Secondary air oxygen-enrichment pulse combustion gas spraying device and method of rotary kiln

A technology of pulse combustion and jet device, applied in combustion methods, combustion equipment, indirect carbon dioxide emission reduction, etc., can solve the problems of reducing atmosphere generation and affecting product quality, improve combustion efficiency, ensure safe and stable operation, and ensure safe and stable operation. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

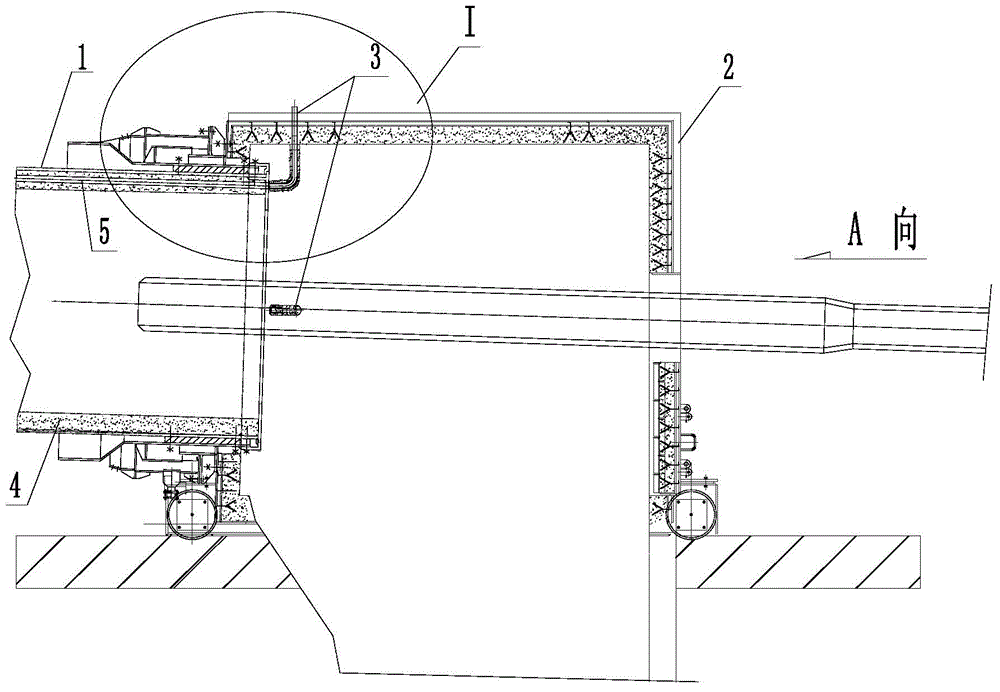

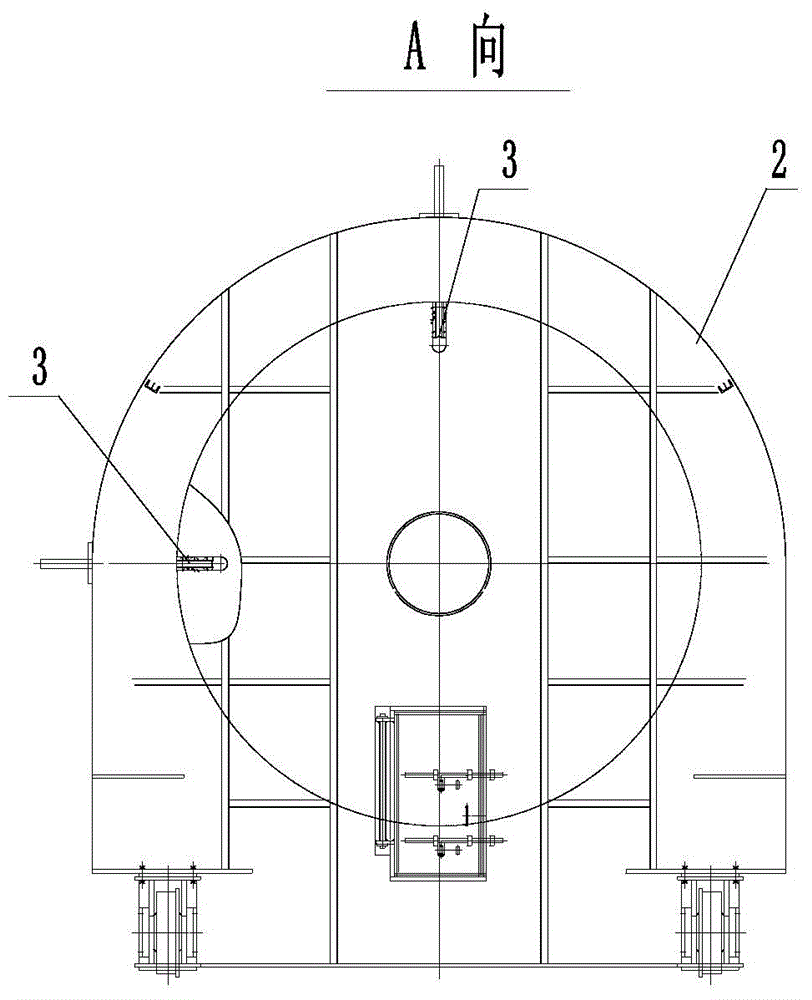

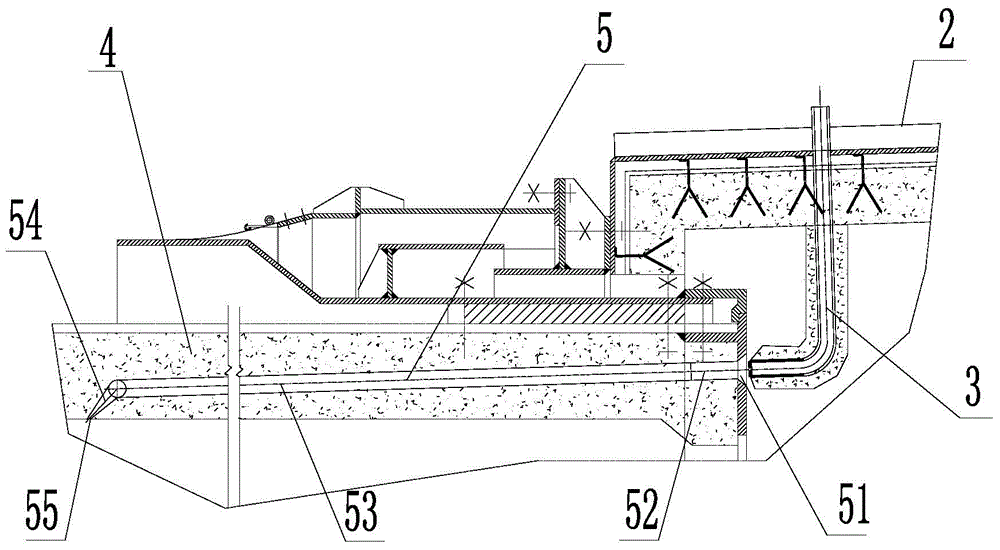

[0032] See Figure 1-Figure 3 , is a schematic structural view of the device of the present invention. The rotary kiln secondary air oxygen-enriched pulse combustion air injection device of the present invention includes several oxygen-enriched spray guns 3 fixed on the rotary kiln hood 2, and the ends of the cooling belt kiln lining 4 corresponding to the nozzles of the oxygen-enriched spray guns 3 An air inlet 51 of an oxygen-enriched secondary air channel is provided, and an outlet 55 of an oxygen-enriched secondary air channel is arranged on the inner wall of the kiln lining 4 of the firing zone.

[0033] There are 1 to 5 oxygen-enriched spray guns 3 evenly arranged along the circumferential direction of the kiln head cover 2 , and the nozzles of the spray guns face the kiln lining 4 of the rotary kiln.

[0034] The air inlet 51 of the oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com