Hollow tube type variable-pitch spiral conveyor for potato pulp dewatering device

A screw conveyor and dehydration equipment technology, applied in lighting and heating equipment, drying solid materials, dryers, etc., can solve the problems of high potato slag, high energy consumption, and failure to achieve ideal dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

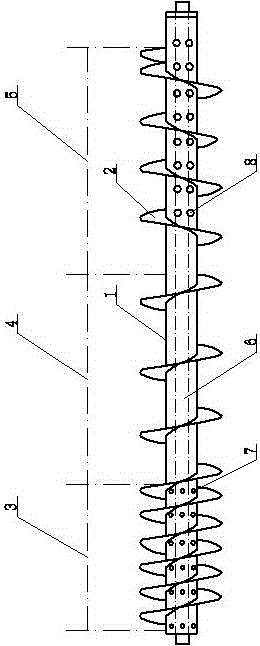

[0019] The hollow tube type variable-pitch screw conveyor for potato residue dehydration equipment includes a screw 1 and a screw blade 2 arranged on the screw 1, wherein the conveyor is mainly composed of a dense helical section 3 located at the front end of the screw 1 and a wide helix located in the middle of the screw 1 Segment 4 and reverse helical segment 5 located at the end of screw 1.

[0020] as attached figure 1 As shown, there is a hollow pipe 6 inside the screw 1, and the hollow pipe 6 runs through the entire screw 1 and is connected with external equipment; the dense spiral section 3 and the reverse spiral section 5 are respectively provided with a first air hole 7 and a second air hole 8; The diameter of the first air holes 7 is smaller than that of the second air holes 8 , and the distribution density of the first air holes 7 is greater than that of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com