Multifunctional furnace with backflow dual combustion-chamber device

A dual-combustion chamber, multi-functional technology, applied in coking ovens, household furnaces/stoves, solid heating fuels, etc., can solve problems such as enlarged furnace structure, insufficient fuel combustion, and rising costs, so as to improve heat transfer efficiency , lengthen the process, and reduce harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

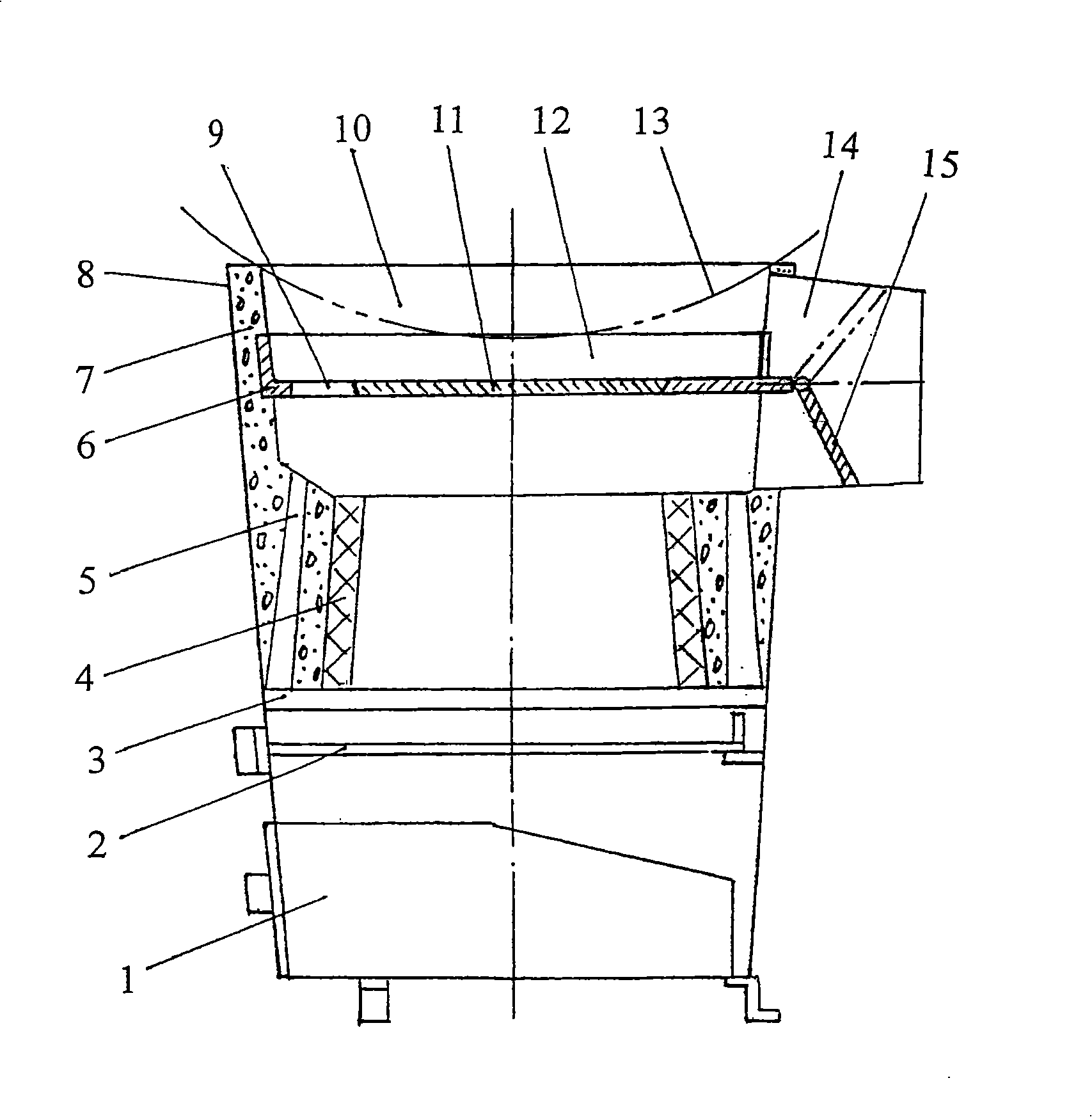

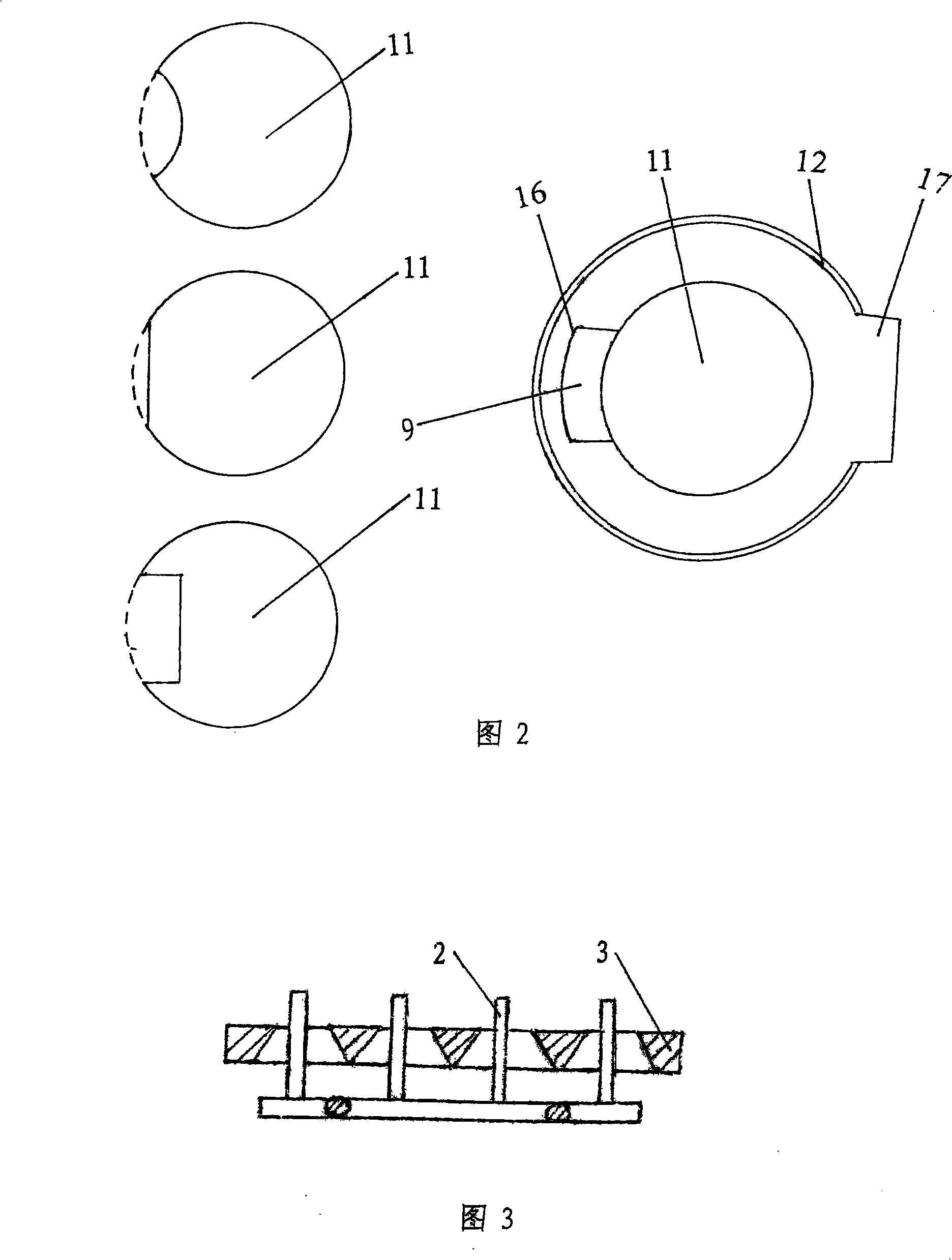

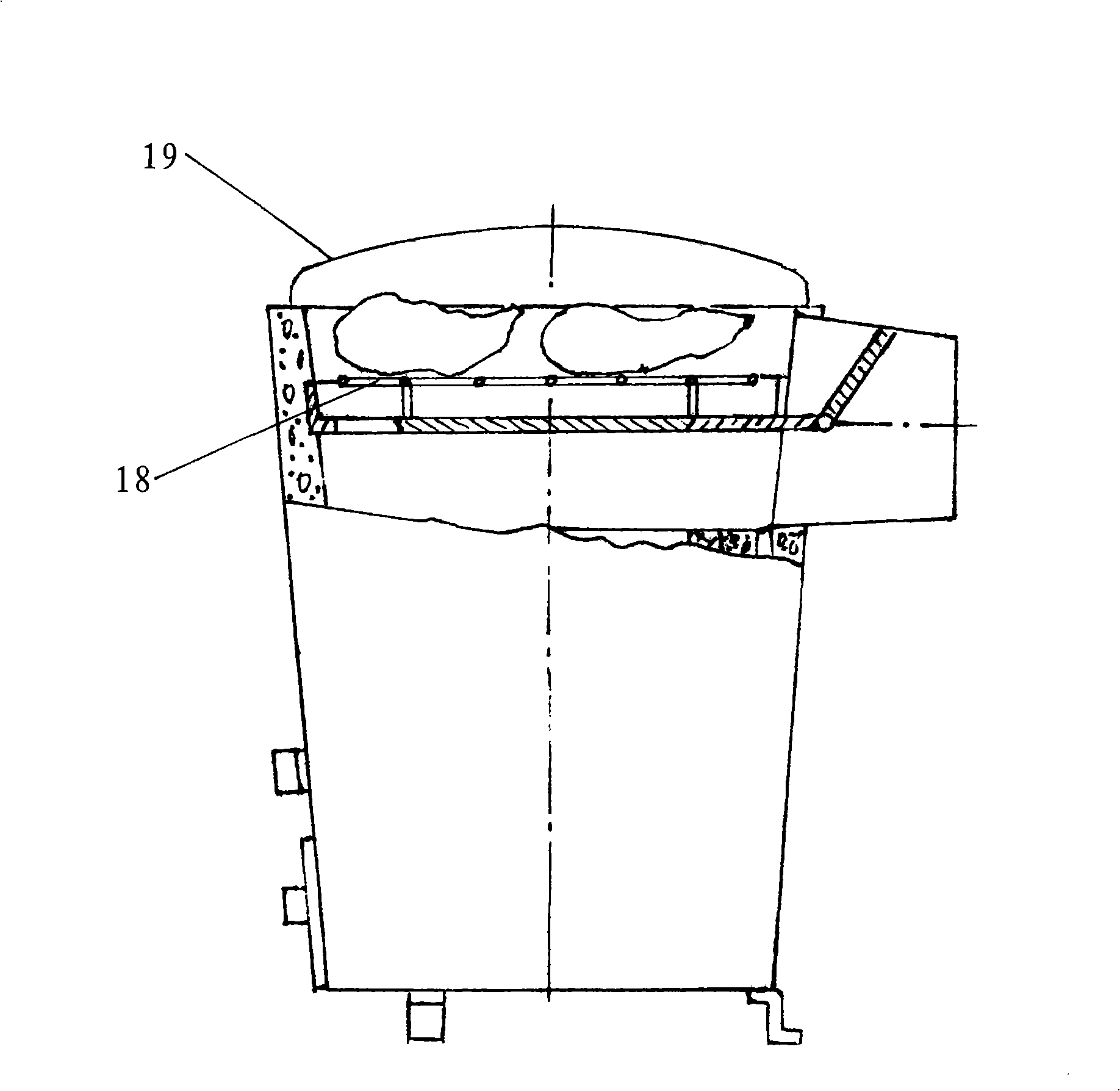

[0028] exist figure 1 Among them, the smoke outlet 14 is taken as the front part of the furnace, and the burner port 9 is located at the rear part thereof, so the burner port 9 is located at the rear part of the partition plate 6 . The further the upper flame port 9 is located, the greater the flame flow resistance, but the longer the heat transfer route. Taking the outflow direction of the smoke in the smoke outlet 14 as the positive direction, the flow from the lower combustion chamber to the upper combustion port 9 is a reverse flow, so it is called reverse flow. A lower combustion chamber is formed between the furnace liner 4 and the partition plate 6 , and an upper combustion chamber is formed between the partition plate 6 and the furnace mouth 10 . Ignite the fire, turn the adjusting plate 15 to the top of the smoke outlet 14, the flame flows out from the bottom of the smoke outlet 14, the resistance is small, the drawing force is large, and the fire is fast. Turn the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com