Patents

Literature

84results about How to "Guaranteed normal drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

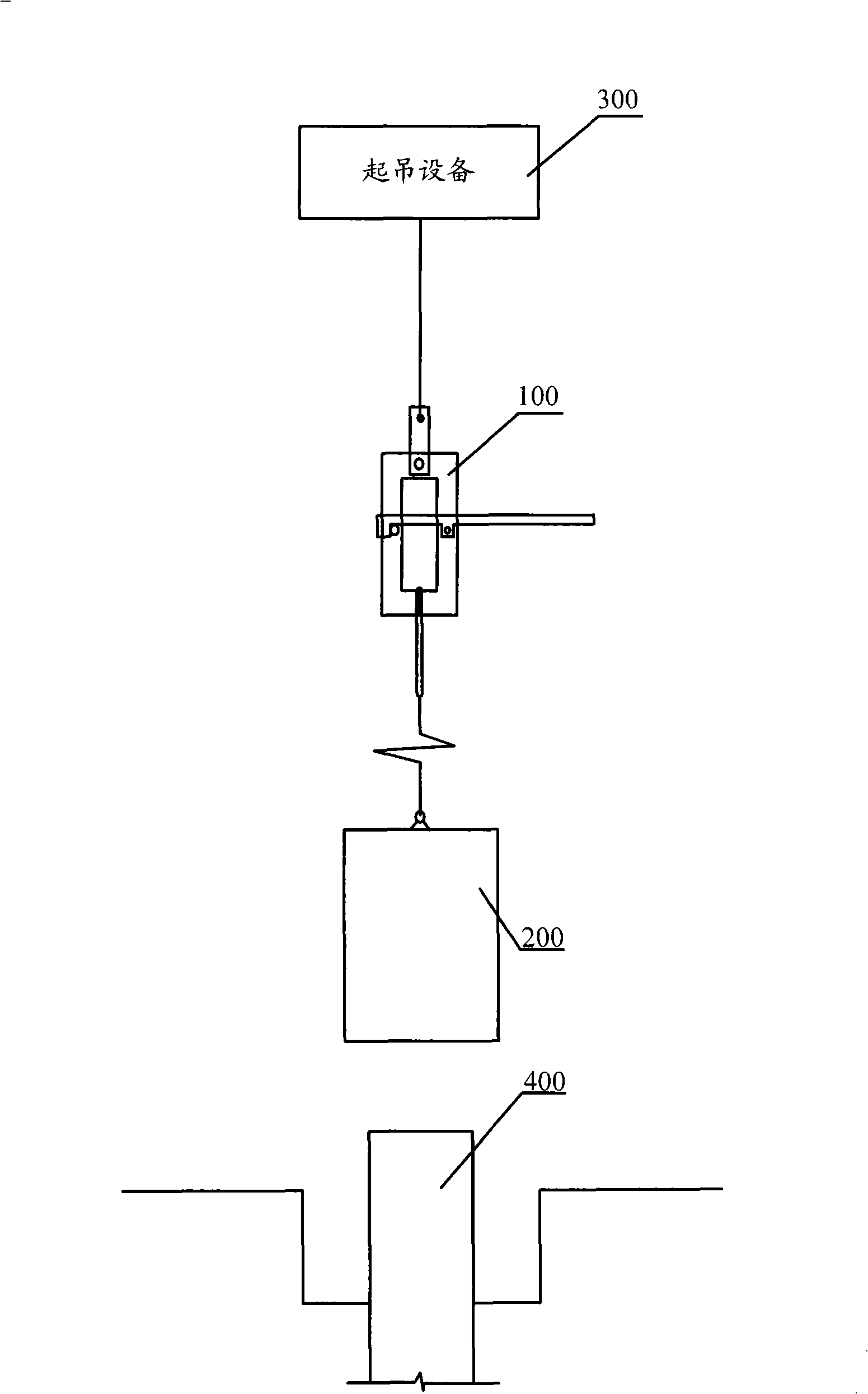

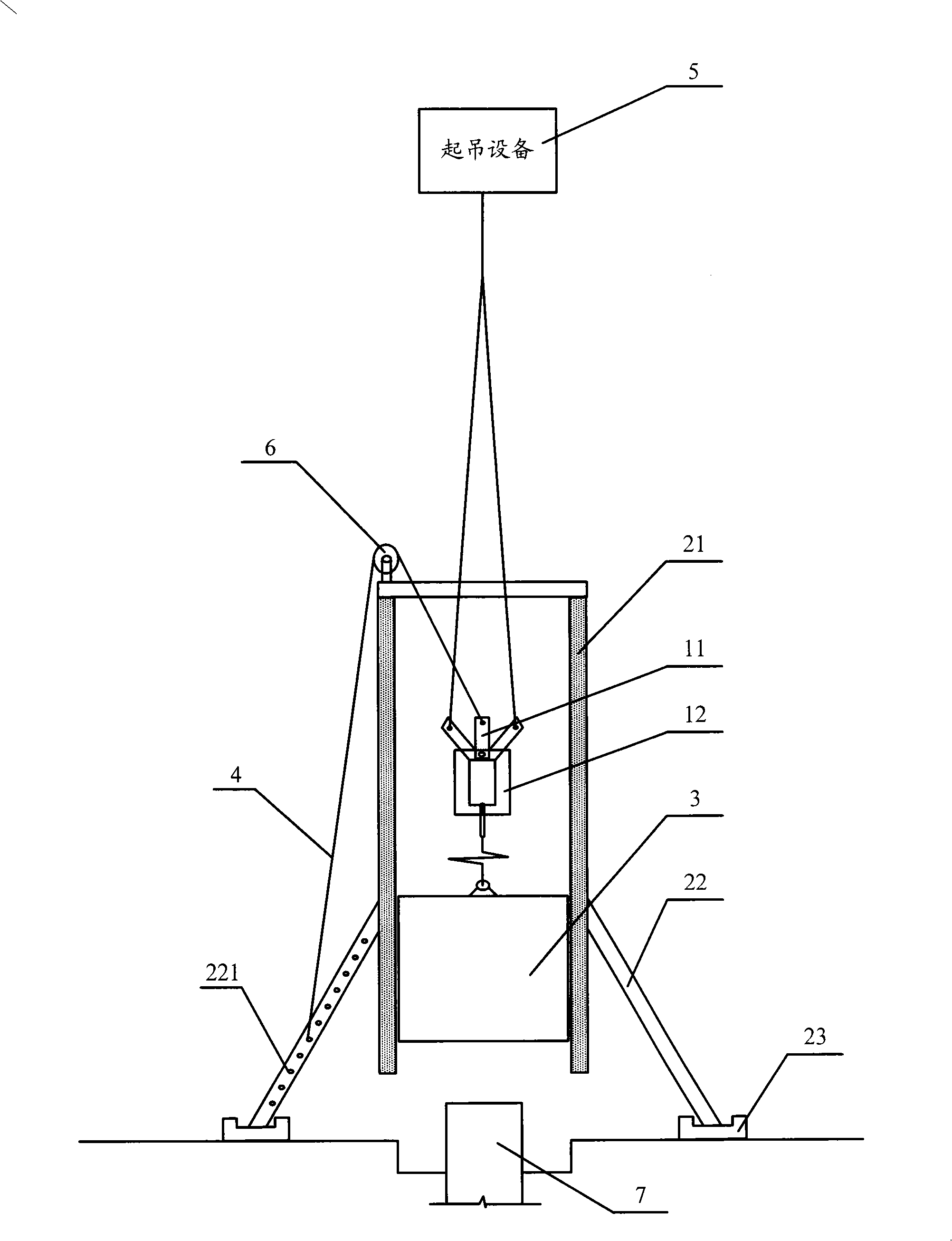

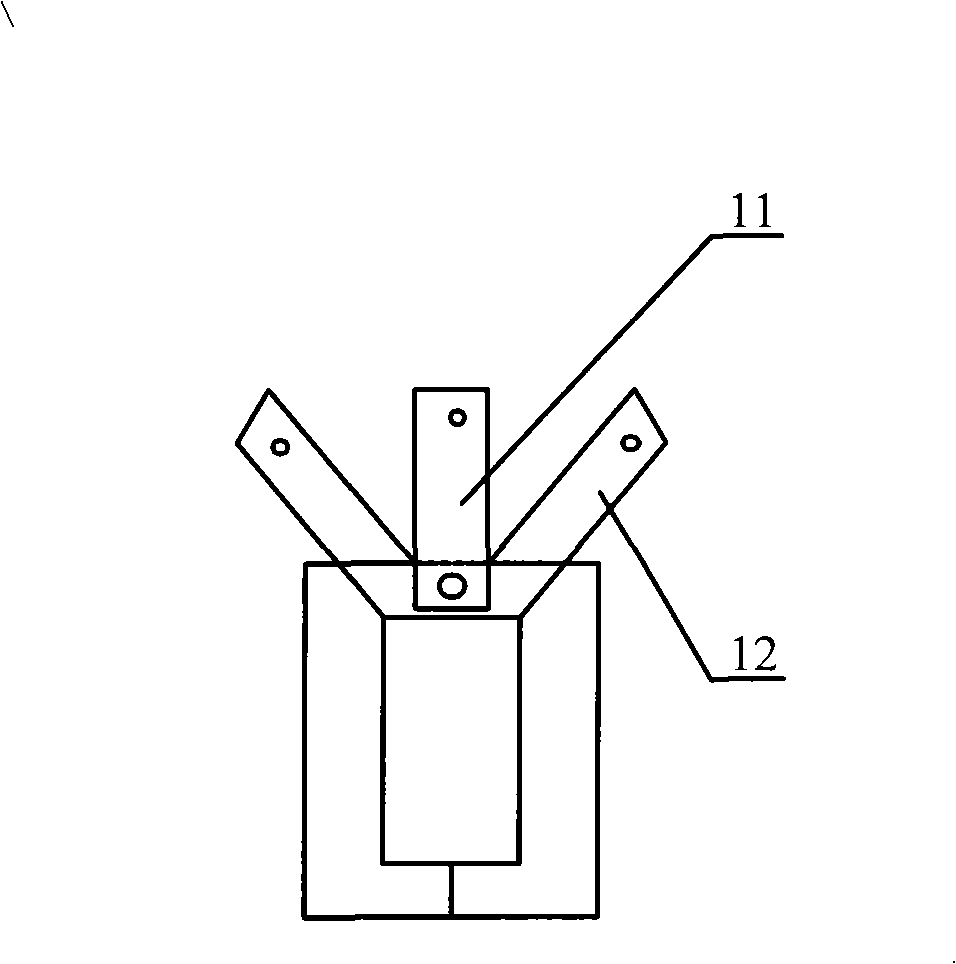

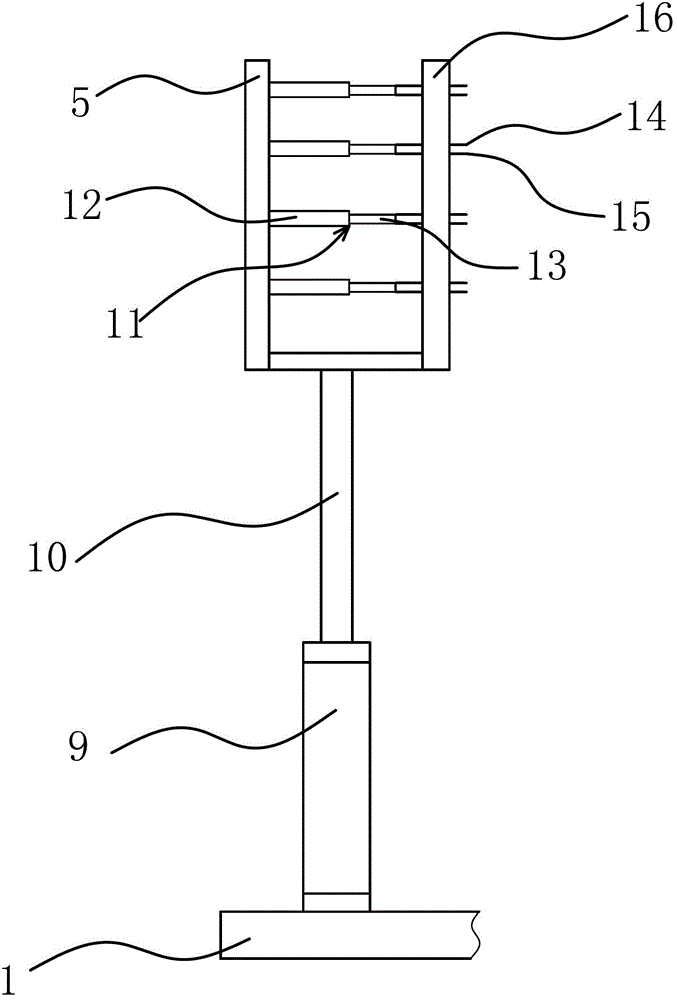

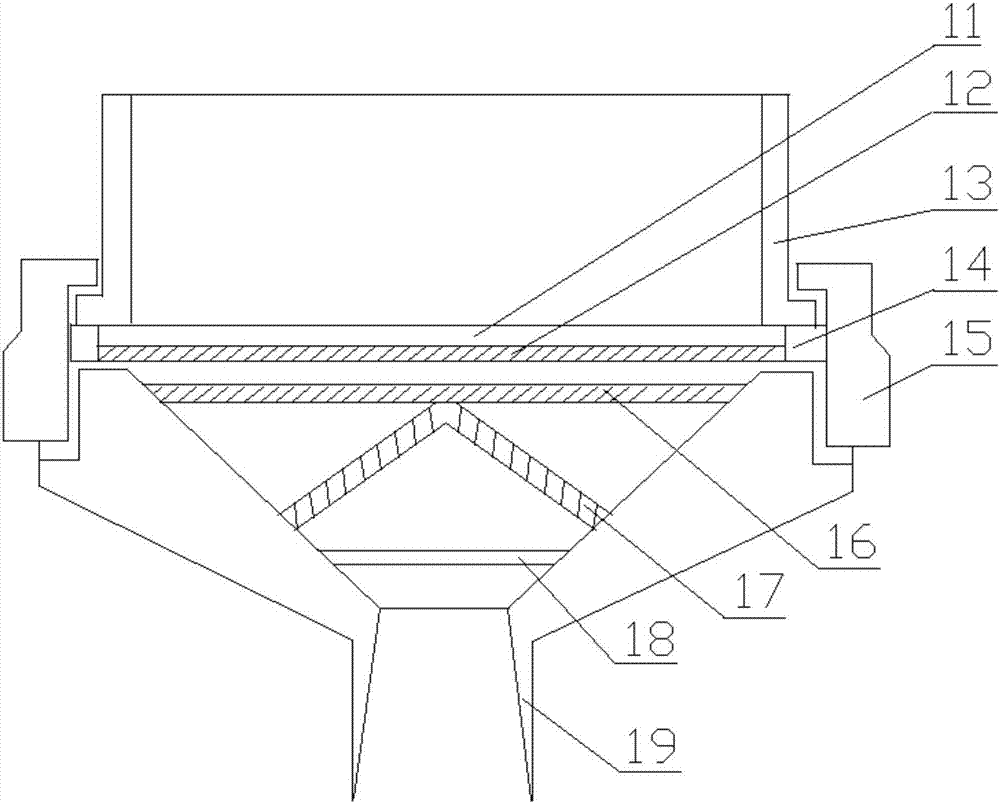

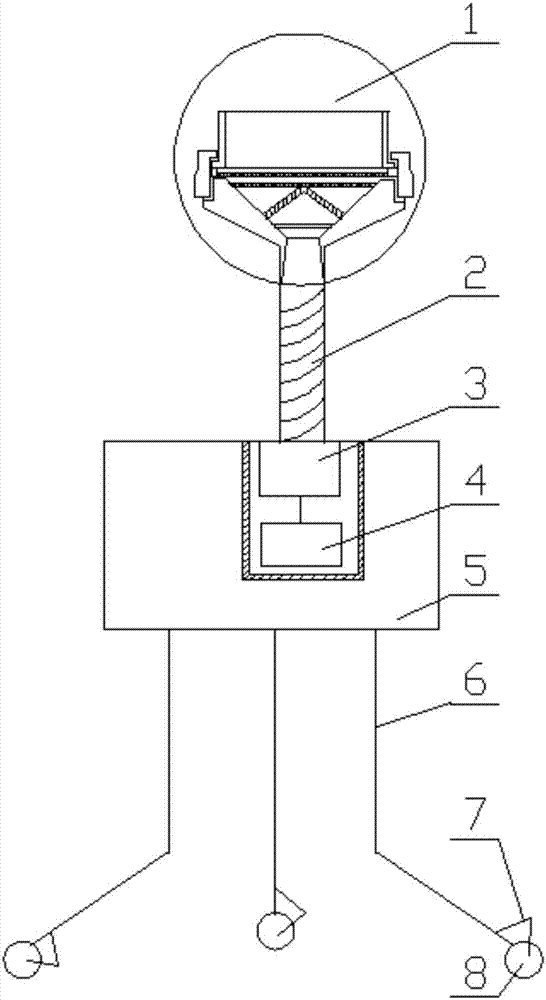

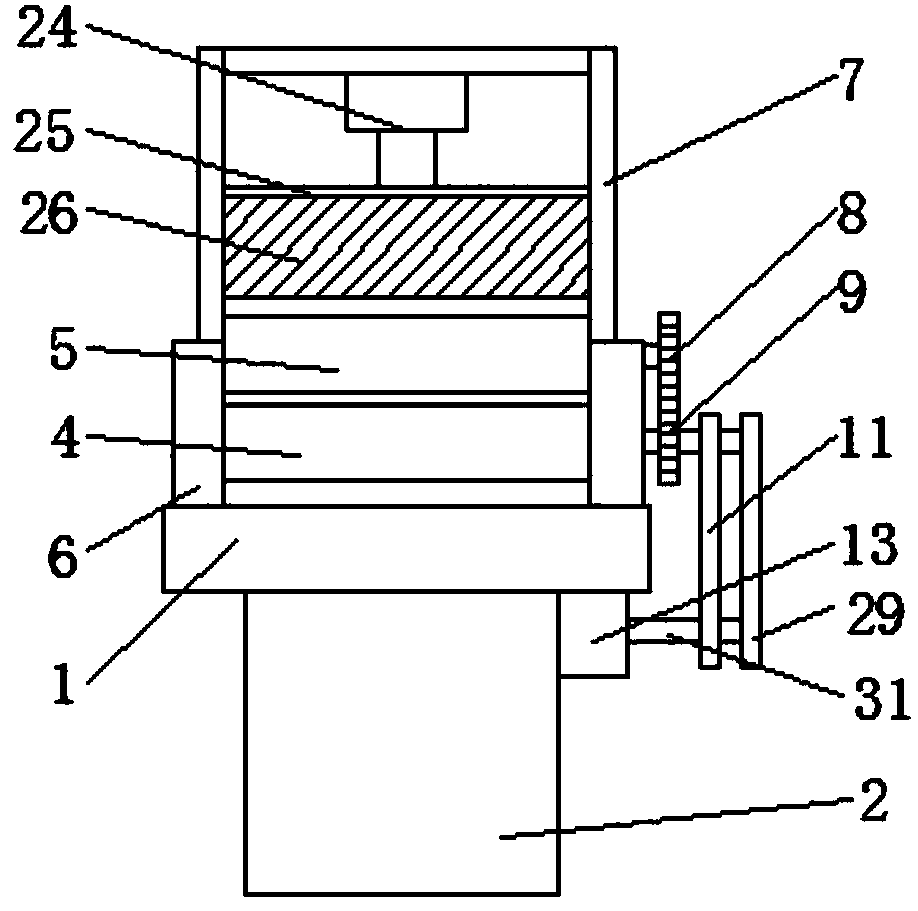

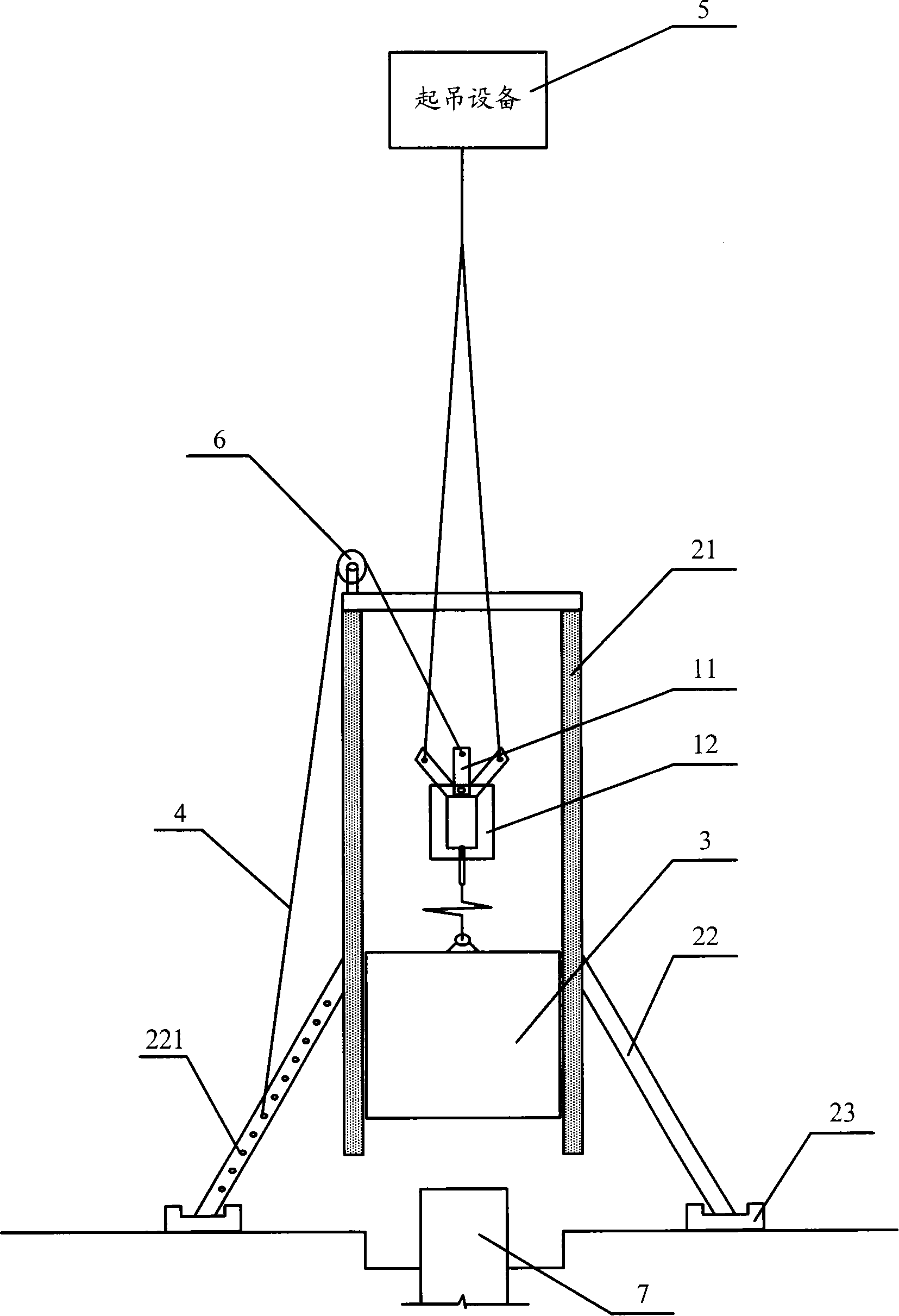

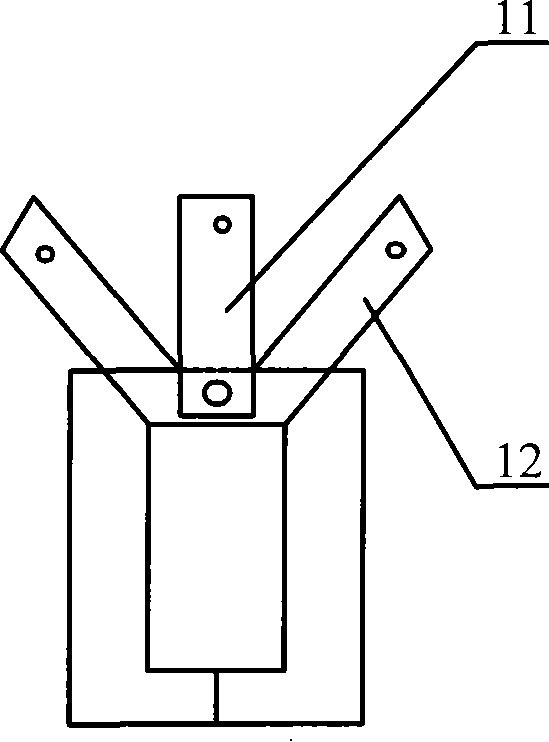

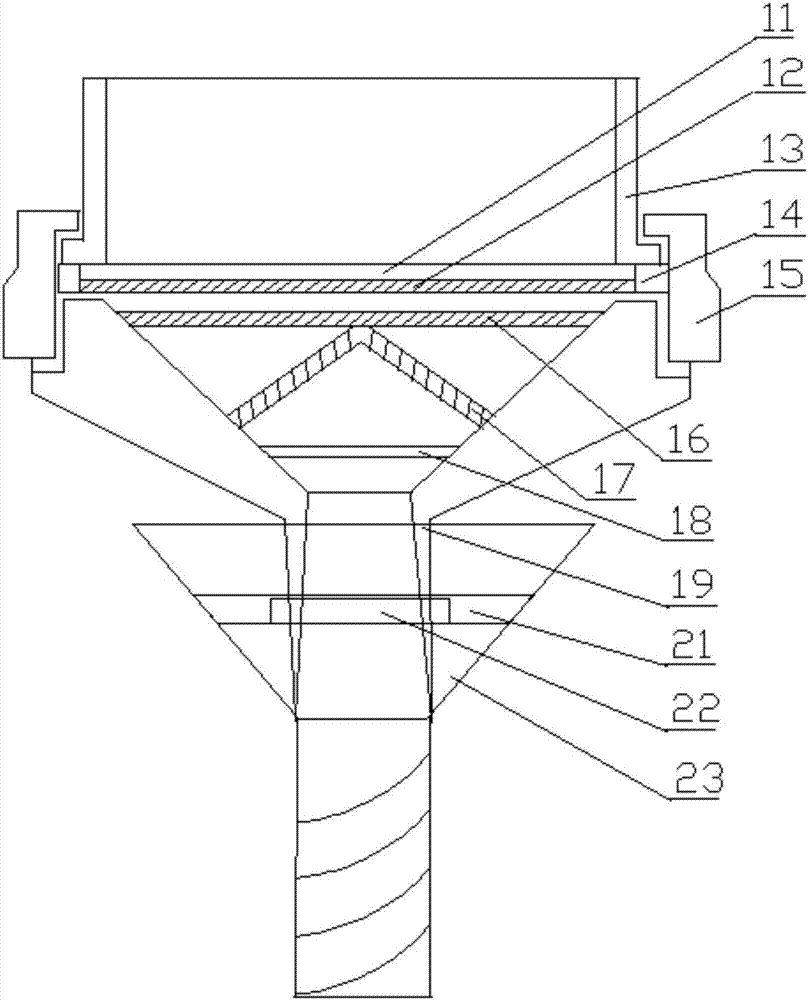

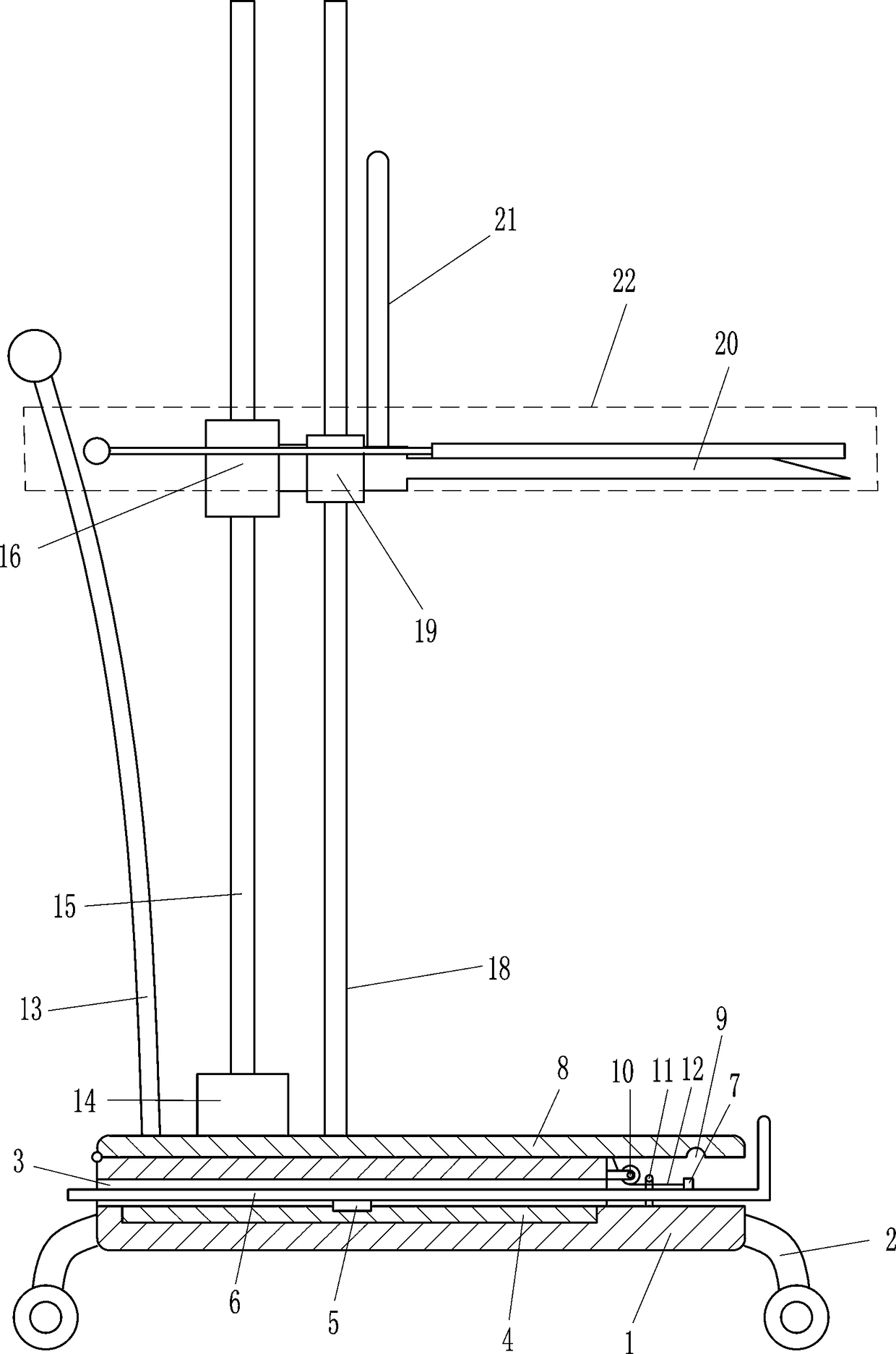

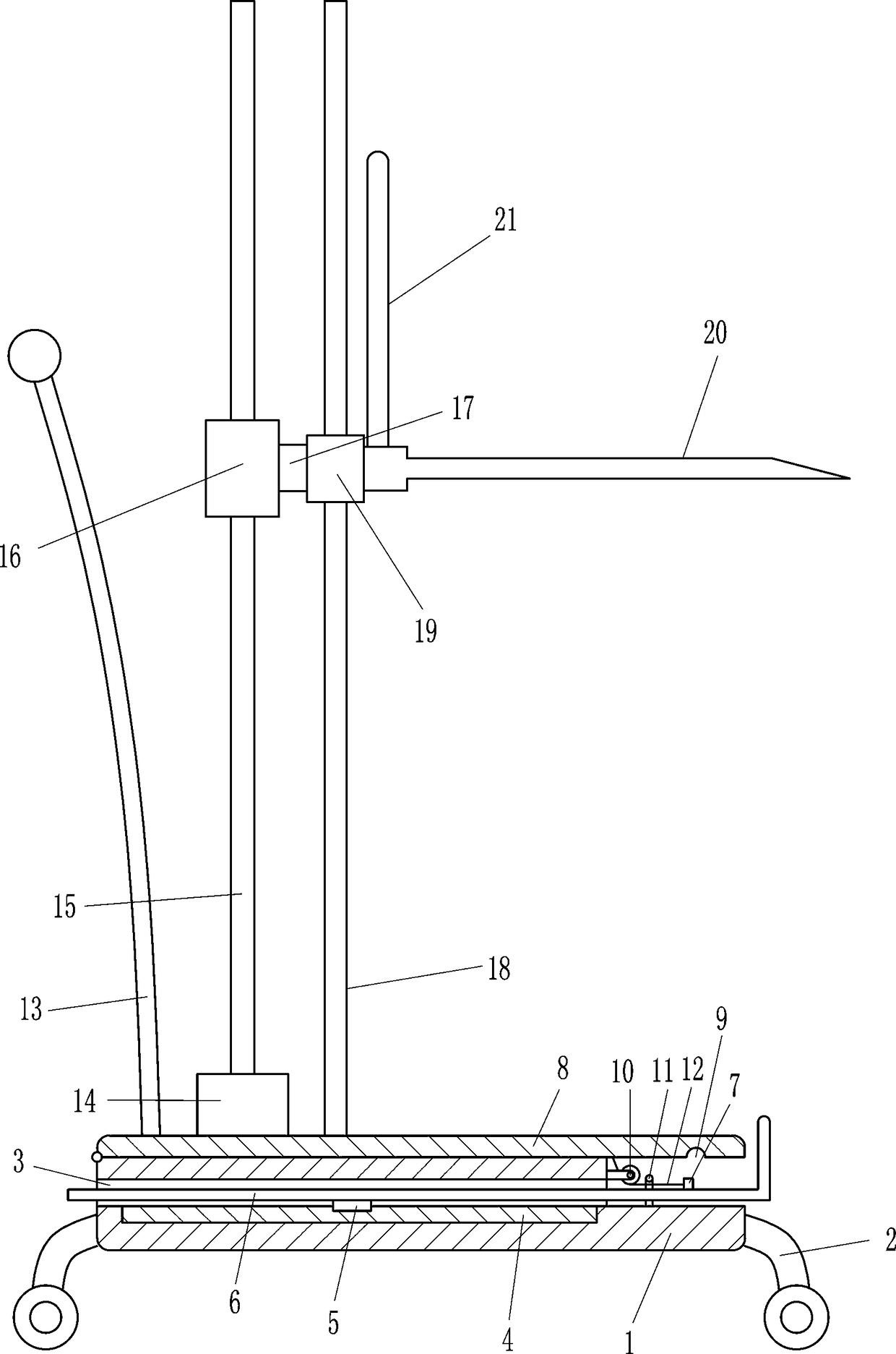

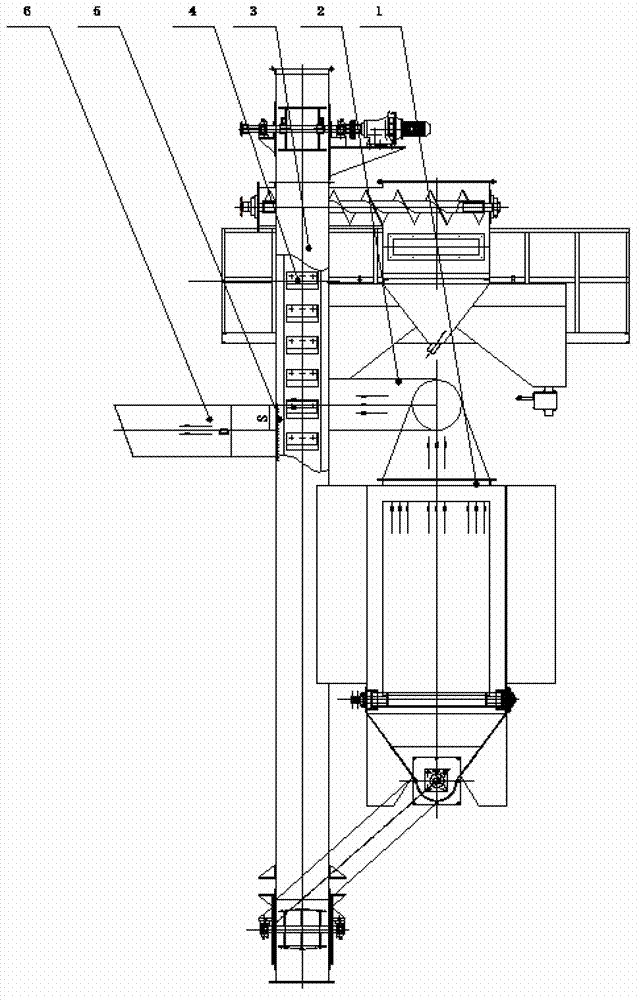

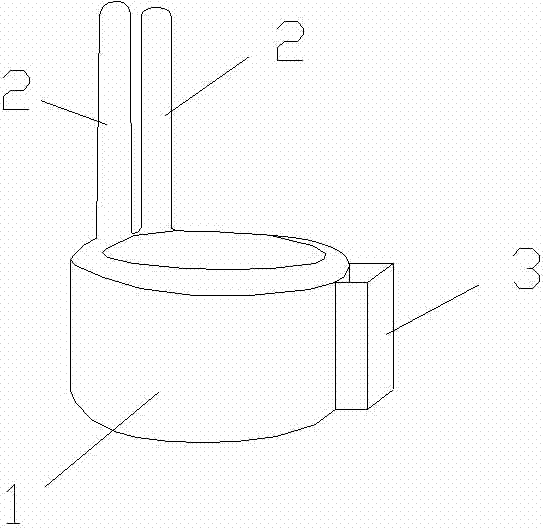

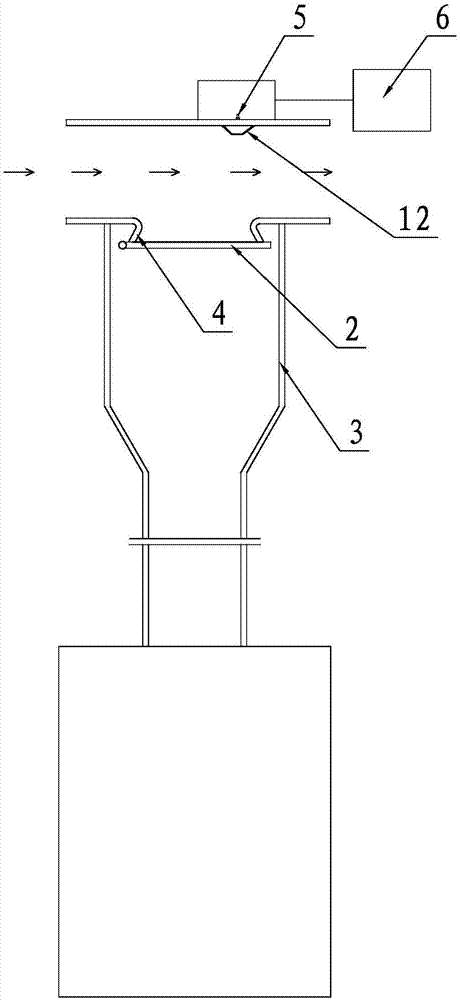

High strain hammering device

InactiveCN101285750AAvoid damageDrop GuaranteeFoundation testingMaterial strength using single impulsive forceBogieEngineering

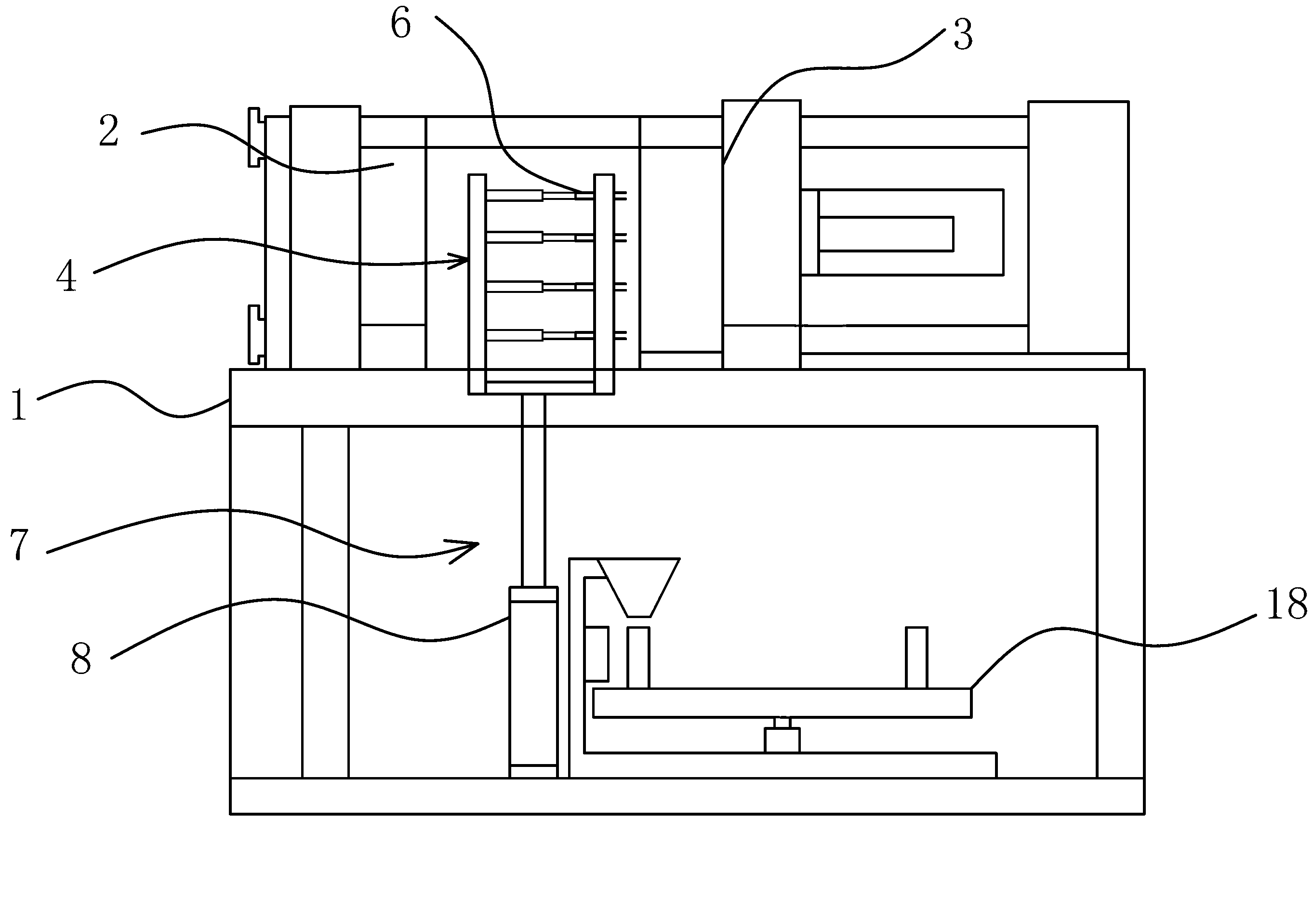

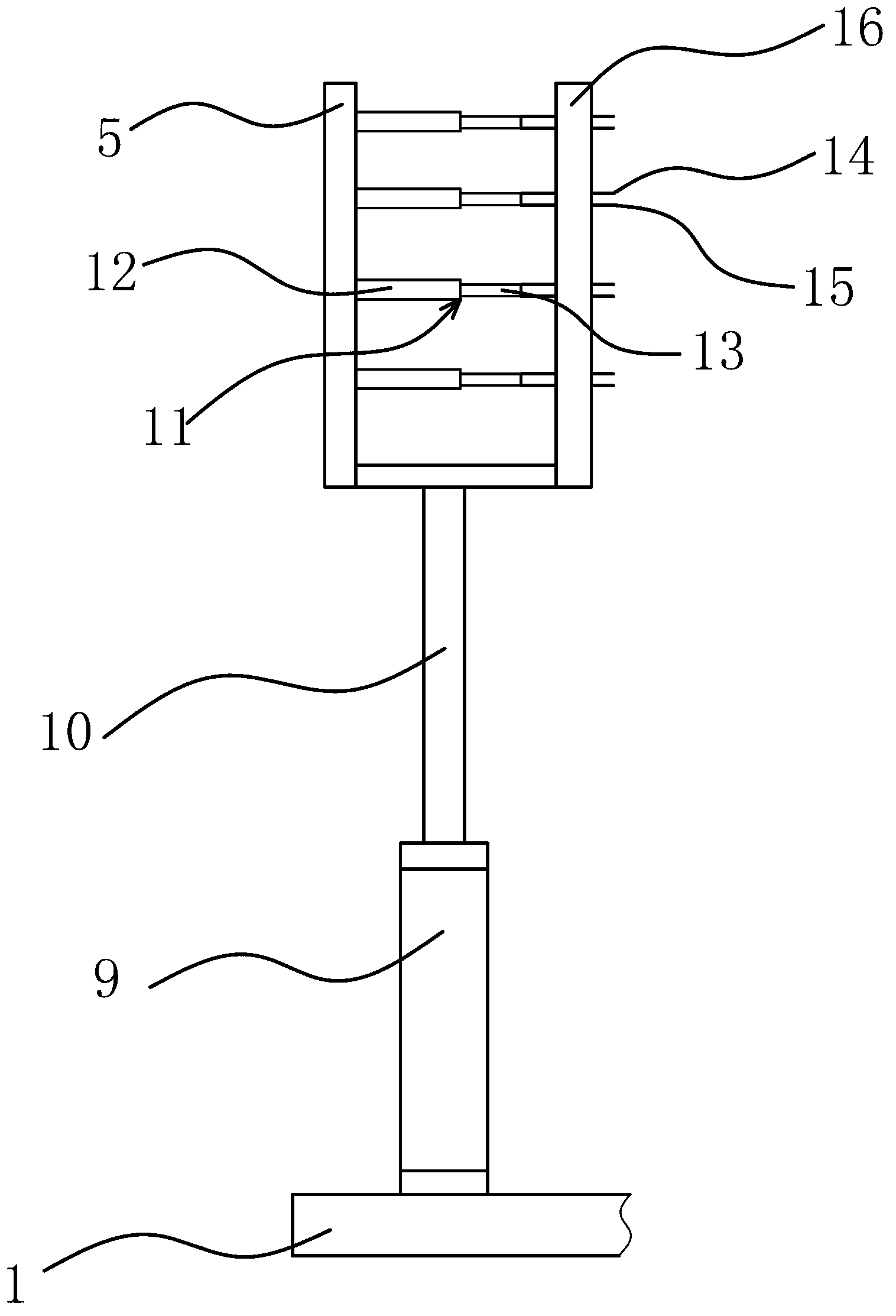

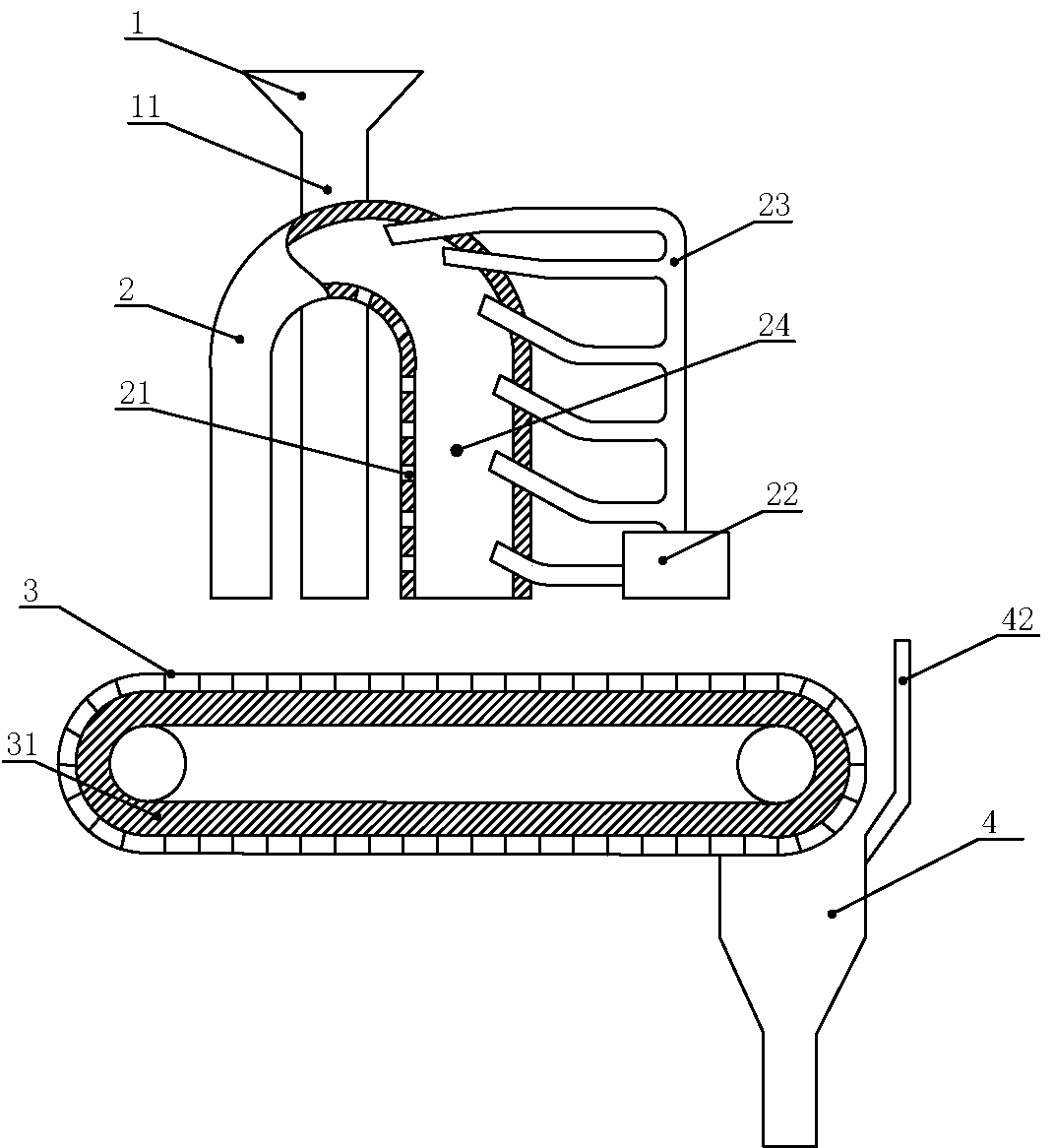

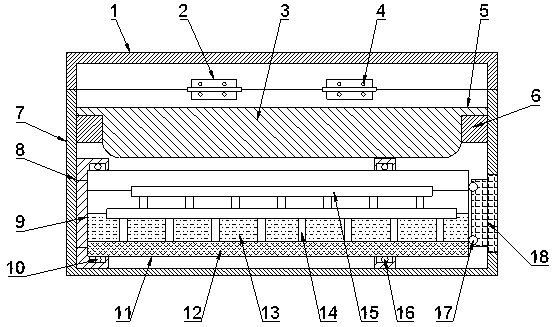

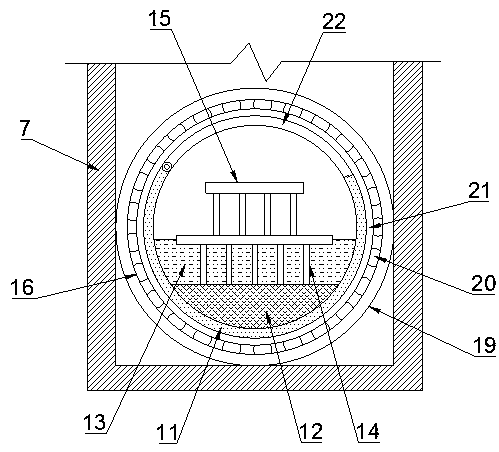

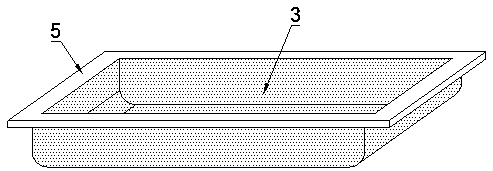

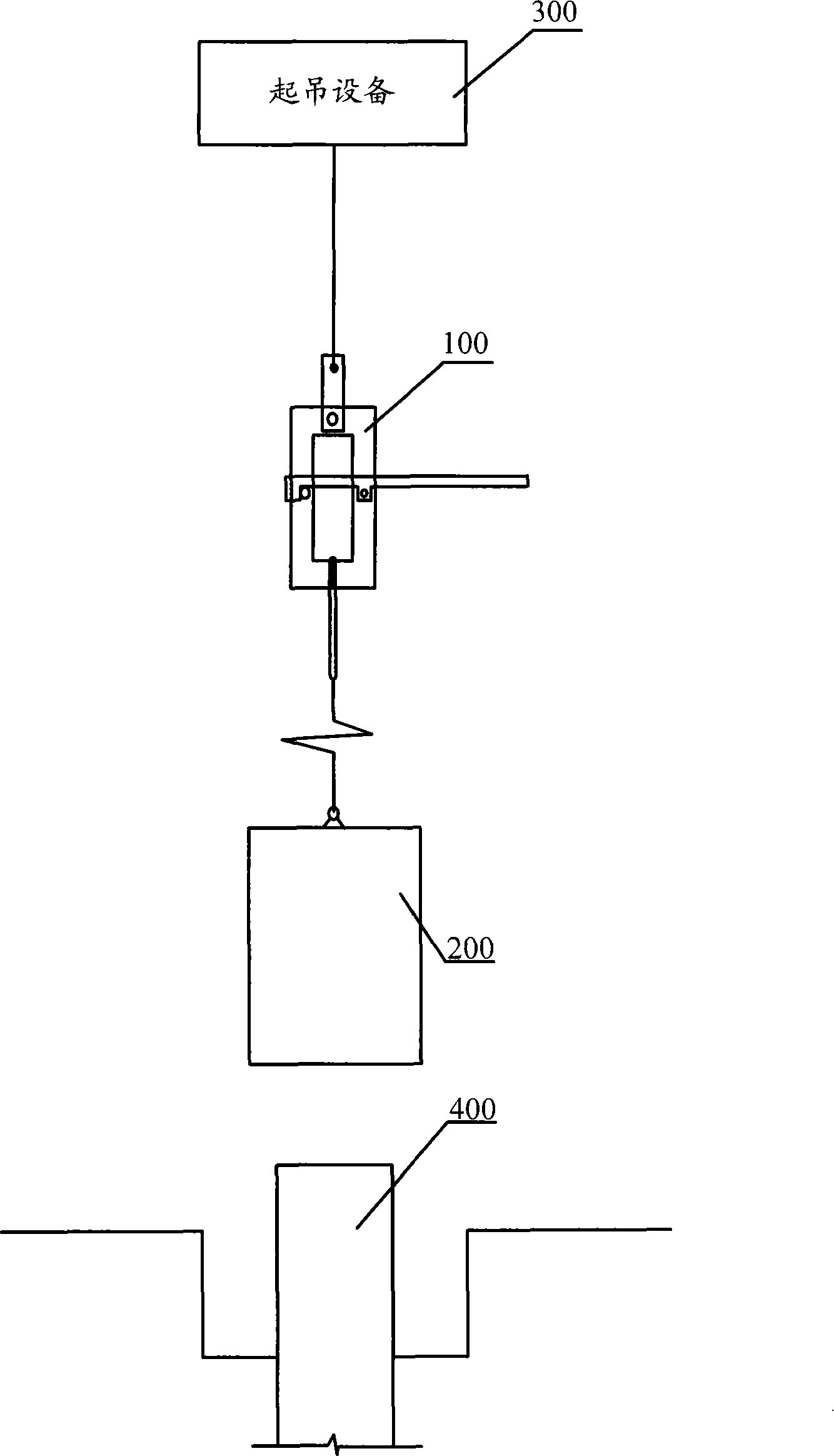

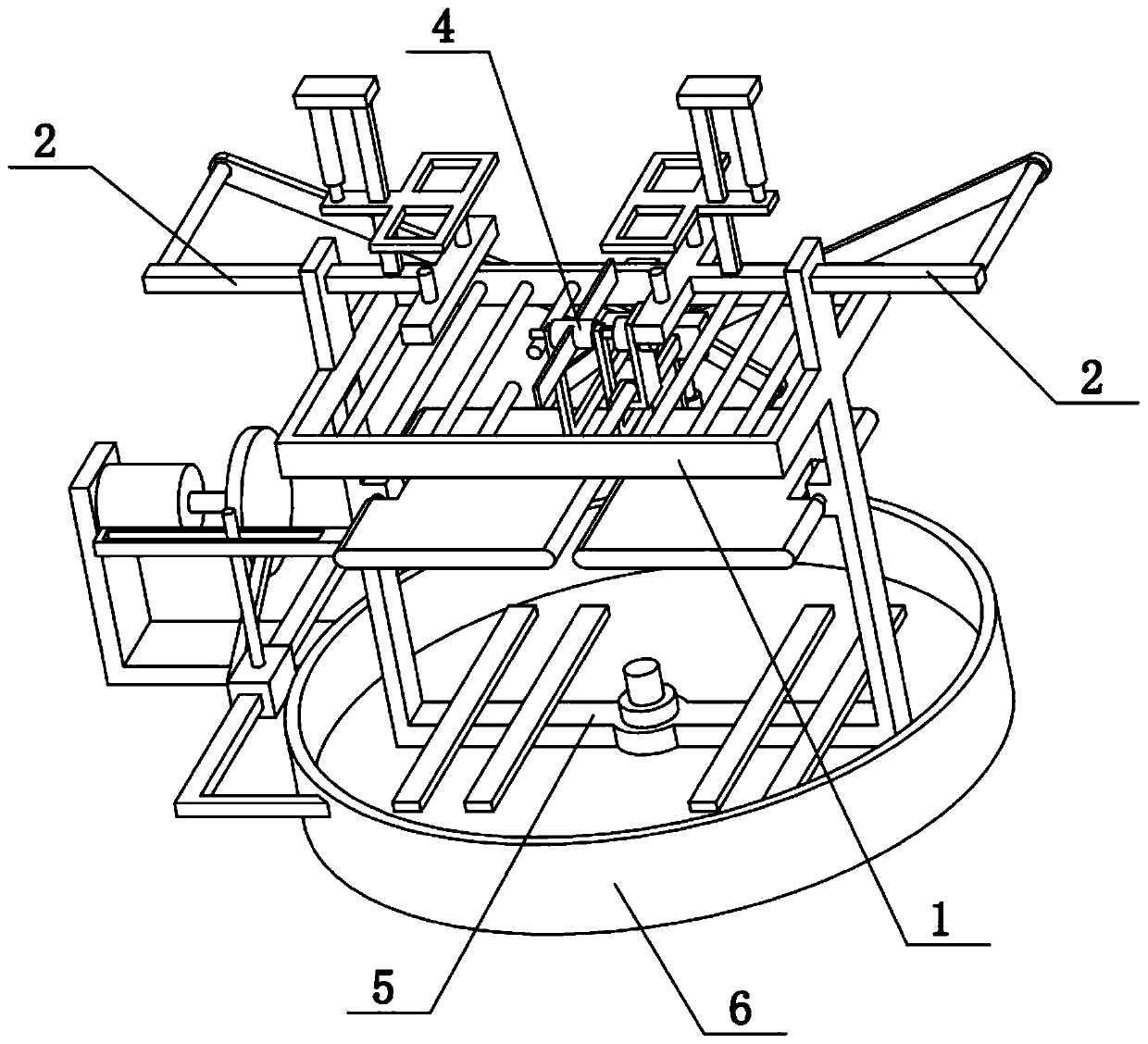

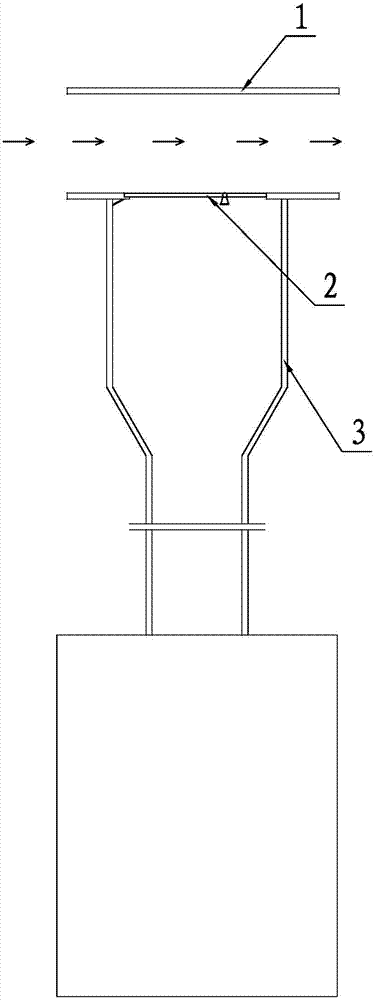

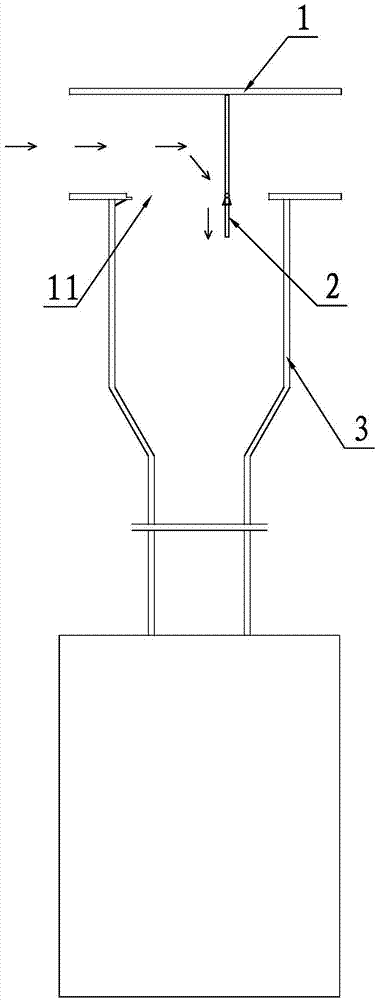

The invention relates to a high strain hammering device, which comprises a hook and a leading bogie, wherein, the hook comprises an intermediate arm and two symmetrically arranged spoon-shaped arms; the intermediate arm is hinged with a clamped position of the two spoon-shaped arms; the leading bogie comprises a guide rail which limits the motion direction of a heavy punch, supporting legs which support a body of the leading bogie, and a pedestal which is integrated with various supporting legs into a whole; the guide rail is fixedly connected with the supporting legs; and cable wires are connected to the supporting legs, pass through the top of the leading bogie and are connected with the intermediate arm of the hook. The high strain hammering device avoids damage of a lifting device due to instant force release, thereby being favorable for protecting the lifting device; moreover, due to arrangement of the leading bogie, the heavy punch is driven to move along the direction limited by the guide rail of the leading bogie during the lifting and falling process and is effectively guaranteed to fall on the center of a foundation pile to be measured, thereby eliminating the potential safety hazard that the heavy punch is fallen off after falling and being favorable for improving the detection safety.

Owner:CHINA ELECTRIC POWER RES INST

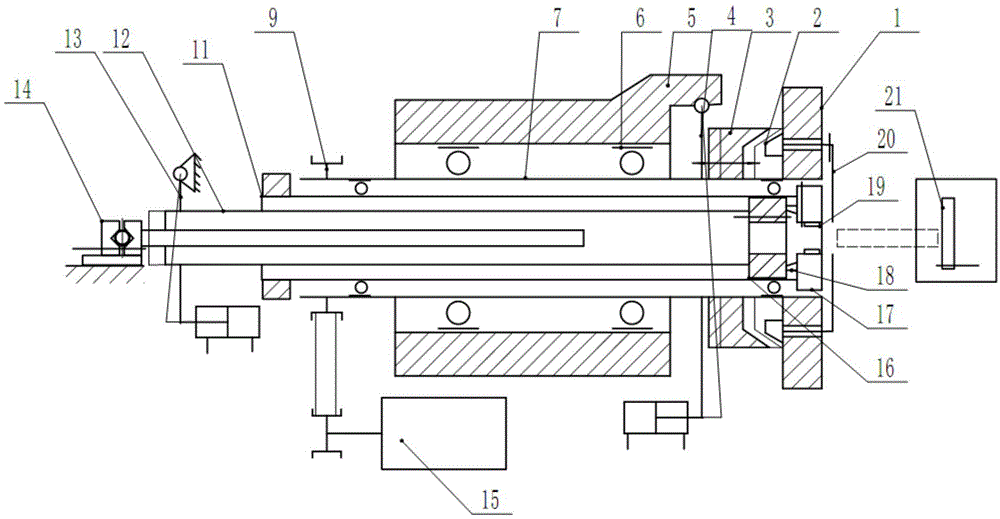

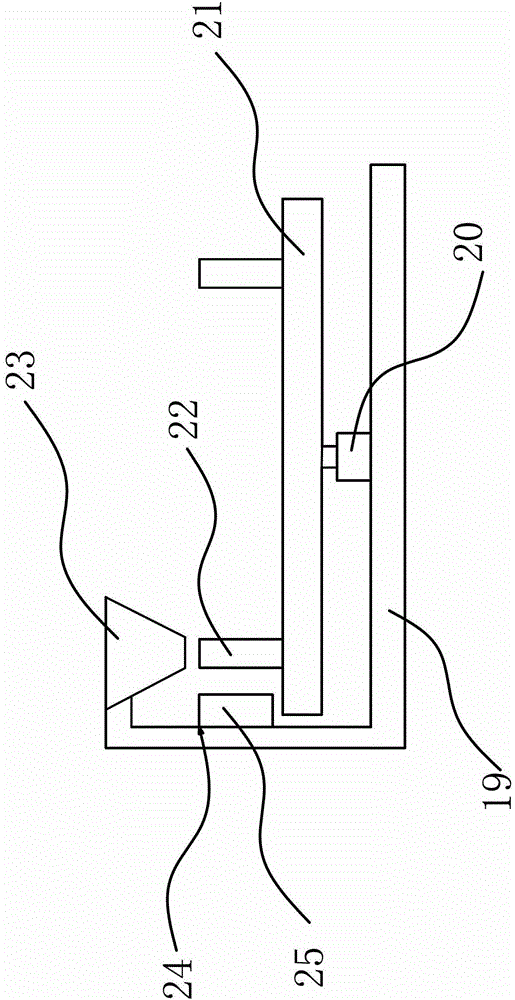

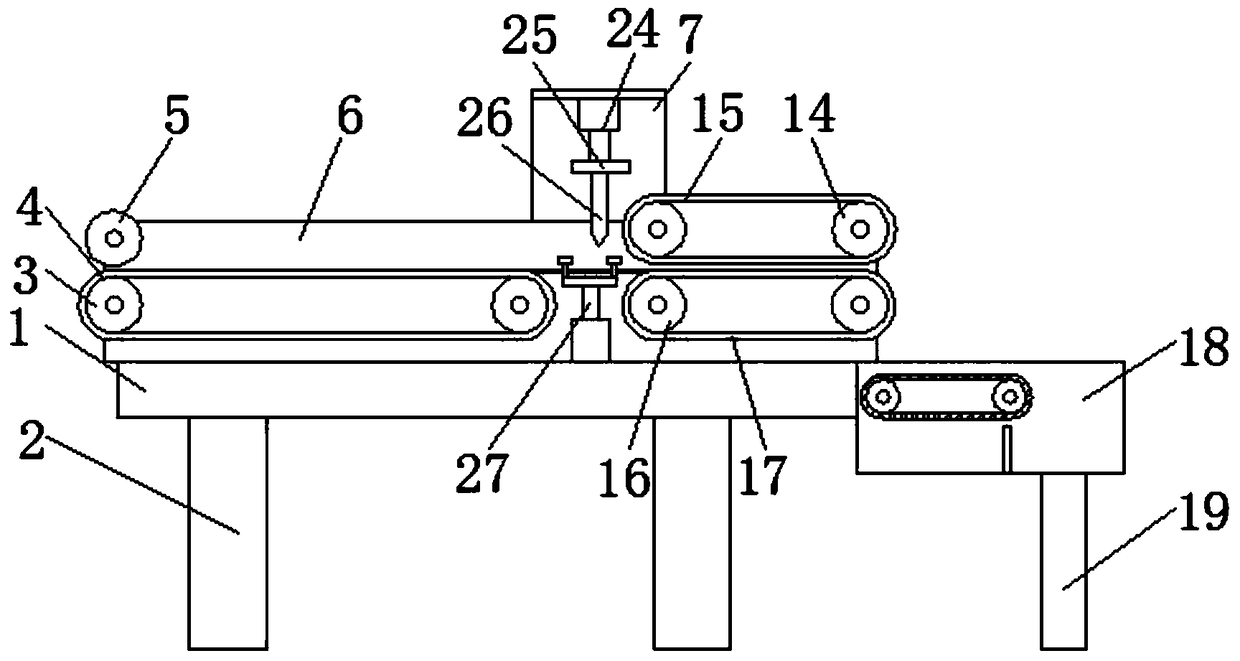

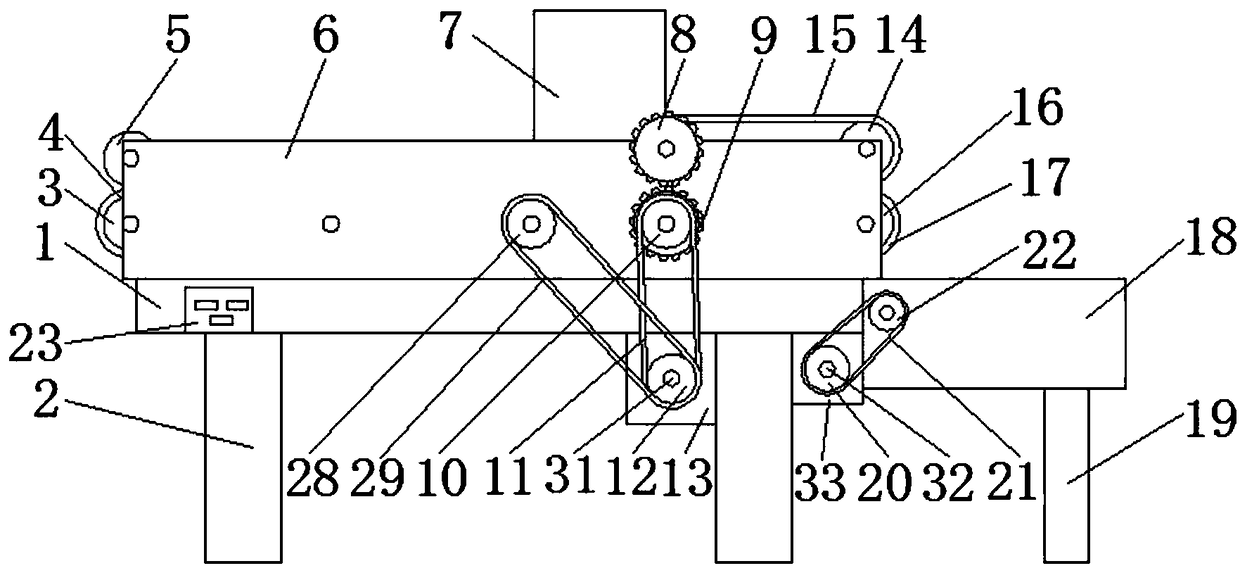

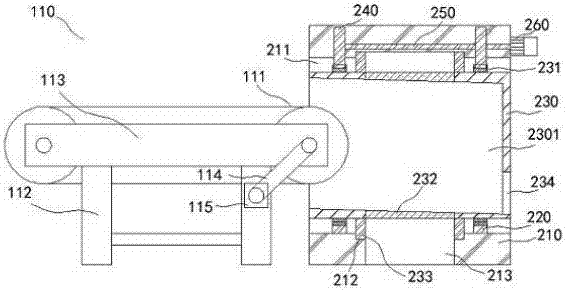

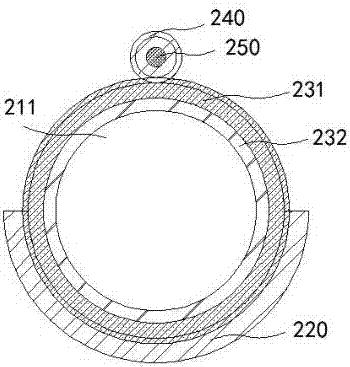

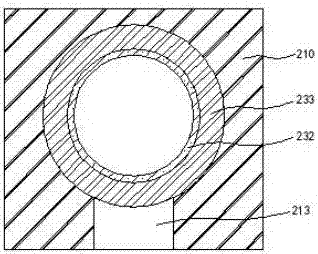

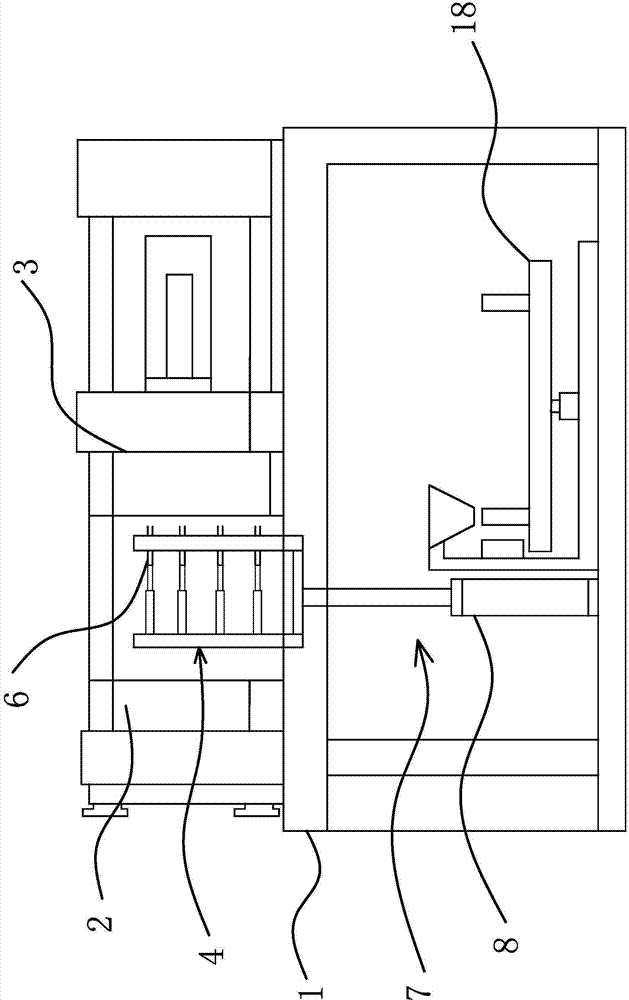

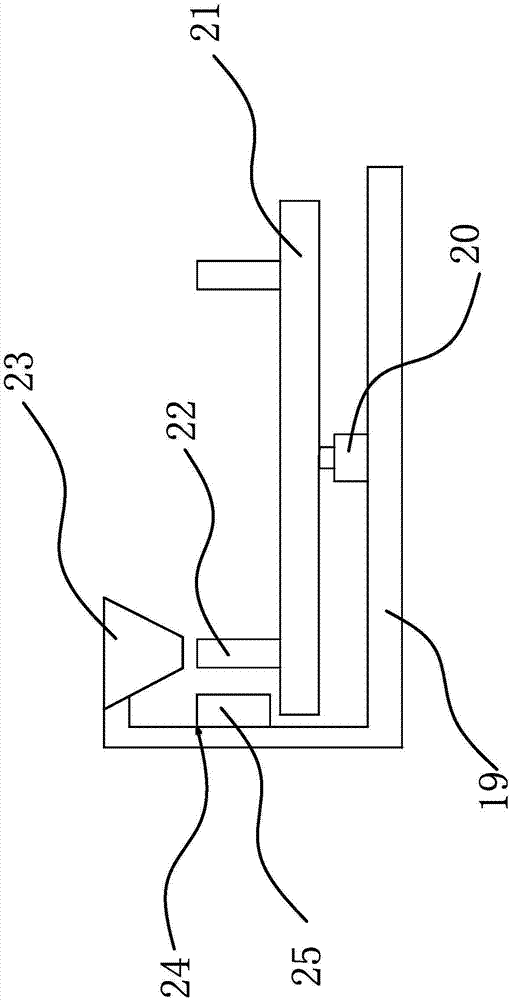

Automatic pipe cutter

ActiveCN104308251AGuaranteed normal dropOvercoming radial forceTube shearing machinesShearing machine accessoriesAxial displacementEngineering

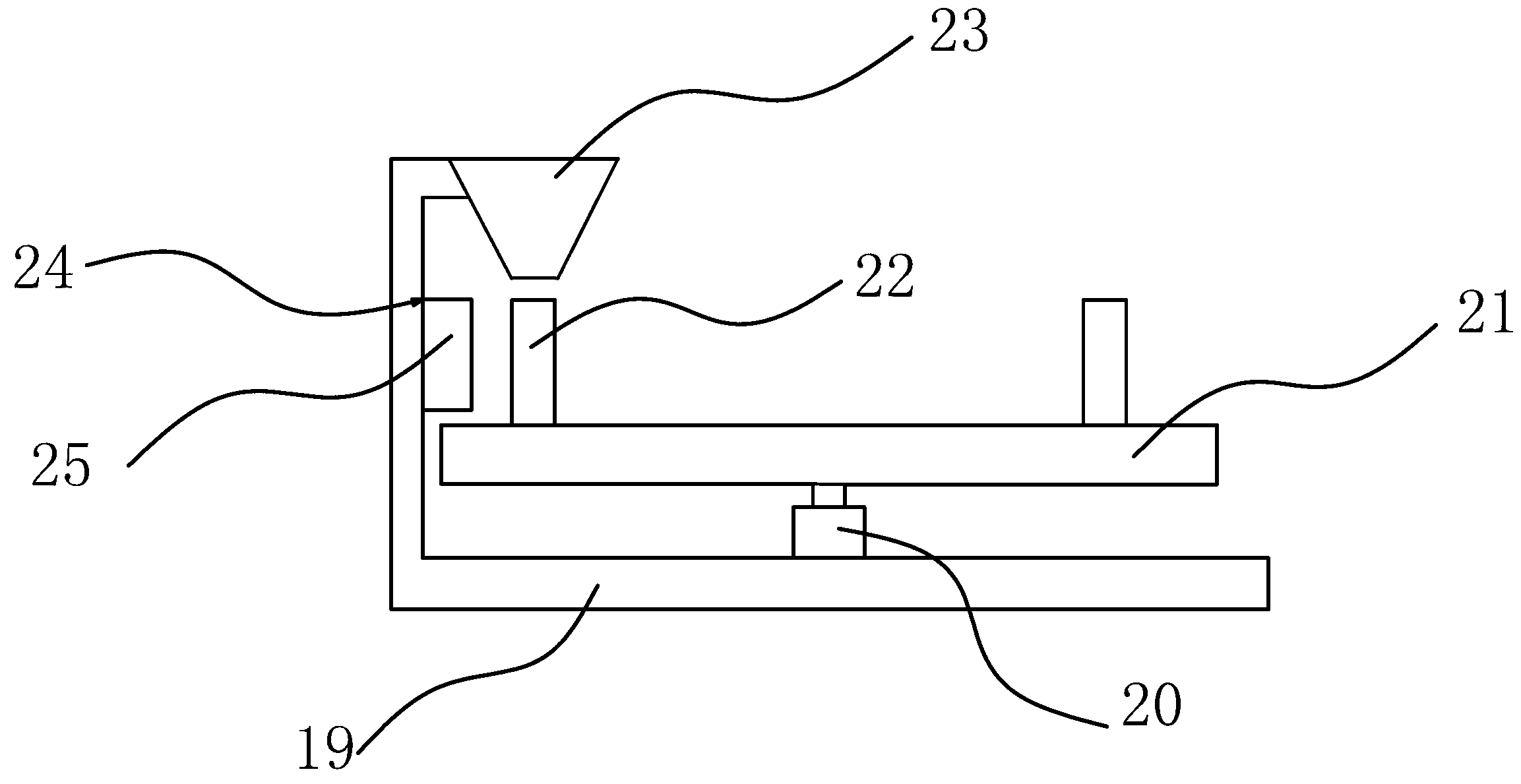

The invention discloses an automatic pipe cutter, which comprises a feeding mechanism, a body, a hollow shaft sleeve, a chuck type clamping mechanism, a cutting mechanism and a limiting backer. The automatic pipe cutter is characterized in that a clamping pushrod is arranged at one end of the chuck type clamping mechanism, wherein one end of the clamping pushrod is connected with a fixed pivoting shaft, and the other end of the clamping pushrod is connected with a cylinder; the axial displacement of the clamping pushrod is converted into the radial displacement of a clamping jaw of the chuck type clamping mechanism through a reversing mechanism to lock a pipe fitting to be cut. According to the automatic pipe cutter, a lever mechanism is used for magnifying pipe fitting locking pressure provided by the cylinder, and meanwhile, thrust is magnified according to a lever principle to drive a direction changing sleeve to move forwards to overcome the radial force during the rotation of the shaft sleeve and the cutting force of a cutting tool; a head is compact in structure, so that the manufacturing cost is greatly lowered; in addition, the clamping direction is the same as the cutting direction, so that the cut pipe fitting is ensured to directly fall.

Owner:WUXI AOTU AUTOMATION TECH CO LTD

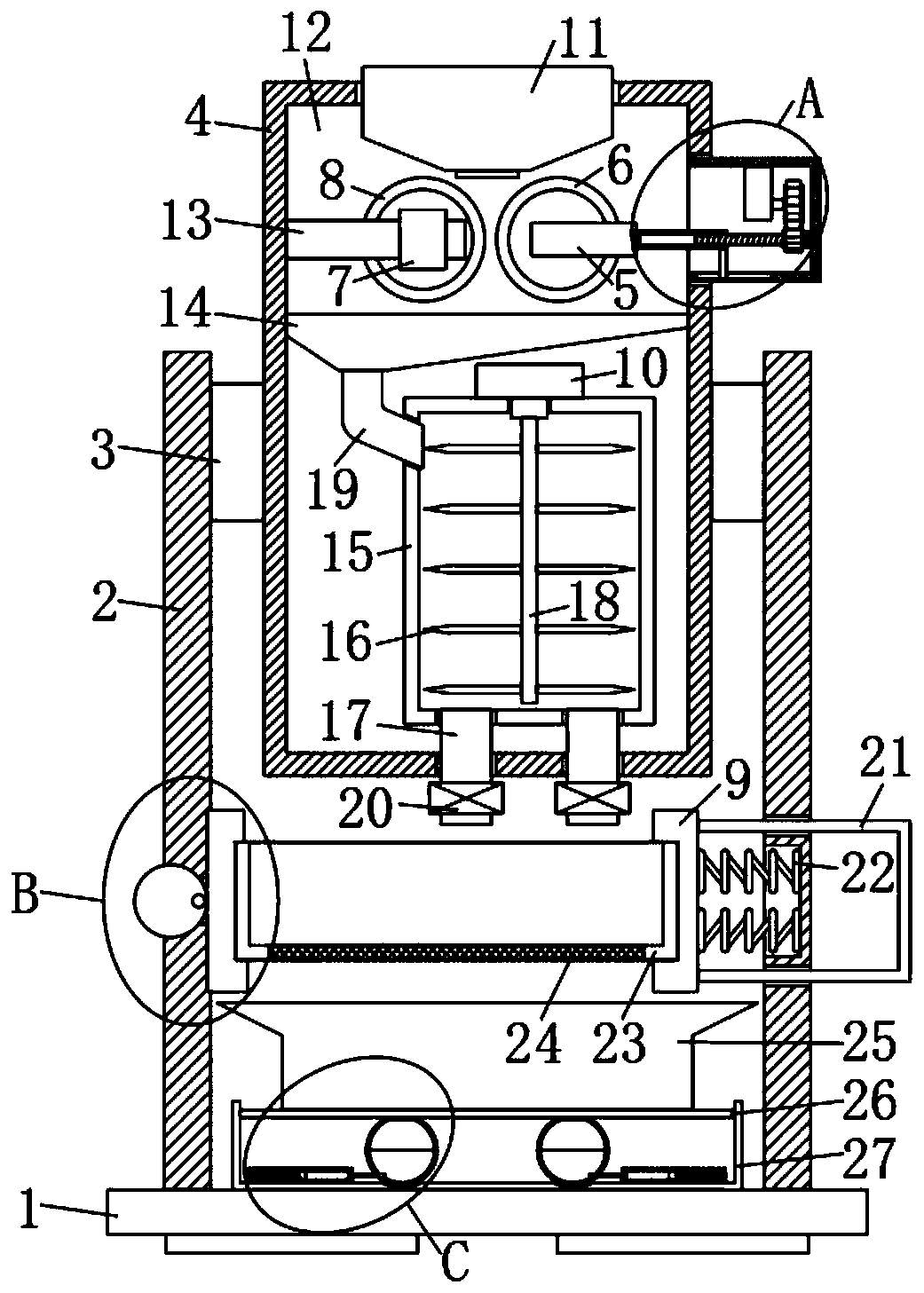

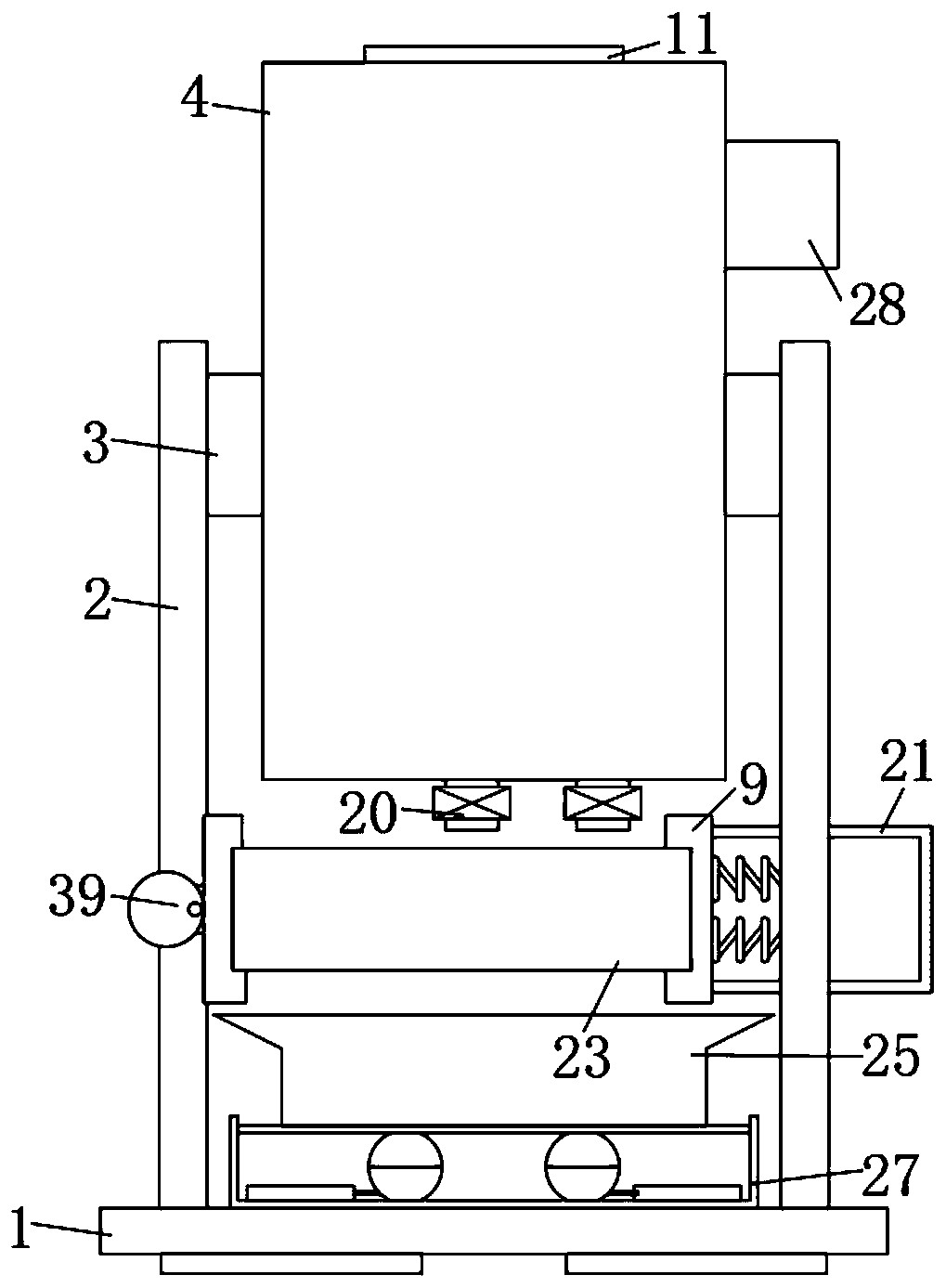

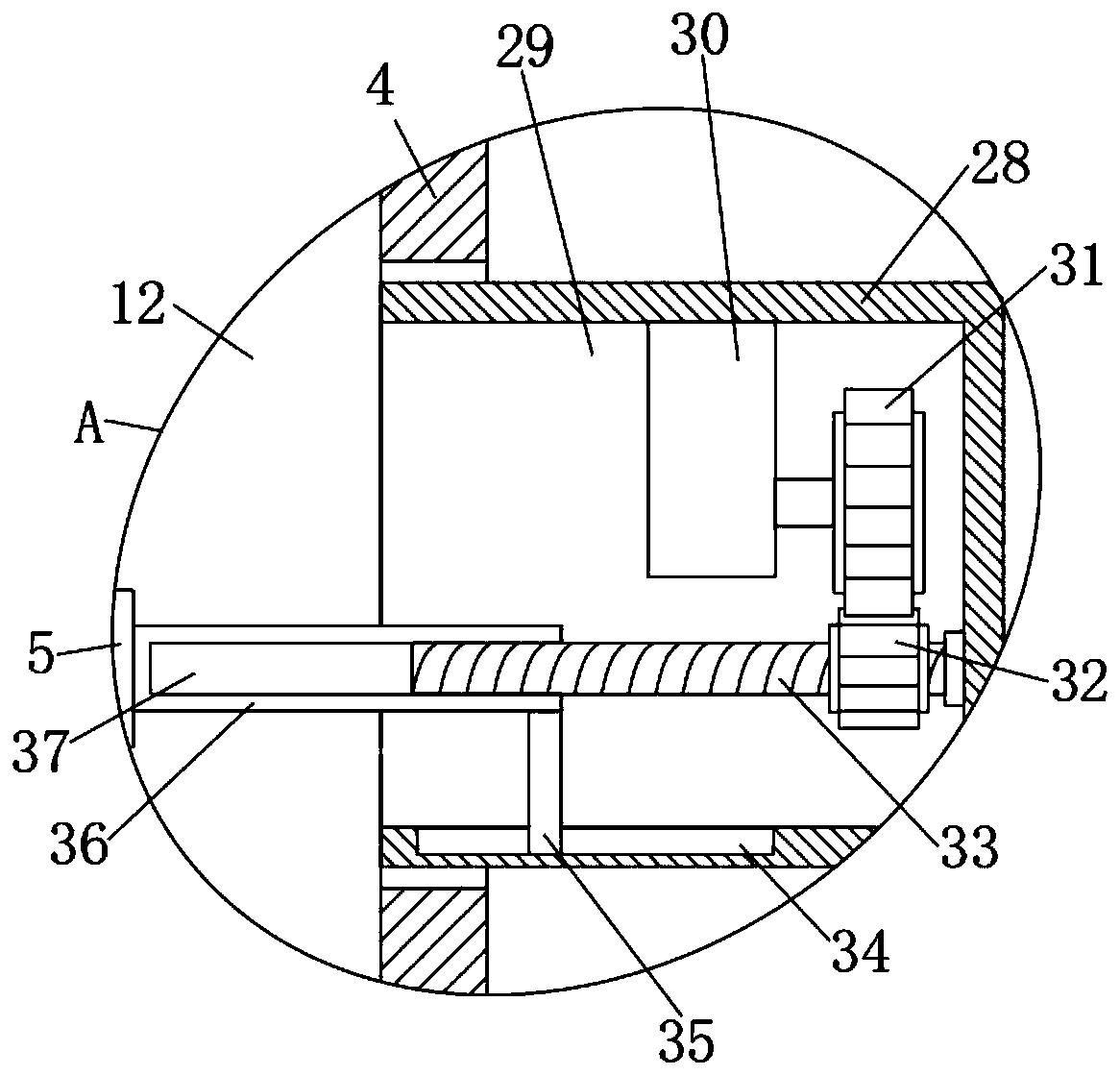

Injection molding machine for producing plastic bottle caps

InactiveCN103302822AImprove running stabilitySimple installation and maintenanceEngineeringReciprocating motion

Owner:佛山市顺德区山德塑胶五金有限公司

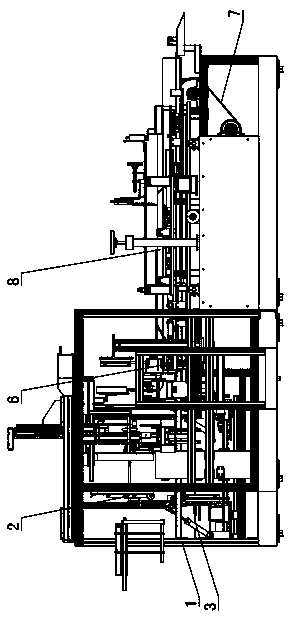

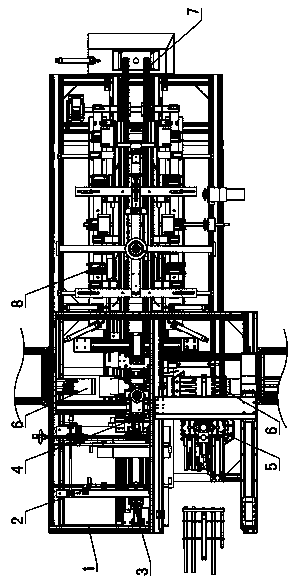

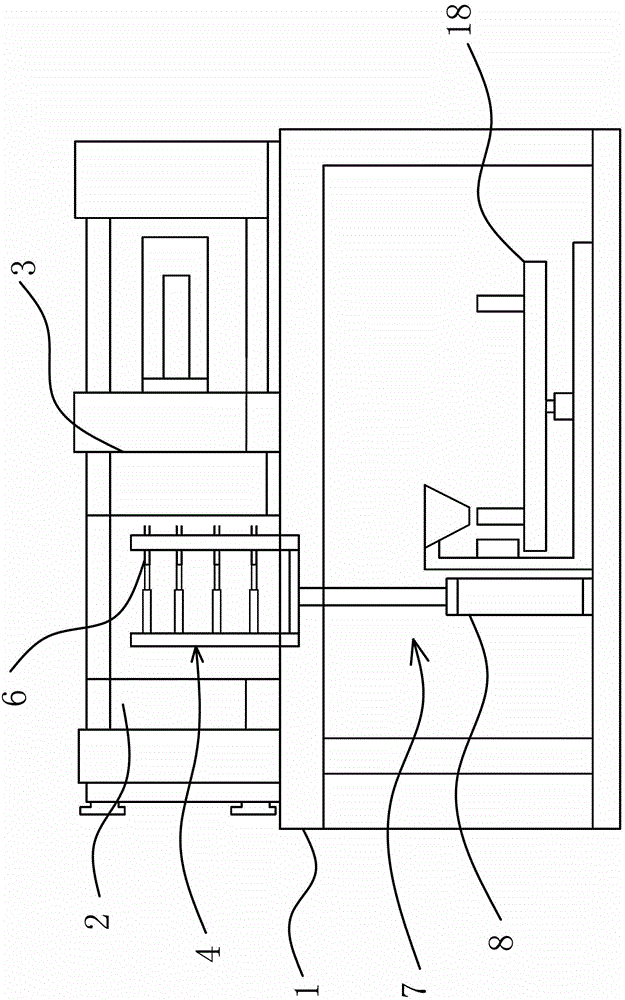

Clamping type automatic box packing machine for soft gloves

A clamping type automatic box packing machine for soft gloves, and belongs to the technical field of soft glove packaging equipment. The machine is characterized in that a box expanding mechanism (3)is arranged at the input end of a box inserting mechanism (8), the upper side of the box expanding mechanism (3) is provided with a packing box bin (2), a box entering bin is arranged is arranged at the input end of the box inserting mechanism, the upper side and end part of the box entering bin are provided with an opening respectively, the side part of the box entering bin is provided with a boxentering gripper, a plurality of clamping fingers are spaced and arranged on the front side of the lower clamping plate (44) of the box entering gripper (6), and a plurality of bit-making ports matched with the fingers are arranged at the bottom of the box entering bin; the box entering gripper (6) is connected with a motor which drives the tripper to translate through a box entering module (43),the side part of the box entering bin is provided with a transfer grip (5), and the transfer gripper (5) sends gloves stocked in a transfer box bin into the box entering bin. The machine achieves theautomatic box entering and packaging of the soft gloves, the packaging speed is high, the packaging quality is stable, and the packaging cost is reduced.

Owner:ZIBO CHENGXUN AUTOMATION EQUIP

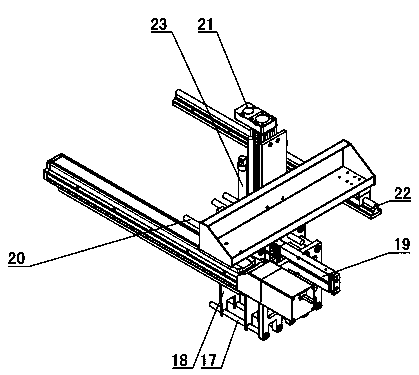

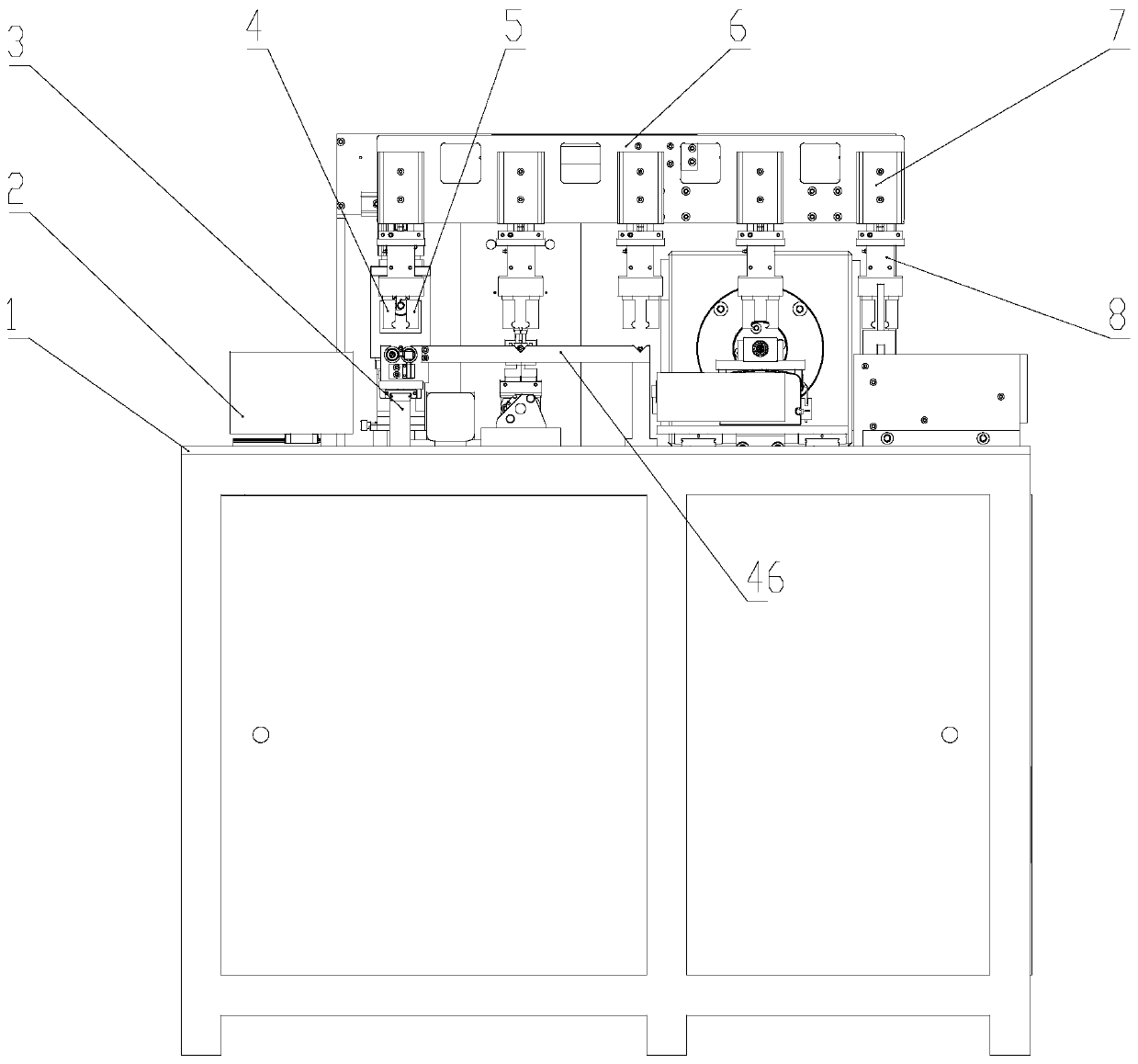

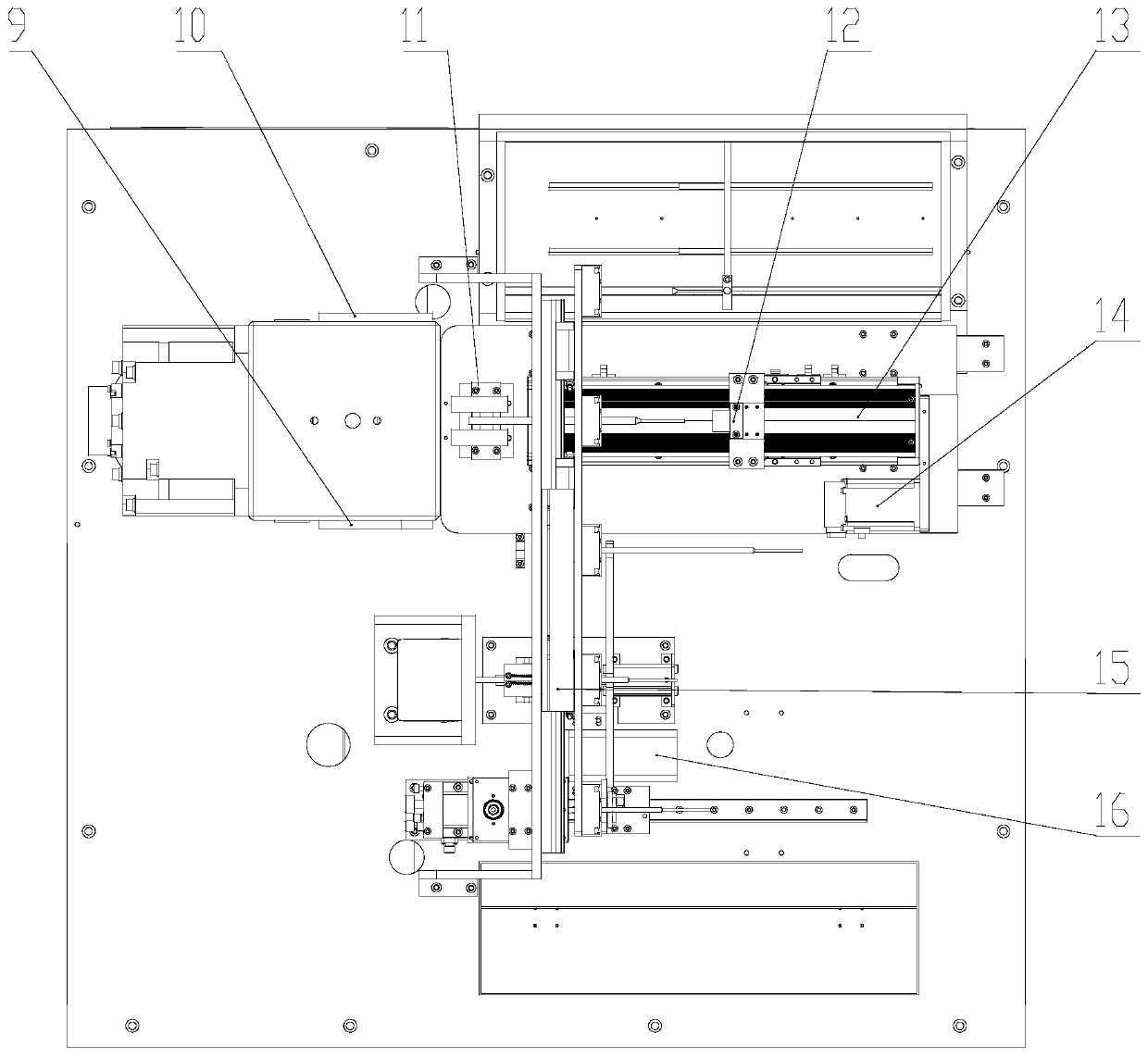

Automatic necking sealing machine for metal pipe materials

PendingCN110421358AEfficient productionGuaranteed normal dropOther manufacturing equipments/toolsTransfer mechanismEngineering

The invention discloses an automatic necking sealing machine for metal pipe materials. A workbench, a pipe material automatic feeding hopper mechanism, a pipe material necking mechanism, a pipe material automatic material cutting mechanism, a pipe material automatic welding sealing mechanism, a material receiving box, a pipe material automatic transferring mechanism and a control system are included, wherein the pipe material automatic feeding hopper mechanism, the pipe material necking mechanism, the pipe material automatic material cutting mechanism, the pipe material automatic welding sealing mechanism and the material receiving box are sequentially arranged on the workbench; the pipe material automatic transferring mechanism is fixedly arranged above the workbench, and used for transferring the pipe materials from the pipe material automatic feeding hopper mechanism to the pipe material necking mechanism, the pipe material automatic material cutting mechanism, the pipe material automatic welding sealing mechanism and the material receiving box in sequence; and the control system comprises a PLC to be in control connection with the pipe material automatic feeding hopper mechanism, the pipe material necking mechanism, the pipe material automatic material cutting mechanism, the pipe material automatic welding sealing mechanism and the pipe material automatic transferring mechanism. The automatic necking sealing machine for the metal pipe materials achieves that the metal pipe material in different hardness, pipe lengths and diameters are subjected to cut-off length fixation and welding after being subjected to automatic necking, integrated production of three procedures can be achieved, the production efficiency is remarkably improved, and wide application prospects are achieved.

Owner:SOUTH CHINA UNIV OF TECH +1

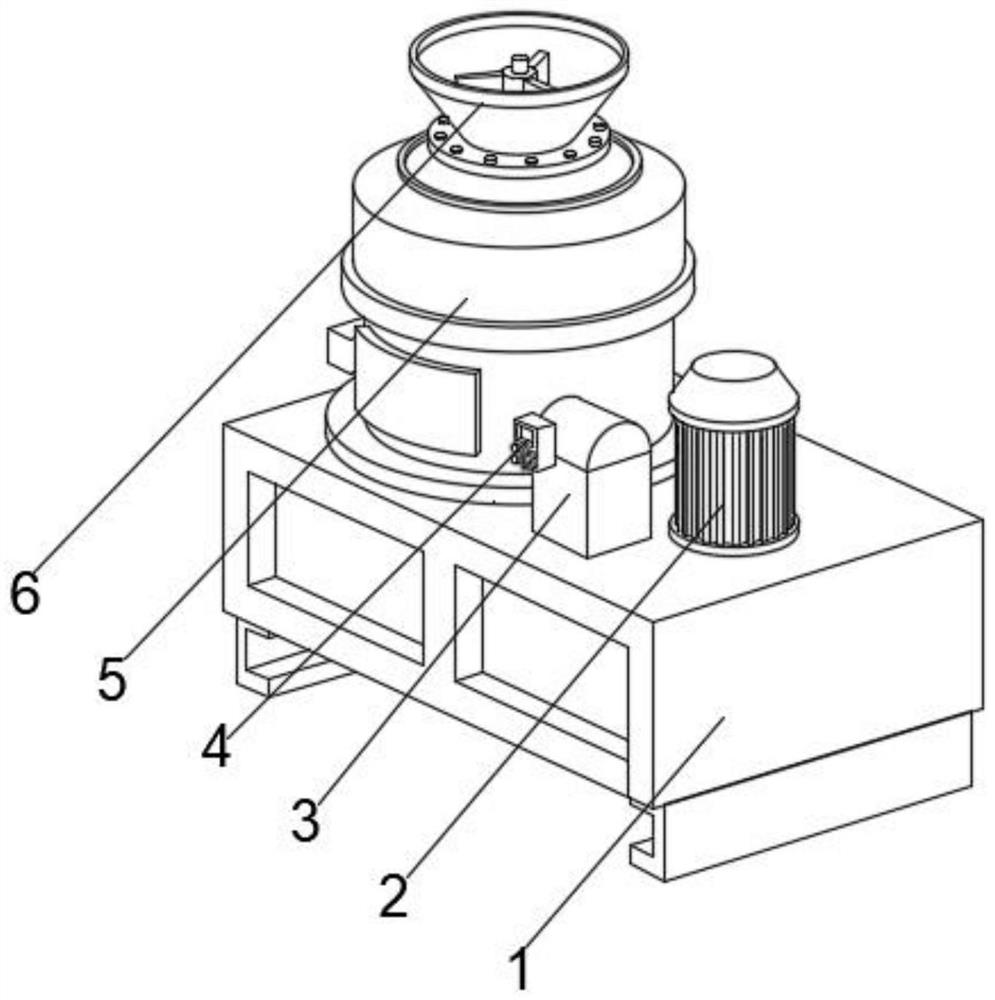

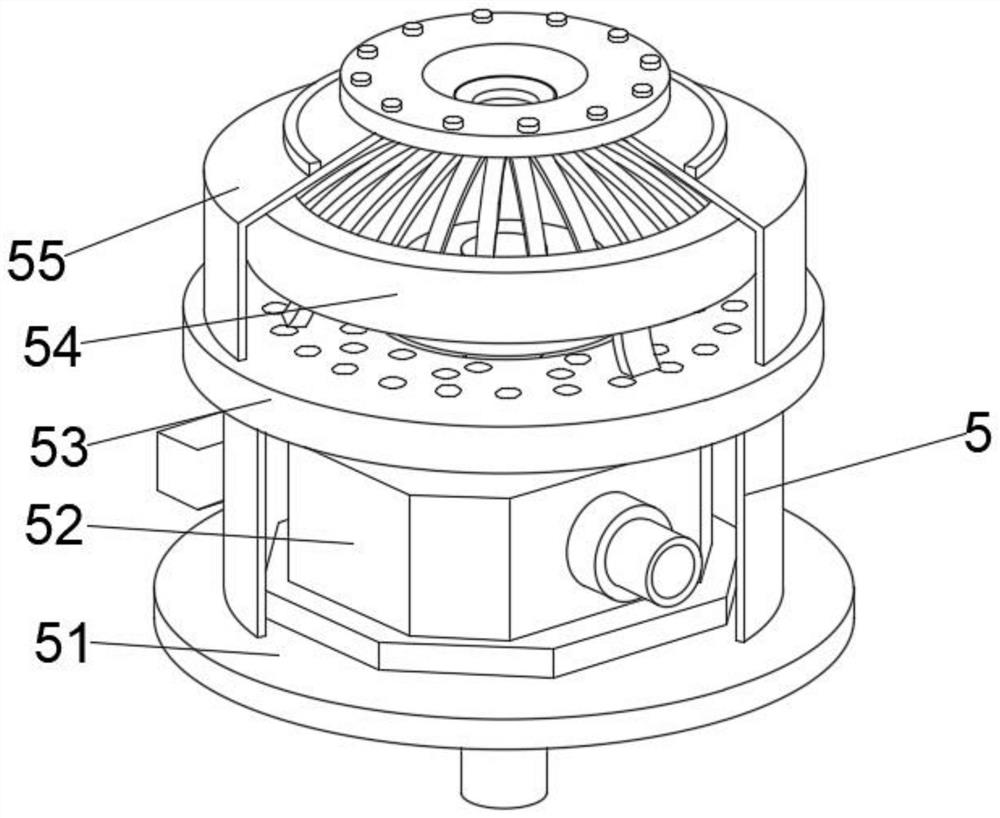

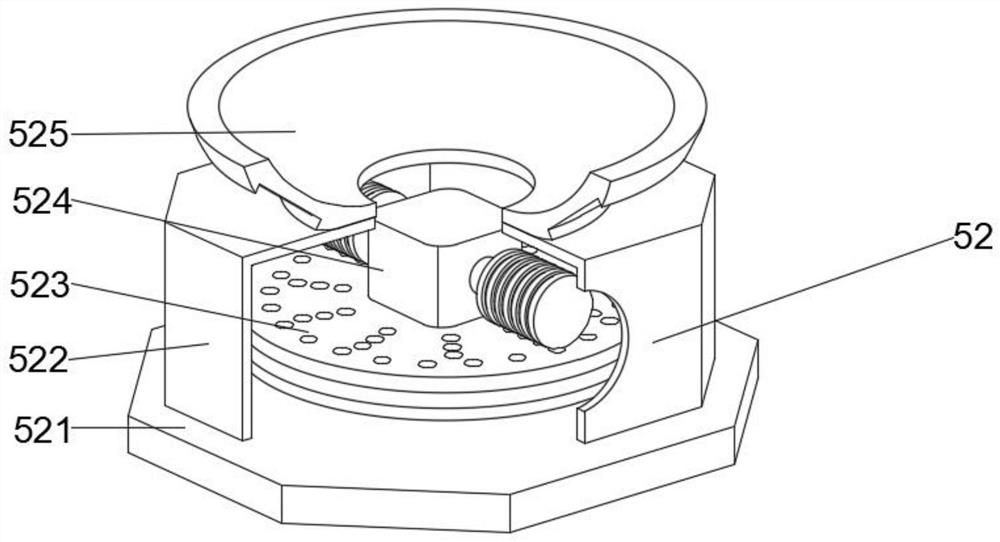

Flour grinding and screening equipment for coarse grains

InactiveCN109909003AAdjust the degree of primary crushing by yourselfIncrease the degree of crushingSievingScreeningElectric machineryEngineering

The invention discloses flour grinding and screening equipment for coarse grains. The flour grinding and screening equipment comprises a base, wherein two support plates are symmetrically arranged atthe upper end of the base; the opposite side walls of the two support plates are fixedly connected with fixed blocks; the opposite side walls of the two fixed blocks are commonly and fixedly connectedwith a first shell; a first hollow cavity is formed in the first shell; a feeding hopper which mutually communicate with the first hollow cavity is arranged at the upper end of the first shell in a penetrating manner; the inner side wall of the first hollow cavity is fixedly connected with a first fixed plate; the side wall of the first fixed plate is fixedly connected with a first motor; an output shaft of the first motor passes through the side wall of the first fixed plate and is fixedly connected with a first press roller; and a mounting plate is arranged on the side wall of the first shell in a penetrating manner. The flour grinding and screening equipment disclosed by the invention is reasonable in structural design, the pulverization degree can be automatically adjusted according to actual demands, and a dedicated material receiving measure is provided while the pulverized rice raw materials are screened at the same time, so that the processing efficiency is further improved.

Owner:李正梅

Injection molding machine for producing plastic bottle caps

Owner:佛山市顺德区山德塑胶五金有限公司

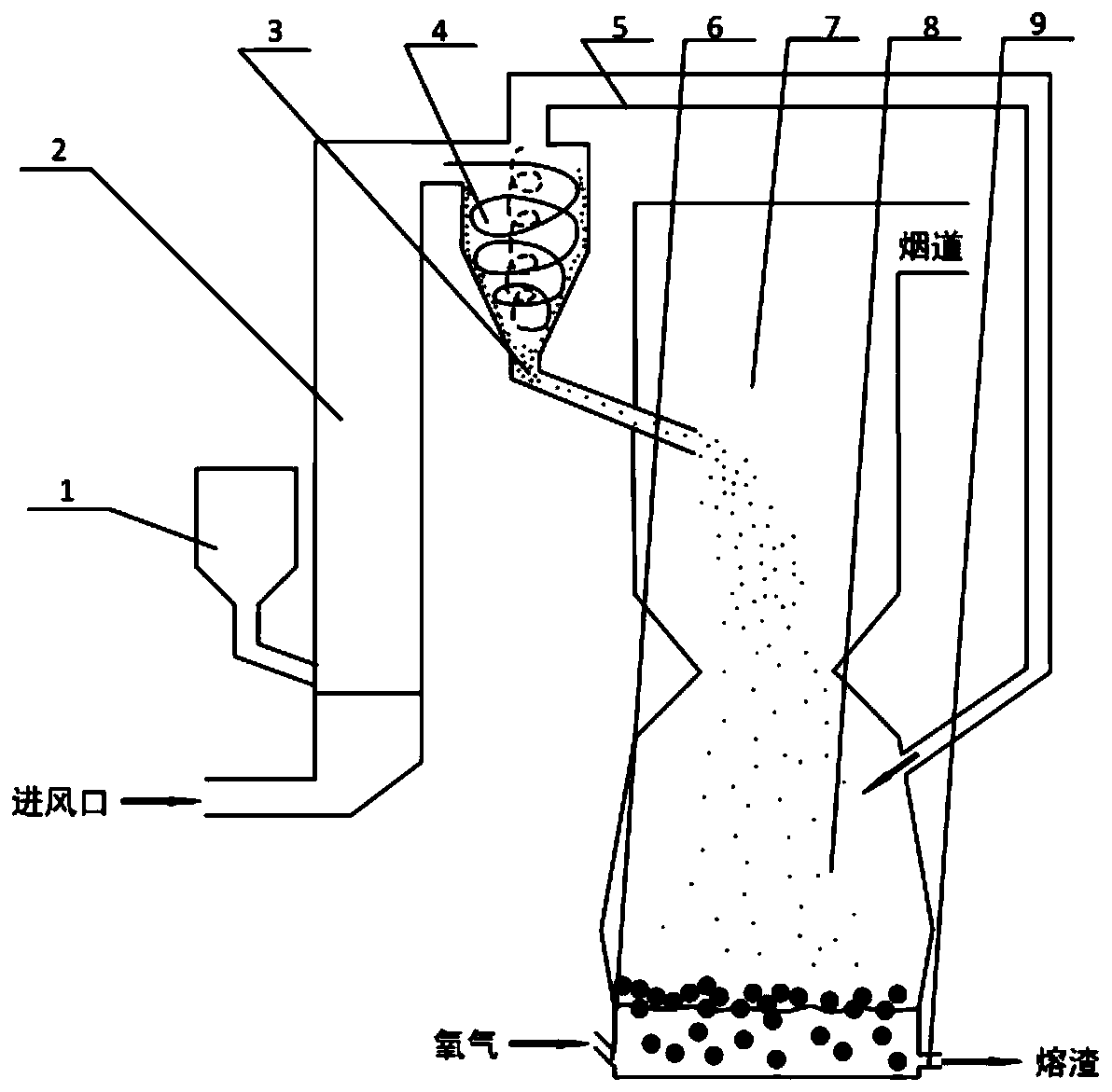

Uniform continuous feeding device for garbage incineration fly ash particles

ActiveCN110566977AFully burntConducive to stable operation at high temperatureIncinerator apparatusLitterFluidized bed

The invention provides a uniform continuous feeding device for garbage incineration fly ash particles. The uniform continuous feeding device comprises a fluidized bed feeder. The fluidized bed feederis provided with a wind inlet and a material storing bin. A tail outlet of the fluidized bed feeder is connected with an inlet of a cyclone material separator. The upper portion of the cyclone material separator is connected to the upper portion of a high-temperature melting furnace through a wind pipe. A solid particle collector is arranged on the bottom of the cyclone material separator. The solid particle collector is connected with a preheating furnace. The connecting position is arranged on the upper portion of the preheating furnace. The preheating furnace is located above the high-temperature melting furnace and communicates with the high-temperature melting furnace. An oxygen inlet and a molten slag outlet are formed in the bottom of the high-temperature melting furnace. Accordingto the uniform continuous feeding device, by means of the coordinative effect of the fluidized bed feeder and the cyclone material separator, continuous uniform feeding of materials is achieved.

Owner:XI AN JIAOTONG UNIV

Atmosphere flue dust collection apparatus

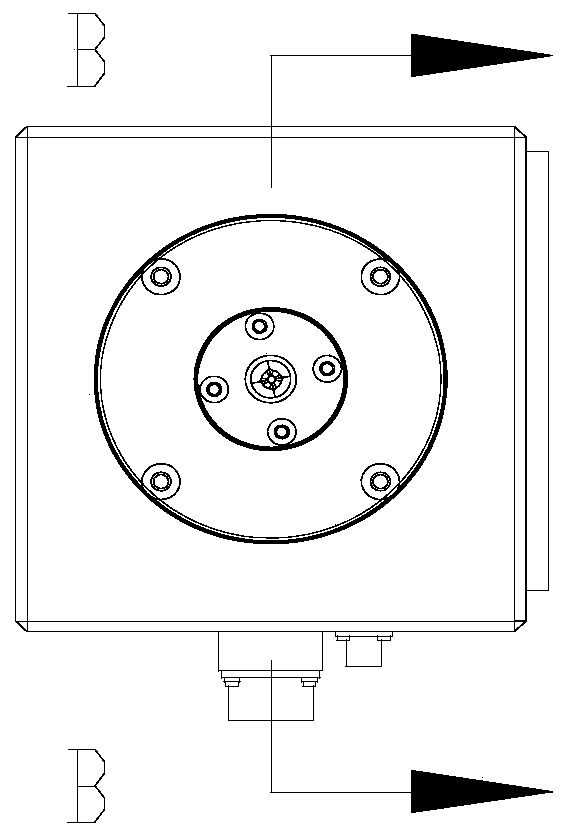

InactiveCN107228783AImprove accuracyGuaranteed normal dropWithdrawing sample devicesParticulatesFiltration membrane

The present invention discloses an atmosphere flue dust collection apparatus, which comprises a filtration material sampling clamper and a supporting component, wherein the filtration material sampling clamper is connected to the upper side of the supporting component, and comprises a connection seat ring, a fastening ring and an interface, the interior of the connection seat ring is sequentially provided with a first filtration membrane and a support net from top to bottom, the interface is hopper-like, the upper end of the interface and the lower end of the connection seat ring form closed contact through a sealing ring, the outer side of the contact position of the interface and the connection seat ring is provided with the fastening ring, the edge position of the hopper opening of the interface is provided with a second filtration screen, the middle portion of the hopper opening of the interface is provided with a third filtration screen, and the bottom portion of the hopper opening of the interface is provided with a four filtration screen. According to the present invention, based on the existing atmosphere collection device, the filtration material sampling clamper is improved, and the multi-layer filtration screen is arranged on the filtration material sampling clamper, such that the particulate matters in the passing air completely fall into the filtration screens so as to improve the data collection accuracy.

Owner:CHENGDU ETC CERTIFICATION GRP CO LTD

Device for cutting synthetic material bristles for glass grinding

ActiveCN109330177AReduce labor intensityShorten the timeBristleGrinding devicesBristleSynthetic materials

The invention provides a device for cutting synthetic material bristles for glass grinding, which comprises a workbench, wherein both edges of the bottom surface of the workbench are fixedly connectedwith a first supporting leg respectively, and the bottom surface of the workbench is fixedly connected with a first motor, the output end of the first motor is fixedly connected with a first rotatingshaft, and the outer surface of the first rotating shaft is fixedly connected with a second rotating wheel and a sixth rotating wheel. The front end and rear end of the top surface of the workbench are fixedly provided with a blocking plate respectively, a guiding roller, two conveying rollers, two upper rollers and two lower rollers are arranged between the two blocking plates, the guiding roller is arranged on one side of the blocking plates, the conveying rollers are arranged under the guiding roller and the two conveying rollers are placed horizontally. The device overcomes the defects inthe prior art and is reasonably designed to automatically cut the bristles. The time and the effort are saved, the production efficiency is improved, and the useless bristles left by the cutting canbe effectively removed, the quality of the bristles is improved.

Owner:安徽省潜山县潜源鬃刷有限公司

Municipal waste disposal device

The invention discloses a municipal waste disposal device, and relates to the technical field of waste disposal devices. The municipal waste disposal device comprises a conveyor and a screening device. The conveyor comprises a conveying belt, the screening device is provided with a cavity, wherein openings are formed in the two ends of the cavity, and no less than two semi-circle-shaped toothed belts are arranged at the bottom of the cavity wall of the cavity; coaxial rotating drums are arranged in the toothed belts, toothed rings are arranged in the circumferential directions of the rotating drums, the toothed rings are engaged with the toothed belts, working chambers are formed in the rotating drums, and one end of the conveying belt extends into the working chambers; a filter screen and two baffle rings are arranged. in the circumferential direction, on the drum wall of each rotating drum, the filter screens communicate with the working chambers, and each filter screen is located between the corresponding two baffle rings; circular grooves are formed in the cavity wall of the cavity, the baffle rings are rotatably clamped in the circular grooves, first discharging holes are formed in the bottom end of the circular grooves, and the first discharging holes correspond to the filter screens up and down; and a gear is arranged at the top of the screening device, the gear is engaged with the toothed rings, the gear is connected on a driving rod in a sleeving mode, and the driving rod is connected with a first motor. According to the municipal waste disposal device, a mode of rotary screening is adopted, and municipal waste can be well screened.

Owner:合肥永泰新型建材有限公司

Garlic planting device

InactiveCN107615959ANo manual operationReduce the amount of manual laborSeed depositing seeder partsEngineeringAir blower

The invention relates to the technical field of crop planting, and particularly relates to a garlic planting device. The garlic planting device comprises a loading pipe, a conveyor belt is arranged onan outlet of the loading pipe, the conveyor belt comprises a leakage net and a placement cavity arranged below the leakage net, and the leakage net is elastic; a discharge pipe is arranged below a discharge end of the conveyor belt, a turnover pipe is arranged above the conveyor belt and comprises a feed pipe and a discharge pipe, a U-shaped pipe is connected between the feed pipe and the discharge pipe, an air blower is arranged on one side of the feed pipe, the air blower and the feed pipe are communicated with a plurality of air outlet pipes, the air outlet pipes are arranged on the innerwall on the side of the feed pipe, and a plurality of air outlets are formed in the inner wall on the other side of the feed pipe. The garlic planting device solves the problem of low yield of the garlic, caused by random seeding, of the existing planting device.

Owner:NINGBO SHENYICAO BIO TECH

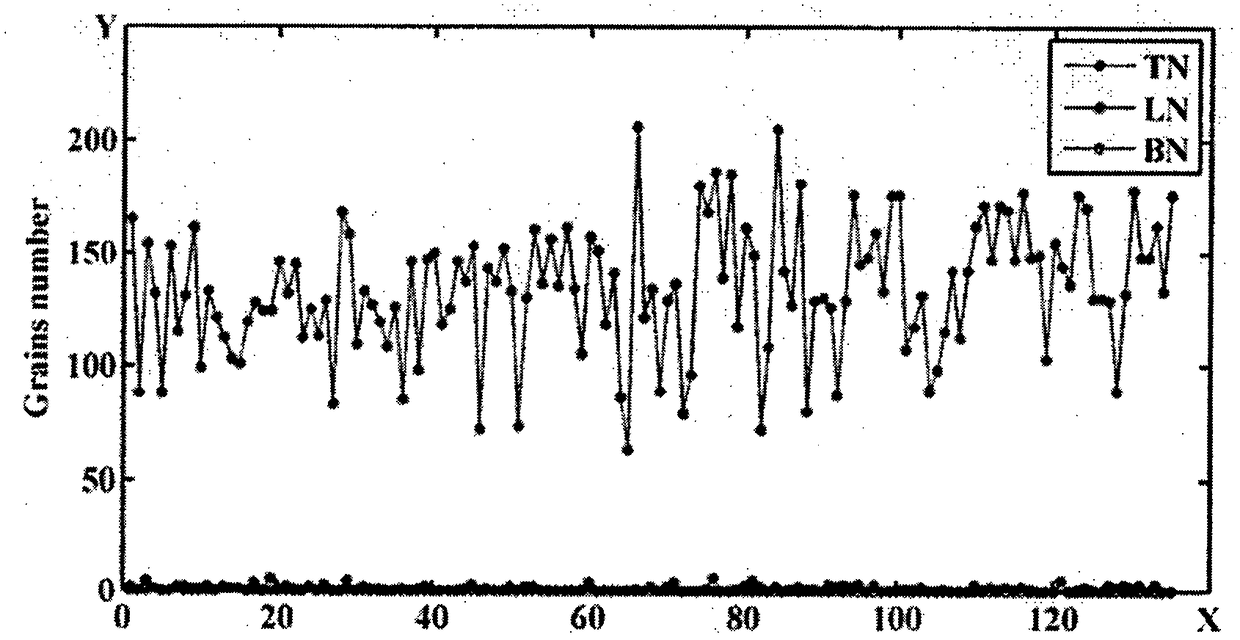

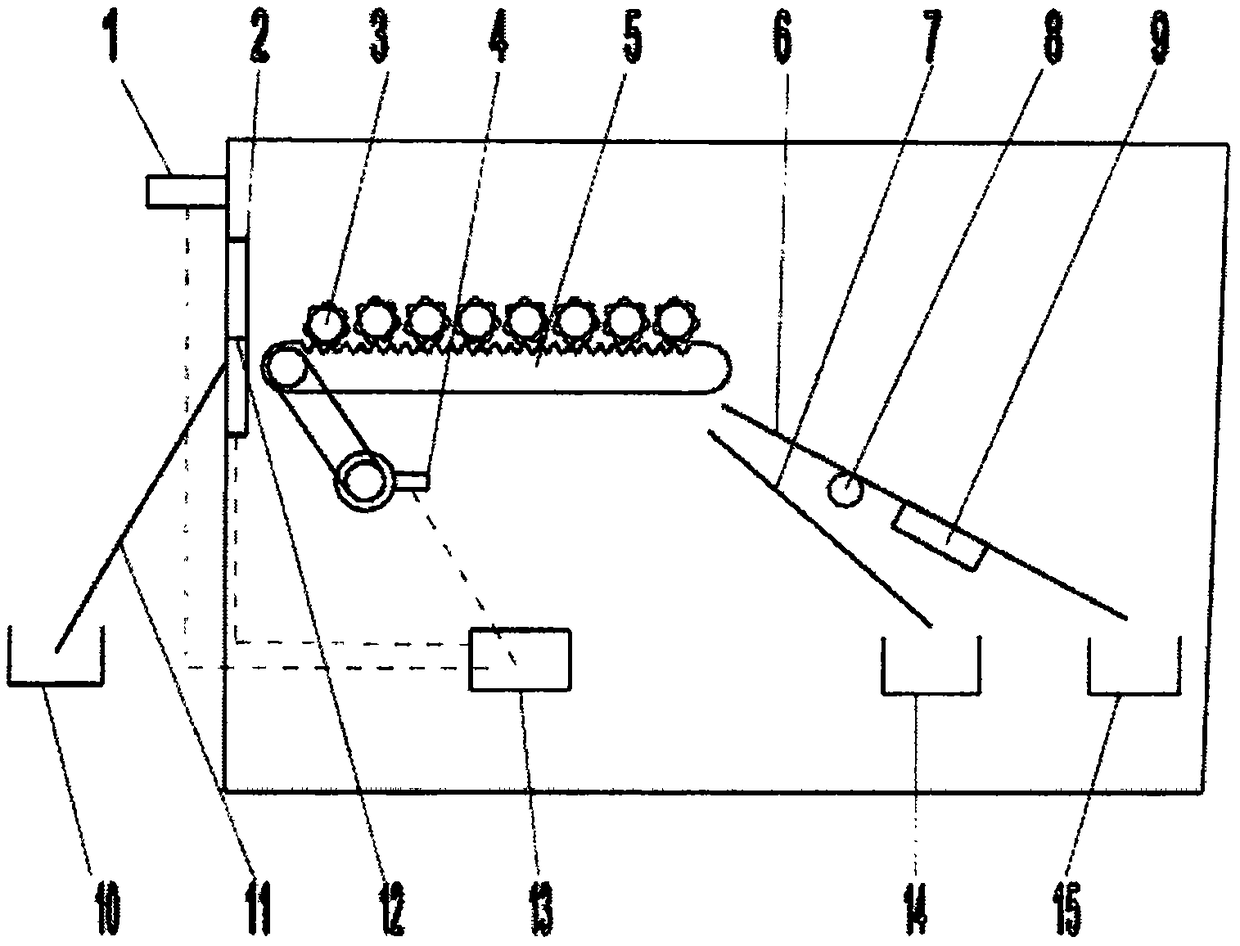

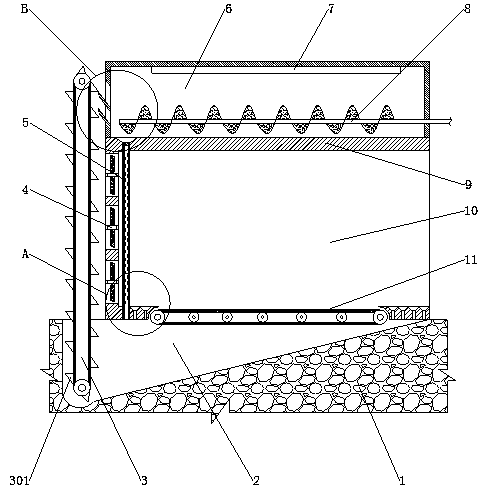

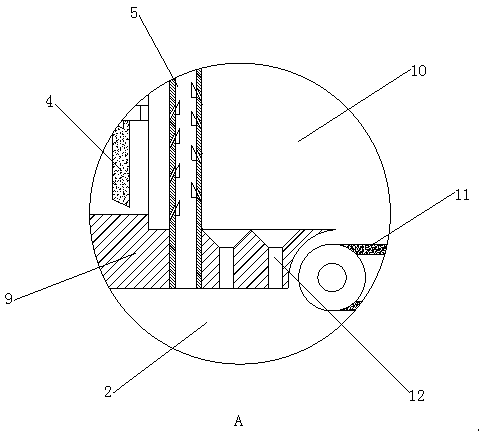

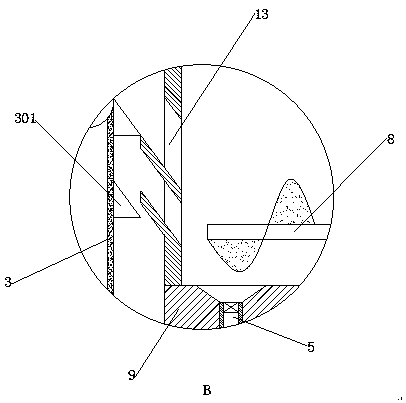

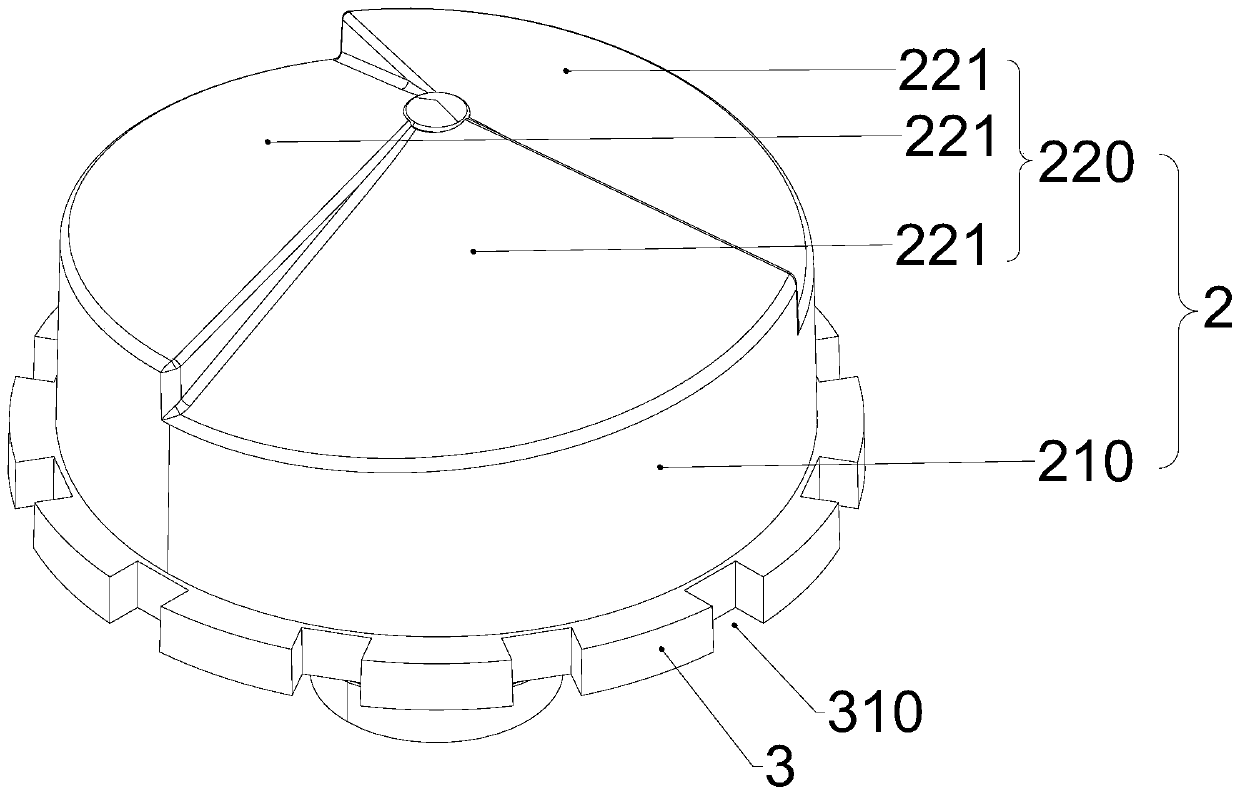

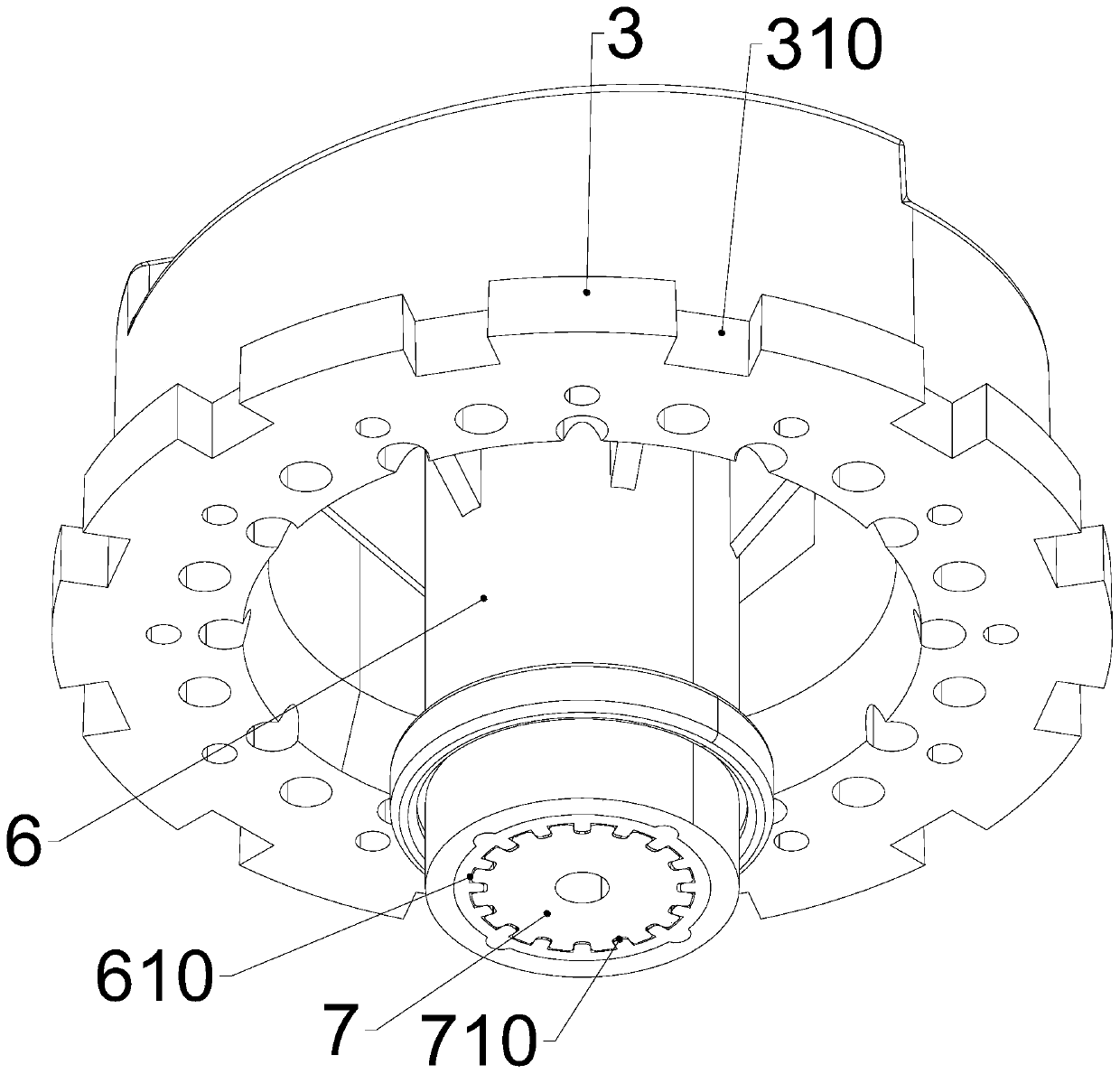

Single-plant high-precision full-automatic threshing system based on combination of scraping type and rolling type

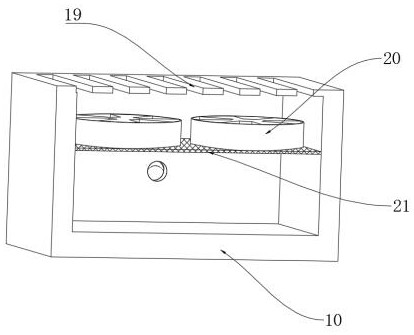

InactiveCN109379992AGuaranteed normal dropFall will notThreshersAutomatic processingAgricultural engineering

The invention discloses a single-plant high-precision full-automatic threshing system based on combination of a scraping type and a rolling type, which comprises a scraping type threshing assembly, arolling type threshing assembly, a shrunken grain and branch-trunk separating assembly, and a PLC controller. The scraping type threshing assembly is obtained through transformation according to artificial threshing, and most of the solid grains can be threshed with almost zero shell breaking rate; the rolling type threshing assembly is used for threshing the shrunken grains which are difficult to thresh, so that the precision of the threshing system is ensured. The threshing system has the advantages of high precision, high efficiency and high automation degree, and the threshing system is suitable for automatic treatment of rice ears in the early stage of single-plant high-precision seed selection, thereby providing powerful support for fine agricultural research.

Owner:武汉谷丰光电科技有限公司

Multifunctional tool box for students

The invention discloses a multifunctional tool box for students. The box comprises a storage box body, a tool box body, a glasses box body, a balancing weight and a glasses box cover. The upper end ofthe tool box body is connected with a tool box cover, a check block is fixed into the tool box body, and the storage box body is placed on the check block; the glasses box body is arranged in the portion, below the check block, of the tool box body, the glasses box cover is connected to the upper portion of the glasses box body, the glasses box body and the glasses box cover are in a cylindricalshape after being closed, and the balancing weight is fixed to the inner wall of the bottom of the glasses box body. According to the multifunctional tool box for the students, the interior of the tool box body is divided into two parts for use, the upper part of the storage box body is used for storing school supplies, the lower part of the storage box body is used for containing the glasses boxbody, and it is guaranteed through the balancing weight in the glasses box body that when a first ball bearing and a second ball bearing are placed in the glasses box body, even the tool box body inclines or topples over, the glasses box cover is always kept upward, cleaning fluid in the glasses box cover is prevented from spilling, and glasses cannot fall down from a storage support; the multifunctional tool box is convenient to use, practical, diverse in function and suitable for being used by the students.

Owner:田浩宇

High strain hammering device

InactiveCN101285750BAvoid damageGuaranteed normal dropFoundation testingMaterial strength using single impulsive forceBogieHigh strain

The invention relates to a high strain hammering device, which comprises a hook and a leading bogie, wherein, the hook comprises an intermediate arm and two symmetrically arranged spoon-shaped arms; the intermediate arm is hinged with a clamped position of the two spoon-shaped arms; the leading bogie comprises a guide rail which limits the motion direction of a heavy punch, supporting legs which support a body of the leading bogie, and a pedestal which is integrated with various supporting legs into a whole; the guide rail is fixedly connected with the supporting legs; and cable wires are connected to the supporting legs, pass through the top of the leading bogie and are connected with the intermediate arm of the hook. The high strain hammering device avoids damage of a lifting device dueto instant force release, thereby being favorable for protecting the lifting device; moreover, due to arrangement of the leading bogie, the heavy punch is driven to move along the direction limited by the guide rail of the leading bogie during the lifting and falling process and is effectively guaranteed to fall on the center of a foundation pile to be measured, thereby eliminating the potential safety hazard that the heavy punch is fallen off after falling and being favorable for improving the detection safety.

Owner:CHINA ELECTRIC POWER RES INST

Injection molding machine with demolding detecting device

InactiveCN104494072AAvoid failureImprove running stabilityReciprocating motionInjection molding machine

The invention provides an injection molding machine with a demolding detecting device, belonging to the technical field of moulds and solving the technical problems of relatively poor operation stability and the like of the injection molding machine in the prior art. The injection molding machine comprises a stand, wherein the stand is provided with a fixed mold plate and a moving mold plate which are connected through a pull rod, the moving mold plate and the fixed mold plate are closed to form a plurality of mold cavities for molding plastic bottle caps, and openings of the plastic bottle caps are outwards arranged after the plastic bottle caps are molded. The injection molding machine also comprises a piece taking device, wherein the piece taking device comprises a piece taking plate; the piece taking plate is provided with a clamping structure capable of fixing or loosing the plastic bottle caps; a rack is fixedly provided with a lifting mechanism capable of driving the piece taking plate to do lifting reciprocation and is also provided with a holding frame for holding the plastic bottle caps; and the holding frame is provided with a demolding detecting device for detecting whether all the plastic bottle caps fall off from the mold cavities. The injection molding machine has the advantages of good operation stability and the like.

Owner:海宁王骏新材料有限公司

Automobile wind sand test workshop for automobile performance test

The invention provides an automobile wind sand test workshop for automobile performance test, which comprises a sand collecting chamber, a lifting belt, fans, a sand leakage pipe, a sand storage chamber, a test workshop and a running belt, wherein the running belt is rotatably arranged on the ground of the test workshop, a floor drain is arranged in the peripheral ground of the running belt, the fans are arranged on the three wall bodies around the test workshop, the sand leakage pipe is fixedly arranged right in front of the fans, the sand storage chamber is arranged above the test workshop,the bottom of the sand storage chamber is rotatably connected with a stirring shaft, a sand inlet is arranged on one side surface of the sand storage chamber, the lifting belt is rotatably arranged onthe outer side of the sand inlet, the surface of the lifting belt is fixedly connected with a lifting bucket, and the bottom of the lifting belt is arranged in the sand collecting chamber. Due to thematching arrangement of the fans and the sand leakage pipe, when the automobile runs on the rotating running belt, the fans can blow up sand leaked from the sand leakage pipe so as to form wind sand,and therefore the wind sand weather performance test can be carried out on the running automobile.

Owner:丁雷

Continuous automatic smoke dust and smoke monitoring apparatus

InactiveCN107219099AImprove accuracyGuaranteed normal dropWithdrawing sample devicesParticulatesSoft materials

The invention discloses a continuous automatic smoke dust and smoke monitoring apparatus. A filter material sampling clamp is connected at the upper side of a supporting part, a connecting piece is sleeved at a junction of the filter material sampling clamp and the supporting part, and a soft material is adopted for the connection; the upper end of a connector contacts the lower end of a joint seat ring in a closing manner by virtue of a sealing ring, the outer side of a contact position between the connector and the joint seat ring is provided with a fastening ring, the middle part of the connector is provided with a third filter net, and the bottom of a block mouth of the connector is provided with a fourth layer filter net; and the connecting piece is a circular-truncated-cone-shaped through pipe, a larger end of an opening of the connecting piece faces the filter material sampling clamp, a smaller end of the opening faces the supporting part, the wall of the inner side of the connecting piece is provided with a circle of connecting piece guide rail, and the outer side of the lower end of the filter material sampling clamp is provided with a circle of connector circular truncated cone matched with the connecting piece guide rail. On the basis of the existing air collector, the filter material sampling clamp is improved, and the filter material clamp is provided with multiple layers of filter nets, so that particulate matters in the air passing through the filter material sampling clamp are ensured to fall on the filter net, and the data collection accuracy can be improved.

Owner:CHENGDU ETC CERTIFICATION GRP CO LTD

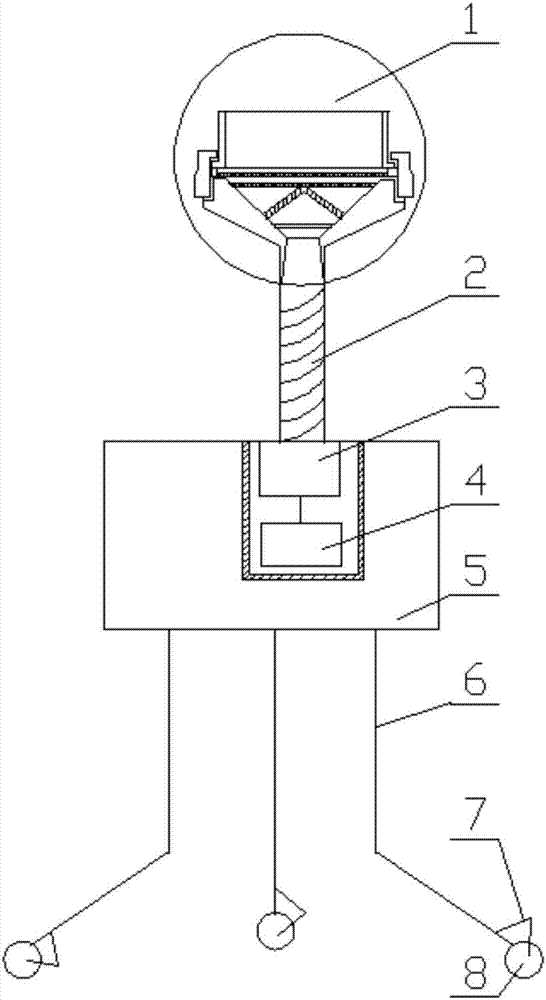

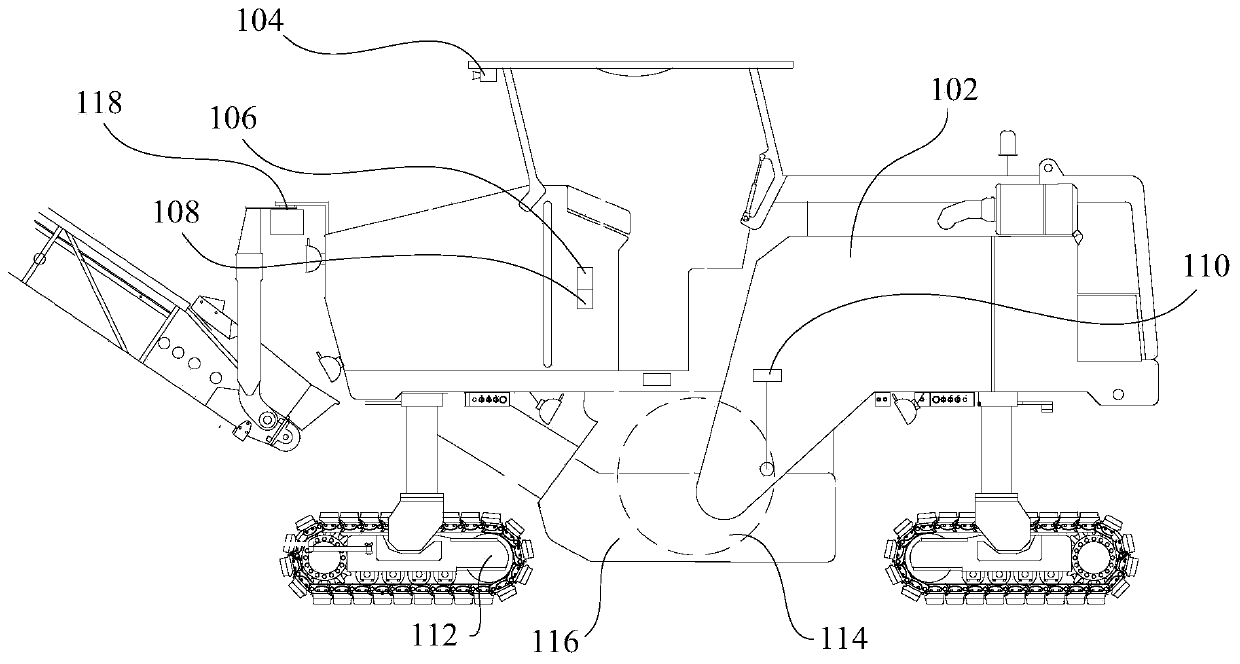

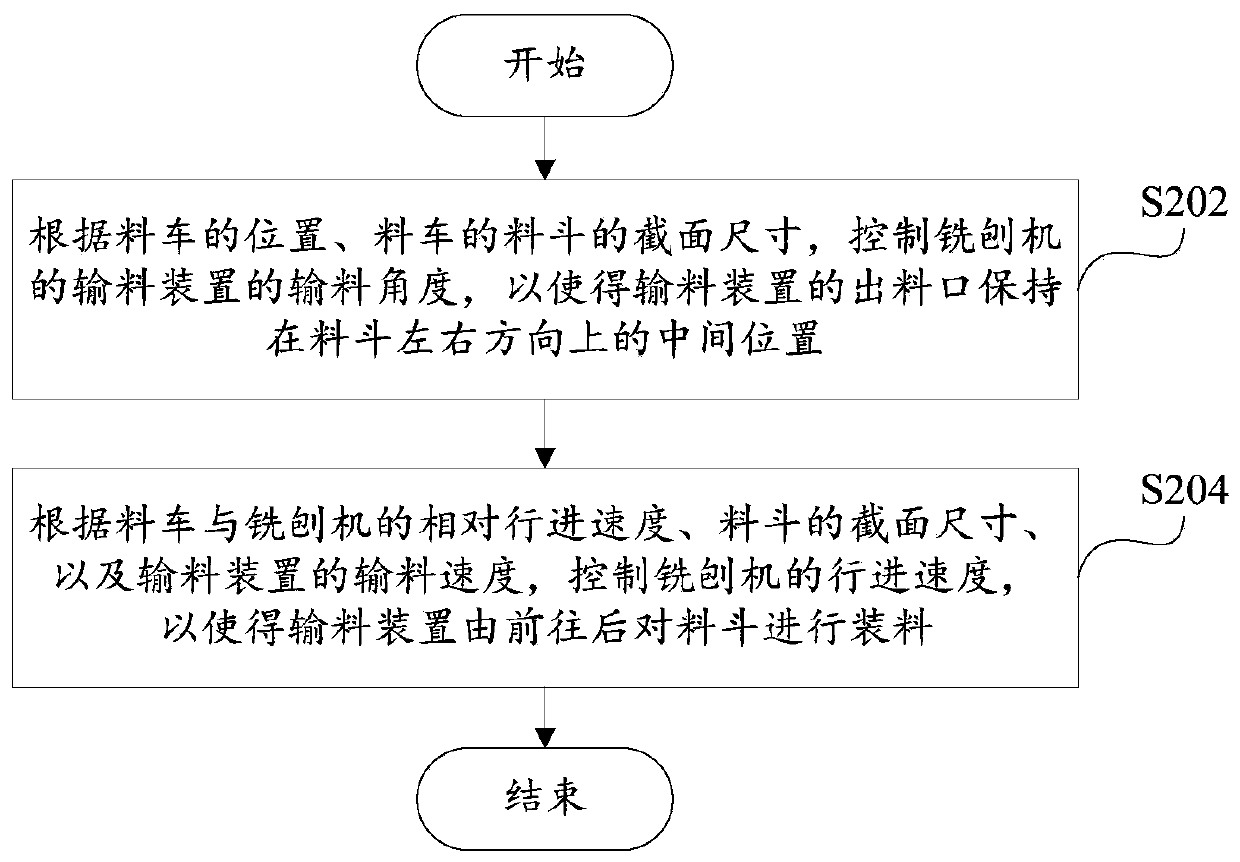

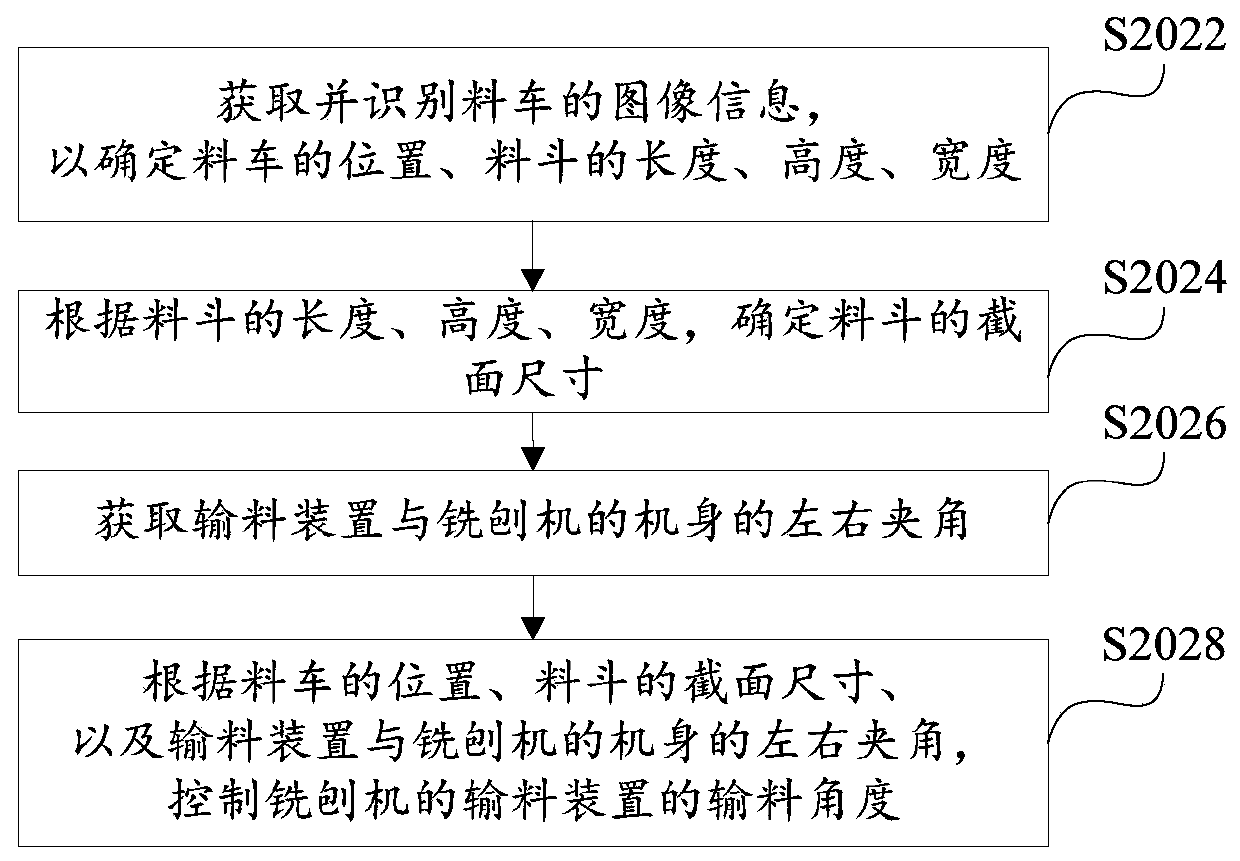

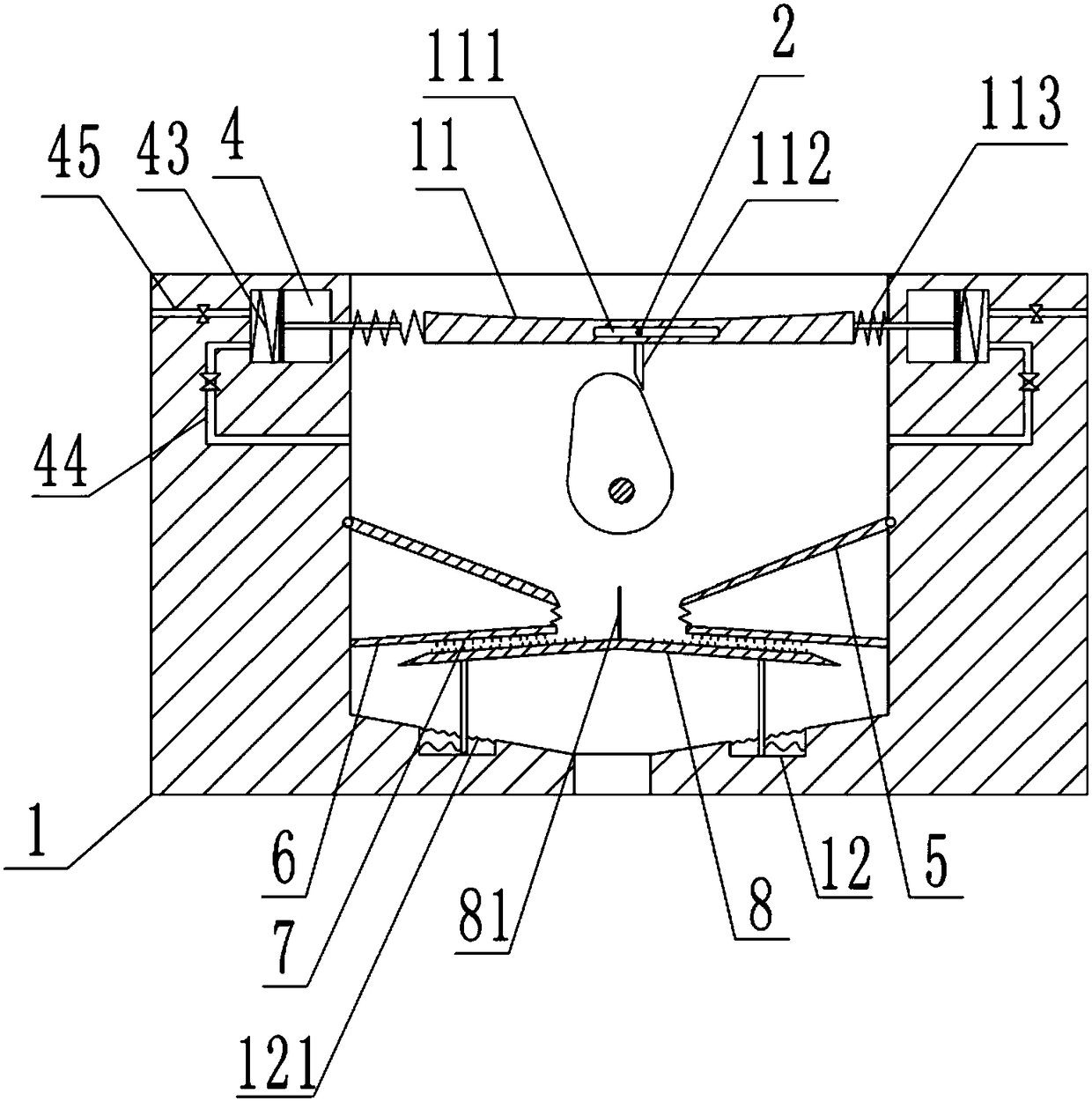

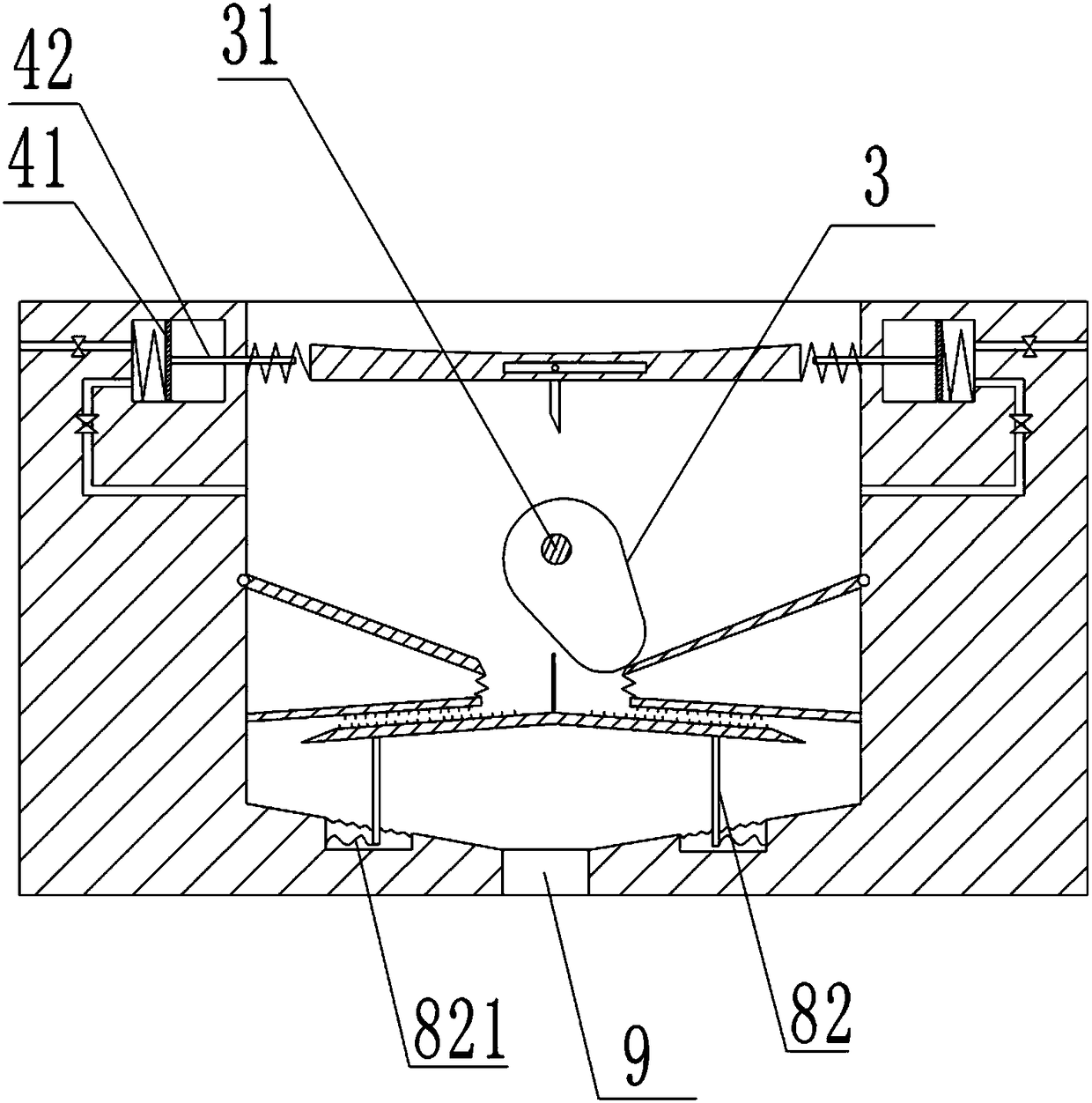

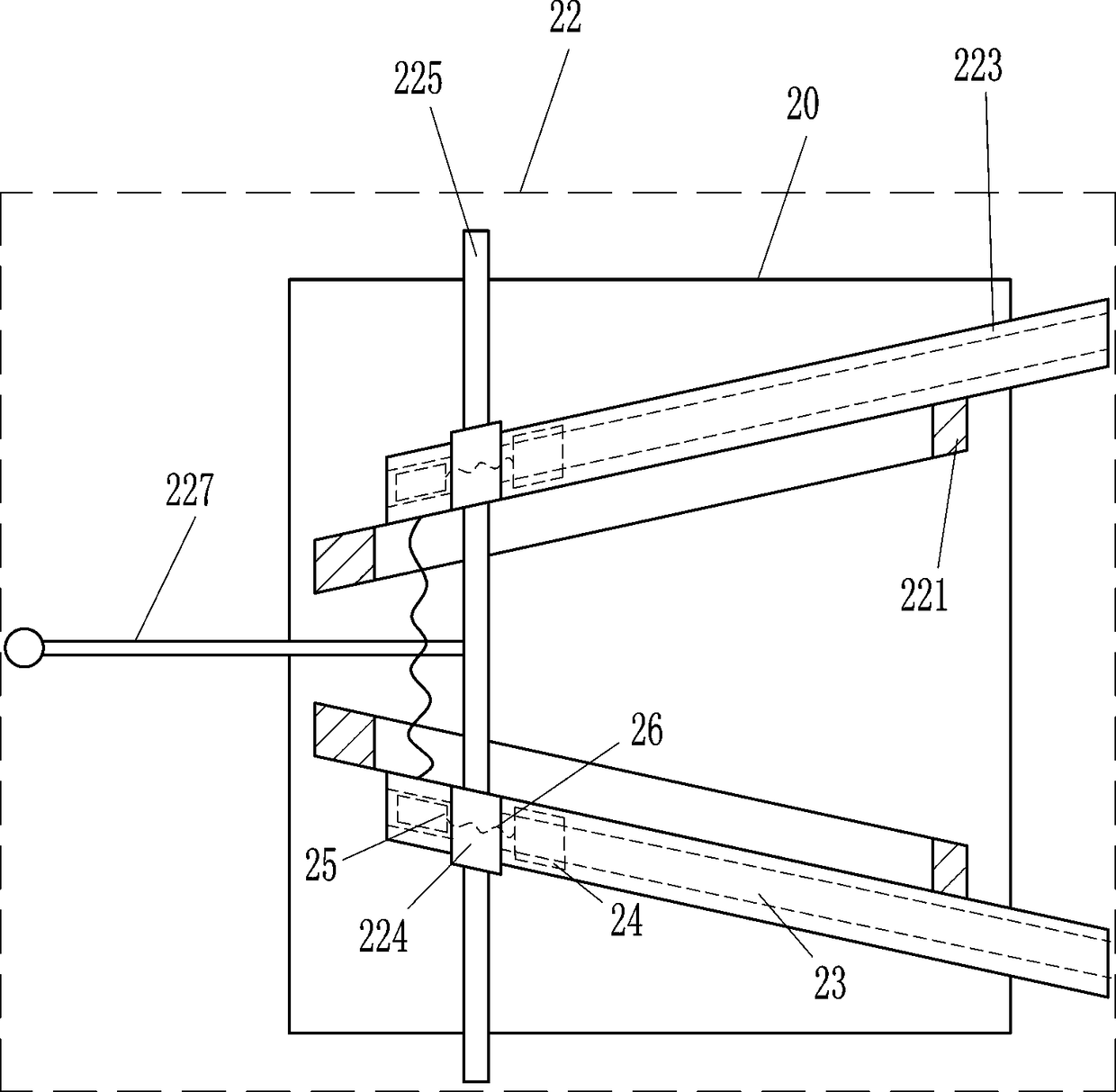

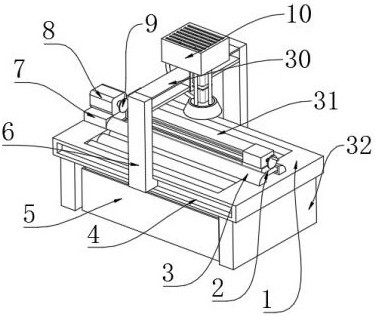

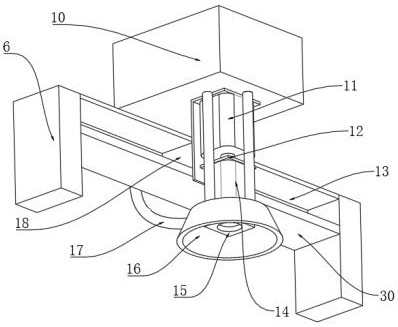

Milling machine and control method of milling machine

InactiveCN110965443AGuaranteed normal dropHigh degree of automationRoads maintainenceVehicle position/course/altitude controlImaging processingAutomatic control

The invention provides a milling machine and a control method of the milling machine, and the milling machine comprises a machine body; a material conveying device movably arranged on the machine body; an image processing device arranged on the machine body, and an image processing device configured to obtain the position of a skip car, wherein the section size of a hopper of the skip car and therelative advancing speed of the skip car and the milling machine; a master controller arranged on the machine body and electrically connected with the image processing device; a main controller whichis configured to control the conveying angle of the conveying device according to the position of the skip car and the section size of a hopper. Materials discharged from a discharge port of the conveying device fall into the middle of the hopper in the width direction. The advancing speed of the milling machine is controlled according to the relative advancing speed of the skip car and the milling machine, the section size of the hopper and the conveying speed of the conveying device, so that the conveying device charges the hopper from front to back, the milling machine provided by the invention can realize automatic control, and the working intensity of operators is reduced.

Owner:SANY AUTOMOBILE MFG CO LTD

Preparation method of traditional Chinese medicine material

InactiveCN108420835AEnsure drying uniformityGuaranteed brushing effectCleaning using toolsHeating arrangementMedicinal herbsCordyceps

The invention relates to the technical field of medicine production, in particular to a preparation method of a traditional Chinese medicine material. The preparation method comprises the following steps: step 1, removing impurities: harvesting fresh cordyceps sinensis and picking out the impurities in the cordyceps sinensis; step 2, screening and drying: taking a drying plate, putting the cordyceps sinensis in the step 1 on the drying plate, wherein the upper surface of the drying plate is an arc surface; shaking the drying plate, wherein the cordyceps sinensis rolls on the arc surface and falls off from the arc surface when the mud on the surface of the cordyceps sinensis is gradually dried, blowing air to the falling cordyceps sinensis, drying again; step 3, vibrating: preparing a sloping panel, using the sloping panel to catch the cordyceps sinensis falling off from the arc surface in the step 2; vibrating the sloping panel to loosen the mud on the surface of the cordyceps sinensis; step 4, clearing: using an hair brush to brush off the mud on the surface of the cordyceps sinensis in the step 3. The technical scheme solves the problems in the prior art that artificially turningthe medicine material is troublesome and the medicine material is not evenly dried.

Owner:王俊涛

Lime unloading equipment for building construction

InactiveCN108792664AGuaranteed normal dropRealize the function of automatic resetLoading/unloadingArchitectural engineeringPulley

The invention relates to unloading equipment, in particular to lime unloading equipment for building construction. In order to solve technical problems in the prior art, the lime unloading equipment which is applied to building construction and has the beneficial effects that the clothes of workers can be prevented from being dirtied when lime is unloaded and the high safety in the lime unloadingprocess can be achieved is provided. According to the technical scheme, the lime unloading equipment for building construction comprises a base, wheels, a first sliding rail, a first sliding block, anL-shaped rod, a first connecting block, a mounting plate, a fixed pulley, a blocking rod, an elastic rope, a pushing rod, a motor and the like, wherein the wheels are connected with both the left andright sides of the base; a through hole is formed in the middle of the base; the first sliding rail is embedded in the inner bottom of the through hole; and the first sliding block is slidably arranged on the first sliding rail. The lime unloading equipment provided by the invention achieves the beneficial effects that the clothes of the workers can be prevented from being dirtied and the high safety in the lime unloading process can be achieved; through the cooperation between a pushing hand and connecting plates, the lime can automatically drop from the lime unloading equipment to a destination; and then the clothes of the workers can be prevented from being dirtied when the lime is unloaded by the workers.

Owner:温州澳鼎建材有限公司

Dustproof environment-friendly wood carving machine for wood sculpture

InactiveCN112109154AHigh recovery rateImprove work efficiencyProfiling/shaping machinesBark-zones/chip/dust/waste removalWorkbenchIndustrial engineering

The invention discloses a dustproof environment-friendly wood carving machine for a wood sculpture, and relates to the technical field of wood carving machines. The dustproof environment-friendly woodcarving machine aims to solve the problem of recycling and cleaning waste wood chips of the wood carving machine. The dustproof environment-friendly wood carving machine specifically comprises a workbench; the outer wall of the bottom end of the workbench is fixedly connected with a support through screws; the outer wall of the top end of the workbench is connected with an arc-shaped electric guide rail through bolts; the inner wall of one side of the arc-shaped electric guide rail is slidably connected with a bearing sliding block; the outer wall of the top end of the bearing sliding block is fixedly connected with an adjusting box through the screws; the outer wall of the top end of the workbench is fixedly connected with a bearing block through the screws; a servo motor is connected tothe outer wall of the top end of the bearing block through the bolts; first electric guide rails are machined on the inner walls of the two sides of the workbench; the inner wall of one side of eachfirst electric guide rail is slidably connected with a supporting sliding block; and the outer walls of one sides of the supporting sliding block are fixedly connected with a beam through the screws.According to the dustproof environment-friendly wood carving machine for the wood sculpture, by arranging a chip removing cover, the purpose of comprehensively recycling wood chips generated during wood carving machining is achieved, the recycling rate of the wood chips is increased, and the working efficiency is improved.

Owner:衡阳市无量雕塑艺术有限公司

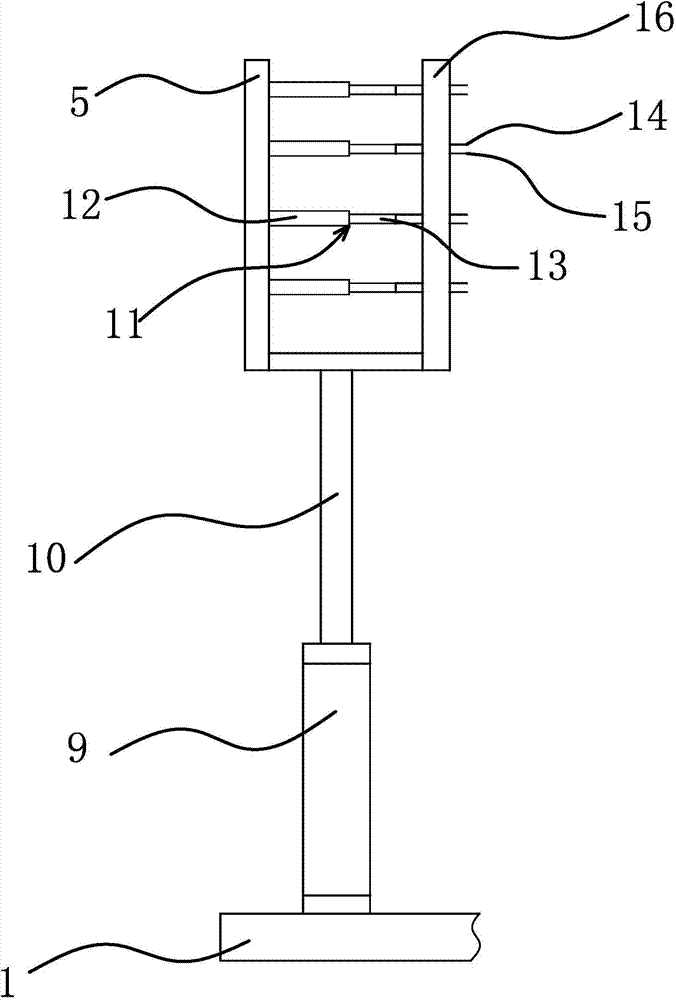

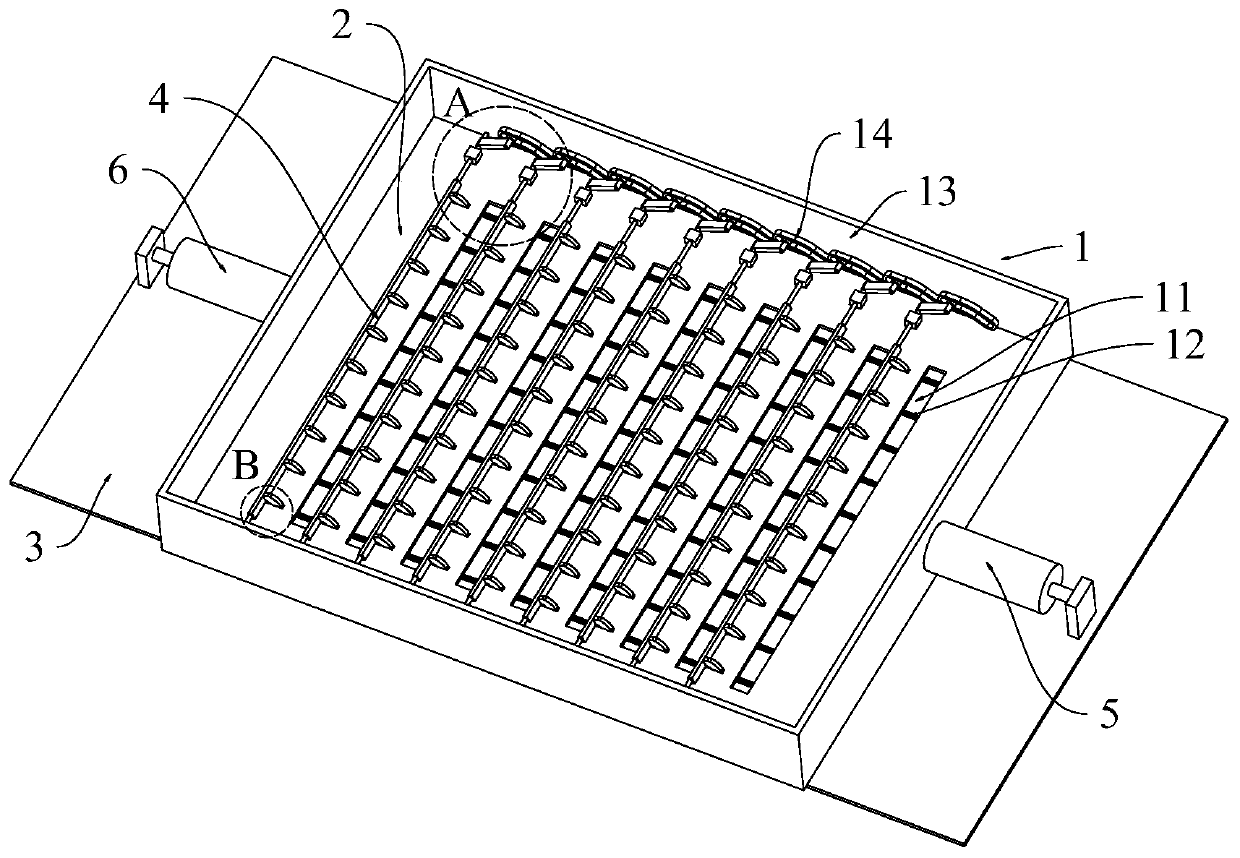

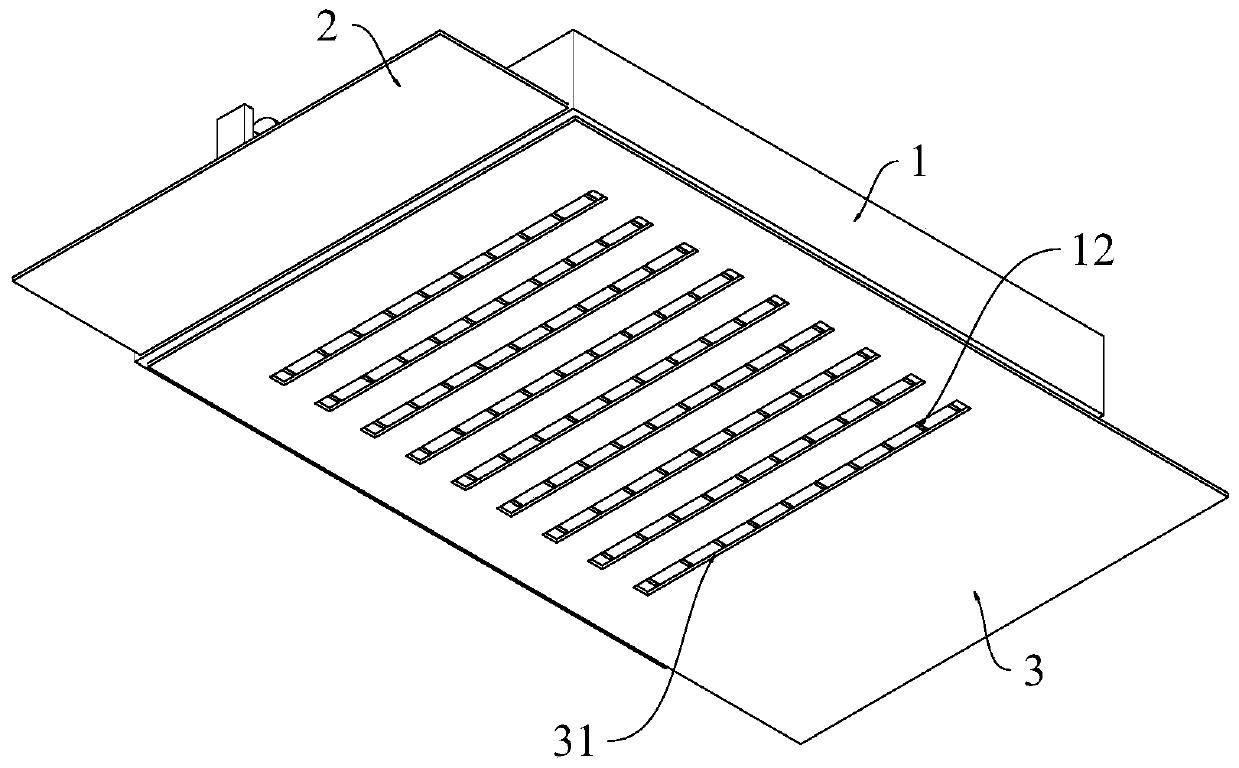

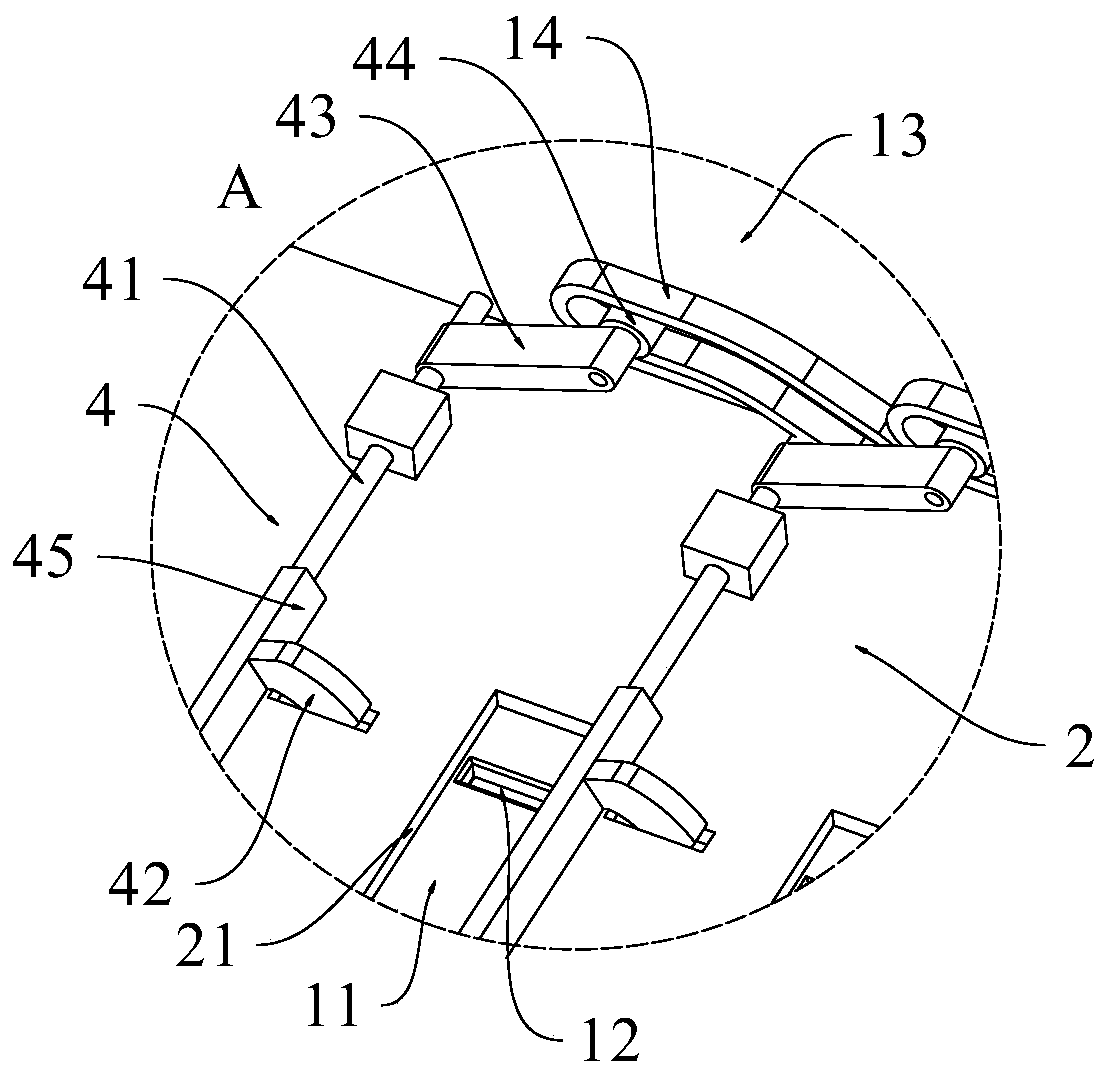

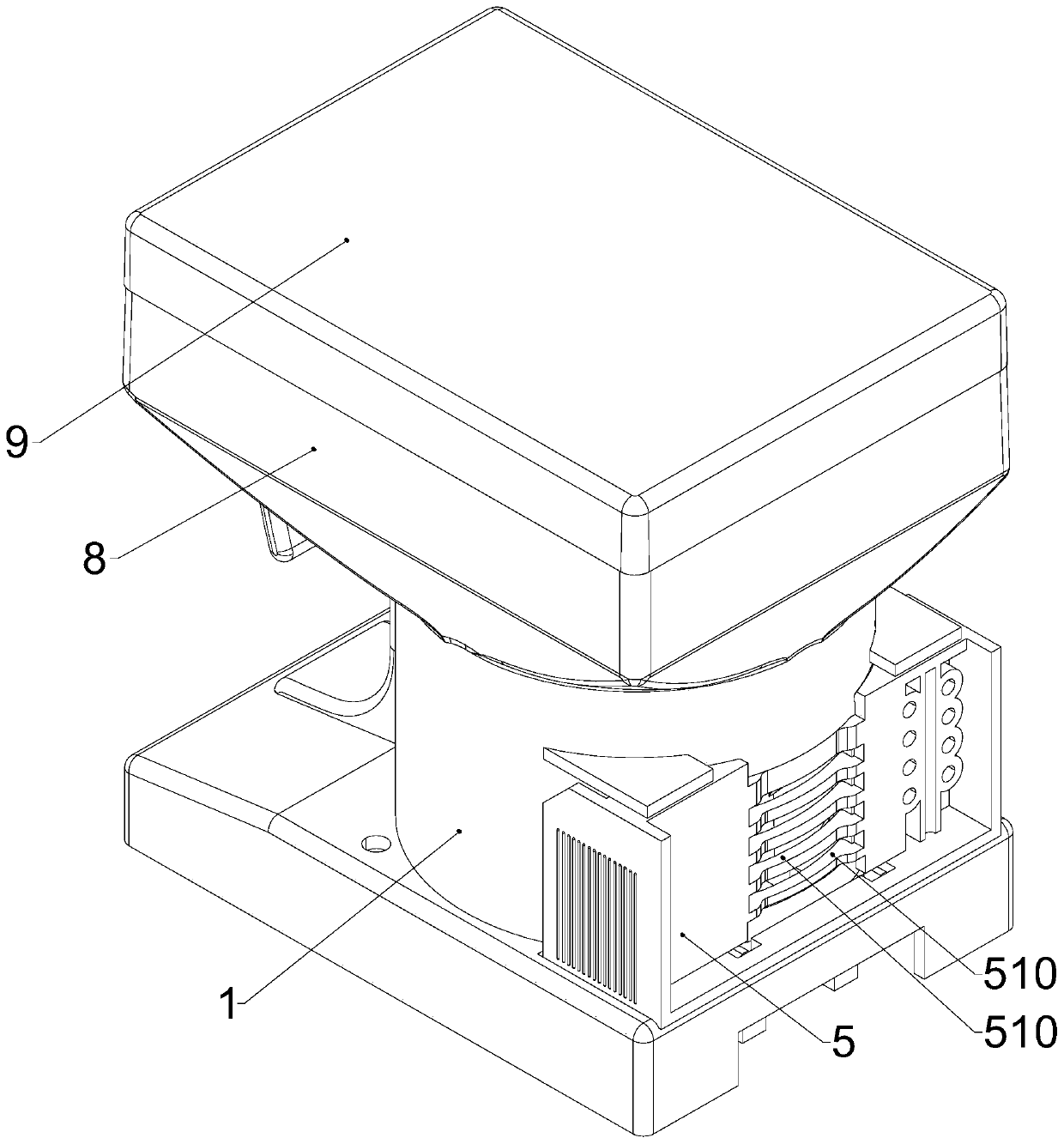

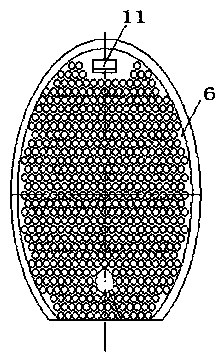

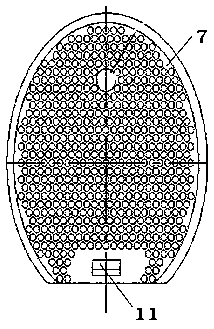

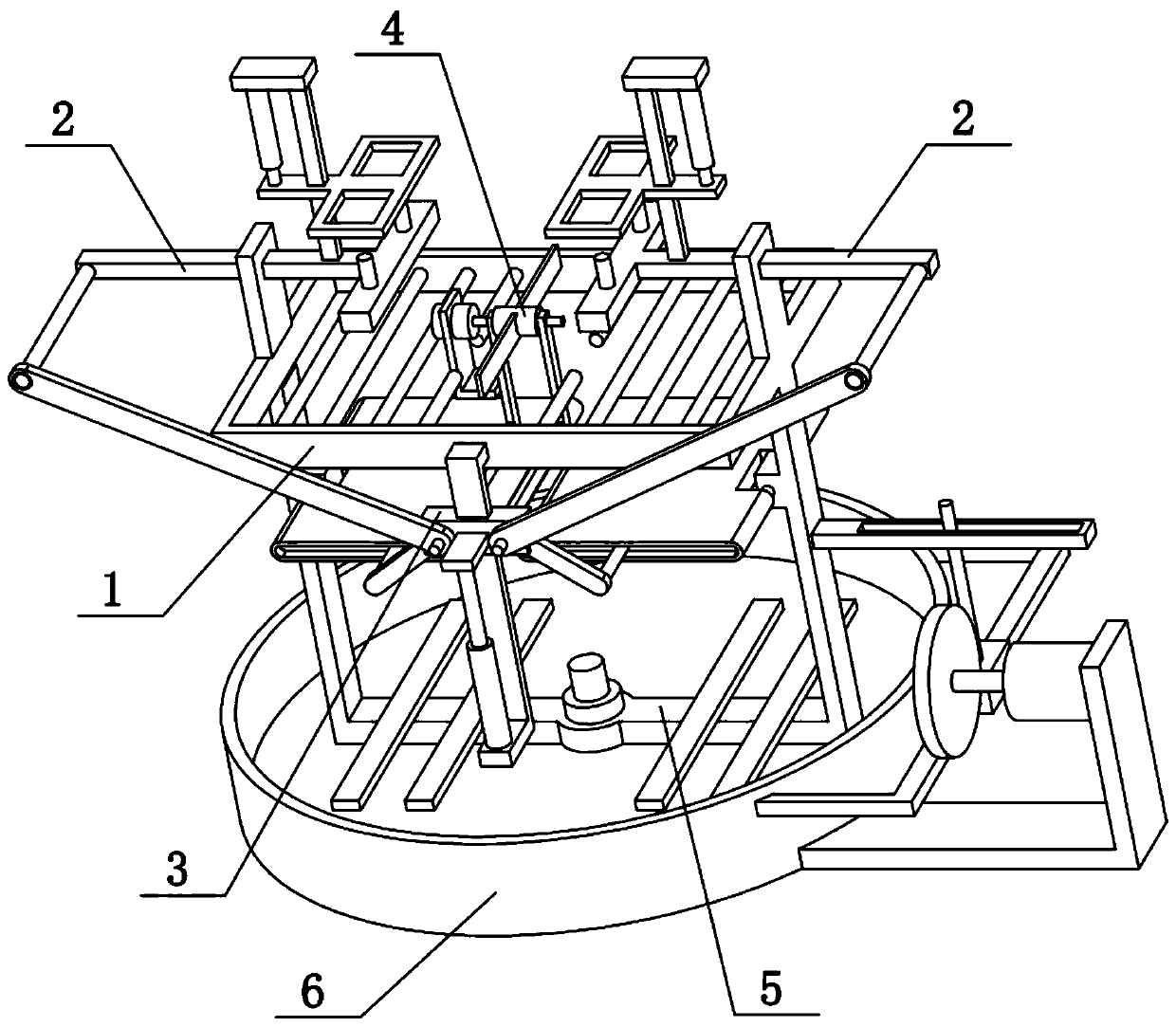

Anti-blocking seed filling structure and method for agricultural precision sowing device

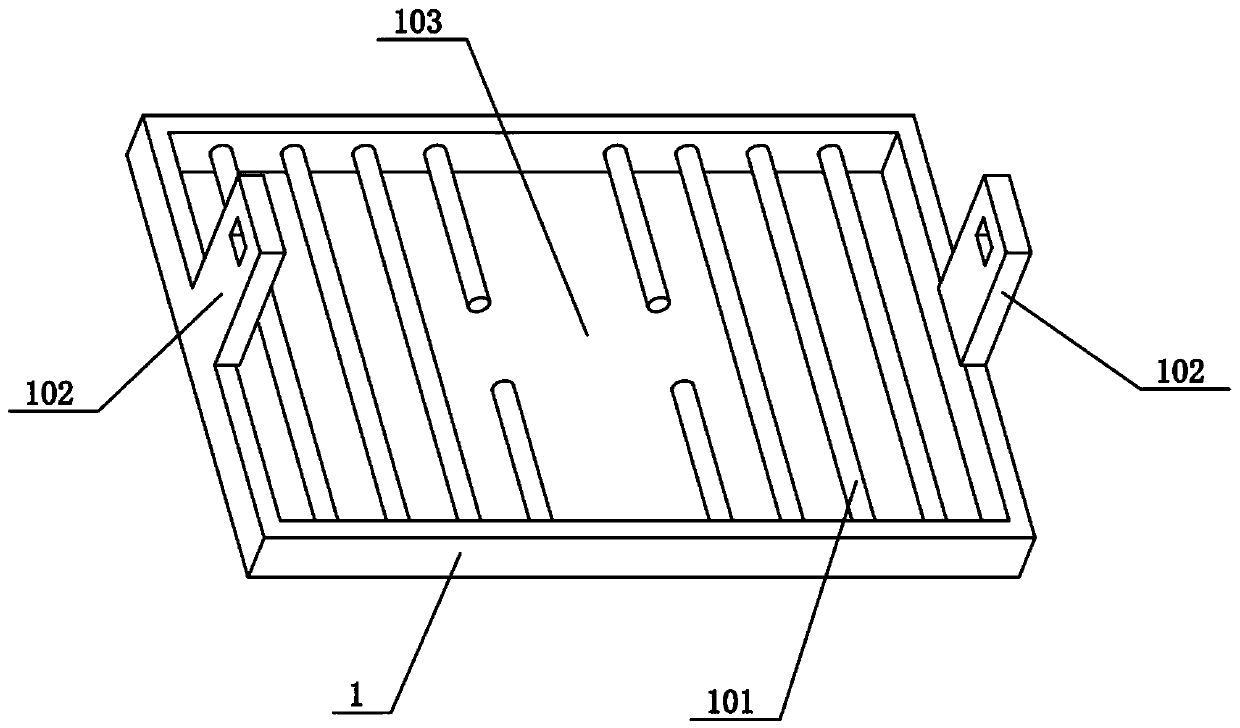

ActiveCN111480429AAvoid cloggingGuaranteed normal dropSeed depositing seeder partsAgricultural engineeringMechanical engineering

The present invention discloses an anti-blocking seed filling structure for an agricultural precision sowing device. The seed filling structure comprises a seed filling sieve, an upper baffle plate, alower baffle plate, a cleaning mechanism and a controller, a plurality of shaped holes are arranged on in a bottom plate of the seed filling sieve in a square array arrangement; the upper baffle plate is attached to an upper side of the seed filling sieve; a first groove part, corresponding to each row of the shaped holes, is formed in the upper baffle plate; the lower baffle plate is attached toa lower side of the seed filling sieve; a second groove part, corresponding to each row of the shaped holes, is formed in the lower baffle plate; the cleaning mechanism is arranged on the upper baffle plate and used for cleaning the shaped holes in the bottom plate to prevent blocking; and the controller connects a first driving element and a second driving element. By arranging the cleaning structure, all the shaped holes can be cleaned by the cleaning structure when seeds are unloaded after each seed filling, the seeds in all the shaped holes are ensured to fall off, the shaped holes are effectively prevented from being blocked by the seeds, and the precision sowing machine is stable in operation and less in fault.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Air pipe component of shot blasting machine

InactiveCN103042472AReduce dropGuaranteed normal dropAbrasive machine appurtenancesGrinding/polishing apparatusEngineeringBlasting machine

The invention provides an air pipe component of a shot blasting machine, and relates to surface treatment equipment, in particular to air pipes of a shot blasting machine dust removal system. The air pipe component comprises two air pipes and is characterized by further comprising a blind window; the air inlet end of the air pipe I is connected with an air intaking port, the opening of the air outlet end of the air pipe I is formed on a side surface of a lifting cylinder of a hoist; on the lifting cylinder, the opening of the air inlet end of the air pipe II is formed on a side surface relative to the opening of the air outlet end of the air pipe I, and the air outlet end of the air pipe II is connected with a dust remover; and on the lifting cylinder, the opening of the air inlet end of the air pipe II is lower than the opening of the air outlet end of the air pipe I, and the opening of the air inlet end of the air pipe II is provided with the blind window. The air pipe component has the advantages that the steel shots in the air pipes can be collected, the air discharge amount is not influenced, the height of the dust remover can be reduced, and the dust in a lifter can be purified.

Owner:YANCHENG FENGTE CASTING MACHINERY

Particle medicine leakage medicine device

PendingCN110667902AHeight clearance adjustmentGuaranteed accuracyWrappingSolid materialMedicineEngineering

The invention discloses a particle medicine leakage medicine device, and belongs to the technical field of particle medicine leakage medicine devices. The particle medicine leakage medicine device canalso ensure that the medicine is discharged one every time for medicine of different thicknesses. The particle medicine leakage medicine device comprises a medicine box, a discharging port is formedin the bottom wall of the medicine box, a material leakage mechanism is rotationally arranged in the medicine box, a material leakage port is formed in the corresponding discharging port of the material leakage mechanism, a positioning port located above the discharging port is formed in the side wall of the medicine box, a fixing frame is arranged on the outer side of the positioning port, a plurality of placing openings are formed in the outer side of the positioning port, a baffle is detachably arranged in the placing opening, the baffle extends into the medicine box and then contacts withthe outer wall of the material leakage mechanism.

Owner:上海林康医疗信息技术有限公司

Ashtray capable of clamping cigarette end conveniently

InactiveCN103494330AEasy to holdGuaranteed normal dropTobacco devicesEngineeringMechanical engineering

The invention discloses an ashtray capable of clamping a cigarette end conveniently. The ashtray comprises a cylindrical tray body with an upper end opening. Two supporting rods are arranged on the edge of the upper surface of the tray body. The included angle between the two supporting rods is 5-10 degrees. The two supporting rods are arranged on the edge of the upper surface of the tray body, the included angle between the two supporting rods is 5-10 degrees, and accordingly a user can clamp various cigarettes with different thicknesses, which are lighted and not smoked up, the fact that ash falls into the tray body is guaranteed, an object storage box is arranged on the side face of the tray body of the ashtray, small objects can be placed conveniently, and accordingly a table top can be clean.

Owner:冯芳兰

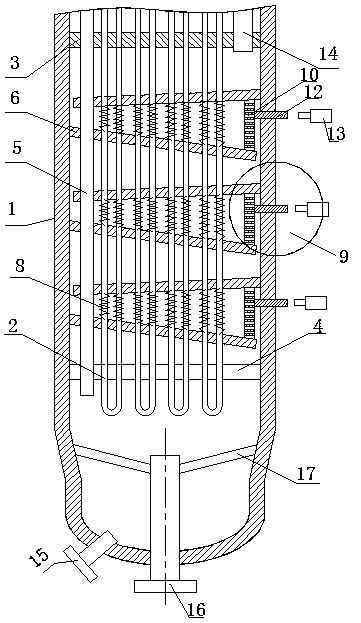

Silicone fluidized bed reactor with vibrating baffle plates

ActiveCN109529733AAvoid accumulationSave time and costChemical/physical processesNuclear engineeringFluidized bed

The invention discloses a silicone fluidized bed reactor with vibrating baffle plates. The silicone fluidized bed reactor comprises a cylindrical shell, a heat exchange tube in the cylindrical shell and a silicon powder feeding tube, at least one baffle device is arranged in the cylindrical shell, the baffle device comprises a baffle plate a and a baffle plate b, the oblique directions of the baffle plate a and the baffle plate b are opposite to each other, an area formed by the two baffle plates has one large end and one small end, and an elastic member is arranged between the baffle plate aand the baffle plate b. The structure of the reactor allows most of generated silicone gas to flow in the fluidized bed reactor in a zigzag direction. Compared with conventional reactors achieving I-shaped flow, the reactor in the invention has the advantages of long reaction time, sufficiency in the reaction of a chloromethane gas and silicon powder, significant reduction of the required height,rapid reduction of the content of the silicon powder under the layer barrier of the baffle plates, ensuring of the purity of the product silicone gas, and avoiding of deposition of the silicon powderthrough driving the baffle plates to vibrate by a driving device.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

Rotary granulation preparation method

The invention discloses a rotary granulation preparation method. A main body is included, a driving part is arranged in the middle of the right side of the top of the main body, a granulating device is arranged on the left side of the top of the main body, and a feeding hopper is arranged in the middle of the top of the granulating device; and a connecting body is fixedly connected to the position, located at the bottom of the right side of the granulating device, of the top of the main body, and a control panel is fixedly connected to the left side of the top of the front face of the connecting body. The invention relates to the technical field of granulation equipment. According to the rotary granulation preparation method, raw materials can be directly treated; a reinforcing part is arranged between a granulation mechanism and a fixing frame, so that the interior is conveniently and accurately controlled, and uniform and consistent output of granules is guaranteed; through connection between an auxiliary mechanism and a protective shell, the situation that the raw materials are scattered in the device is avoided; and small holes in the surface of a transition plate can protect internal parts, so that an internal space is conveniently limited, and the purpose of fully heating the interior is achieved.

Owner:王坤

Building sand mixer

ActiveCN111298691AEasy to pourEasy to pull and tearShaking/oscillating/vibrating mixersTransportation and packagingArchitectural engineeringBaluster

The invention relates to the field of buildings, in particular to a building sand mixer which comprises a rectangular frame, handrails, protruding plates, transverse sliding columns, protruding pins and lower seat rods and can facilitate pouring of sand out of a package. The plurality of handrails are evenly distributed on the rectangular frame from left to right, the protruding plates are fixedlyconnected to the left end and the right end of the upper side of the rectangular frame, the transverse sliding columns are transversely connected to the two protruding plates in a sliding mode, the lower seat rods are fixedly connected to the inner ends of the two transverse sliding columns, and two protruding pins are fixedly connected to the upper side of each of the two lower seat rods. The upper sides of the transverse sliding columns are fixedly connected with stand columns, lifting pieces are vertically connected to the stand columns in a sliding mode, pressing plates are fixedly connected to the inner ends of the lifting pieces, square holes are formed in the front end and the rear end of the pressing plate, and the two square holes are located above the two corresponding protruding pins respectively. One end of each electric push rod I is fixedly connected to the upper portion of the corresponding stand column, and the other end of each electric push rod I is fixedly connectedto the corresponding lifting piece.

Owner:安徽良策建工集团有限公司

Air curtain type cotton flow turning and impurity removing device

PendingCN107227514AWon't happenBlock deliveryFibre cleaning/opening machinesAgricultural engineeringStructural engineering

An air curtain type cotton flow diversion and miscellaneous removal device, including a cotton feeding pipe, a nodding flap, a nodding pipe and a connecting sleeve. The nodding flap is hinged on the connecting sleeve. The plate covers the blanking hole tightly, and the upper end surface of the waste flap coincides with the inner cavity surface of the cotton delivery pipe. A high-pressure air curtain generator is arranged on the upper surface of the cotton delivery pipe. The air pressure of the high-pressure air curtain is greater than that in the cotton delivery pipe. The material conveying air pressure, the noil flap is driven by the rotating mechanism, and the high-pressure air curtain and the noil flap rotating mechanism are controlled by the electric control device. It changes the principle of blocking the cotton flow from the cotton delivery tube to the nodding tube, which can effectively block the problematic cotton flow from entering the nodding tube. It will only fall into the miscellaneous removal box and will not cause a fire. At the same time, the conversion speed of the miscellaneous removal and blanking is fast, which eliminates the hanging at the miscellaneous discharge port and eliminates the risk of systemic fires in the cotton delivery pipe.

Owner:AMP TECHNOLOGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com