Single-plant high-precision full-automatic threshing system based on combination of scraping type and rolling type

A fully automatic, high-precision technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve the problems of insufficient precision, insufficient automation, high threshing and shell breaking rate, and achieve low shell breaking rate and solve the problem of threshing The effect of high shell breaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

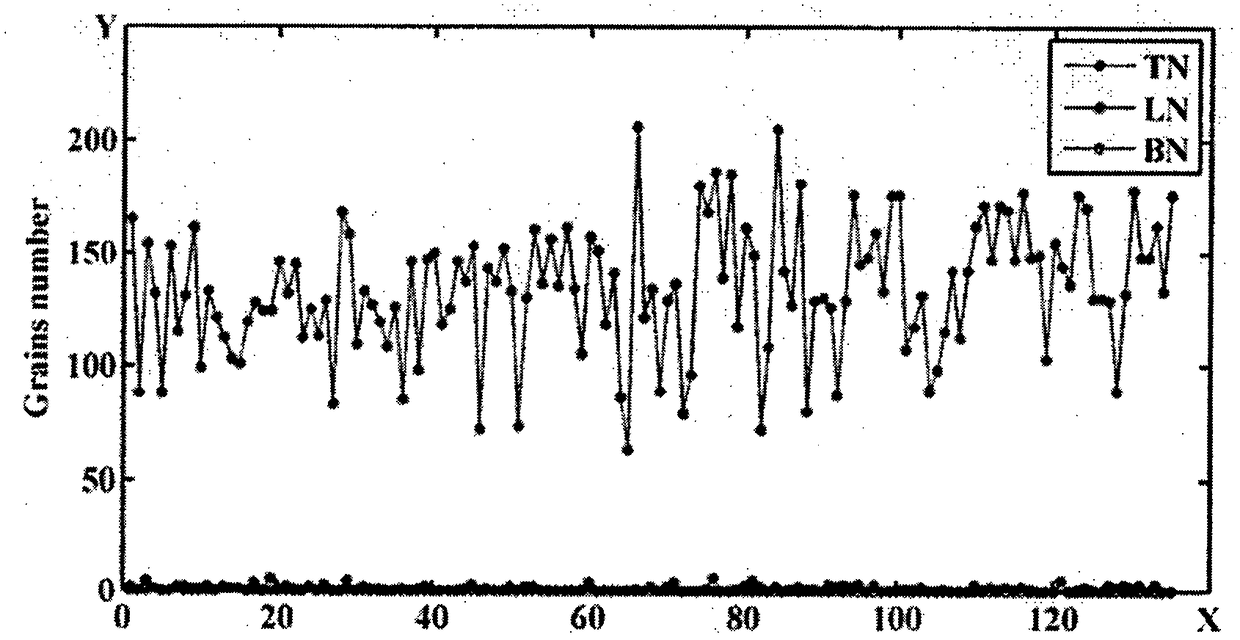

[0021] Randomly select 135 rice ears, cut the ears and dry them in the sun, then put the rice ears into the threshing system for threshing, collect the grains from the grain collection device, the shriveled grain collection device and the branch recovery device respectively, calculate and analyze all The total number of grains (TN), the number of unshed grains (LN), the number of broken grains (BN), the attached instructions Figure 5 It is the result of the test of the present invention. The average threshing error (ATLP) and average threshing damage rate (ABTP) of the system were statistically analyzed, and the average threshing error of the threshing system was about 0.87%, and the threshing damage rate was about 0.05%. It can be seen that the threshing system meets the threshing requirements of automation, high precision and high efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com