Continuous automatic smoke dust and smoke monitoring apparatus

An automatic monitoring and flue gas technology, applied in the direction of measuring devices, sampling devices, sampling, etc., can solve the problems of particles bouncing back or blowing away, low collection efficiency, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

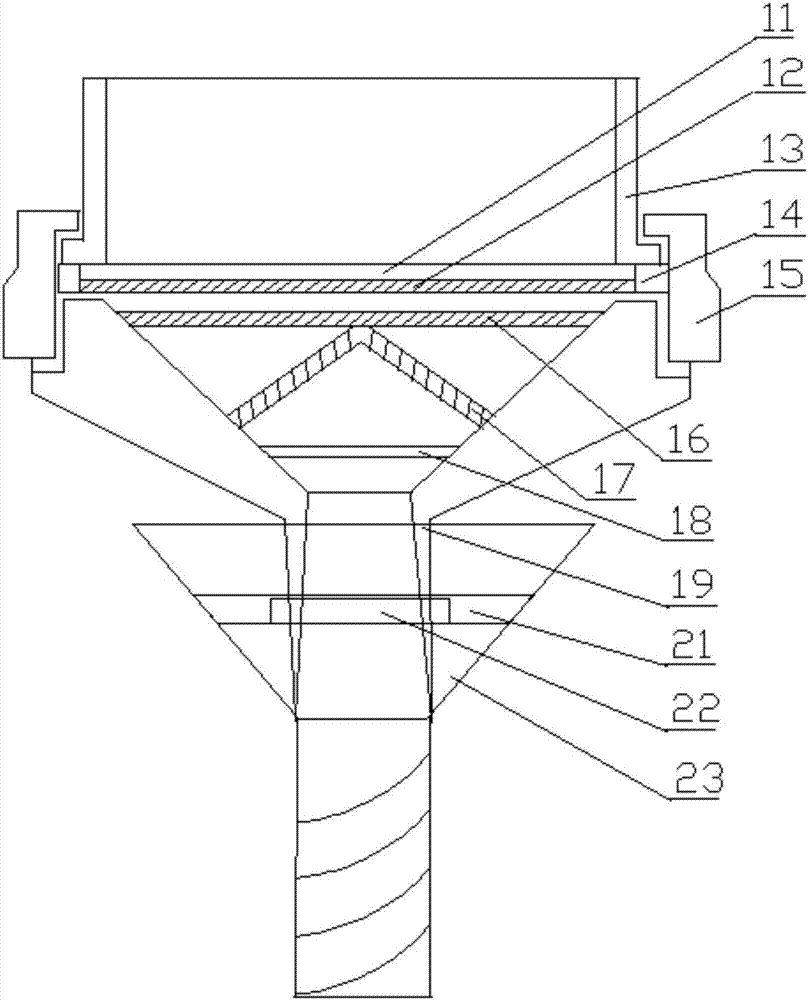

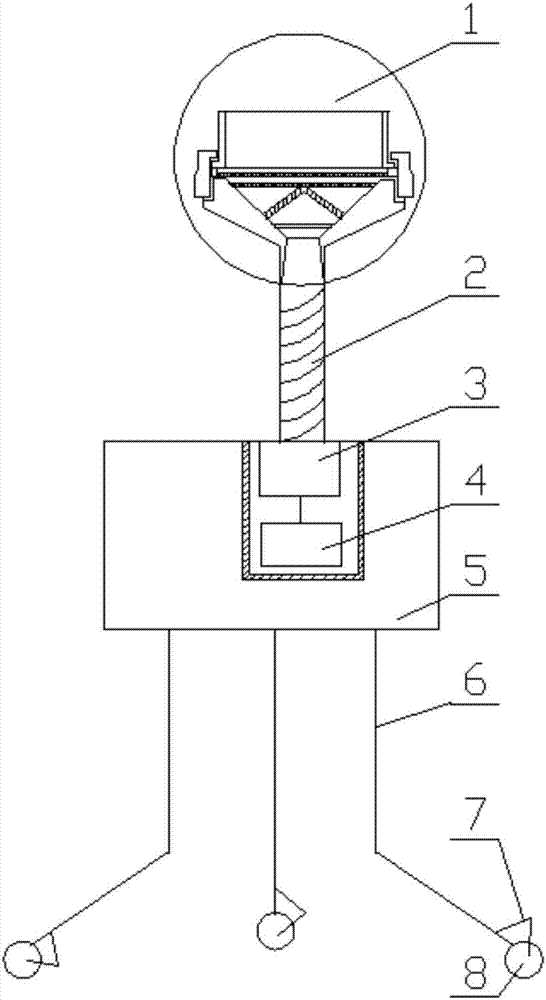

[0020] Such as figure 1 and figure 2 As shown, a continuous automatic monitoring device for smoke, dust and smoke includes a filter material sampling clip 1, a connecting piece 23 and a supporting part, the filter material sampling clip 1 is connected to the upper side of the supporting part, and the connecting part 23 is sleeved on the filter The connection between the material sampling clip 1 and the support member is connected through soft materials; the filter material sampling clip 1 includes a seat ring 13, a fastening ring 15 and an interface 19, and the inside of the seat ring 13 is sequentially arranged from top to bottom. The first filter membrane 11 and the support net 12 are set; the interface 19 is bucket-shaped, and the upper end of the interface 19 and the lower end of the seat ring 13 are in closed contact with the sealing ring 15, and the contact between the interface 19 and the seat ring 13 is arranged outside Fastening ring 15, the edge of the mouth of the...

Embodiment 2

[0024] The difference between this embodiment and Embodiment 1 is that the third filter screen 17 is in the shape of an inverted bucket, its apex is fixed on the second filter screen 16, and its edge is fixed on the edge between the second filter screen 16 and the fourth filter screen 18. On the inner wall of the interface 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com