Calcium aluminate powder for water treatment agent and preparation method thereof

A technology of calcium aluminate powder and water treatment agent, which is applied in water/sewage treatment, water/sludge/sewage treatment, alkaline earth metal aluminate/alumina/aluminum hydroxide preparation, etc., which can solve the dissolution rate of alumina Low cost, poor practicability, complicated preparation and other problems, to achieve the effects of shortening the sintering time, easy melting and crystallization, and lowering the calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A calcium aluminate powder for water treatment agent, the weight ratio of raw materials of bauxite (60% by mass of alumina), limestone and borax is 60:30:1.

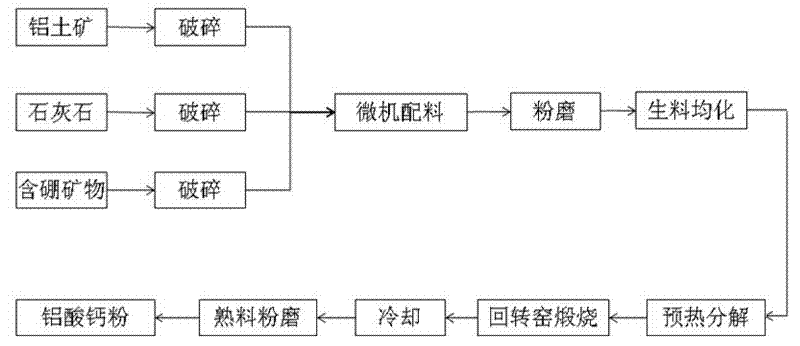

[0024] The preparation method of above-mentioned calcium aluminate powder, technological process sees figure 1 ,Specific steps are as follows:

[0025] 1) The bauxite, limestone, and borax are subjected to coarse crushing and secondary crushing in the jaw crusher and double-roller crusher respectively to obtain pellets with a particle size of 5 mm, and then put the pellets into a ball mill according to the above weight ratio to mix Grind evenly to obtain 180 mesh raw meal;

[0026] 2) Send the raw meal into the preheating device, the temperature of the tail gas at the kiln tail is 600-900°C, preheat and pre-decompose for 40 minutes;

[0027] 3) The raw meal that has been preheated and pre-decomposed is sent to the rotary kiln for calcination, and the temperature in the kiln is controlled at 1200-1350°C, and sint...

Embodiment 2

[0030] A calcium aluminate powder for water treatment agent, the weight ratio of the raw materials of bauxite (65% by mass of alumina), limestone, borax and boronite is 70:42:0.25:0.25.

[0031] The preparation method of above-mentioned calcium aluminate powder, technological process sees figure 1 ,Specific steps are as follows:

[0032] 1) Perform coarse crushing and secondary crushing of bauxite, limestone, borax, and boronite in the jaw crusher and double-roller crusher respectively to obtain pellets with a particle size of 5mm, and then put the pellets into Mix and grind evenly in a ball mill to obtain 180 mesh raw meal;

[0033] 2) Send the raw meal into the preheating device, the temperature of the tail gas at the kiln tail is 600-900°C, preheat and pre-decompose for 40 minutes;

[0034] 3) The raw meal that has been preheated and pre-decomposed is sent to the rotary kiln for calcination, and the temperature in the kiln is controlled at 1200-1350°C, and sintered for 20...

Embodiment 3

[0037] A calcium aluminate powder for water treatment agent, the weight ratio of the raw materials of bauxite (72% by mass of alumina), limestone, borax, boronite is 80:45:1:1.

[0038] The preparation method of above-mentioned calcium aluminate powder, technological process sees figure 1 ,Specific steps are as follows:

[0039] 1) Perform coarse crushing and secondary crushing of bauxite, limestone, borax, and boronite in the jaw crusher and double-roller crusher respectively to obtain pellets with a particle size of 5mm, and then put the pellets in accordance with the above weight ratio Mix and grind evenly in a ball mill to obtain 180 mesh raw meal;

[0040] 2) Send the raw meal into the preheating device, the temperature of the tail gas at the kiln tail is 600-900°C, preheat and pre-decompose for 40 minutes;

[0041] 3) The raw meal that has been preheated and pre-decomposed is sent to the rotary kiln for calcination, and the temperature in the kiln is controlled at 1200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com