A vertical U-shaped structure oil-fired gas boiler with burner overhead

A gas-fired boiler and burner technology, which is applied to steam boilers, water heaters, fluid heaters, etc., can solve the problems of low heat transfer enhancement capacity, increase near-wall disturbance, and expensive land costs, and achieve an increase in the average heat transfer rate. Heat coefficient and heat transfer area, reduction of steel consumption and boiler manufacturing cost, effect of reduction in footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

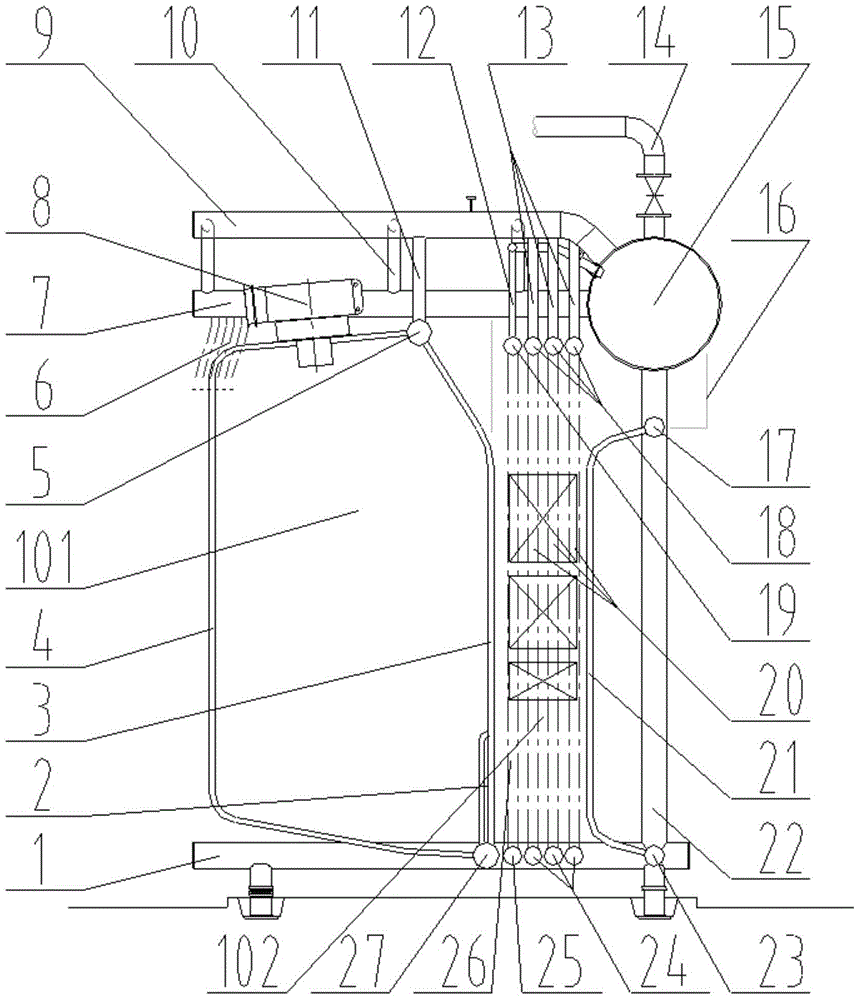

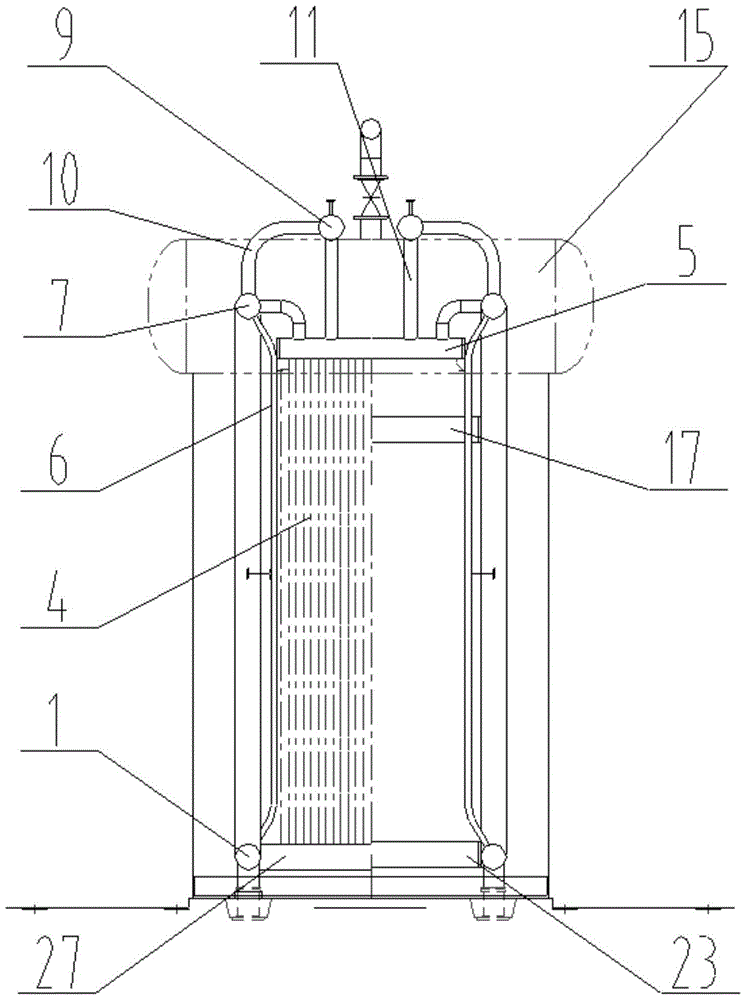

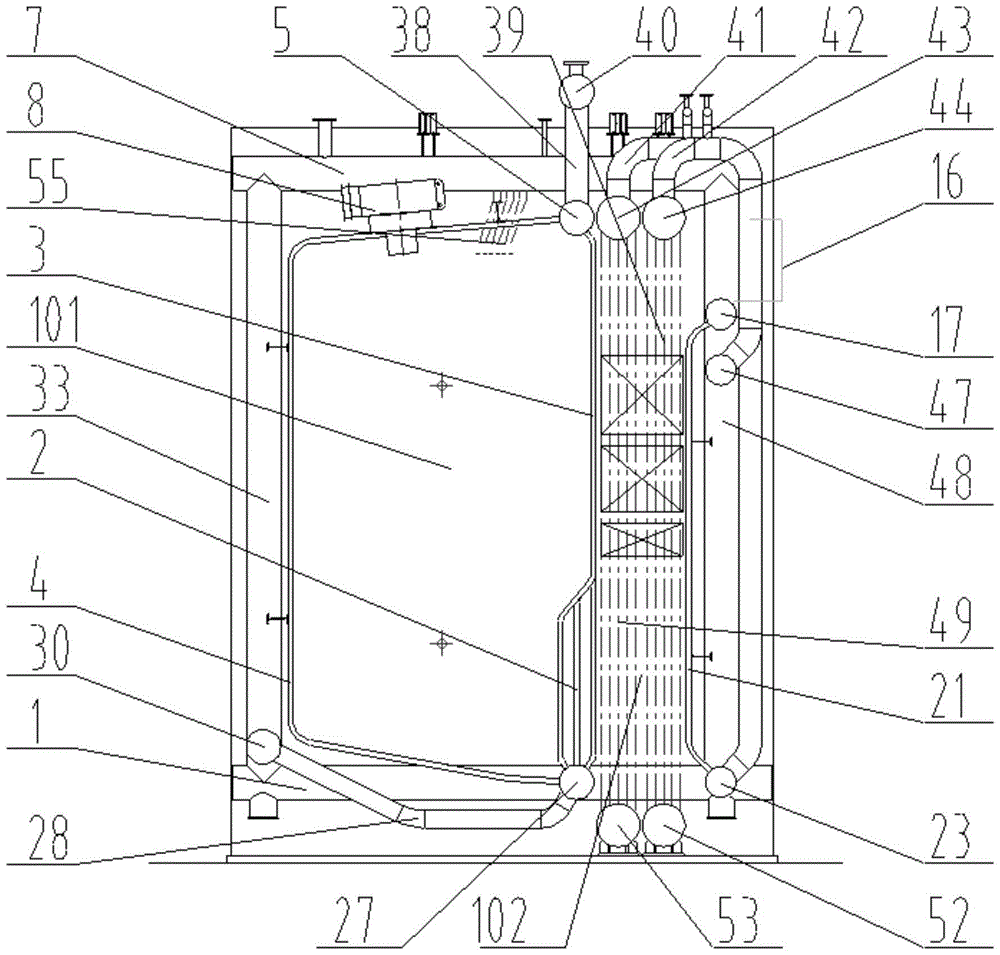

[0033] The present invention is a vertical U-shaped structure oil-fired gas boiler with a burner on the top, and its steam furnace structure diagram is as follows figure 1 and figure 2 As shown in the figure, the radiation heating surface of the furnace is all made of flat steel and smooth tubes, and the convection tube bundle is all made of plate-fin-strengthened tube-panel convection heating surfaces, and the centerline of the burner is perpendicular to the front wall of the furnace Type water wall, arranged vertically. It includes a furnace 101 and a convection shaft 102 arranged behind the furnace 101. Above the furnace 101, a header 7, a steam separation tube group 10, a steam collector 9, Furnace front and rear wall water cooling wall collection header box 5, second connecting pipe 11, plate-fin economizer tube bundle collection box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com