Rotary multi-station honing machine special for connecting rod

A rotary, multi-station technology, applied in the direction of honing machine tools, manufacturing tools, metal processing equipment, etc., can solve the problems of consuming human resources, low processing efficiency, difficult to control processing costs, etc., to achieve a compact overall structure and improve production efficiency , to achieve the effect of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

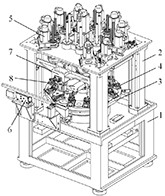

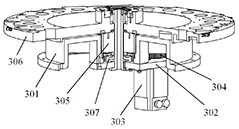

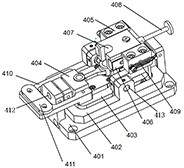

[0022] Such as Figure 1-Figure 6 As shown, the present invention discloses a specific embodiment of a rotary multi-station connecting rod special honing machine, including a fuselage base 1, a column 2, a rotary table 3, a floating fixture 4, a honing processing module 5, a vibration type Automatic feeding device 6, rotary synchronous grasping manipulator 7, clamp switch device 8. The column 2 is fixedly installed on the fuselage base 1, the rotary table 3 is fixedly installed in the center of the fuselage base 1, 12 floating fixtures 4 are installed on the rotary table, and the honing processing module 5 is fixedly installed on the top of the column 2 , The vibrating automatic feeding device 6 is fixedly installed on one side of the fuselage base 1, the rotary synchronous grabbing manipulator 7 is fixedly installed between the two columns 2, and the clamp switch device 8 is fixedly installed on the rotary table 3.

[0023] In the embodiment of the present invention, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com