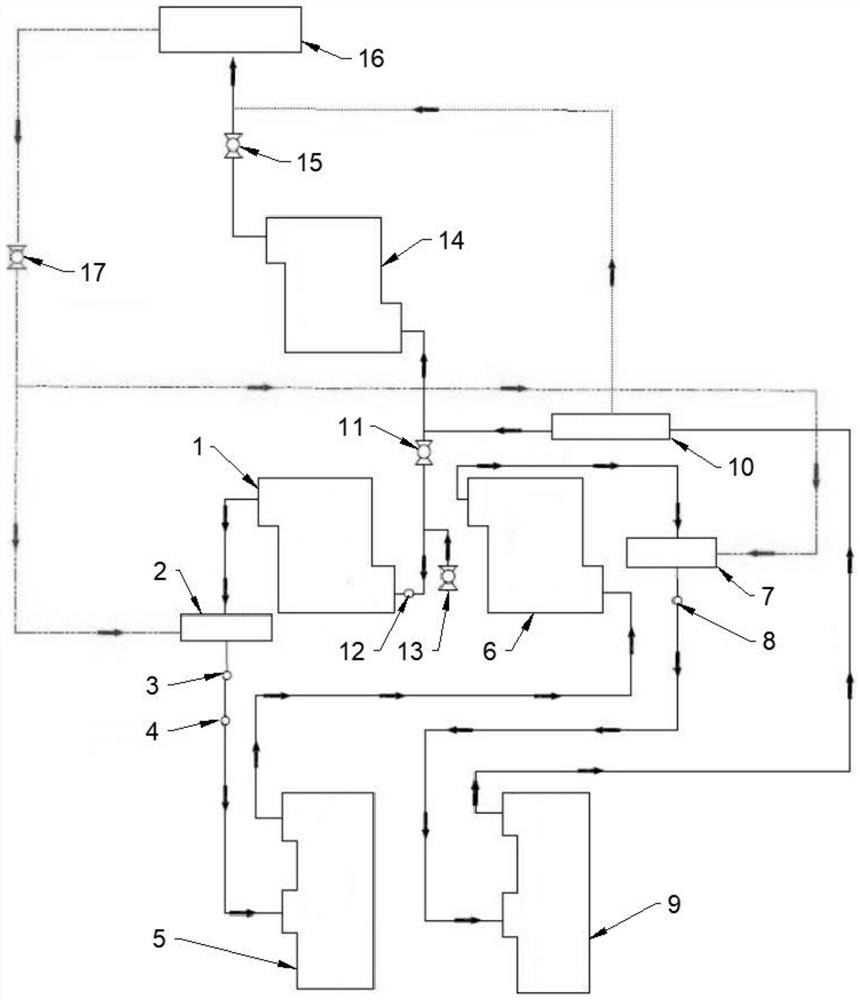

Flue gas recycling combustion system

InactiveCN109945160AWell mixedEmission reductionSolid fuel combustionBafflesCombustion systemGrating

The invention discloses a flue gas recycling combustion system, and relates to a semi-coke return and auxiliary flue gas recycling combustion technology in collaboration with a furnace partitioning device for generating low nitrogen oxide in a chain boiler. The problem that in an existing chain boiler low nitrogen combustion technology, the NOx emission and the stable operation of the boiler cannot be controlled simultaneously through the fuel graded combustion technology and the flue gas recycling technology is solved. The flue gas recycling combustion system comprises a chain boiler, a dustremover, a flue gas pipeline, and an induced fan, the coal powder is burned in the chain boiler, dust removing of the dust remover is conducted on the exhausted flue gas with the dust, then the flue gas after dust removing is exhausted into the air through the induced air, and the dust remover communicates with the induced fan through the flue gas pipeline; and the flue gas recycling combustion system further comprises a first flue gas recycling branch arranged on the chain boiler externally, and the first flue gas recycling branch sends the partial flue gas in the fuel gas pipeline back to the wind chambers corresponding to the combustion area and the partial main combustion area on a grating of the chain boiler. The flue gas recycling combustion system mainly carries out the low-nitrogencombustion.

Owner:HARBIN INST OF TECH +1

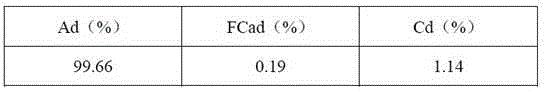

Oxygen producer for increasing coal burn-off rate

The invention discloses an oxygen producer for increasing coal burn-off rate. The oxygen producer comprises the following components in percentage by weight: 15-25% of potassium hypermanganate, 30-35% of petroleum coke powder, 13-20% of magnesium oxide, 10-16% of sodium chloride and 8-15% of active carbon. A catalyst for increasing coal burn-off rate is added into coal according to the coal amount of 0.4% and uniformly mixed with the coal for combustion; the coal burn-off rate reaches up to more than 99.5%; after the catalyst is added, the coal can be fully combusted and is burnt off, and the carbon content of flying ash and coal slag after combustion is reduced, equivalently the coal is saved by 2.25%.

Owner:广州中科高成环保科技有限公司

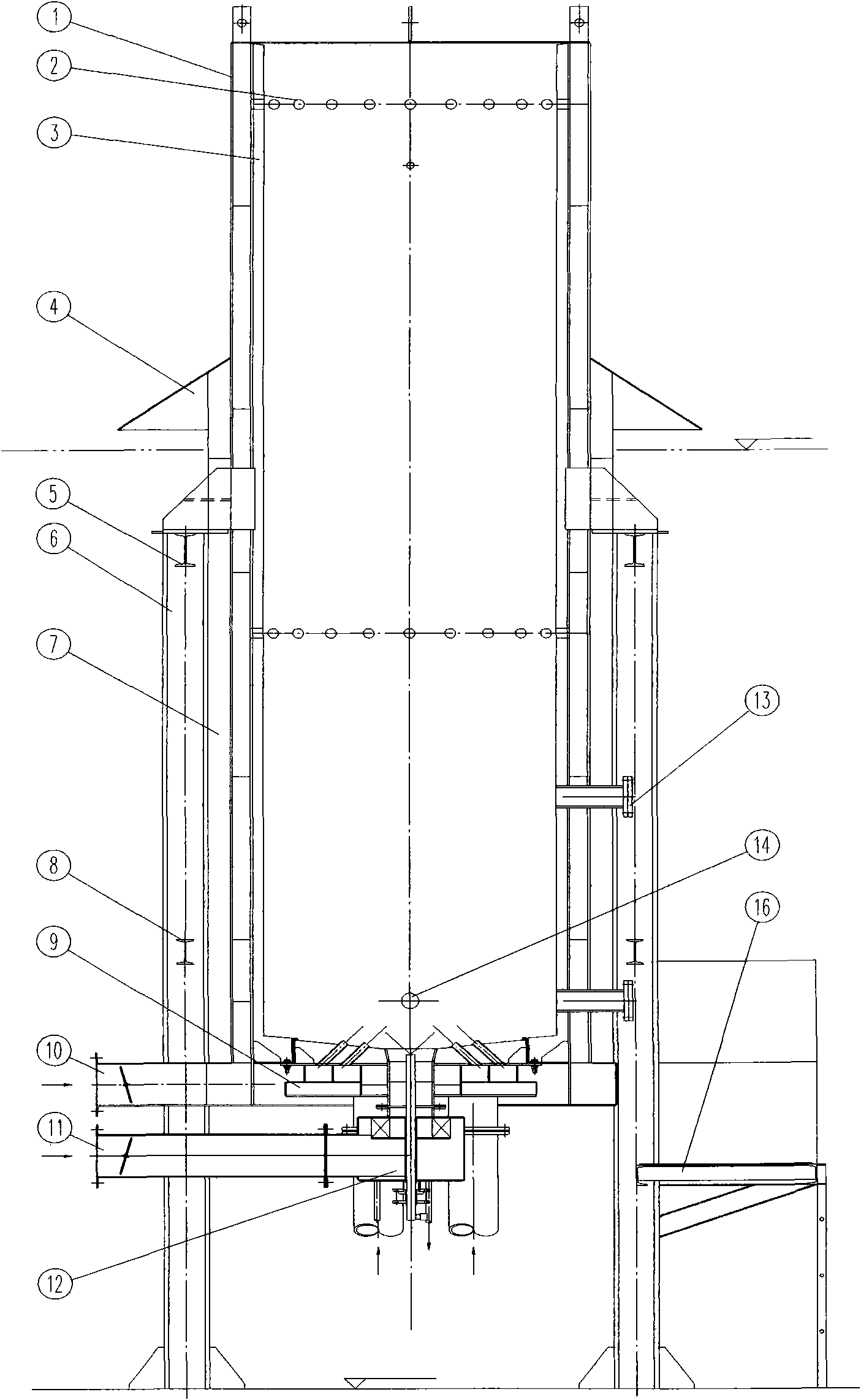

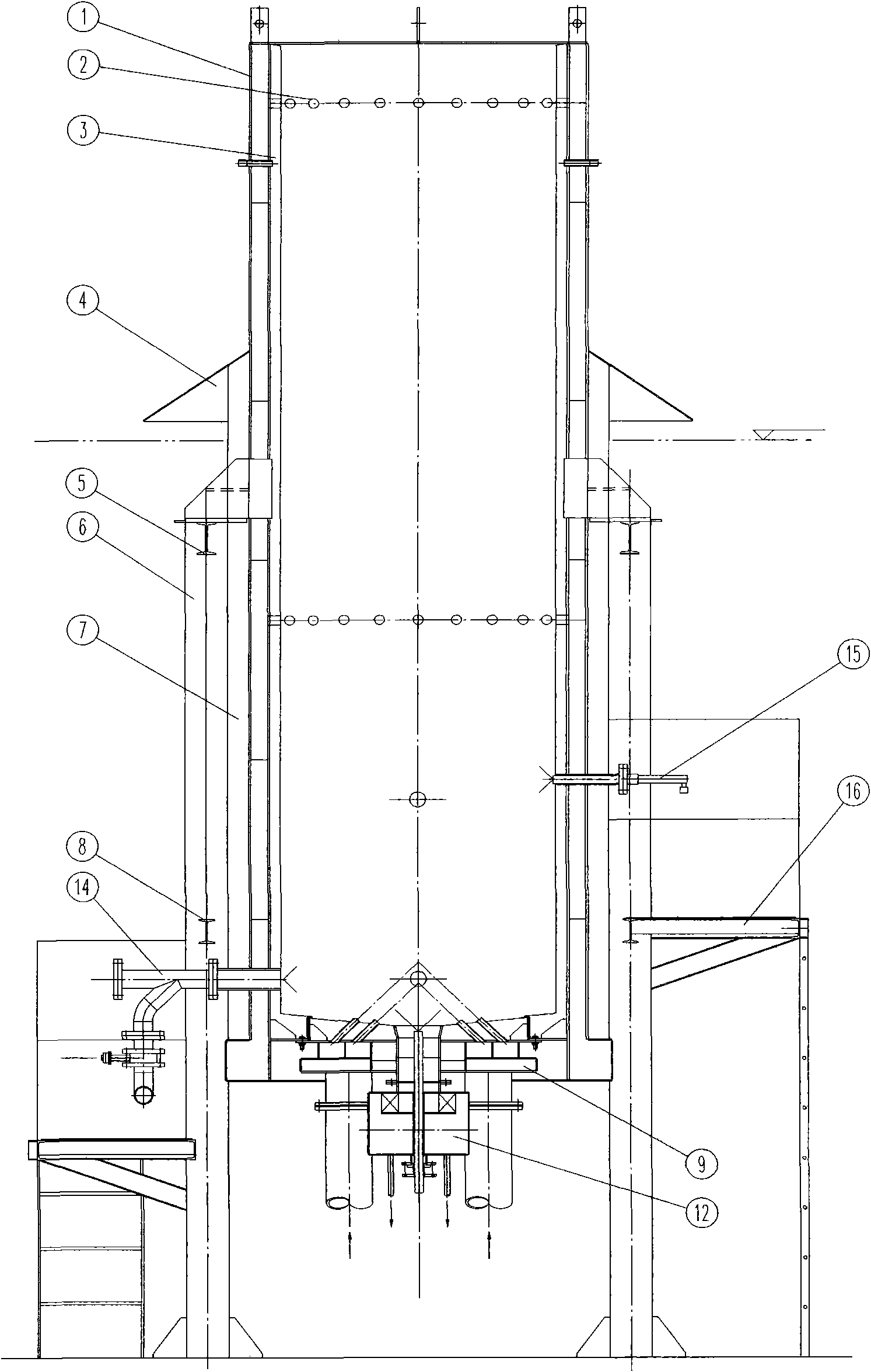

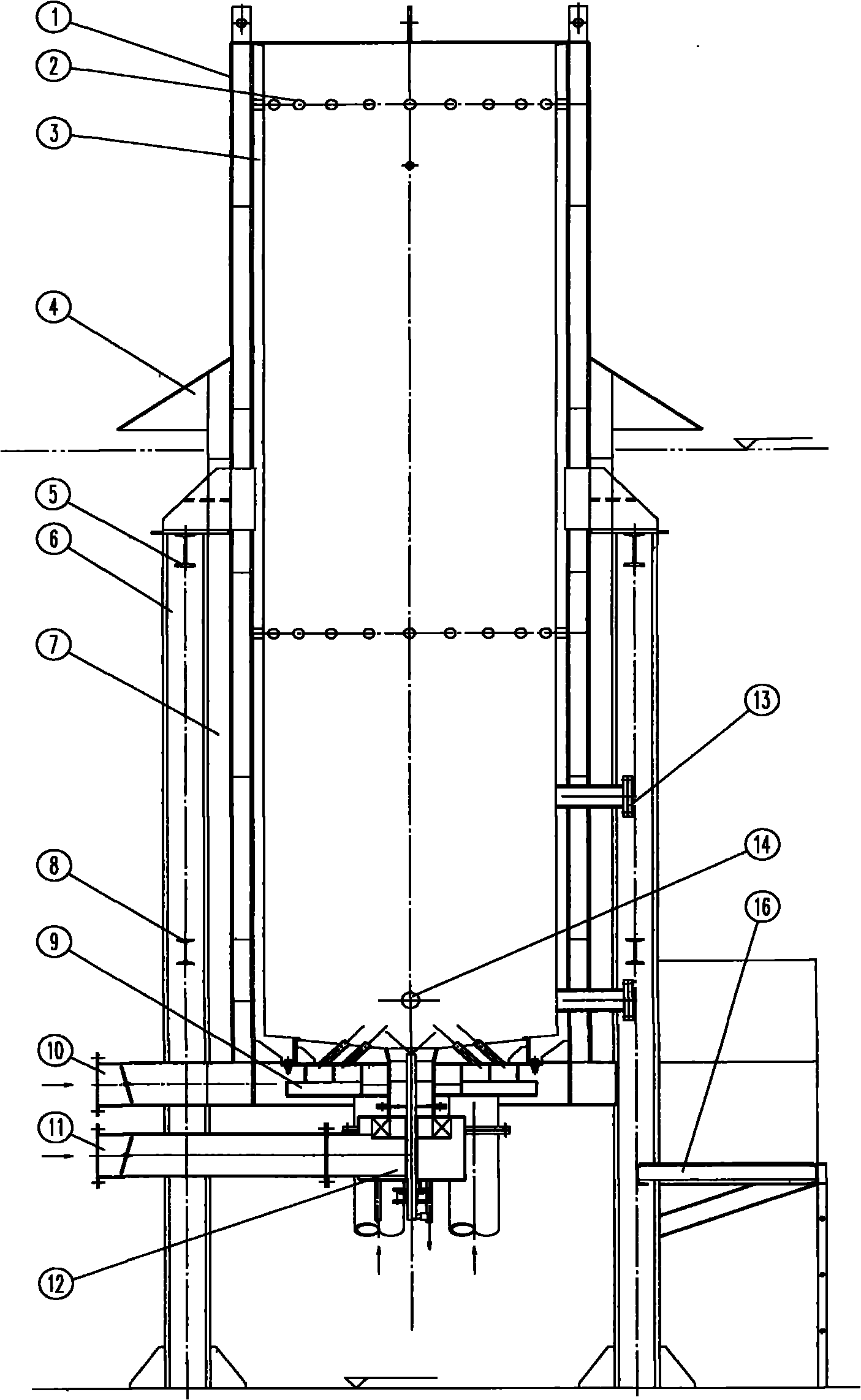

A vertical U-shaped structure oil-fired gas boiler with burner overhead

ActiveCN105042556BGuaranteed normal outputSmall footprintWater heatersSteam boilersCombustorEvaporation

The invention discloses a vertical U-shaped structure oil-fired gas boiler with a burner on the top. The boiler is composed of a drum, a furnace and a convection heating surface; The convection heating surface of the furnace type is composed of 1~n groups of plate-fin evaporator tube bundles and 1~m groups of plate-fin economizer tube bundles and headers connected by side-by-side convection tube panels, convection shaft front, rear walls, side walls and other additional heating The convection heating surface of the water heater is composed of side-by-side convection tube panels connected by 1~n groups of plate-fin tube bundles and headers, the front and rear walls of the convection shaft, and additional heating surfaces such as the walls on both sides; the length of the plate-fin varies with The temperature of the flue gas decreases and increases successively; the high-temperature flue gas generated by the combustion of the present invention first descends in the furnace, passes through the chimney and then turns 180°, scours the convective tube bundle strengthened by plate-fin segments, and then discharges from the rear wall; this type of boiler has a compact structure, Small footprint, high combustion efficiency, and excellent enhanced heat transfer performance.

Owner:XI AN JIAOTONG UNIV

Oxygen producer for increasing coal burn-off rate

The invention discloses an oxygen producer for increasing coal burn-off rate. The oxygen producer comprises the following components in percentage by weight: 15-25% of potassium hypermanganate, 30-35% of petroleum coke powder, 13-20% of magnesium oxide, 10-16% of sodium chloride and 8-15% of active carbon. A catalyst for increasing coal burn-off rate is added into coal according to the coal amount of 0.4% and uniformly mixed with the coal for combustion; the coal burn-off rate reaches up to more than 99.5%; after the catalyst is added, the coal can be fully combusted and is burnt off, and the carbon content of flying ash and coal slag after combustion is reduced, equivalently the coal is saved by 2.25%.

Owner:广州中科高成环保科技有限公司

Smokeless energy-saving air return furnace

PendingCN112710005AOvercome unsolvable problemsAvoid distributingDomestic stoves or rangesLighting and heating apparatusAutomotive engineeringCombustion chamber

The invention discloses a smokeless energy-saving air return furnace. The smokeless energy-saving air return furnace comprises a base and a combustor installed on the base, a fuel storage box, a driving device and a pulse igniter are installed inside the combustor, the pulse igniter is connected with a first electrode and a second electrode through a first wire and a second wire, an air bag cover is installed on one side of the combustor, a combustion chamber outer shell is installed at the top of the air bag cover, a heat insulation device is installed at the top of the combustion chamber outer shell, a combustion chamber inner shell is installed inside the combustion chamber outer shell, and a combustion chamber device is installed between the air bag cover and the combustion chamber inner shell. Before ignition, the driving device is firstly controlled to spray a certain amount of combustible liquid to solid fuel in a combustion chamber, then the pulse igniter works, the pulse igniter can control the first electrode and the second electrode to generate electric arcs, so that the combustible liquid in the combustion chamber is ignited, and the solid fuel in a combustion chamber body is quickly ignited under the combustion-supporting action of the combustible liquid, so that smoke is not generated.

Owner:FOSHAN CHUANGXING PRECISION SHEET METAL

A multi-stage swirl combustor with double return flow

ActiveCN104776451BEnhance swirling shearImprove mixing uniformityContinuous combustion chamberCycloneCombustor

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A kind of ferrite material for thermosensitive sensor

The invention discloses a ferrite material for a heat-sensitive sensor. The ferrite material mainly contains the ingredients in percentage by weight: 16-25% of ZnO, 5-8% of MgO, 3-7% of CuO, 1-3% of NiO, 0.008-0.01% of Al2O3, 0.008-0.02% of Nb2O5, 0.003-0.01% of Bi2O3 and the balance of Fe2O3. The ferrite material for the heat-sensitive sensor is prepared mainly through the steps of weighing and mixing, carrying out vibrated-grinding, pelletizing, prefiring, sanding, carrying out spraying granulation and the like. By adopting the ingredients and the preparation method, the crystal grain of the ferrite material for the heat-sensitive sensor can be fine and uniform, the initial magnetic permeability can be improved, the sintering temperature can be lowered, the magnetic core sintered density can be improved, and the range of Curie temperature can be narrowed; the volatilization of zinc oxide can be inhibited, the specific temperature coefficient is increased, the maximum slope of magnetic permeability temperature change is high, and the temperature control accuracy is high; due to vibrated-grinding, large granules and agglomerated powdery materials in mixed powder can be crushed, so that the gluing and mixing are uniform.

Owner:东莞时富电子有限公司

3D printing photosensitive resin for jewelry casting and preparation method thereof

The invention discloses a 3D printing photosensitive resin for jewelry casting. The components and weight percentages are as follows: polyether acrylate resin 40%-60%; polyether monomer 30%-50%; photoinitiator 3% to 6%; UV absorber 0.5% to 5%; dye 0.02% to 0.15%; Initiator, ultraviolet absorber, dye and polymerization inhibitor are added into the reaction kettle according to the proportion of the formula, and stirred at a constant temperature of 70 ° C to 80 ° C for 0.5 to 1 hour. After the components are completely dissolved, they can be discharged and filled to obtain the finished product. The 3D printing photosensitive resin for jewelry casting of the present invention has the advantages of fully combustible performance, less residual ash, good jewelry casting effect, reduced polishing time, improved processing efficiency, and reduced processing cost.

Owner:惠州市大亚湾华鑫新材料有限公司

Heating stove

InactiveCN105526706AGuaranteed temperatureAvoid getting lostWater heatersCombustionCombustion chamber

The invention relates to a heating stove which comprises a stove body and a water jacket, wherein the water jacket comprises an outer water jacket and an inner water jacket communicating with the outer water jacket; a heat preservation and insulation layer wraps the outside of the outer water jacket; the stove body is internally provided with a hearth and a plurality of heat exchange water pipes arranged at the internal upper part of the hearth; the heat exchanger water pipes communicate with the outer water jacket; a combustion chamber is arranged at the bottom of the hearth; a lower combustion supporting air inlet is formed at one side of the combustion chamber; an upper combustion supporting air inlet is formed above the lower combustion supporting air inlet; the outer sides of the upper and lower combustion supporting air inlets are provided with on-off gates for controlling the upper and lower combustion supporting air inlets to respectively communicate with the outside; the inner water jacket divides the hearth into a fuel combustion area and a gaseous phase combustion area which are independent from each other; and the gaseous phase combustion area is located at the rear side of the fuel combustion area and communicates with the bottom. According to the heating stove provided in the invention, due to arrangement of the inner water jacket and the heat preservation layer, quick heating is achieved, and heat dissipation is small.

Owner:TIANJIN CAOSHI BOILER

RST circulating thickening and emission reduction heat treatment equipment and system

PendingCN114440238AHigh emission concentrationEmission reductionIncinerator apparatusPrinting press partsEnvironmental engineeringLaboratory oven

The invention provides RST circulation thickening and emission reduction heat treatment equipment and system, relates to the technical field of organic waste gas treatment, and solves the problem that thickening and emission reduction cannot be truly achieved in the prior art. The RST circulation thickening and emission reduction heat treatment equipment comprises a first fan, a first color cell heat oven, a second fan, a second color cell heat oven and a second valve which are sequentially connected through pipelines; the air inlet end of the first valve communicates with the external environment, and the air outlet end of the first valve is connected into a pipeline from the air outlet end of the second valve to the air inlet of the first fan. An air inlet of the third fan is connected into a pipeline from an air outlet of the second color cell heat oven to the air inlet end of the second valve through a pipeline; the air inlet end and the air outlet end of the third valve are respectively connected with an air outlet of the third fan and waste gas treatment equipment through pipelines. Compared with the prior art, thickening and emission reduction of VOCs organic waste gas of the hot drying oven of the printing machine can be truly achieved, the efficiency of waste gas treatment equipment is better improved, and energy conservation and consumption reduction are achieved.

Owner:广东和炫环保智能科技有限公司

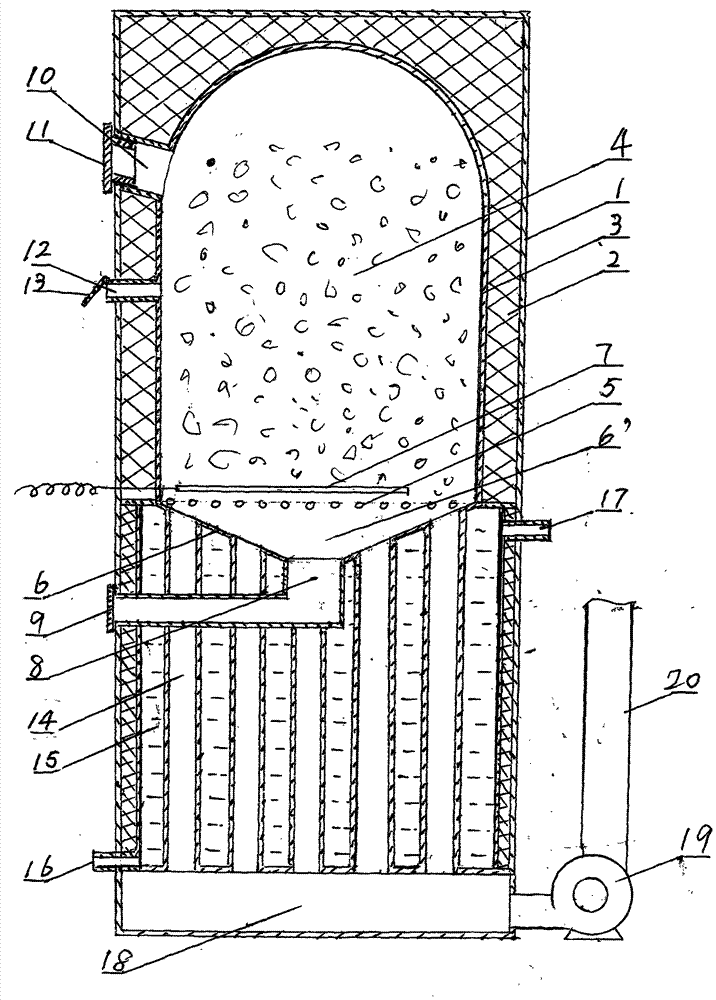

A high-efficiency gasification incinerator

InactiveCN104696966BIncrease temperatureIntensified temperatureIncinerator apparatusDestructive distillationFlammable gas

The invention discloses a high-efficiency gasifying incinerator, and relates to furnaces. The high-efficiency gasifying incinerator comprises an incinerator body, a heat preservation layer, an incinerator liner, an incinerator chamber as a destructive distillation gasifying room, a feed opening, a breeze regulating hole, incinerator grates, a fire rod, a cone-shaped incinerator basin as an inverted burning room, fire penetrating pipes, a water bag, an air inducing machine and a chimney, wherein the air inducing machine is connected with the chimney. The high-efficiency gasifying incinerator disclosed by the invention has the benefits that after firing, air is induced by the air inducing machine and compensated through the breeze regulating hole, an anoxic destructive distillation condition exists in the incinerator chamber, and a lot of flammable gas is generated by pyrolysis and gasification; when the air is induced downwards by the air inducing machine, a violent oxic inverted-fire burning condition exists in the cone-shaped incinerator basin, so that the temperature in the incinerator chamber above the cone-shaped incinerator basin is raised, and the pyrolysis and the gasification in the incinerator chamber are further facilitated; any burning-supporting material is not needed in the incinerator chamber, and the burning of the flammable gas is generated by the pyrolysis and the gasification of garbage; an inverted burning flame penetrates through the fire penetrating pipes and heats water in the water bag and can supply hot water and can be used for heating; the destructive distillation gasifying and the inverted burning are organically combined by the high-efficiency gasifying incinerator, the burning is sufficient, smoke and dust are not generated, the garbage is efficiently treated in an environment-friendly manner, and the high-efficiency gasifying incinerator is particularly suitable for the incineration of domestic garbage and medical garbage.

Owner:卢昱帆 +1

A horizontal boiler with staggered arrangement of sncr and ofa

ActiveCN107606602BEmission reductionComplete restorationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorPoor adaptive skills

The invention provides a horizontal boiler with SNCR and OFA arranged in a staggered manner and relates to an industrial boiler. The horizontal boiler with the SNCR and the OFA arranged in the staggered manner aims at solving the problems that a horizontal industrial coal powder boiler in the prior art is high in denitration cost, consequently, the NOx emission amount of an industrial coal powderboiler is high, the coal powder over-fire effect is poor, the adaptive capacity on load changes is poor, and the heat efficiency is low. The horizontal boiler with the SNCR and the OFA arranged in thestaggered manner comprises a combustor, a hearth, an upstream flue, a set of primary amino reducing agent spraying ports, a set of primary over-fire air spraying ports, a set of secondary over-fire air spraying ports, a set of secondary amino reducing agent spraying ports and two sets of temperature sensors; the combustor is installed at the front end of the hearth; the upstream flue is communicated with the top of the rear end of the hearth; the primary amino reducing agent spraying port and the primary over-fire air spraying port are fixedly installed on the side wall, from the front end tothe back end, of the hearth; and the secondary over-fire air spraying port and the secondary amino reducing agent spraying port are sequentially installed on the side wall of the upstream flue from bottom to top. The invention is used in the industrial boiler coal powder combustion field.

Owner:HARBIN INST OF TECH

Multifunctional furnace with backflow dual combustion-chamber device

InactiveCN101749737BExtension of timeIncrease spaceDomestic stoves or rangesLighting and heating apparatusCombustion chamberEngineering

The invention provides a multifunctional furnace with a backflow dual combustion-chamber device, belonging to a household living furnace which has simple structure and can completely combust fuels. A partition plate is arranged in the furnace, an upper fire opening is arranged at the rear part of the partition plate, and an adjusting plate is arranged in a smoke outlet. Flames flow back from the upper fire opening, flow to an upper combustion chamber from a lower combustion chamber, and flow to a chimney from the upper part of the smoke outlet after passing through the upper combustion chamber and the lower combustion chamber, so as to realize adjustable fire power. The semi-gasification multifunctional furnace has the following characteristics: a furnace mouth does not discharge smoke tothe indoor part, smokeless baking can be carried out, the effects of energy saving and emission reducing are obvious, the manufacturing is easy, and the cost is low.

Owner:任玉珊

A double-line drying combustion tower and its combustion method

ActiveCN106016311BExtension of timeInsufficient combustionIncinerator apparatusParticulatesCombustion

The invention discloses a double-wire drying combustion tower which comprises a combustion box body. A combustion cavity capable of prolonging the combustion time, a combustion gas gathering cavity used for gathering combustion gas and a cooling cavity used for cooling combusted gas are formed in a combusting cavity of the combustion box body in sequence from bottom to top. A control box used for controlling the temperature of the combustion box body is arranged on the front side or the rear side of the combustion box body. By means of the double-wire drying combustion tower and the combustion method thereof, a bottom-to-top layer-by-layer combustion manner is adopted, ventilation partition plates are arranged in a staggered manner, so that the time for waste gas particles to pass through each combustion area is prolonged, the waste gas particles can be combusted more sufficiently in each combustion area, and gas discharged afterwards reaches the marked discharging grade. By means of the combustion manner of the combustion tower, discharging of the waste gas particles can be greatly reduced, discharged gas can be more environment-friendly, all dust generated after combustion of the particles can be thoroughly removed through a dust collector, and collecting and cleaning of the combustion tower are facilitated.

Owner:FOLUNGWIN AUTOMATIC EQUIP CO LTD

Hazardous waste multiphase cooperative treatment device and hazardous waste treatment method thereof

InactiveCN112393256AThe generation of solutionAchieve reductionEmission preventionAir/fuel supply for combustionParticulatesCombustion chamber

The invention discloses a hazardous waste multiphase cooperative treatment device and a hazardous waste treatment method thereof, and relates to a hazardous waste treatment device and a hazardous waste treatment method thereof. The problem that a large amount of acid gas and incompletely combusted organic components and furnace slag are generated by incineration of hazardous wastes in an existingincineration method is solved. The hazardous waste multiphase cooperative treatment device comprises an air blower, a feeding machine, a waste liquid tank, a high-pressure oxygen meter, an ammonia water tank, a multiphase reactor, an ammonia water spray gun, a rapid cooler, a dust remover, an induced draft fan, a waste gas spray head, a waste gas tank and a second flue. The process method comprises the steps that solid waste is placed on an air distribution plate of a combustion chamber, the air blower introduces air into the combustion chamber, and the waste liquid tank introduces waste liquid into the combustion chamber for combustion decomposition and waste gas burnout; primary removal is carried out on nitrogen oxide in the flue gas; and the rapid cooler is used for performing secondary denitration and absorbing the heat of the flue gas, then the dust remover is used for filtering particles in the flue gas, and the induced draft fan is used for leading out the flue gas to enter anacid making procedure.

Owner:中晟工程技术(天津)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com