Automobile wind sand test workshop for automobile performance test

A test workshop and test room technology, applied in the field of automobile sandstorm test workshop, can solve the problems of time-consuming and manpower-consuming, and the size of sandstorm cannot be controlled artificially, so as to improve fluidity and avoid agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

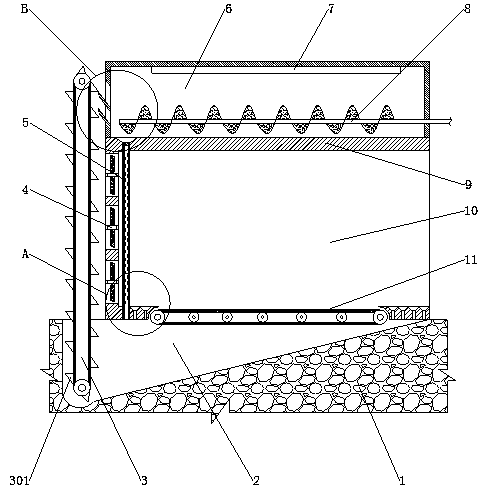

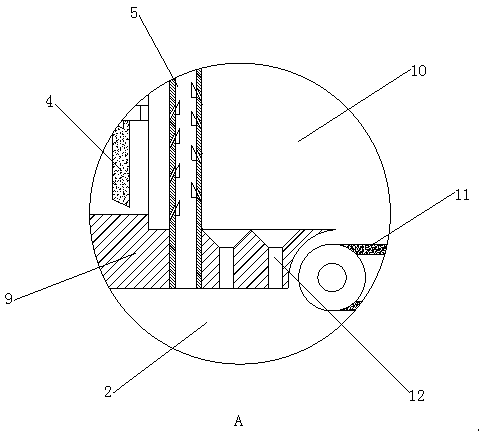

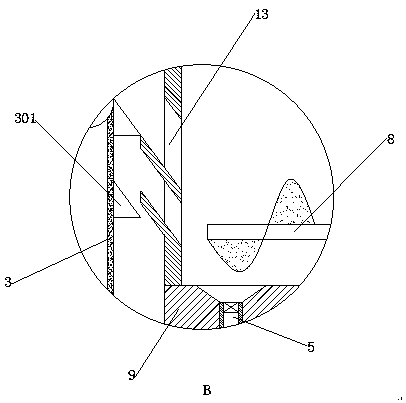

[0028] as attached figure 1 to attach Image 6 Shown:

[0029] The present invention provides an automobile sandstorm test workshop for automobile performance testing, comprising a foundation 1, a sand collection chamber 2, a lifting belt 3, a lifting bucket 301, a fan 4, a sand leakage pipe 5, a deflector slant plate 501, and a sand leakage hole 502 , sand storage room 6, infrared heating pipe 7, stirring shaft 8, wall body 9, test room 10, driving belt 11, floor drain 12, sand inlet 13, sand collection room 2 is opened inside the foundation 1, and the top of the foundation 1 Fixedly connected with body of wall 9, the inside of body of wall 9 is test room 10, and the ground of test room 10 is provided with driving belt 11, and the outer peripheral ground of driving belt 11 is all provided with floor drain 12, and the bottom of floor drain 12 and sand collection chamber 2 In the same way, fans 4 are installed on the three walls 9 around the test room 10, and the sand leakage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com