Injection molding machine with demolding detecting device

A detection device and injection molding machine technology, applied in the field of injection molding machines, can solve problems such as low work efficiency, high risk, and slow speed, and achieve the effects of improving operation stability, easy installation and maintenance, and good operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

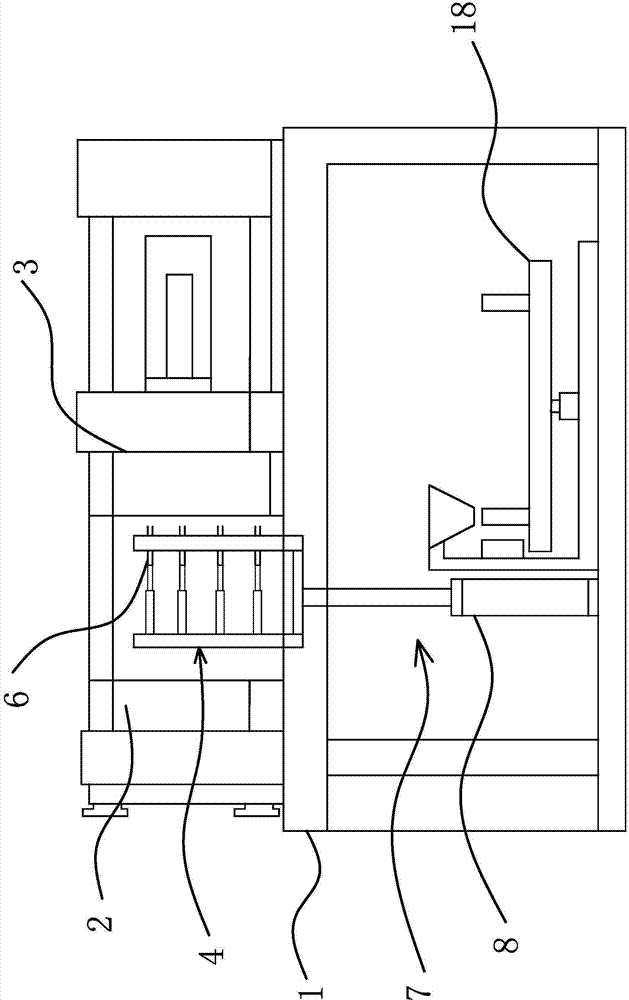

[0031] Such as figure 1 As shown, the injection molding machine with a demoulding detection device includes a base 1 on which a fixed template 2 and a movable template 3 are arranged. The fixed template 2 and the movable template 3 are connected by a tie rod, and the movable template 3 and the fixed template 2 are closed. A plurality of mold cavities for forming plastic bottle caps are formed, and the opening of the plastic bottle cap is set outward after the plastic bottle cap is formed.

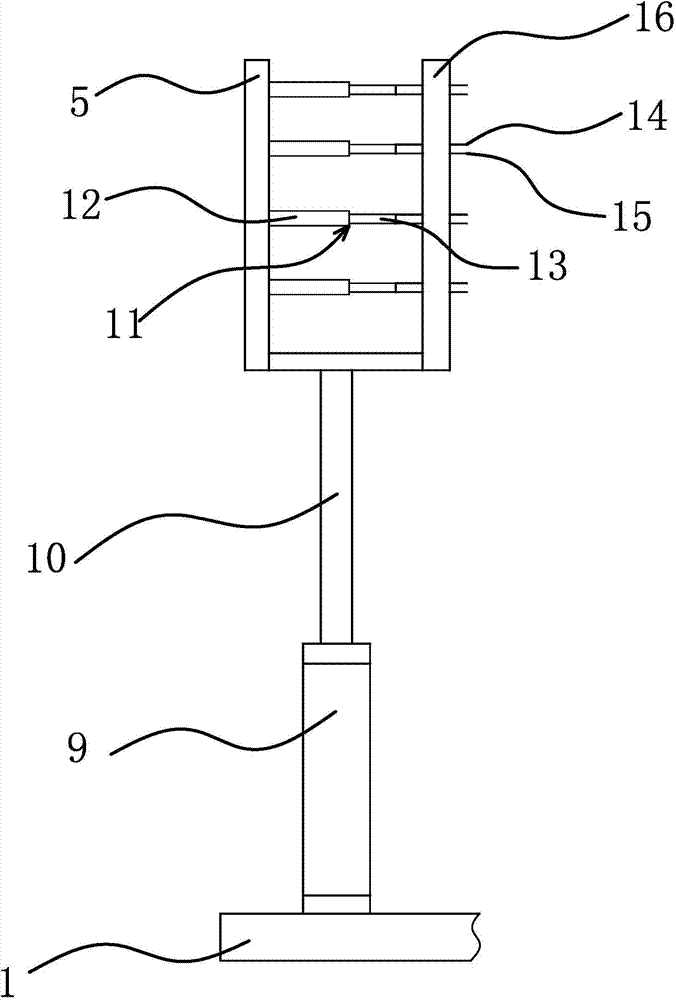

[0032] Such as figure 1 , figure 2 As shown, this injection molding machine also includes a pick-up device 4, and the pick-up device 4 includes a pick-up plate 5, and the pick-up plate 5 is provided with a clamping structure 6 that can fix or loosen the plastic bottle cap. A lifting mechanism 7 capable of driving the pick-up plate 5 to move up and down reciprocatingly is provided. Lifting mechanism 7 among the present embodiment comprises several cylinders one 8 that are arranged in ver...

Embodiment 2

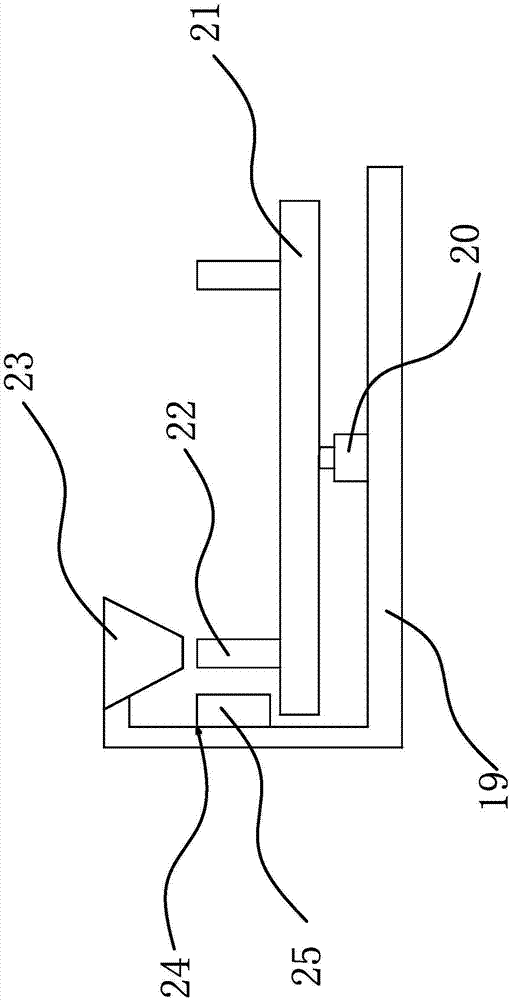

[0037] Such as Figure 4 , Figure 5 As shown, this embodiment is roughly the same as Embodiment 1, the difference is that a fixing seat 26 is provided at the outer end of the piston rod 10 in this embodiment, and a cylinder 3 27 is arranged on the fixing seat 26 along the horizontal direction. , cylinder three 27 comprises cylinder body three and piston rod three, and the inner end of piston rod three is inserted in cylinder body three and can do telescopic reciprocating motion, and the outer end of piston rod three is fixed on the pick-up plate 5, and pick-up plate 5. A cylinder 28 is arranged along the horizontal direction. The cylinder 28 includes a cylinder body 28 and a piston rod 4. The inner end of the piston rod 4 is inserted in the cylinder body 4 and can perform telescopic reciprocating motion. The outer end of the piston rod 4 is fixed There is a baffle plate 29 parallel to the pick-up plate 5, the clamping structure 6 includes several tweezers, the tweezers inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com