Combustion intensifying device in furnace

A combustion device and combustion chamber technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve problems such as easy to emit black smoke, insufficient combustion of domestic waste, etc., and achieve the goals of protecting the environment, reducing operating costs, and reducing workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

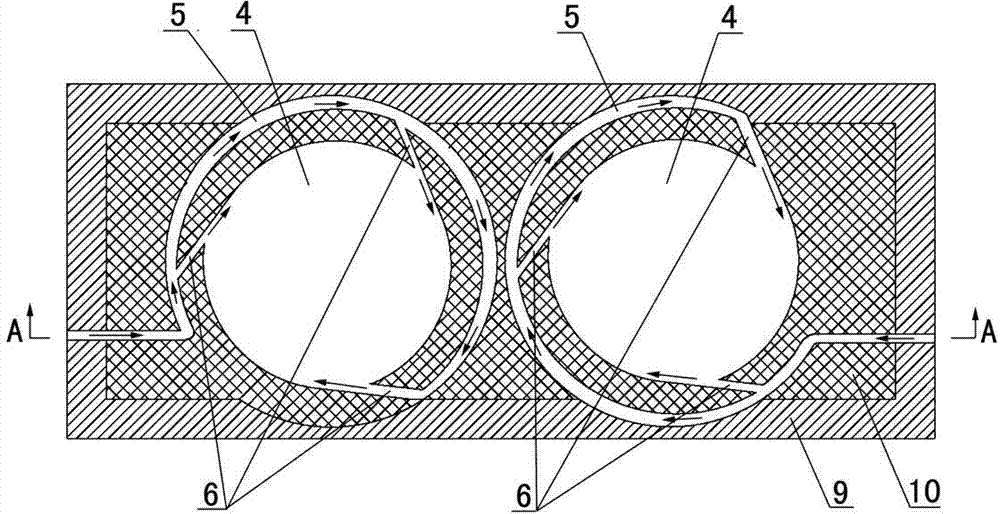

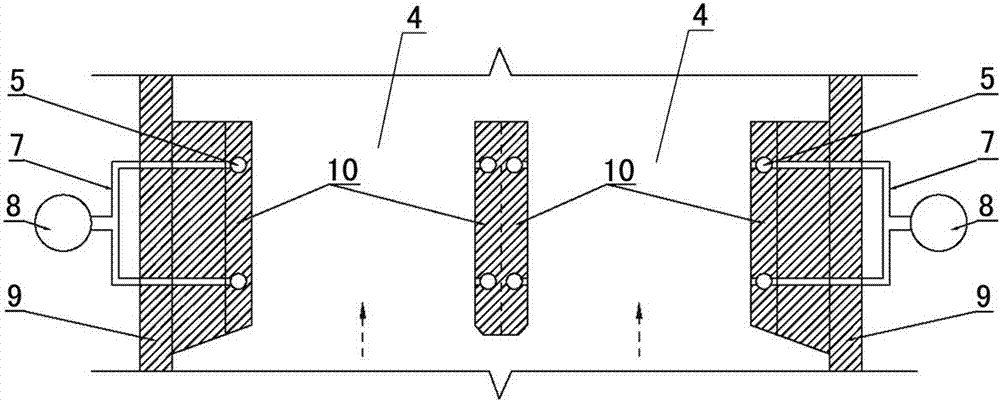

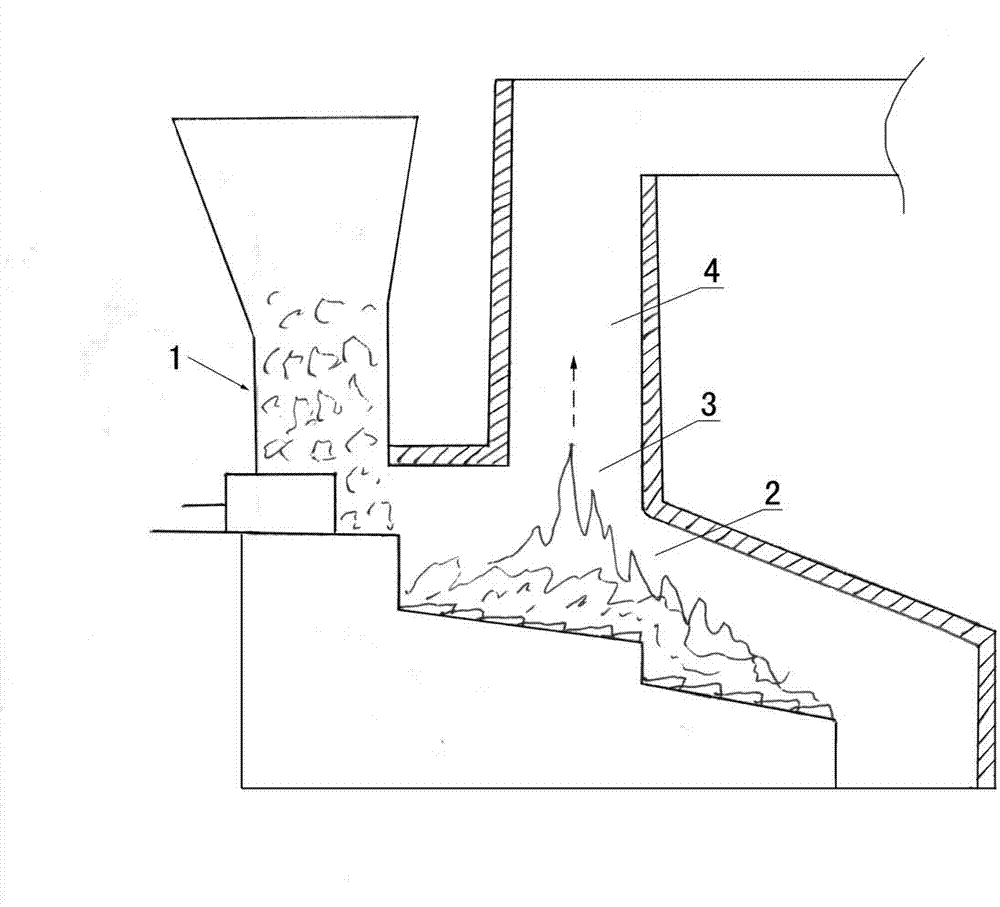

[0022] Examples see Figure 1-3 As shown, this intensified combustion device in the furnace is arranged on the fire outlet 3 of the first combustion chamber 2 of the mechanical grate type domestic waste incinerator 1, including the second combustion chamber wall, the second combustion chamber located inside the second combustion chamber wall chamber, and the oxygen fan 8 positioned outside the wall of the second combustion chamber.

[0023] The second combustion chamber is composed of two cylindrical strong combustion chambers 4, the bottom of the strong combustion chamber 4 communicates with the first combustion chamber 2 through the fire outlet 3, and the top of the strong combustion chamber 4 communicates with the waste heat boiler.

[0024] The wall body of the second combustion chamber is provided with a turbulent oxygen delivery channel, which includes an annular oxygen delivery channel 5 and three tangential oxygen injection channels 6 uniformly distributed along the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com