Low-nitrogen burner boiler

A low-nitrogen burner and burner technology, applied in the field of combustion boilers, can solve problems such as low burner efficiency, achieve the effects of improving boiler efficiency, broad application prospects, and preventing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

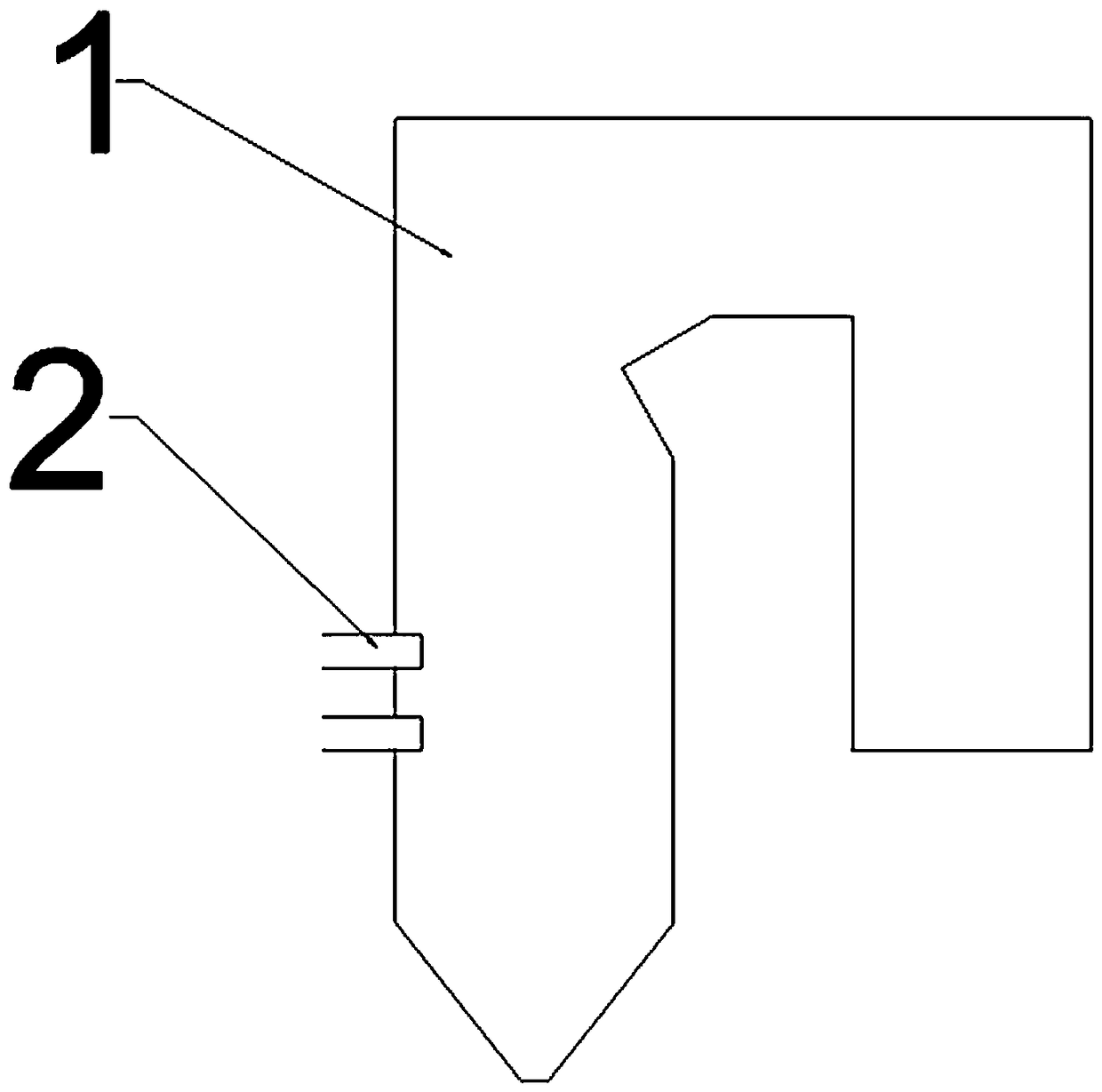

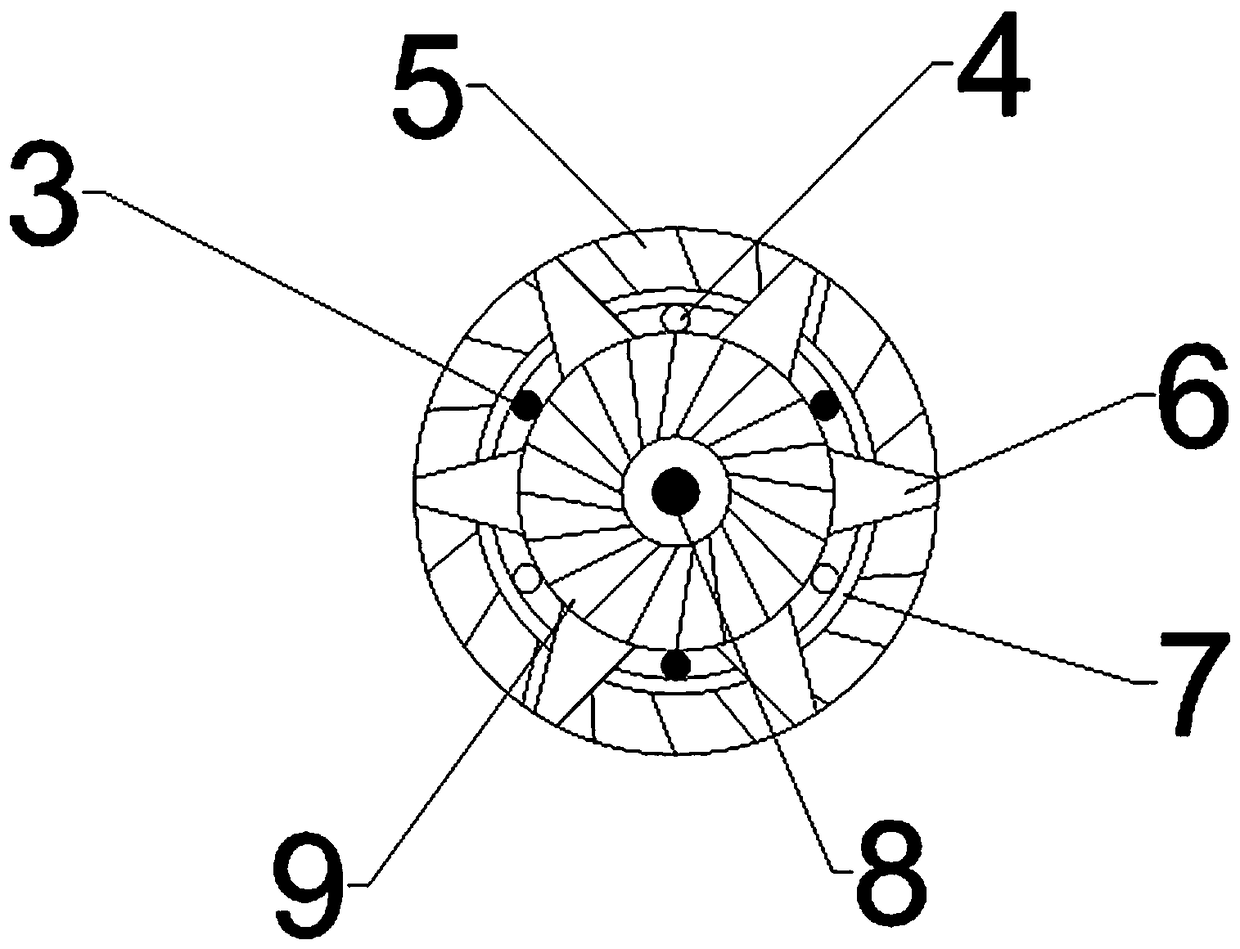

[0022] The pulverized coal is sprayed out through the pulverized coal spray gun 3 and the central pulverized coal spray gun 8 at an exit velocity of 10~20m / s, and the high axial velocity airflow generated by the primary swirling wind wheel 9 ensures that it can penetrate the furnace The air flow improves the mixing of the central air and the central coal, and then the secondary air turbine 5 swirls into the furnace at the periphery to ensure that the air and the unburned particles in the combustion products are fully mixed, forming a package outside the flow pattern of the central swirling air The swirl wind provides excess air for the coal combustion in the periphery, and improves the combustion time of the air and the coal through the swirl flow. The use of the swirl wind at the outermost side helps to form the high-temperature flue gas backflow inside the furnace at the root of the flame, and the well-organized At the same time as the aerodynamic field, it can be ignited in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com