Automatic pipe cutter

A pipe cutting machine, automatic technology, applied in the direction of pipe shearing device, shearing device, shearing machine accessories, etc., can solve the problems of increased manufacturing cost, and achieve the effect of reduced manufacturing cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

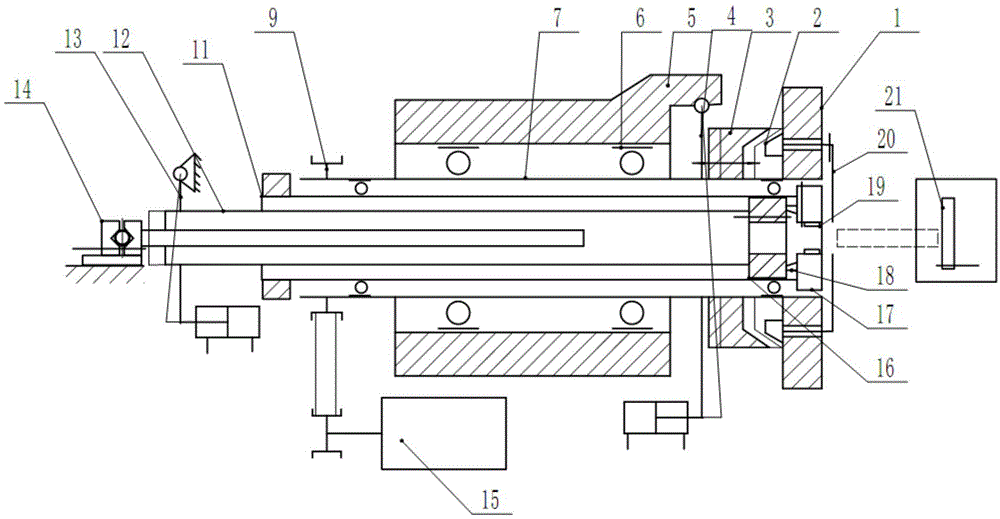

[0021] Such as figure 1 An automatic pipe cutting machine shown includes a feeding mechanism 14, a body 5, a hollow shaft sleeve 7, a chuck type clamping mechanism, a cutting mechanism and a limit backer 21; the feeding mechanism 14 is arranged at one end of the body 5, It is used to transport the pipe to be cut to the chuck-type clamping mechanism; the chuck-type clamping mechanism is located in the sleeve 7 and is used to clamp and lock the pipe to be cut; the sleeve 7 is set on the body 5 It is driven by a motor to rotate inside; the cutting mechanism is connected with the sleeve 7 and rotates with the sleeve 7 to cut the pipe to be cut; the limit backer 21 is set at the other end of the body 5 to control the length of the cut pipe ; One end of the chuck type clamping mechanism is provided with a clamping push rod 13; one end of the clamping push rod 13 is connected with a fixed pivot shaft, and the other end is connected with a cylinder; The radial displacement of the jaw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com