Scraper type film evaporator

A thin-film evaporator and scraper-type technology, applied in vertical tube evaporators, evaporator accessories, evaporation, etc., can solve the problems of limited application scope, waste, surface expansion, etc., to achieve stable and efficient separation effect, continuous and uniform feeding, Good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

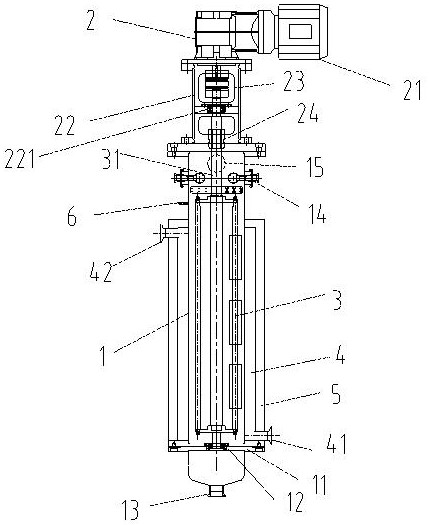

[0032] A scraped film evaporator, such as Figure 1-5 As shown, it includes the evaporator cylinder 1 and the driving structure 2 arranged on the upper side of the evaporator cylinder 1, the scraper cage structure 3 is arranged in the evaporator cylinder 1, the upper side is connected to the driving structure 2, and the lower side is The position is limited by the bearing 12 on the lower head 11 at the bottom of the evaporator cylinder 1 , and the lower side of the lower head 11 is provided with a discharge port 13 .

[0033] In terms of the heat exchange mechanism, the side wall of the evaporator cylinder 1 is provided with a water chamber 4, and the water chamber 4 is provided with a water inlet 41 and a water outlet 42, that is, the heat exchange liquid enters from the bottom and exits from the top.

[0034] The outer side of the water chamber 4 is provided with an insulating layer 5 to ensure a better heat exchange effect.

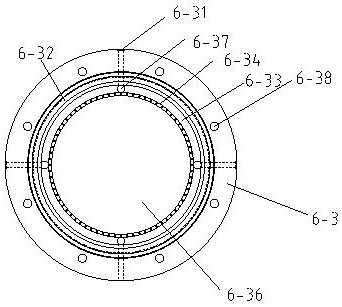

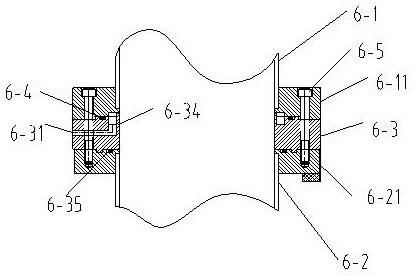

[0035] The evaporator cylinder 1 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com