Method and apparatus for preparing fuel gas or synthetic gas through biomass fluidized bed gasification

A fluidized bed gasification, biomass raw material technology, applied in the direction of gas fuel, granular/powder fuel gasification, fuel, etc., can solve the problems of inability to continuously feed, increase the difficulty of industrial application, and affect the continuity of production, etc. Achieve stable metering and stable transportation, which is beneficial to large-scale gasification and fluidization reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

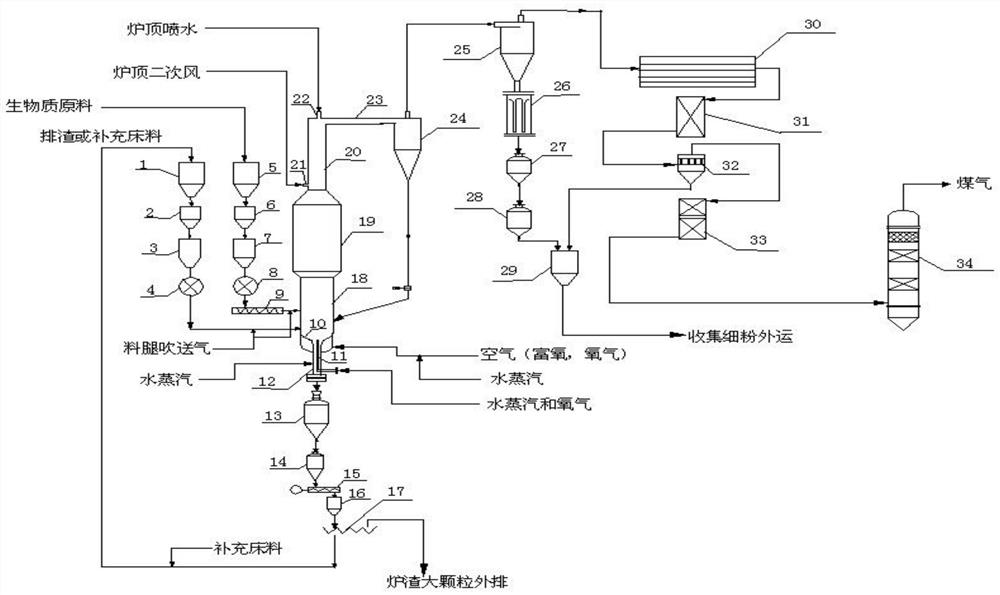

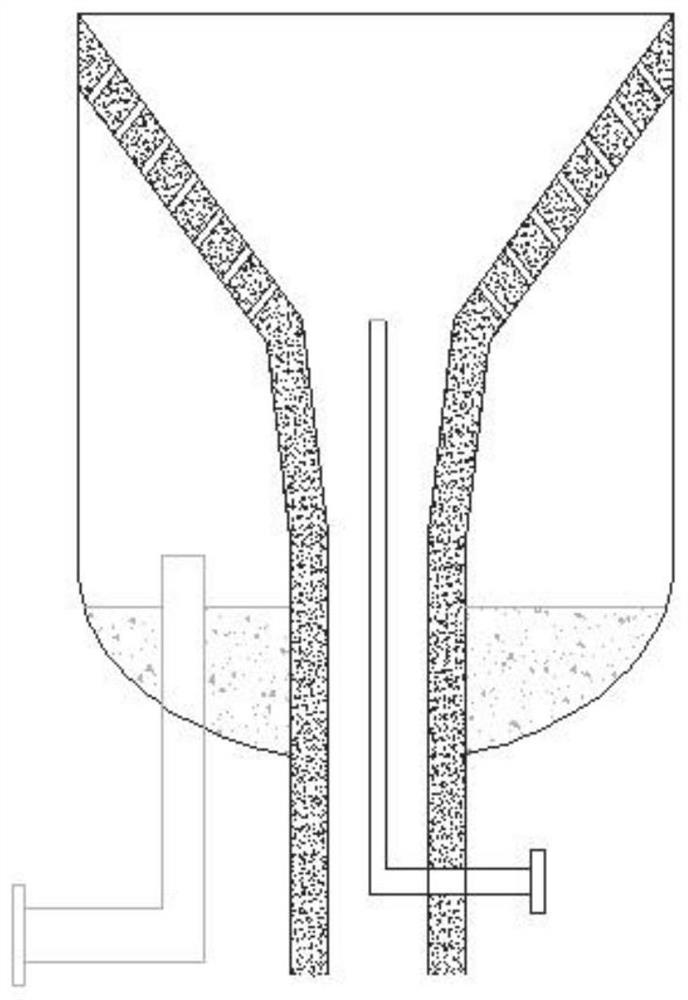

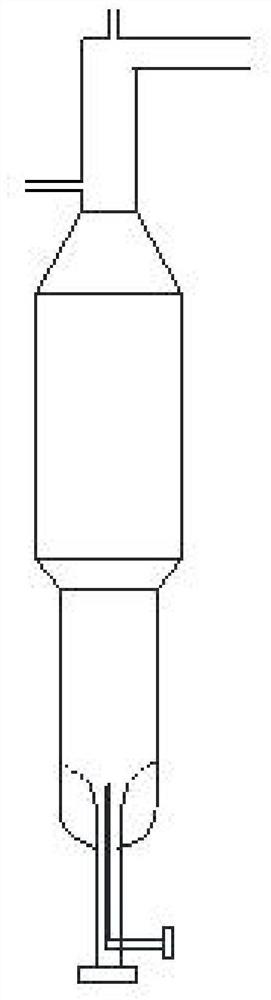

[0039] Such as Figure 1 to Figure 3 Shown, a kind of biomass fluidized-bed gasification prepares the method for fuel gas or synthesis gas, comprises the following steps:

[0040] Step 1, feeding: Metering the bed material and the biomass raw material separately through the feeding device, and blowing them to the lower section 18 of the gasifier respectively, so that the bed material and the biomass raw material form a stable bed in the fluidized bed, and then The biomass raw material is fluidized and gasified; the bed material is any one of coal, semi-coke, petroleum coke, boiler slag, coal gangue, quartz sand, limestone or high alumina bauxite. The particle size of the bed material is 0-10mm, and the component with a particle size of 0.2-1.0mm accounts for 40%-80%. When the bed material is coal, the moisture content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com