Dehydrated tailing precise blending and forced homogenizing preparation structural flow filling technology and filling system

A kind of tailings and precise technology, which is applied in the direction of filling, mining equipment, earth cube drilling and mining, etc., can solve the problems of inability to adjust the transient error, large fluctuation of filling slurry-cement ratio and mass concentration, and pipeline wear. The effect of low volume utilization, controlling filling quality and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

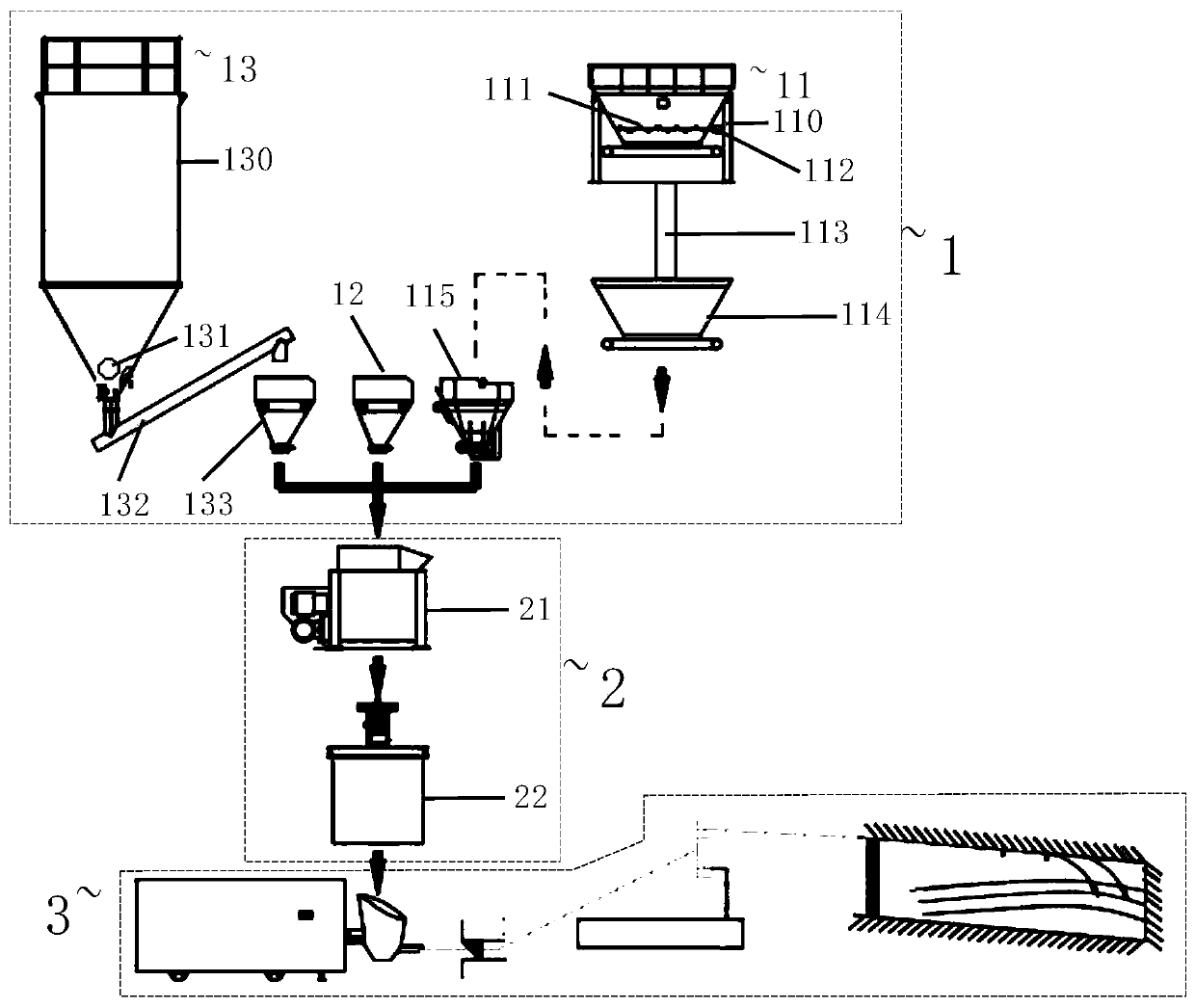

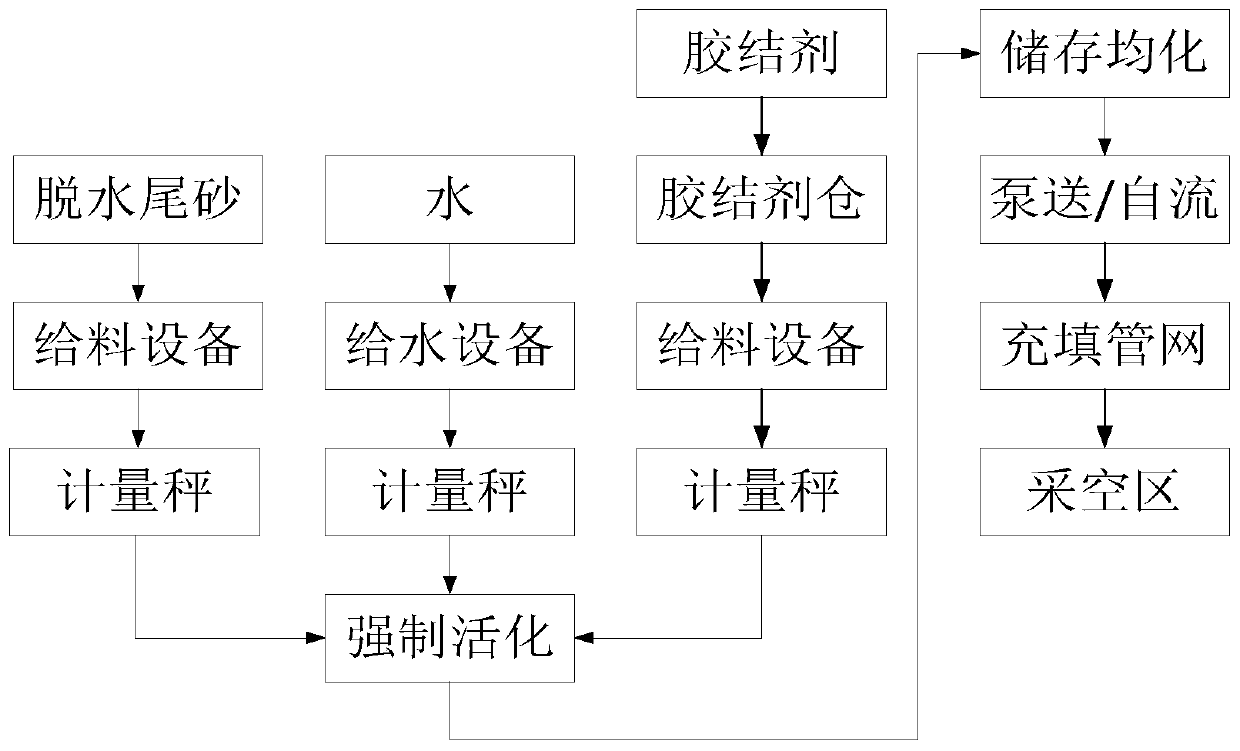

Method used

Image

Examples

Embodiment 1

[0068] 1. Project overview and process parameters

[0069] The mining production scale of the mine is 150,000 tons, the annual operation time is 300 days, and the ore weight is 2.65t / m 3 , the amount of newly added vacant space in mining is 188.68m 3 , calculated according to the settlement rate of 1.05 and the slurry loss coefficient of 1.05, the average daily filling volume is 208m 3 , the annual filling volume is 62,400 m 3 .

[0070] After calculation and combined with the test results of filling materials, the main filling process parameters: flow rate 60m 3 / h; filling concentration ≥ 72%; lime-sand ratio is adjustable from 1:30 to 1:4.

[0071] 2. Filling materials

[0072] (1) Dewatered tailings

[0073] Due to the high degree of ore body concentration, small production scale, small number and small volume of mining goafs, large unbalanced filling coefficient, and concentrated production time of the filling system, in order to solve the gap between the output of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com