Continuous automatic feeding machine

An automatic feeding machine and silo technology, which is applied in tea, food forming, food science, etc., can solve the problems of material breaking, high labor intensity, and low efficiency, and achieve continuous and uniform feeding, fast feeding speed, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

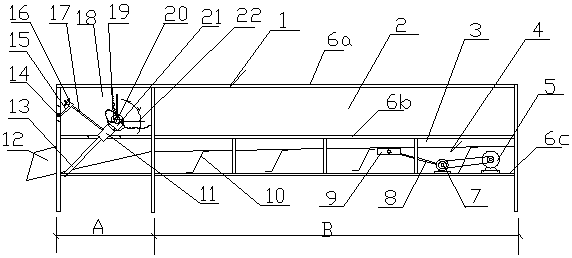

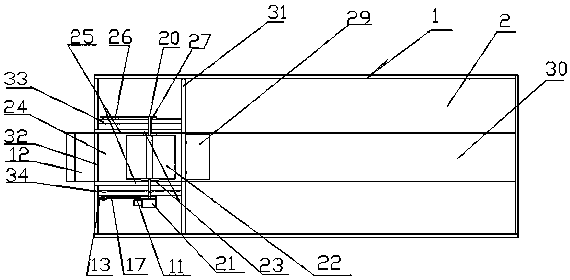

[0013] Embodiment 1: as figure 1 -4, continuous automatic feeding machine, including a frame 1 and a silo 2, the bottom of the silo 2 is set as an opening 30, a material vibration tank 3 is provided under the opening 30, and a vibrator 4 is provided under the material vibration tank 3, and the The front of the feed bin 2 is provided with a uniform material bin 24, and a tea uniform wheel 22 rotating counterclockwise is arranged in the uniform material bin 24.

[0014] Further, the cross-section of the silo 2 is set to be bucket-shaped, or approximately bucket-shaped, such as U-shaped, inverted trapezoidal, etc.

[0015] Further, the frame 1 is configured as an upper layer 6a, a middle layer 6b, and a lower layer 6c with three layers and a two-stage frame structure of section A and section B.

[0016] Further, the storage bin 2 is arranged between the upper layer 6a and the middle layer 6b of the B section of the frame 1 .

[0017] Further, the material vibration tank 3 is ar...

Embodiment 2

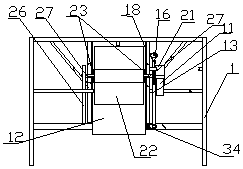

[0023] Embodiment 2: as Figure 5 -6, according to the continuous automatic feeding machine exemplified in embodiment 1, on both sides of the arc-shaped hole 19 on the side wall 18 of the even material bin 24, the parallel arc-shaped hole 19 is provided with a guide groove 35, and in the guide groove 35 A baffle 36 passing through the transverse shaft 20 is sleeved. Guide groove 35 and baffle plate 36 can be made into arc shape, also can be made into linear shape, when making straight line shape, guide groove 35 will be set wider, will ensure that baffle plate 36 does not get stuck when moving, also can not fall . When the horizontal axis 20 was adjusted up and down in the arc hole 19, the arc baffle 36 could always block the arc hole 19 when moving up and down with the transverse axis 20, preventing the material from overflowing from the arc hole 19. The length of the arc-shaped baffle 36 will ensure that the arc-shaped hole 19 can be blocked during the maximum displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com