Oxygen producer for increasing coal burn-off rate

A technology of burnout rate and oxygenation agent, which can be used in fuel, solid fuel, petroleum industry, etc., and can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

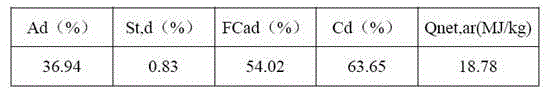

Embodiment 1

[0057] Potassium permanganate 15%;

[0058] Petroleum coke powder 35%;

[0061] Activated Charcoal 15%.

[0062] Weigh the above components, and then mix them evenly to make oxygen enhancer.

Embodiment 2

[0064] Potassium permanganate 18%;

[0065] Petroleum coke powder 34%;

[0068] Activated Charcoal 14%.

[0069] The preparation steps are the same as in Example 1.

Embodiment 3

[0071] Potassium permanganate 20%;

[0072] Petroleum coke powder 34%;

[0074] Sodium chloride 16%;

[0075] Activated Charcoal 15%.

[0076] The preparation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com