A high-efficiency gasification incinerator

An incinerator, high-efficiency technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of air pollution, environment, sanitation pollution, promotion and other problems, and achieve the effect of sufficient combustion and high combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

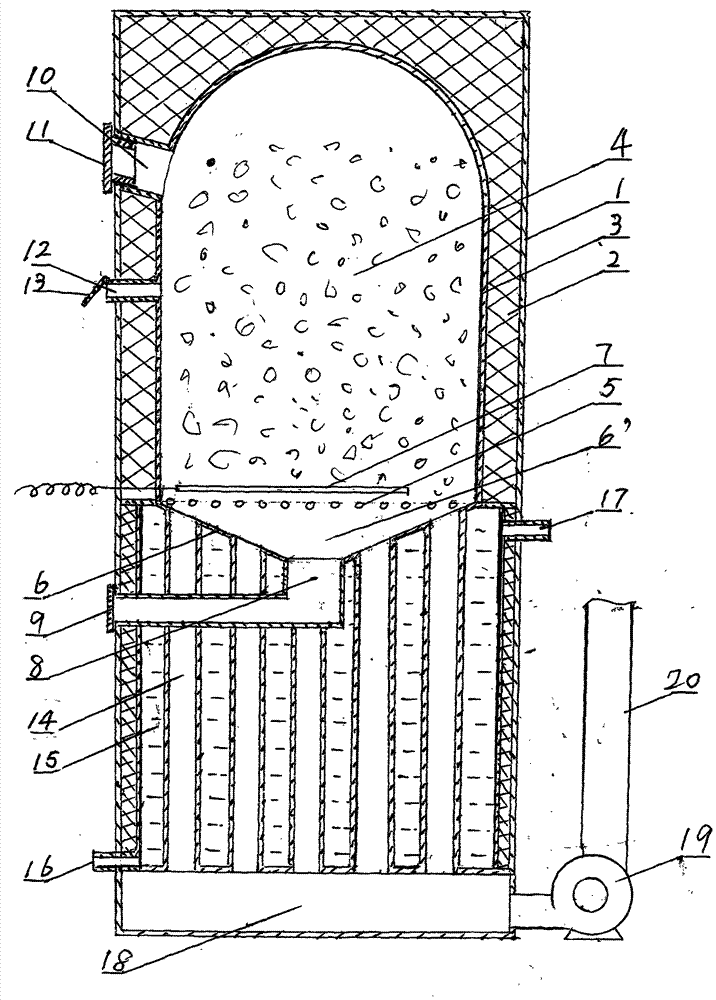

[0010] attached figure 1 It is a specific embodiment of the present invention, and its structural features are described below in conjunction with the accompanying drawings.

[0011] The structure of the furnace includes a furnace body 1, which can be in the shape of a cylinder or a square column. There is an insulation layer 2 inside the furnace shell, and a furnace 3 is arranged in the insulation layer. , One side of the upper part of the retort gasification chamber of the furnace is provided with a charging port 10, and the charging port is equipped with a movable tight cover 11, which will be sealed after charging. One side of the furnace retort gasification chamber is provided with a breeze air inlet hole 12 and an air inlet opening adjustment cover 11 . At the beginning of ignition, the regulating cover is fully opened, and as the combustion gradually becomes normal, its opening degree is gradually closed. A furnace grate 5 is arranged at the lower part of the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com