Air curtain type cotton flow turning and impurity removing device

An air curtain type, cotton flow technology, applied in the direction of fiber opening and cleaning machine, etc., can solve the problems of easy friction and fire, damage to the wind pressure of the cotton conveying pipe 1, overload mechanical damage, etc., to prevent collision friction and ignition, and ensure cotton conveying work. Pressure, the effect of solving sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

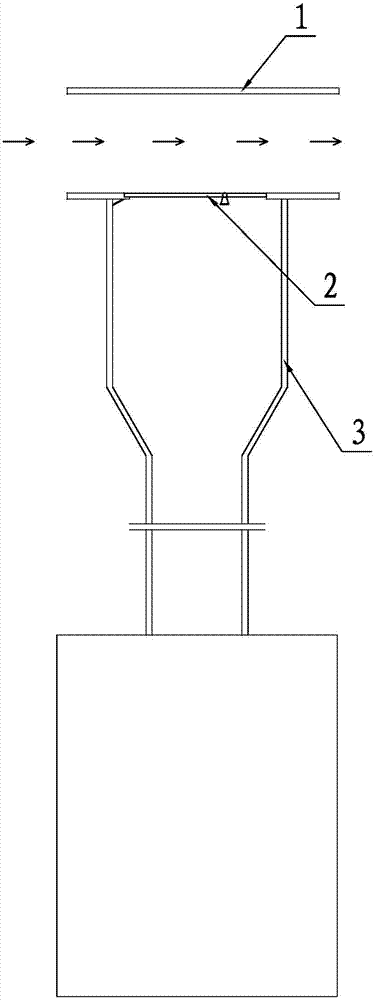

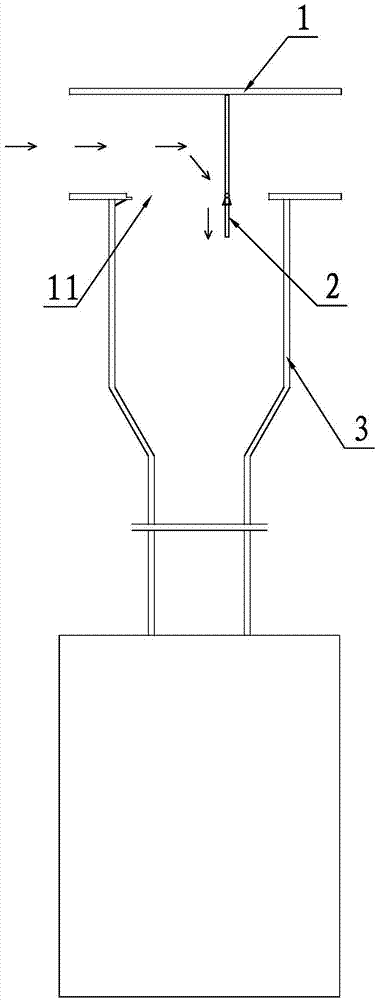

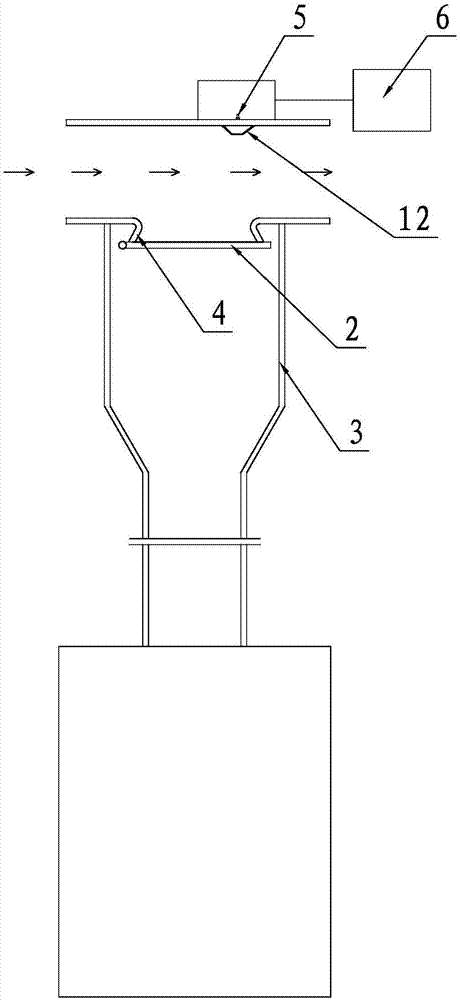

[0039] An air curtain type cotton flow diversion device, such as Figure 3 ~ Figure 5As shown, it includes a cotton feeding pipe 1, a waste flap 2, a cotton feeding pipe 3 and a high-pressure air curtain generator. The cotton feeding pipe 1 is arranged horizontally, and a feeding hole 11 is opened at the bottom of the cotton feeding pipe 1. The upper end of the cotton feeding tube 1 is sealed with the lower end surface of the cotton feeding tube 1 along the axial direction of the cotton feeding tube 1, and the upper port of the cotton feeding tube 3 communicates with the inner cavity of the cotton feeding tube 1 through the blanking port 11 of the cotton feeding tube 1. The inner cavity of the cotton pipe 3 communicates with the inner cavity of the cotton delivery pipe 1 through the blanking opening 11. The maximum aperture of the blanking opening 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com