Silicone fluidized bed reactor with vibrating baffle plates

A silicon fluidized bed and baffle technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of time-consuming and labor-intensive, irregular cleaning, easy accumulation on baffles, etc. Time and labor costs, the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

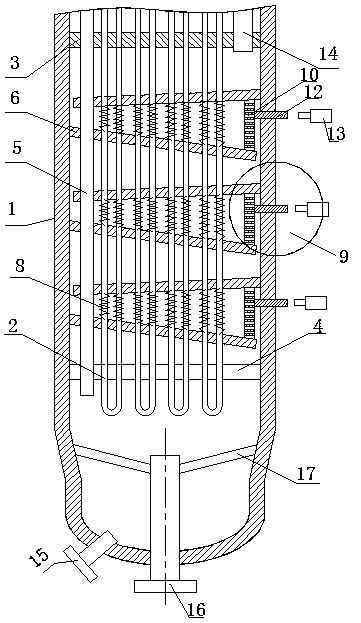

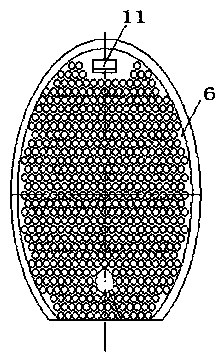

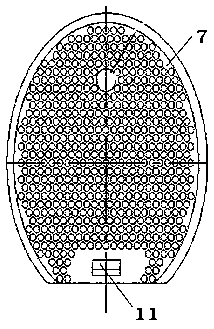

[0029] Such as Figure 1-7 Shown, a kind of organosilicon fluidized-bed reactor with vibrating baffle plate comprises cylinder body 1, heat exchange tube 2 and silicon powder feed pipe 5 in cylinder body 1, and in said cylinder body 1 The upper and lower ends are respectively fixedly connected to the solid fixed tube sheet 3 and the hollowed-out fixed tube sheet 4, and the heat exchange tube 2 and the silicon powder feeding tube 5 are fixedly connected to the solid fixed tube sheet 3 and the hollowed-out fixed tube sheet 4, There are five groups of baffle devices in the cylinder 1, the baffle devices include baffle a6 and baffle b7, and the heat exchange tube 2 and the silicon powder feed pipe 5 pass through the baffle a6 and the baffle b7 respectively. The baffle b7, the baffle a6 and the baffle b7 are arranged in opposite directions, and the area formed by the two is large at one end and small at the other end. The angle α between them is 35°, the baffle a6 and the baffle b...

Embodiment 2

[0034] Such as Figure 8 As shown, compared with Example 1, the further improvement of Example 2 is the top baffle a6 and the solid type Elastic parts 8 are also provided between the fixed tube sheets 3 and between the bottom baffle b7 of the bottom set of baffle devices and the hollowed-out fixed tube sheet 4. The advantage of this solution is to increase the baffle a6 and fold The vibration between the flow plates b7 has a better vibration effect and better avoids the accumulation of silicon powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com