Uniform continuous feeding device for garbage incineration fly ash particles

A technology of waste incineration fly ash and uniform particles, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of long-distance conveying difficulty, waste of screw conveyor, uneven feeding of belt conveyor, etc., and achieve stable operation at high temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

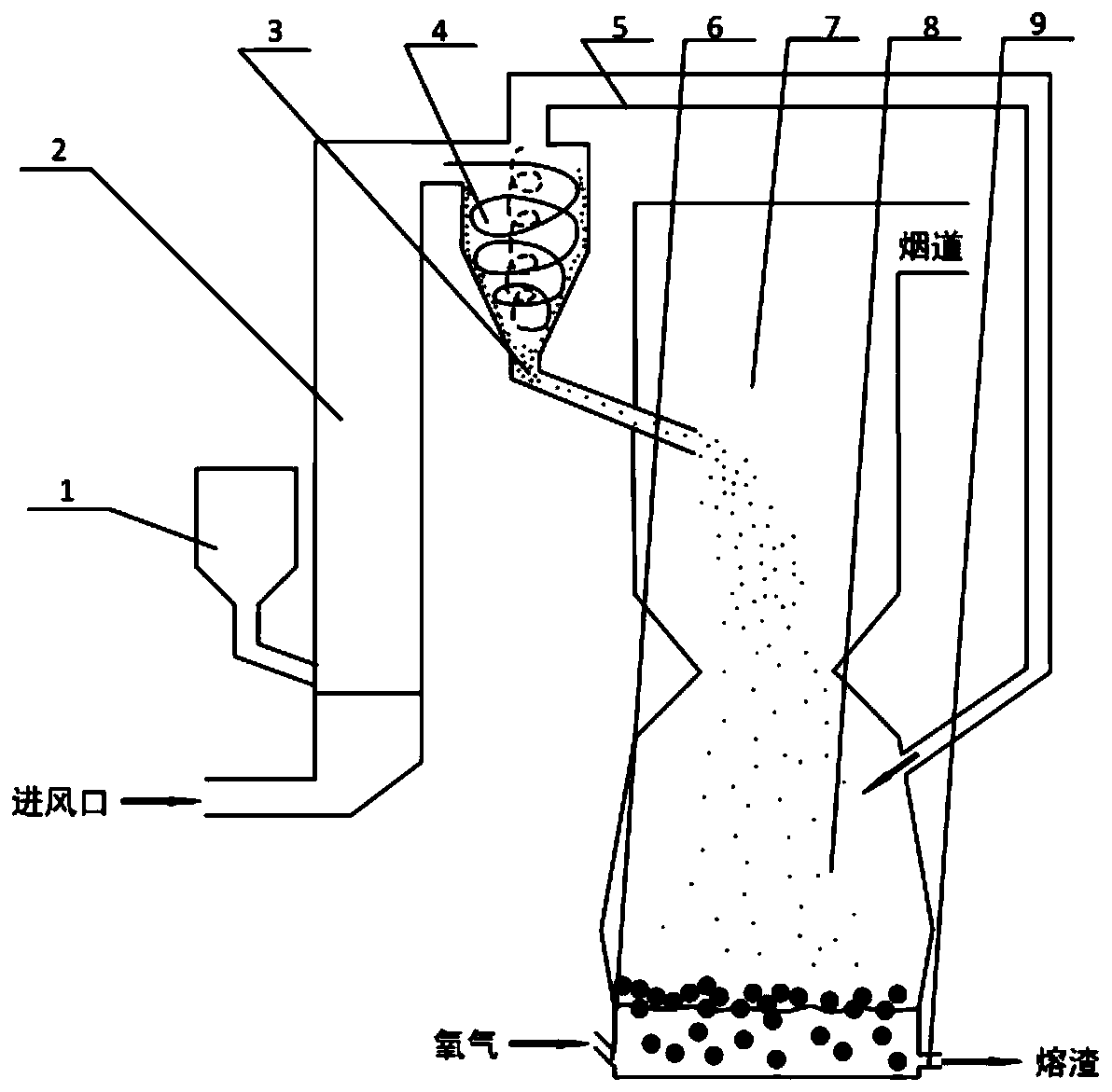

[0020] Such as figure 1 As shown: the device for uniformly and continuously feeding waste incineration fly ash particles, its main structure includes a fluidized bed feeder 2 , a cyclone material separator 4 , a preheating furnace 7 and a high temperature melting furnace 8 . The fluidized bed feeder 2 is provided with an air inlet and a storage bin 1, the fluidized bed feeder 2 is connected with the cyclone material separator 4, and the outlet direction of the tail part is tangent to the inner wall surface of the cylinder of the cyclone material separator 4. The top of the cyclone material separator 4 is connected to the high-temperature melting furnace 8 through the air duct 5, and the connection is located at the upper part of the high-temperature melting furnace 8; the bottom of the cyclone material separator 4 is provided with a solid particle collector 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com