A double-line drying combustion tower and its combustion method

A combustion tower and combustion zone technology, applied in the field of exhaust gas combustion equipment, can solve the problems of increased economic loss, harmful exhaust gas explosion, high operating cost, etc., and achieve the effects of sufficient combustion degree, longer time, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

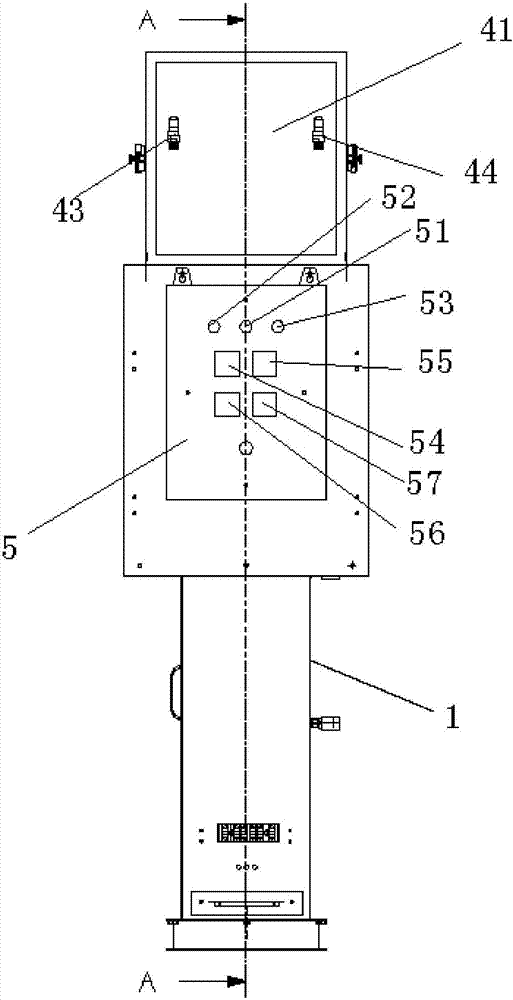

Image

Examples

Embodiment 1

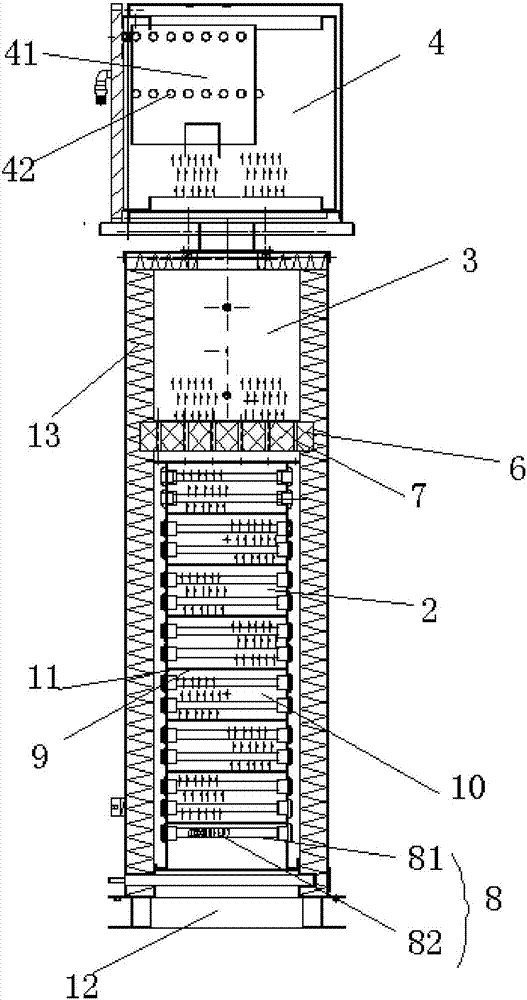

[0036] Embodiment one: a kind of combustion method of double-line drying combustion tower, comprises the following steps:

[0037] A) Set the combustion cavity, and set a combustion cavity that can gradually burn the exhaust gas from bottom to top;

[0038] B) Set a combustion gas concentration cavity at the gas outflow position at the upper end of the combustion cavity;

[0039] C) At the gas outlet position of the concentrated cavity, a cooling cavity that can cool the fully combusted gas and discharge it; the cooling cavity is equipped with a circulating water condenser; the cooling pipe of the circulating water condenser is S-shaped;

[0040] D) Multiple combustion zones are set in the combustion cavity of step A), and each combustion zone is arranged sequentially from bottom to top, and every two adjacent combustion zones are separated by a gas-permeable partition, and each gas-permeable partition A plurality of through-holes are arranged at intervals at one end of each; t...

Embodiment 2

[0042] Embodiment two: a kind of combustion method of double-line drying combustion tower, comprises the following steps:

[0043] A) Set the combustion cavity, and set a combustion cavity that can gradually burn the exhaust gas from bottom to top;

[0044] B) Set a combustion gas concentration cavity at the gas outflow position at the upper end of the combustion cavity;

[0045] C) At the gas outlet position of the concentrated cavity, a cooling cavity that can cool the fully combusted gas and discharge it; a circulating water condenser is installed in the cooling cavity; the cooling pipe of the circulating water condenser is U-shaped;

[0046] D) Multiple combustion zones are set in the combustion cavity of step A), and each combustion zone is arranged sequentially from bottom to top, and every two adjacent combustion zones are separated by a gas-permeable partition, and each gas-permeable partition A plurality of through-holes are arranged at intervals at one end of each; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com