Anti-blocking seed filling structure and method for agricultural precision sowing device

An anti-blocking and precise sowing technology, which is applied to the parts of the seeder, can solve the problems of hole blockage, high failure rate, affecting the filling structure and unloading operation, etc., and achieves the effect of stable operation and less failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

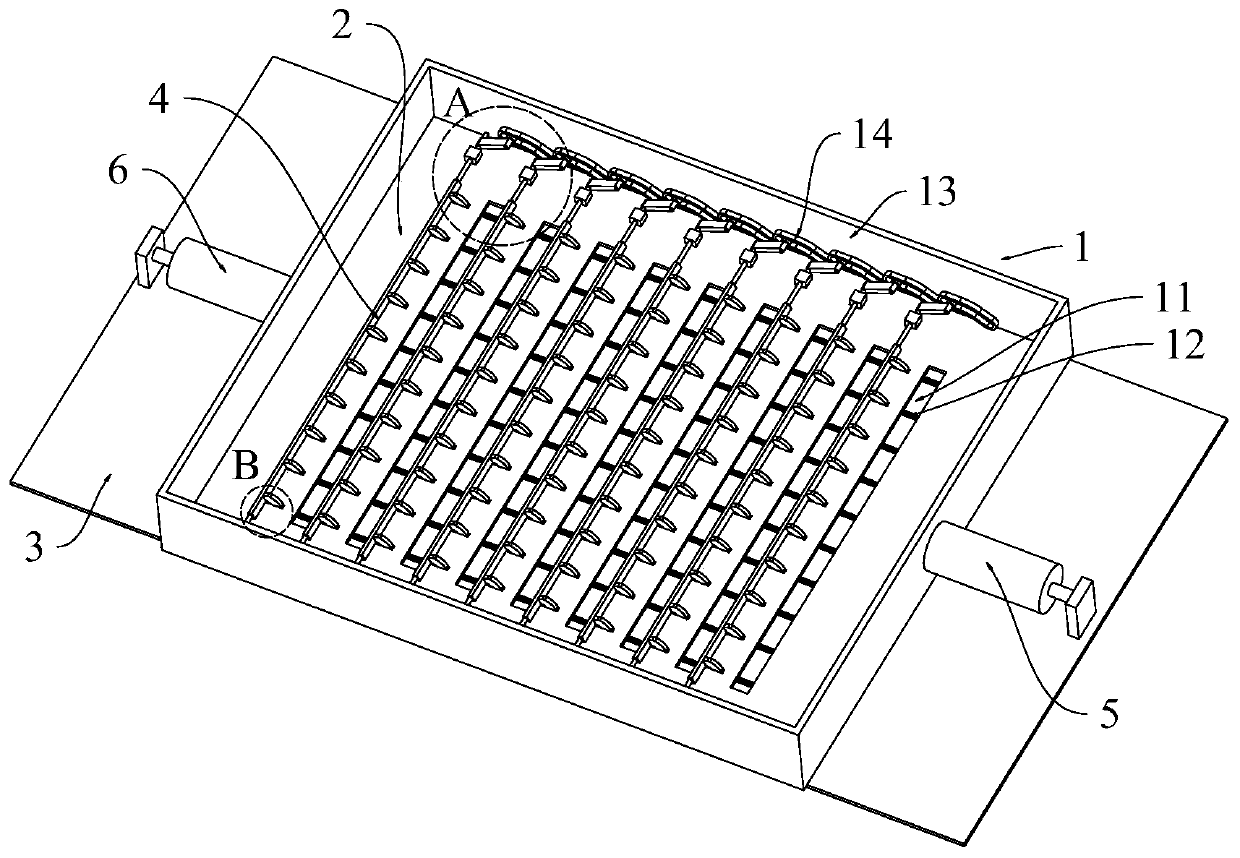

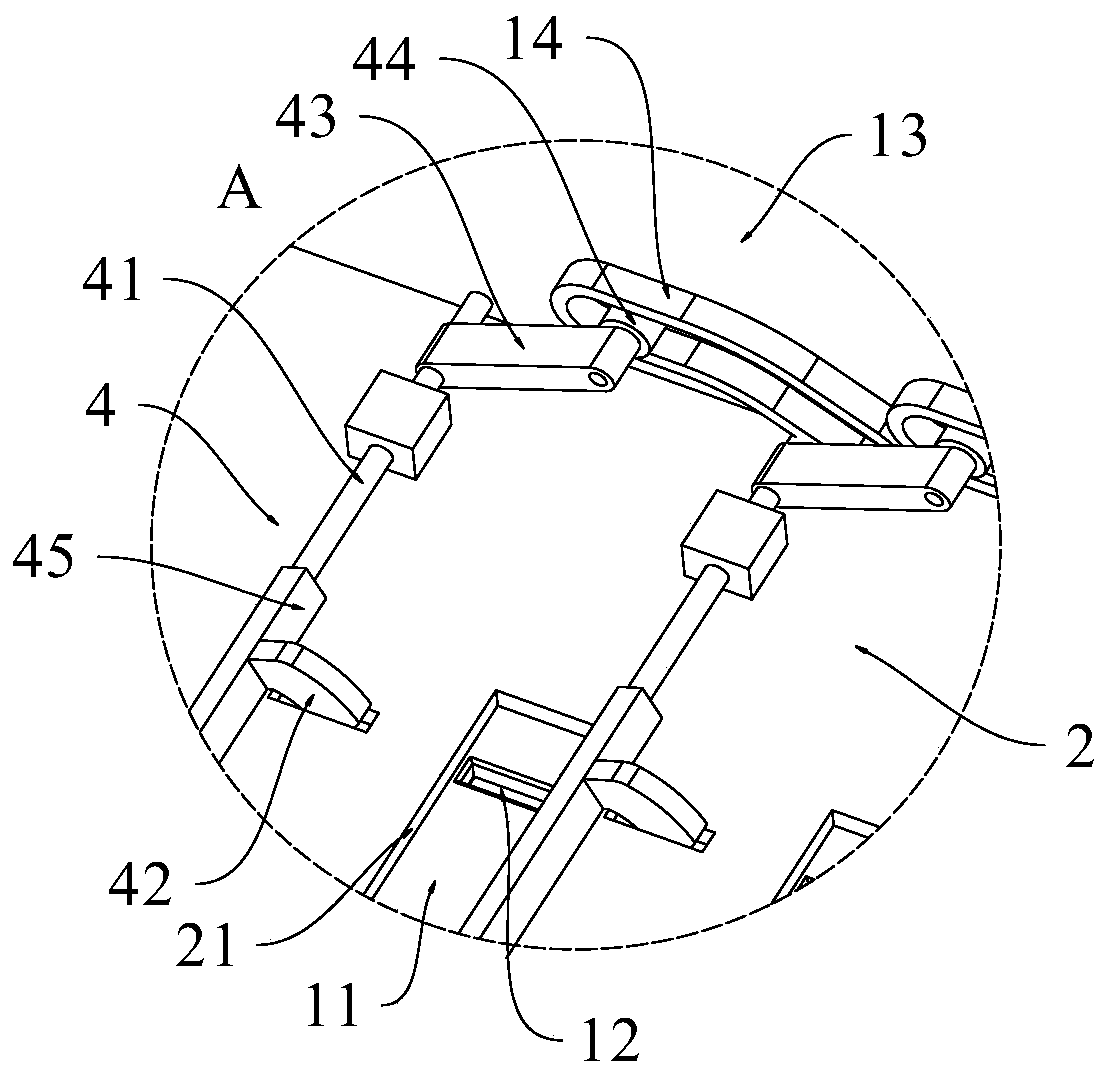

[0031] as attached figure 1 with attached figure 2 The anti-blocking seed filling structure of the agricultural precision sowing device shown includes a seed filling screen 1, an upper baffle 2, a lower baffle 3, a cleaning mechanism 4 and a controller.

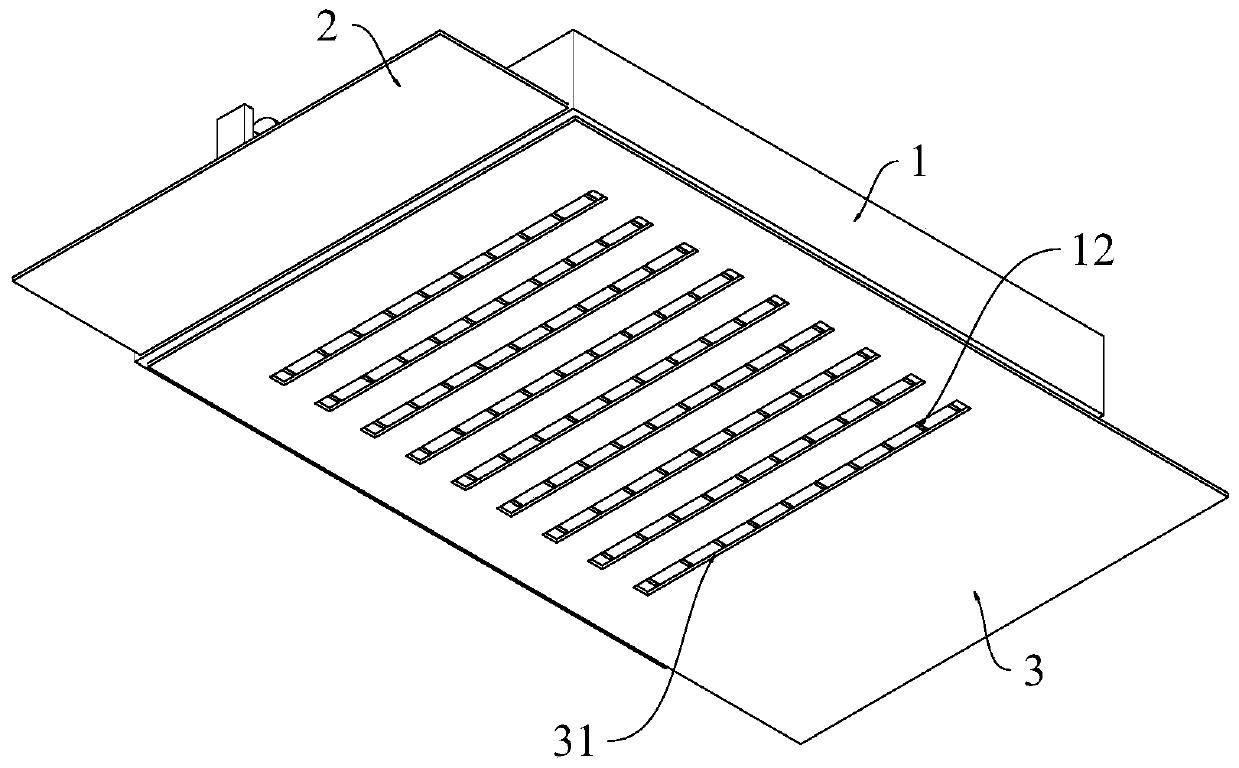

[0032] Wherein, the bottom plate 11 of the seed-filling screen 1 is provided with a plurality of type holes 12 in a square array; The seed-filling screen 1 slides; a first groove 21 is formed corresponding to each column of the type holes 12; the lower baffle plate 3 is installed against the lower side of the seed-filling screen 1, and it can be formed by the first Two driving elements 6 drive to slide relative to the described seed filling screen 1; a second groove portion 31 is formed corresponding to each column of the type holes 12; the cleaning mechanism 4 is installed on the upper baffle plate 2 for Clean up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com