Milling machine and control method of milling machine

A milling machine and milling technology, which is applied in the control of milling machines and in the field of milling machines, can solve problems such as smashing people and vehicles around, spilling waste materials, and misoperation, so as to ensure the output position of materials and realize automatic control , Guarantee the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

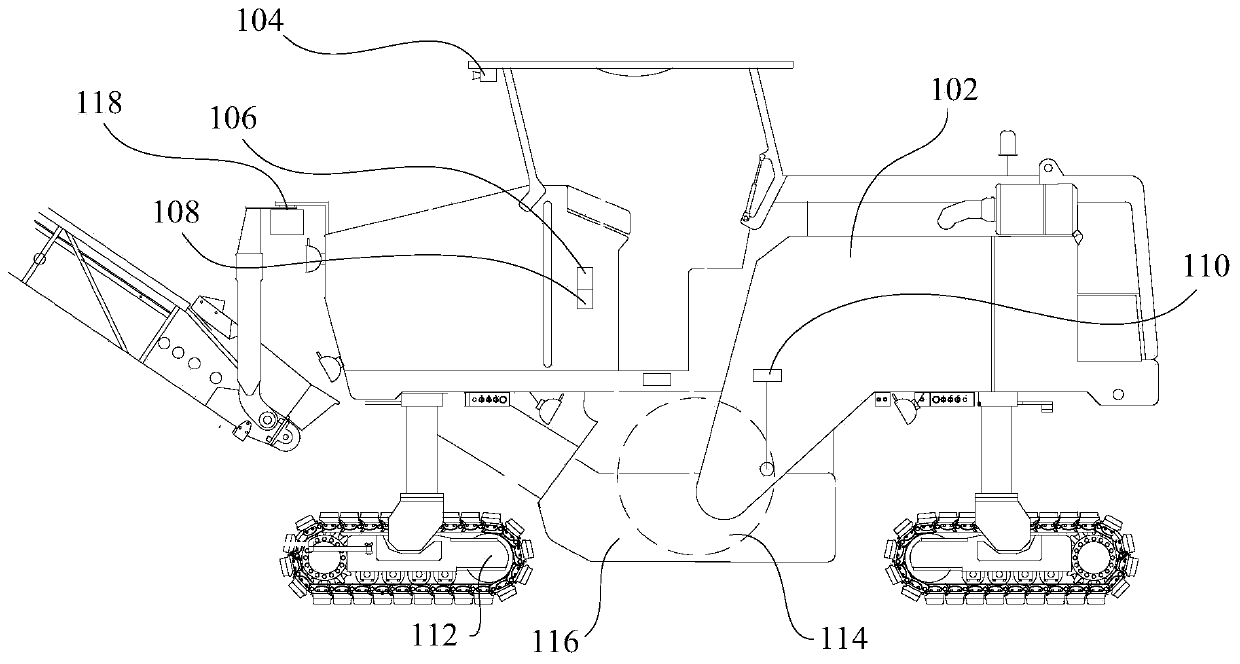

[0052] like figure 1 As shown, the first embodiment of the present invention provides a milling machine, including: a body 102 , a feeding device, an image processing device and a main controller 108 .

[0053] Among them, the milling machine is used in conjunction with the feeding car, the milling machine is used for milling the ground, and the materials generated by the milling are transported to the feeding car through the feeding device, and the feeding car is used for conveying the materials.

[0054] The image processing device can obtain the position of the feeding cart, and judge the relative speed of the feeding cart and the milling machine according to the position change of the feeding cart, and the image processing device can also obtain the cross-sectional size of the hopper of the feeding cart.

[0055] The main controller 108 is electrically connected with the image processing device. After obtaining the cross-sectional size of the hopper, the main controller 10...

Embodiment 2

[0064] like figure 1As shown, the second embodiment of the present invention provides a milling machine, including: a body 102 , a feeding device, an image processing device, a detection device and a main controller 108 .

[0065] Among them, the milling machine is used in conjunction with the feeding car, the milling machine is used for milling the ground, and the materials generated by the milling are transported to the feeding car through the feeding device, and the feeding car is used for conveying the materials.

[0066] The image processing device can obtain the position of the feeding cart, and judge the relative speed of the feeding cart and the milling machine according to the position change of the feeding cart, and the image processing device can also obtain the cross-sectional size of the hopper of the feeding cart.

[0067] The main controller 108 is electrically connected with the image processing device. After obtaining the cross-sectional size of the hopper, th...

Embodiment 3

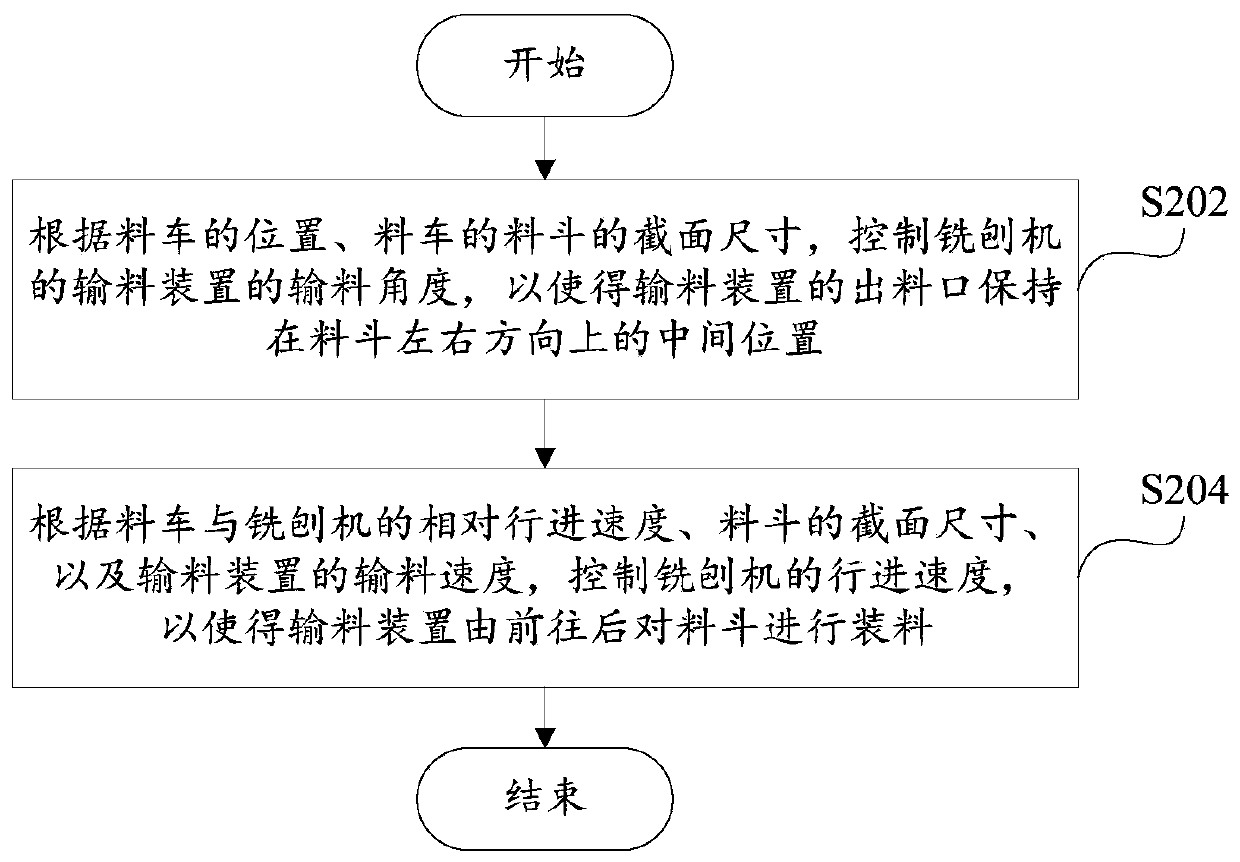

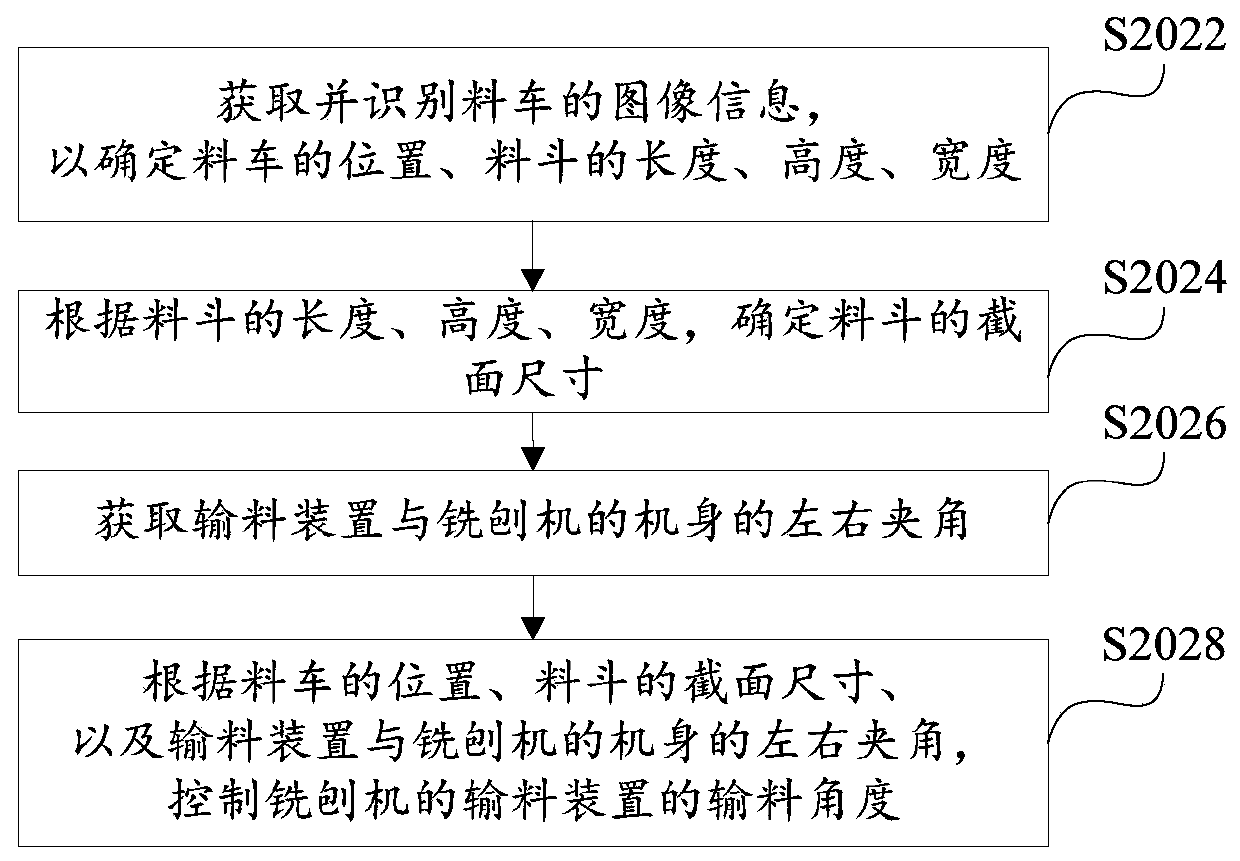

[0075] figure 2 It is a schematic flowchart of a control method of a milling machine according to an embodiment of the present invention, such as figure 2 As shown, the control method of the milling machine includes:

[0076] Step 202, according to the position of the feeding car and the cross-sectional size of the hopper of the feeding car, control the feeding angle of the feeding device of the milling machine, so that the outlet of the feeding device is kept at the middle position in the left and right direction of the hopper;

[0077] Step 204, according to the relative traveling speed of the feeding car and the milling machine, the cross-sectional size of the hopper, and the feeding speed of the feeding device, control the traveling speed of the milling machine, so that the feeding device can load the hopper from front to back .

[0078] The control method of the milling machine proposed in this embodiment firstly obtains the position of the feeding car and the cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com