Hazardous waste multiphase cooperative treatment device and hazardous waste treatment method thereof

A co-processing, multi-phase reactor technology, applied in the combustion method, combustion product treatment, combustion air/fuel supply, etc., can solve the problem of producing a large amount of acid gas organic components and slag, and achieve no secondary production. The effect of pollution, high economic efficiency and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

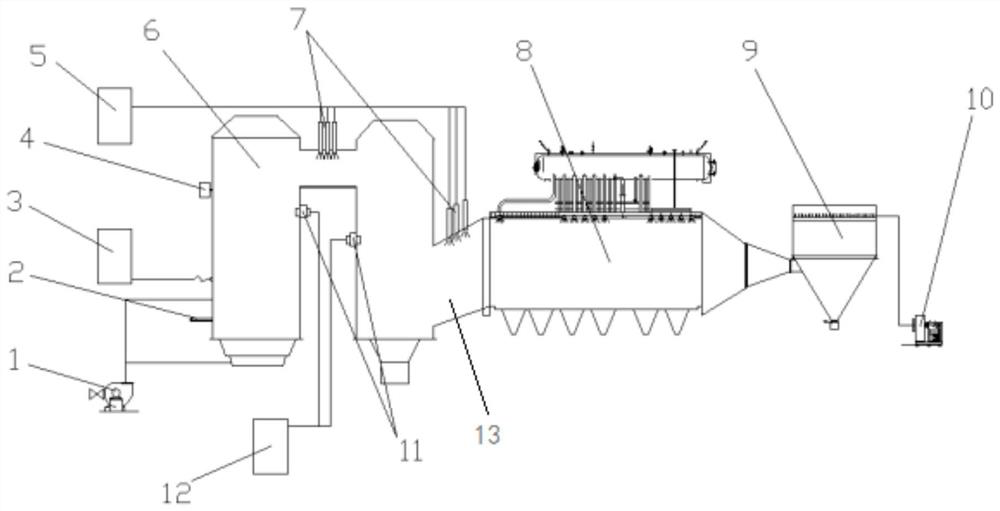

[0030] Specific implementation mode one: combine Figure 1 to Figure 2Specifically, this embodiment is a hazardous waste multi-phase co-processing device, which includes a blower 1, a feeder 2, a waste liquid tank 3, a high-pressure oxygen meter 4, an ammonia water tank 5, a multi-phase reactor 6, an ammonia water spray gun 7, Rapid cooling device 8, dust collector 9, induced draft fan 10, exhaust gas nozzle 11, exhaust gas tank 12 and second flue 13;

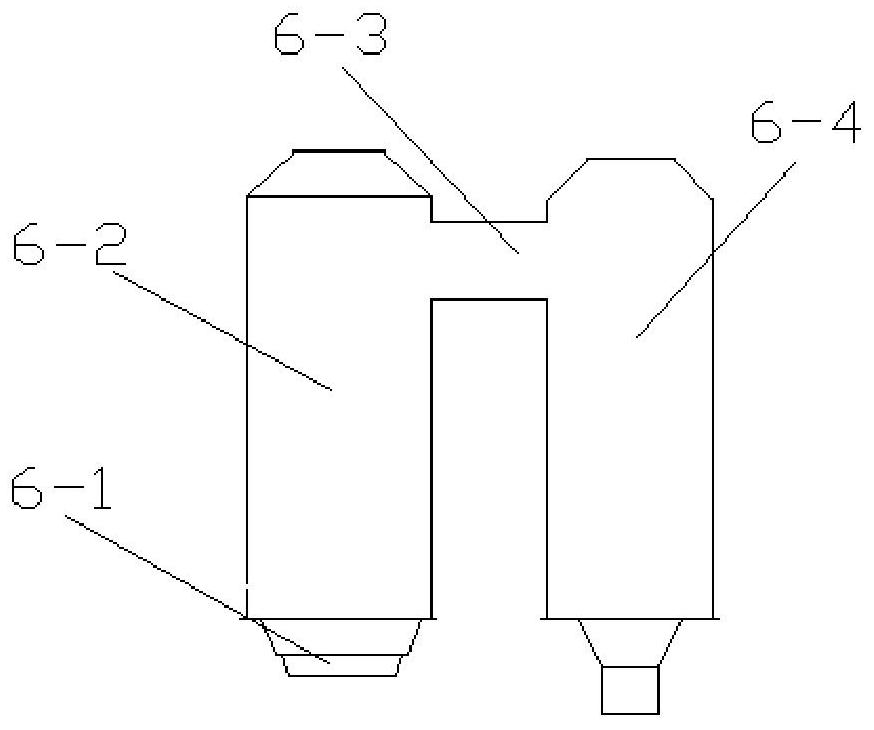

[0031] The multiphase reactor 6 is composed of an air chamber 6-1, a combustion chamber 6-2, a first flue 6-3 and a second combustion chamber 6-4; the combustion chamber 6-2 and the second combustion chamber 6 -4 are connected through the first flue 6-3, and the bottom of the combustion chamber 6-2 is provided with an air chamber 6-1; the combustion chamber 6-2 is provided with an air distribution plate;

[0032] The first flue 6-3 and the second flue 13 are provided with an ammonia spray gun 7, and the water inlet of the ammo...

specific Embodiment approach 2

[0044] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the exhaust gas inlets of the combustion chamber 6-2 and the second combustion chamber 6-4 communicate with the exhaust gas tank 12 through stainless steel pipes respectively; the combustion chamber The waste liquid injection port of 6-2 communicates with the waste liquid spray port of the waste liquid tank 3 through a stainless steel pipe. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0045] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the multiphase reactor 6 adopts an adiabatic furnace; the dust collector 9 is a bag filter. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com