Ultra-broad width full-wire type non-polar speed governing feeder

A technology of stepless speed regulation and feeder, which is applied in the direction of charging device, petroleum industry, coke oven, etc., can solve the problems of uneven coal feeding, difficult adjustment of speed, and low efficiency, so as to improve the service life and cake formation Speed, the effect of fast cake formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

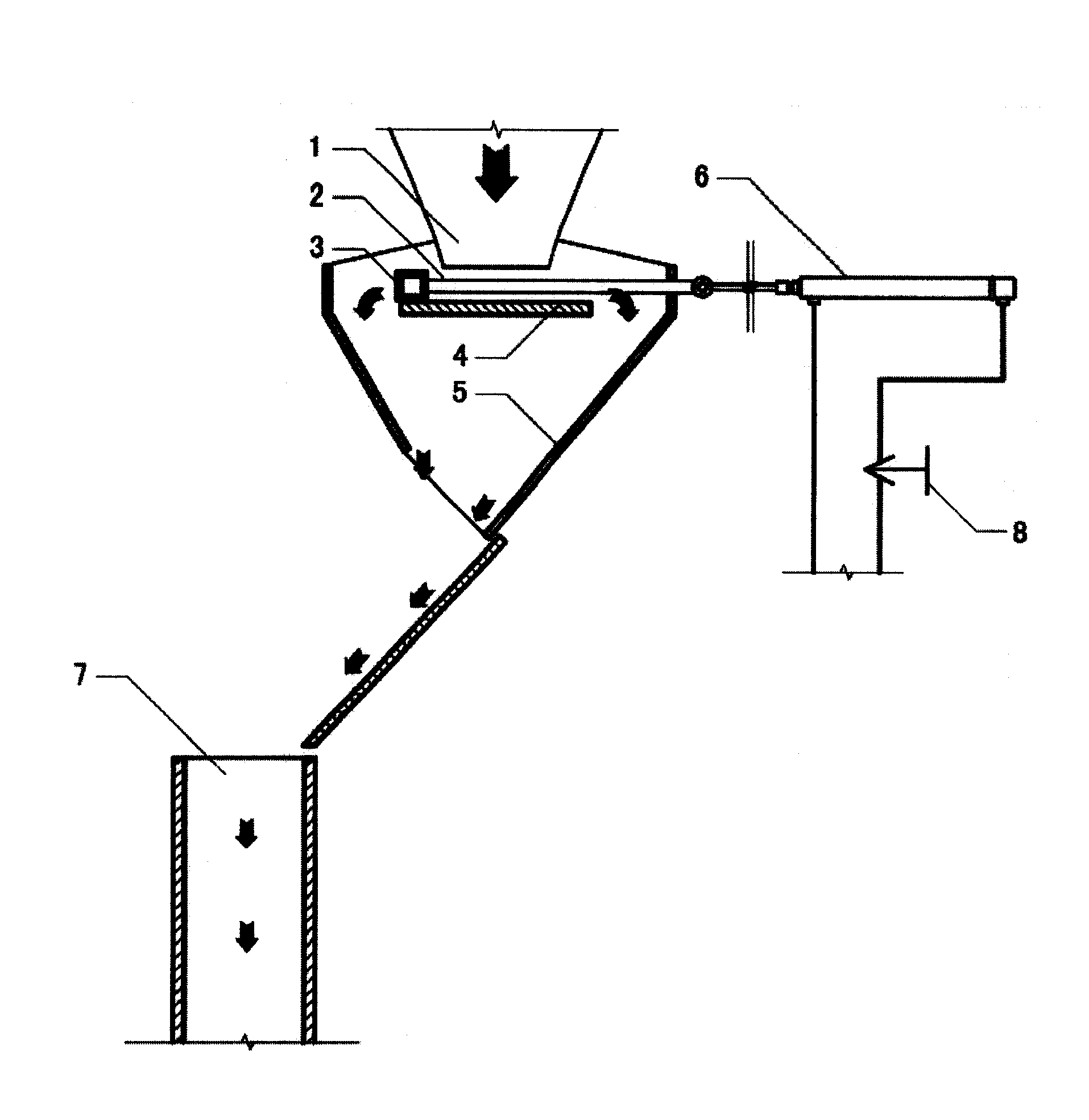

[0020] Referring to the accompanying drawings, the ultra-wide full-line stepless speed-adjustable feeder is composed of a hopper, a material receiving plate, a material guide groove, a material push plate, a connecting rod and a hydraulic device. The coal material in the hopper 1 falls on the material receiving plate 4 under the action of gravity, and after the accumulation forms a natural stop, the unloading stops naturally; the hydraulic device 6 drives the material pushing plate 3 to reciprocate on the upper surface of the material receiving plate 4 through the connecting rod 2, The coal material is alternately pushed out from both sides of the material receiving plate 4, falls into the material distribution guide groove 5, and then slides down from the lower opening of the material distribution guide groove 5 into the coal tank 7 of the side-loading coal car; the coal material continues to fall from the hopper 1 to supplement the material receiving coal on the board. Adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com