A method and system for reducing dioxins in flue gas produced by waste incineration

A technology of waste incineration and dioxin, a method and system field of dioxin applied in flue gas, which can solve the problems of high pressure difference value, damage of dust layer, easy falling off of the whole piece, etc., and increase the start-up frequency. , the effect of reducing the impact force and reducing the penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for reducing dioxins in flue gas produced by waste incineration, comprising:

[0040] Steps to control the injection method of activated carbon: the flue gas generated after the garbage is burned in the incinerator is introduced into the semi-dry desulfurization tower for desulfurization treatment after cyclone dust removal. The dioxin in the air is adsorbed, the particle size of the activated carbon is 200 mesh, and the injection volume is 15kg / h;

[0041] Steps to control the size of the bag: the flue gas after adsorption and purification by activated carbon is introduced into the bag dust removal device to remove dust particles. The bag in the bag dust removal device is made of PTFE bag. s;

[0042] Steps to control the differential pressure on both sides of the bag: control the differential pressure between the inlet and outlet of the bag to be 800pa-1000pa, start the online dust cleaning mode when the differential pressure of the bag exceeds 1200pa, and u...

Embodiment 2-5 and comparative example 1

[0049] For the operation steps of Examples 2-5 and Comparative Example 1, refer to the treatment method of Example 1 above, and refer to Table 1 for the design of operating parameters.

[0050] Table 1:

[0051]

[0052] The study found that in the bag dust removal process, by optimizing the working parameters (such as controlling the size of the bag, the flow rate of the flue gas, and the differential pressure on both sides of the bag), an optimal control parameter is found, that is, the bag uses 1092 PTFE bags, smoke The airflow velocity drops to 0.63m / S, and the differential pressure on both sides of the bag is stable at 800pa-1000pa. The concentration of dioxins in the exhaust gas of Example 1 can be controlled within 0.08ngTEQ / m3, which can achieve the minimum concentration of dioxins , Through the comparison between the examples, it is found that the main parameters affecting the concentration of dioxin emissions are the flue gas flow rate and the pressure difference ...

Embodiment 6

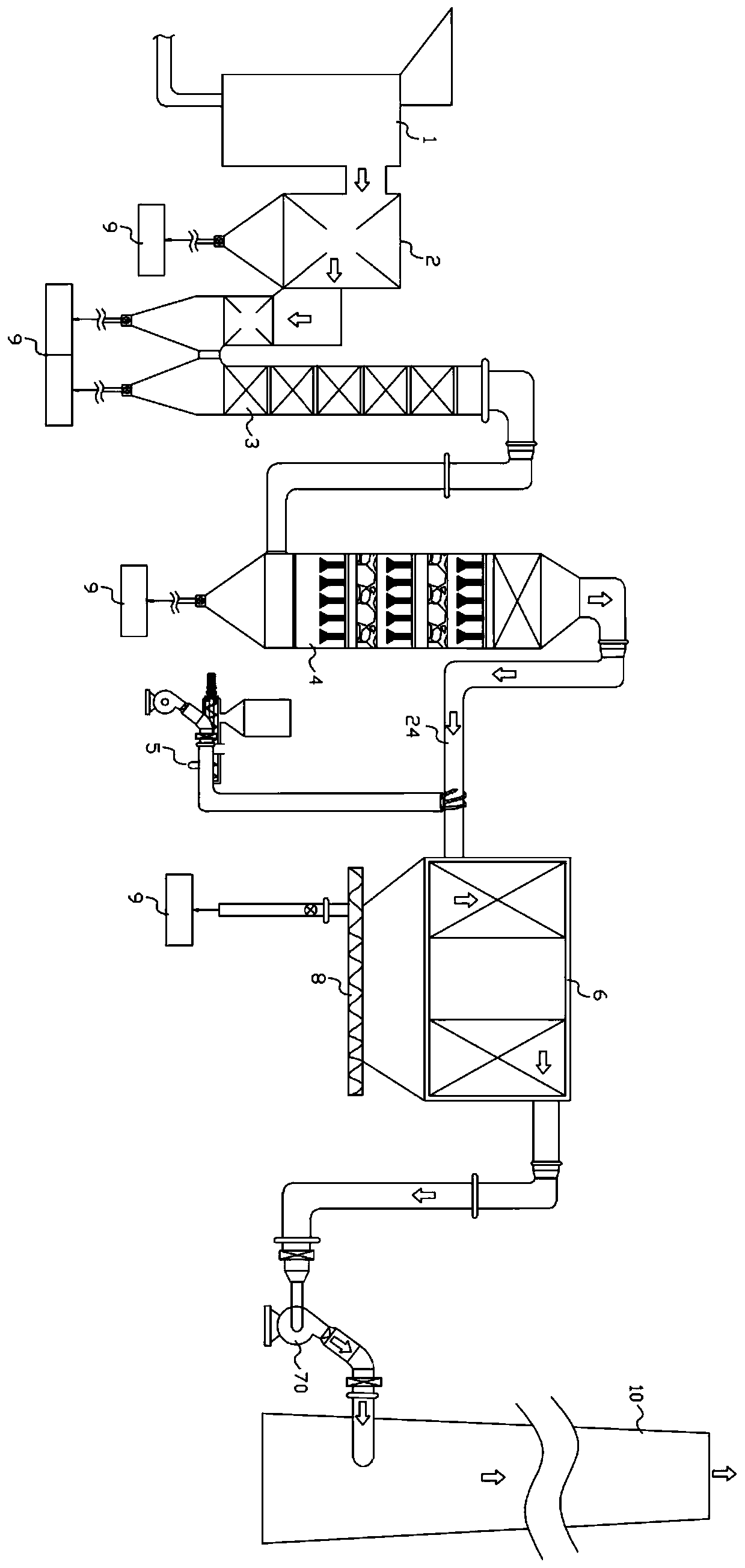

[0054] Such as figure 1 As shown, the flue gas treatment system adopting the above-mentioned method for reducing dioxins in the flue gas produced by garbage incineration includes an incinerator 1, a waste heat boiler 2, an economizer 3 and a desulfurization tower 4 arranged in sequence, and its characteristics That is, an activated carbon injection device 5 and a bag dust removal device 6 are also included, and the activated carbon injection device 5 is arranged between the desulfurization tower 4 and the bag dust removal device 6 .

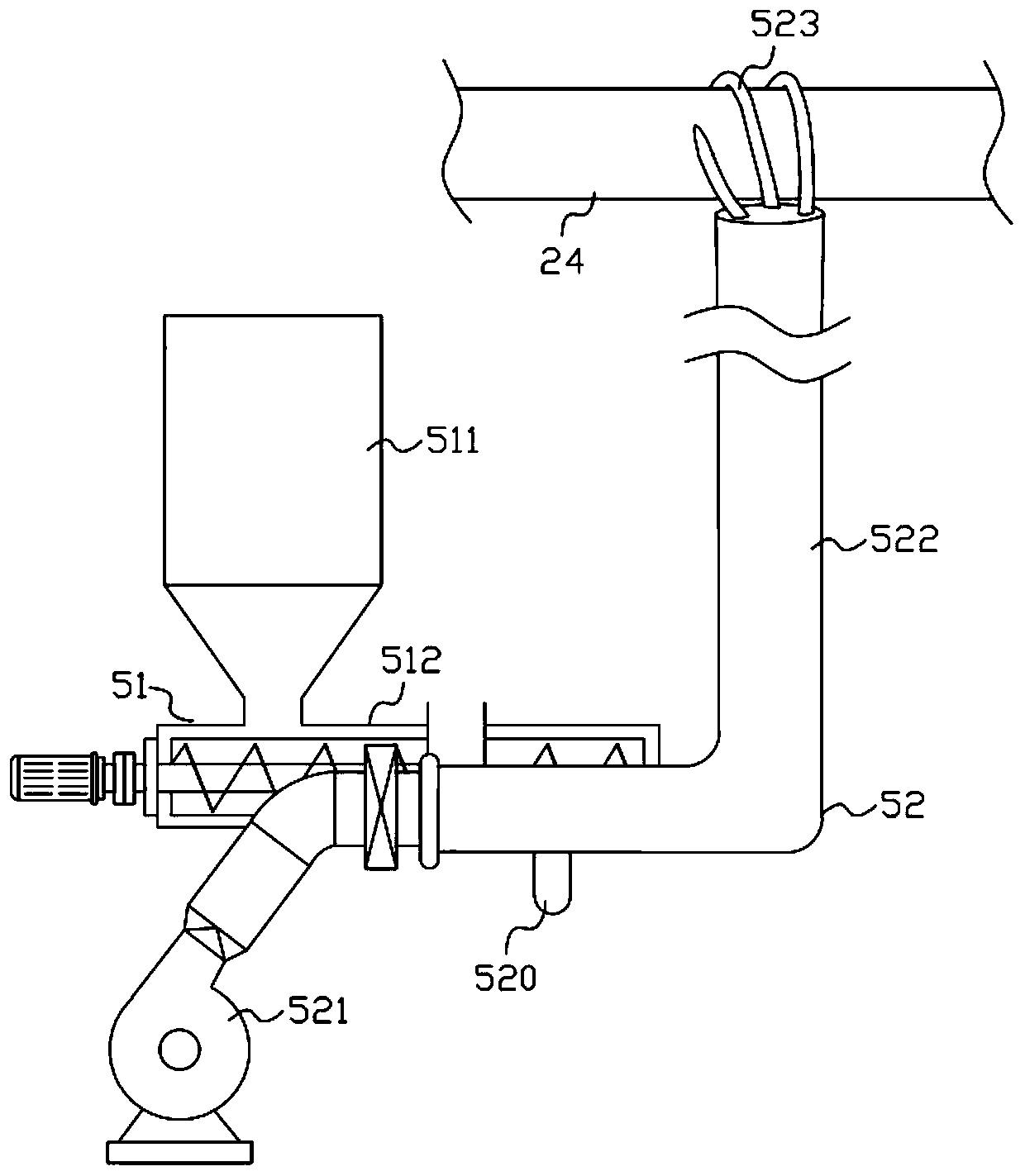

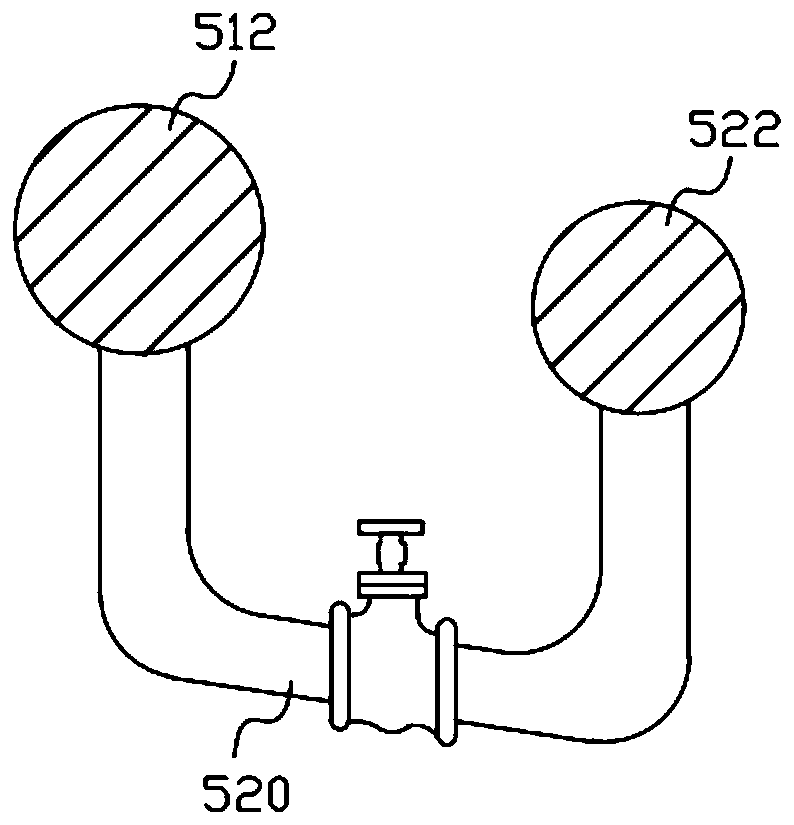

[0055] As preferred, such as Figure 2-4 As shown, the activated carbon injection device 5 includes a feeding system 51 and an injection system 52, and the feeding system 51 includes a silo 511 and an auger feeder 512 communicated with the outlet of the silo 511, so The injection system 52 includes a high-pressure Roots blower 521, a nozzle assembly 523, and a gas pipeline 522 connected between the high-pressure Roots blower 521 and the nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com