Incinerator for processing pulping foul gas in paper mills

A technology for incinerators and paper mills, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of large influence of environmental factors, difficulty in ensuring full combustion of odor, inconvenient adjustment and organization of combustion air volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

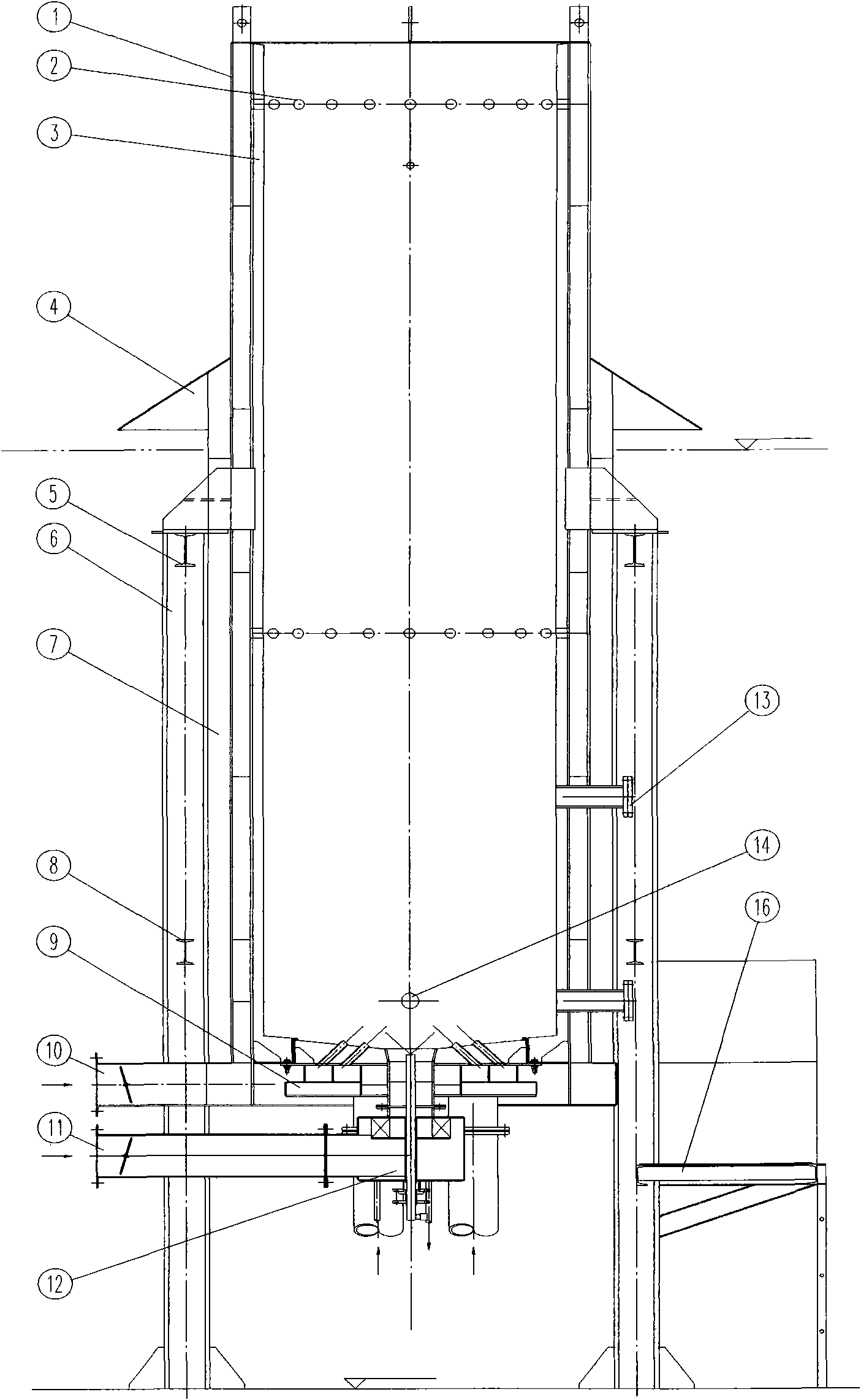

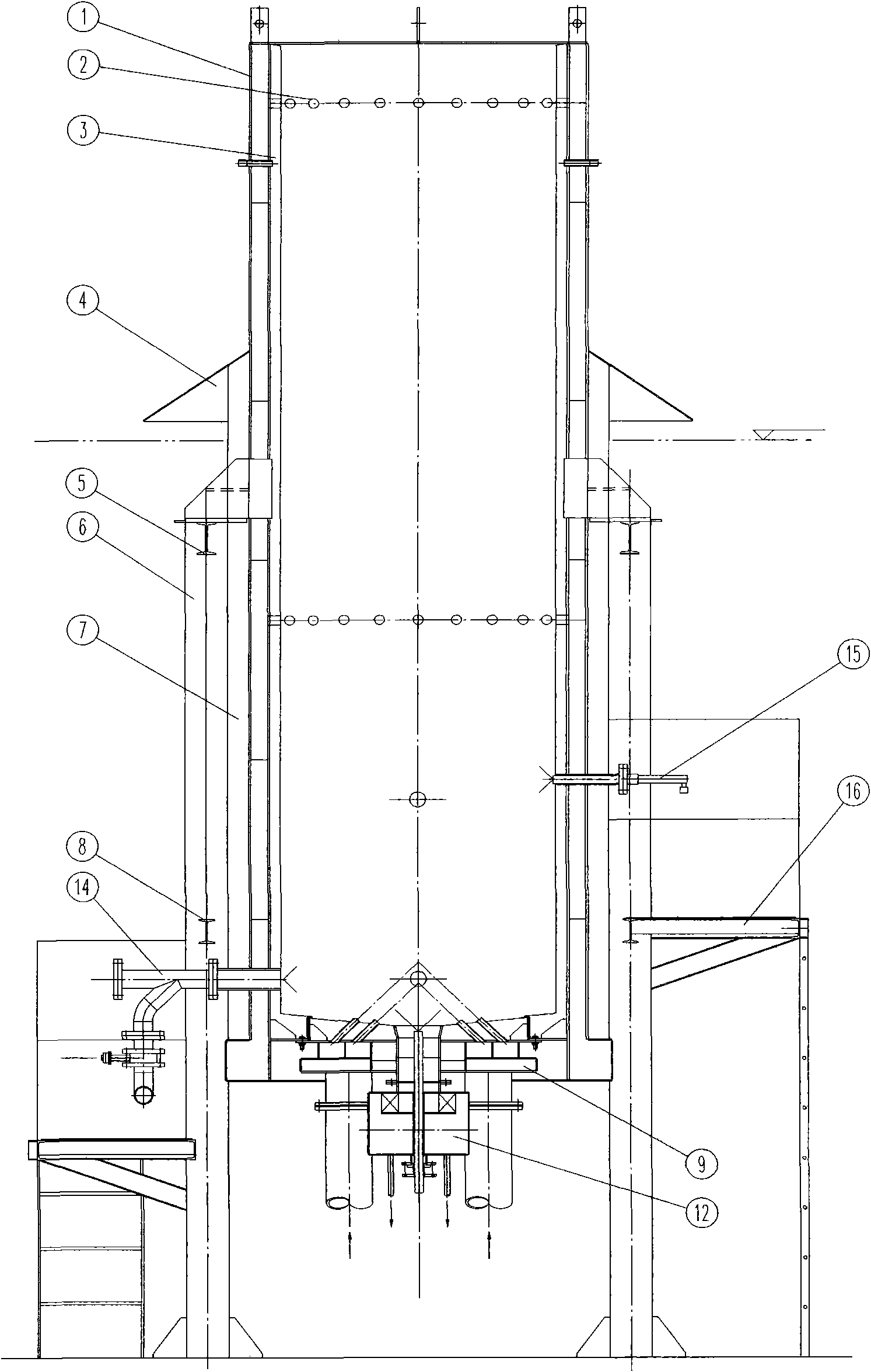

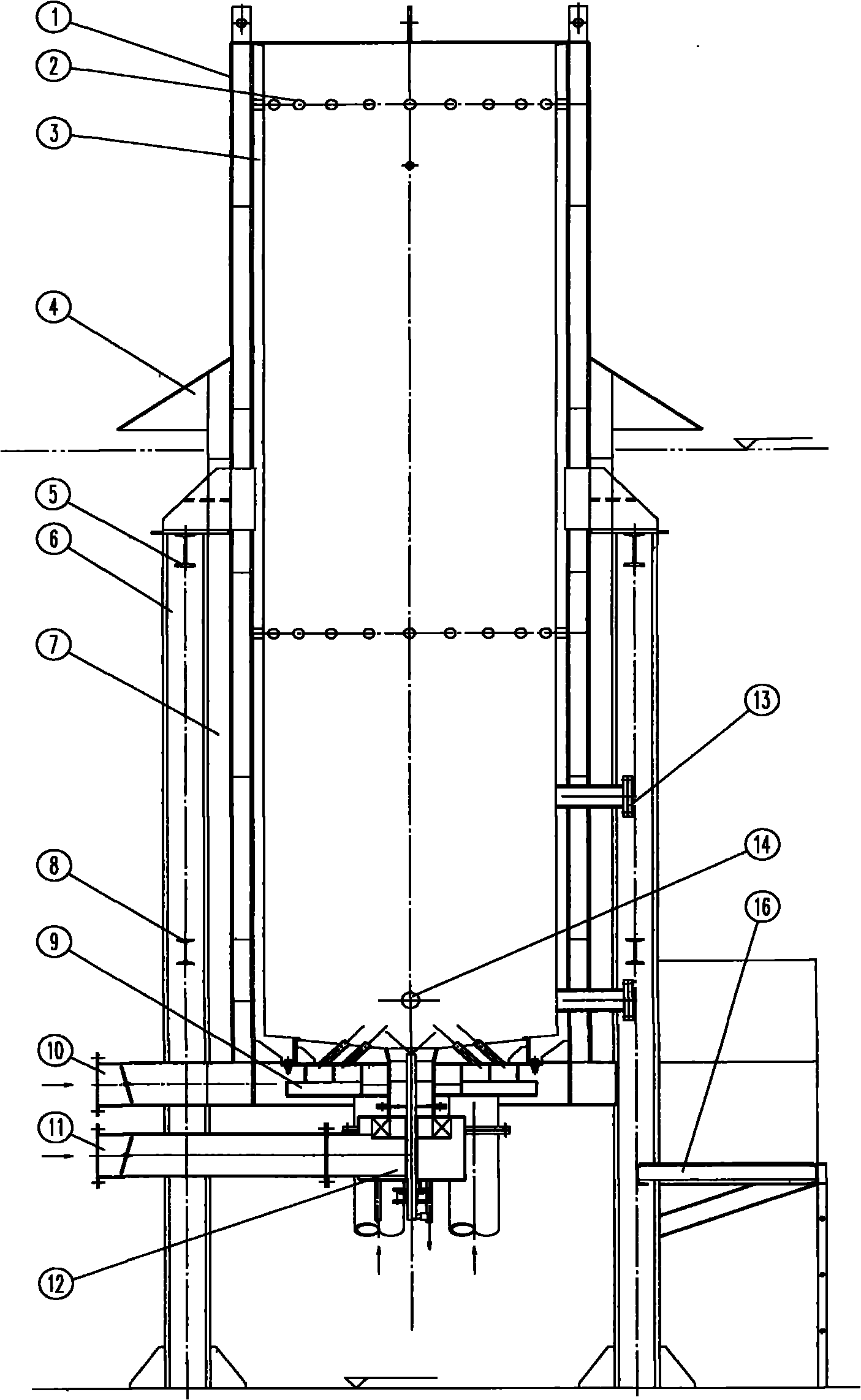

[0019] The odor incineration device of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

[0020] see Attachment

[0021] An incineration device for treating pulping odor in a paper mill. The incineration device is composed of a cylinder body 1, a combustion system, a support frame, a fan, an air duct, a pipe, and a valve. The main equipment of the odor incineration device—the cylinder body 1 is a The double-jacketed adiabatic combustion chamber, the cylinder 1 is vertically arranged on the top frame beam of the alkali furnace supported by the frame. The main burner 12 is arranged at the center of the bottom of the cylinder body 1 , and the odor burner 9 is arranged around the main burner 12 at the bottom of the cylinder body 1 . The cylinder body 1 is supported by a frame composed of columns 6 and main beams 5, etc., and the support frame is firmly connected with the frame beam on the top of the alkali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com