Patents

Literature

33results about How to "Stable and continuous operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

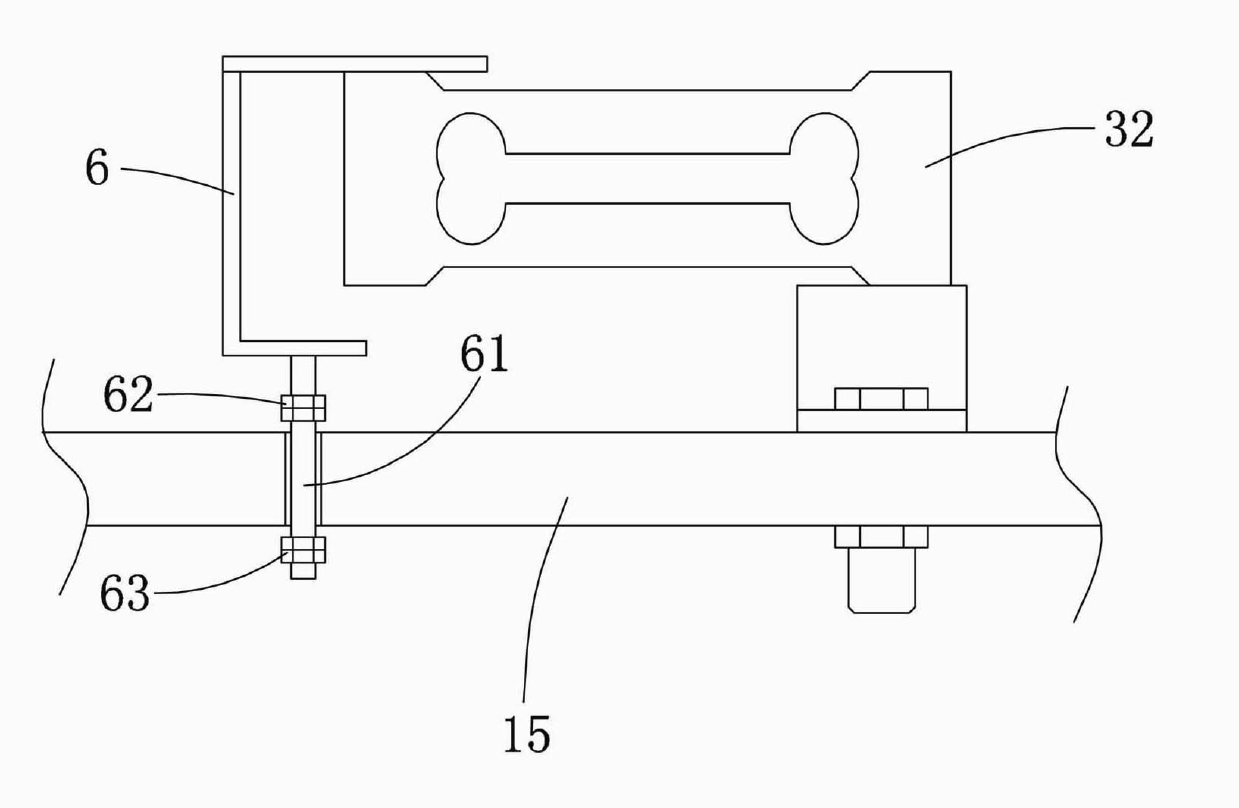

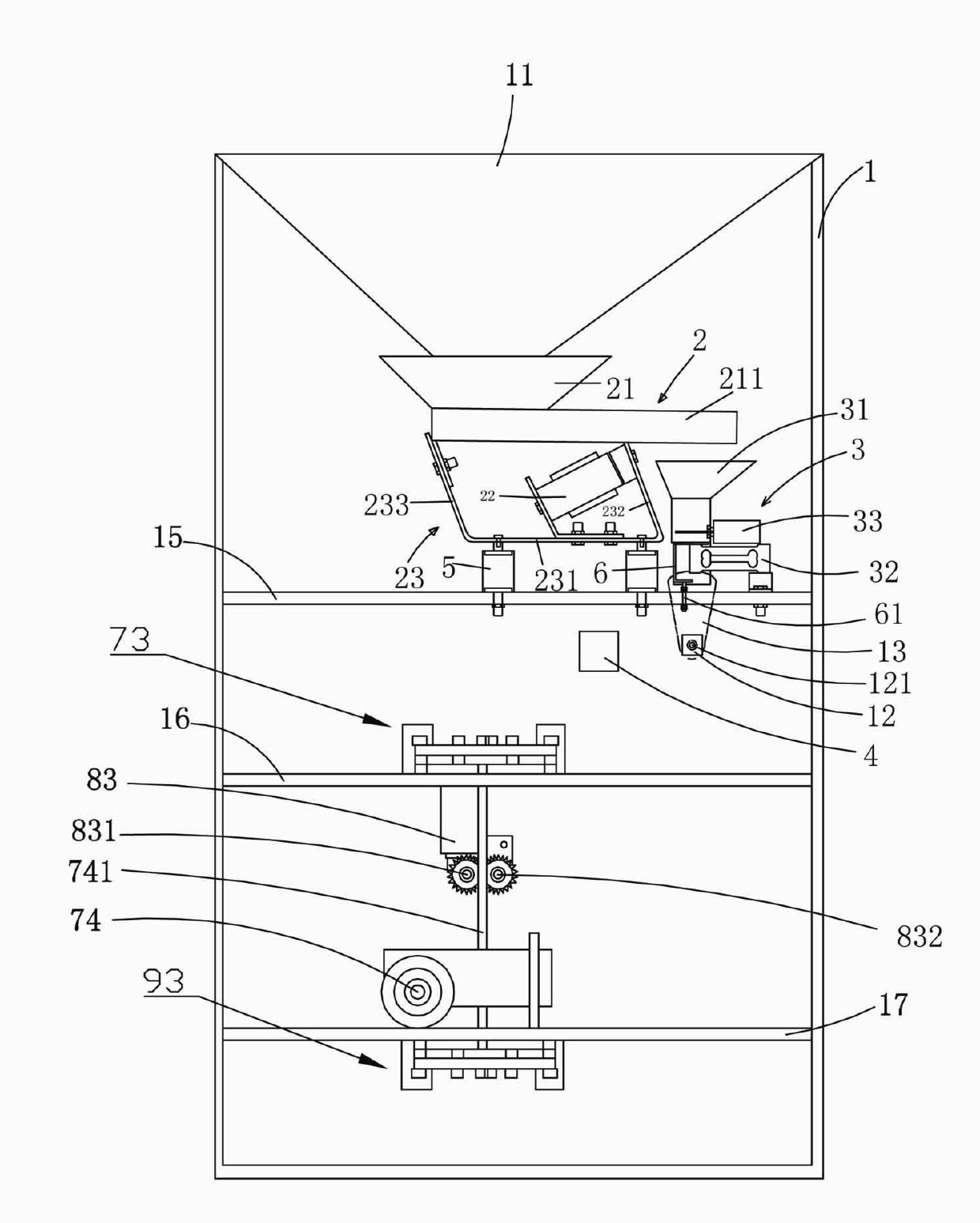

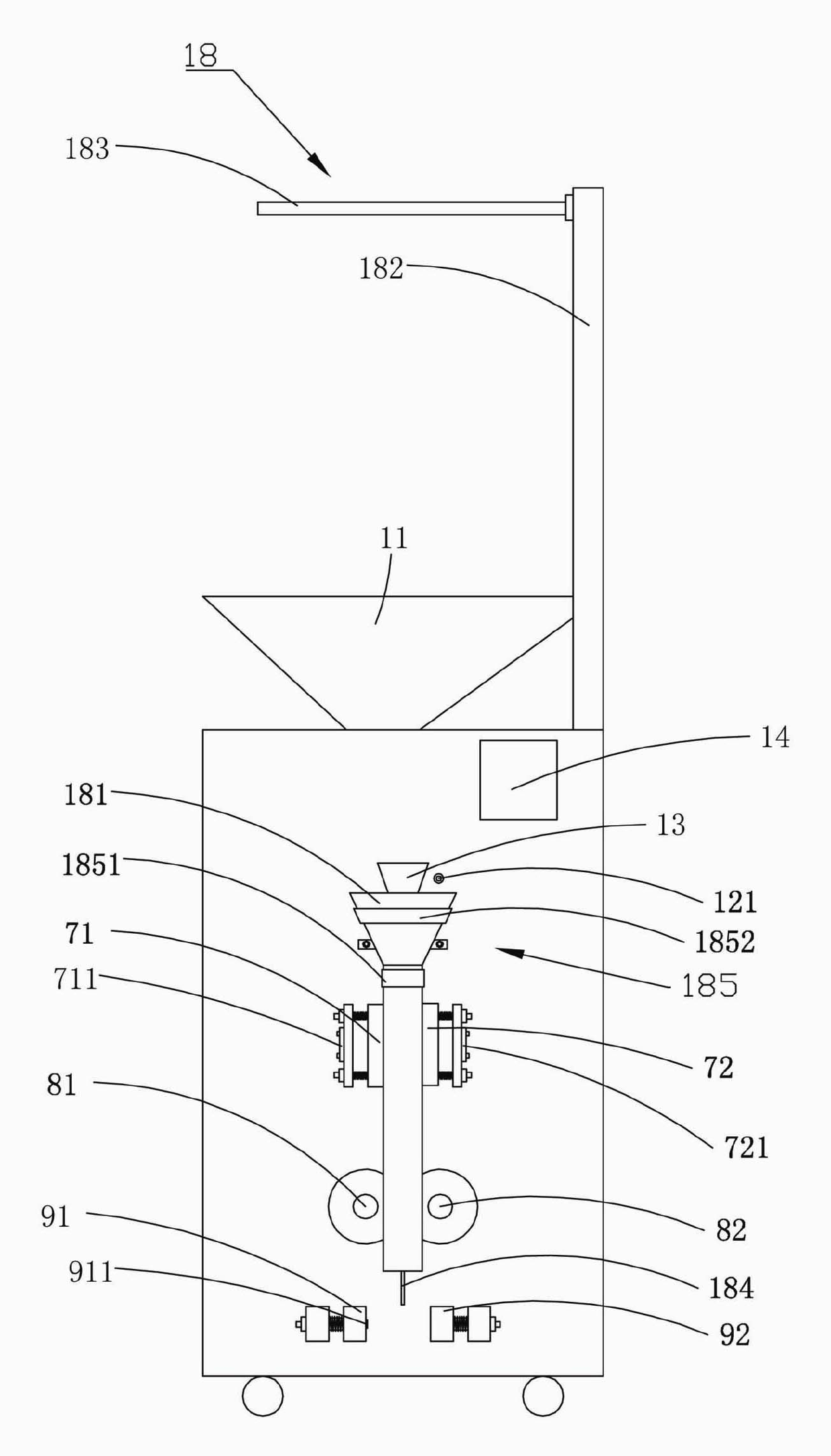

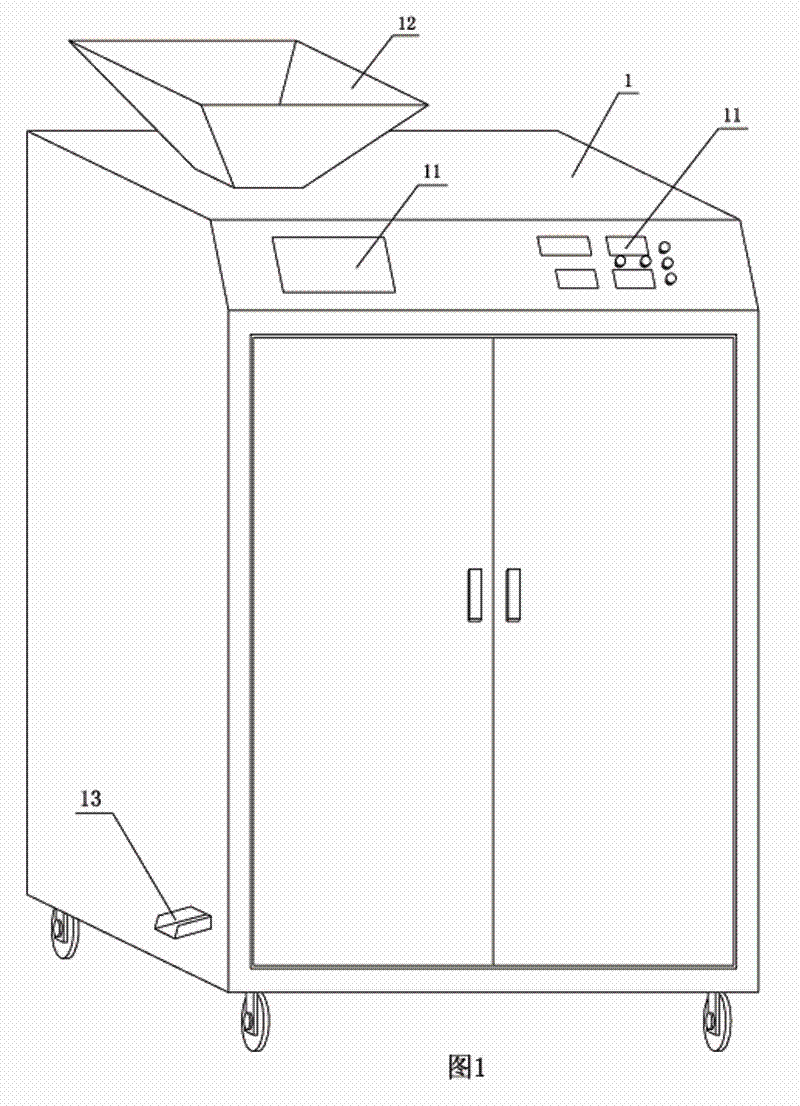

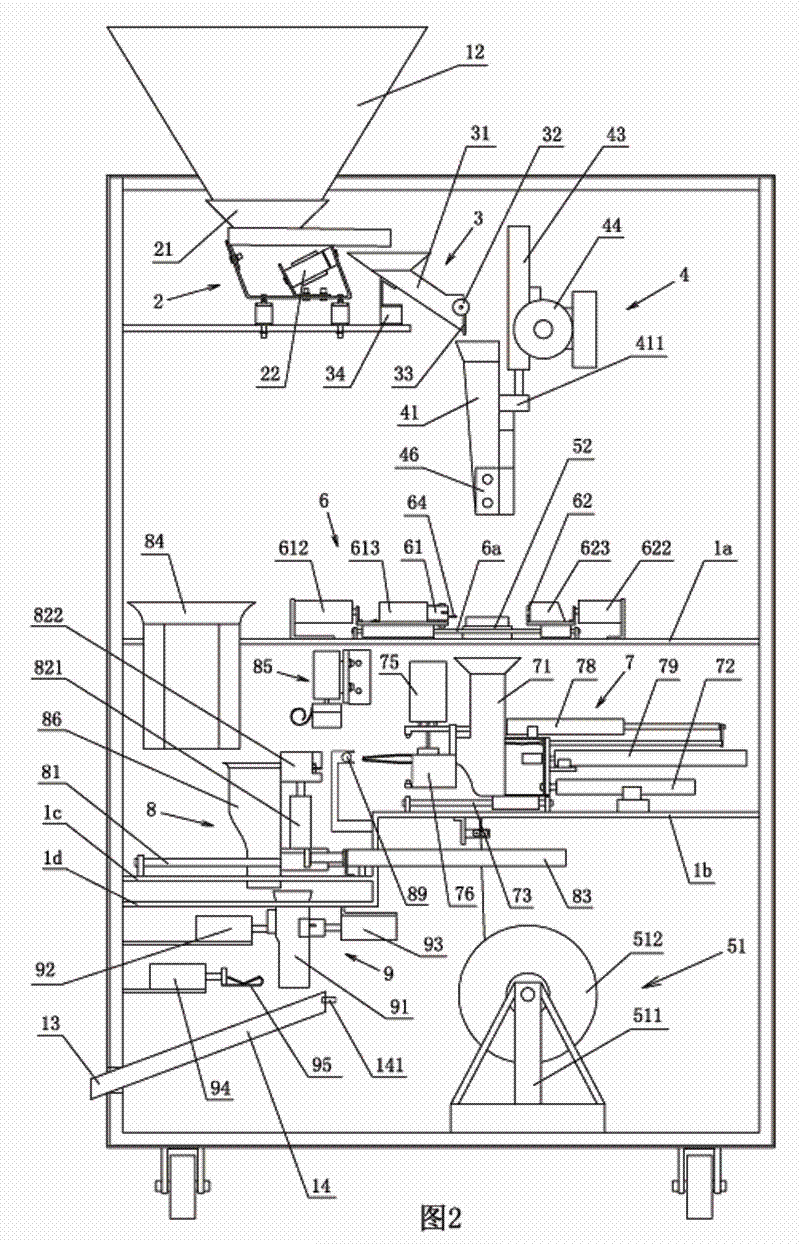

Machine integrating tea weighing with film inner bag making and loading

InactiveCN102001457AHigh degree of automationIncrease productivityWrapping material feeding apparatusWrapper twisting/gatheringEngineering

The invention provides a medicine integrating tea weighing with film inner bag making and loading, which comprises a casing, a reel device fixed on the casing and used for installing a film reel for making an inner bag, and a precise automatic tea weighing device and a film inner bag making and loading device which are arranged on the casing from top to bottom. Through reasonably integrating the tea weighing, the film inner bag making and the tea bagging together, the machine is more convenient and practical for use, improves the production efficiency and is more beneficial to massive production.

Owner:李文峰

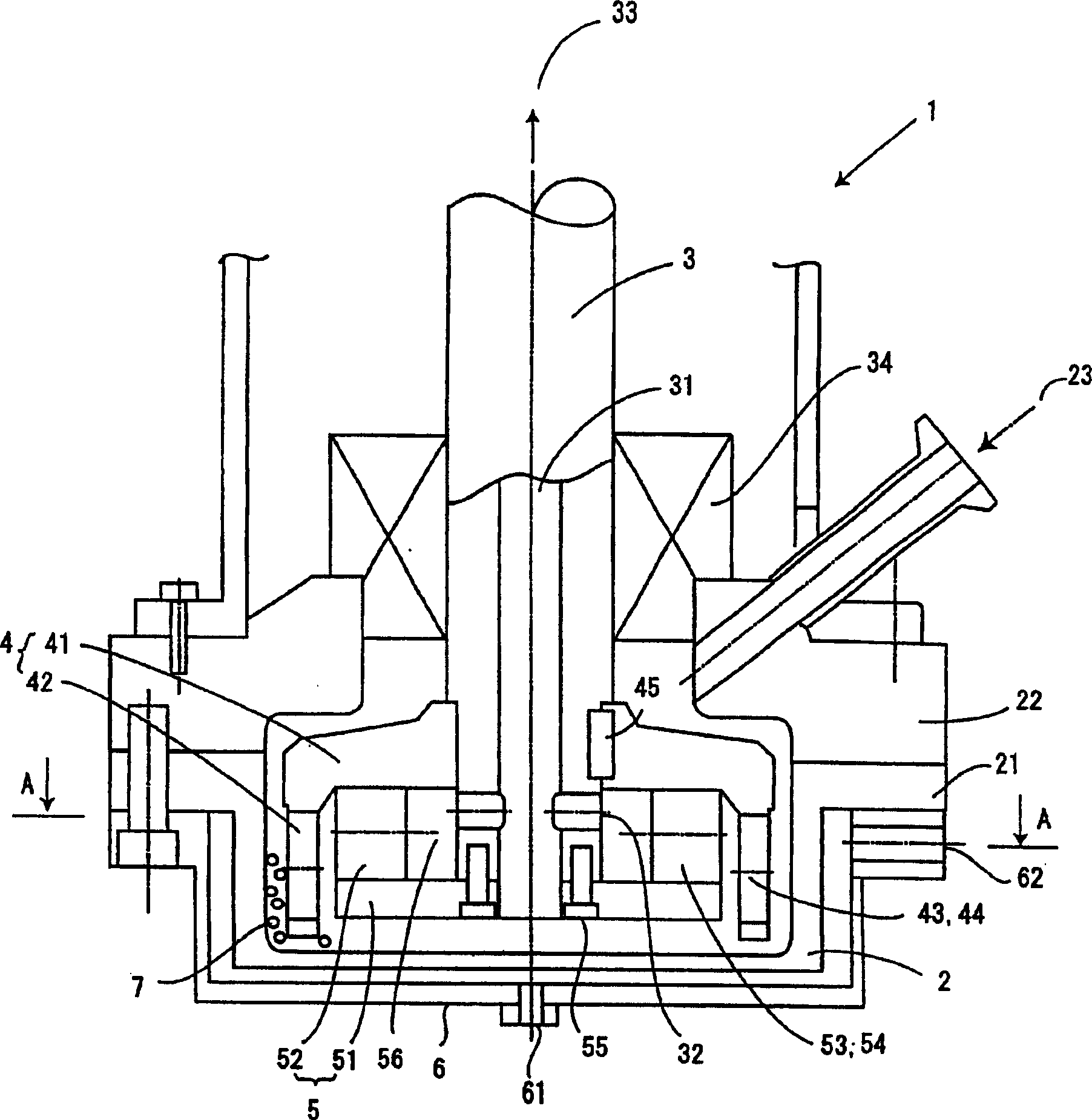

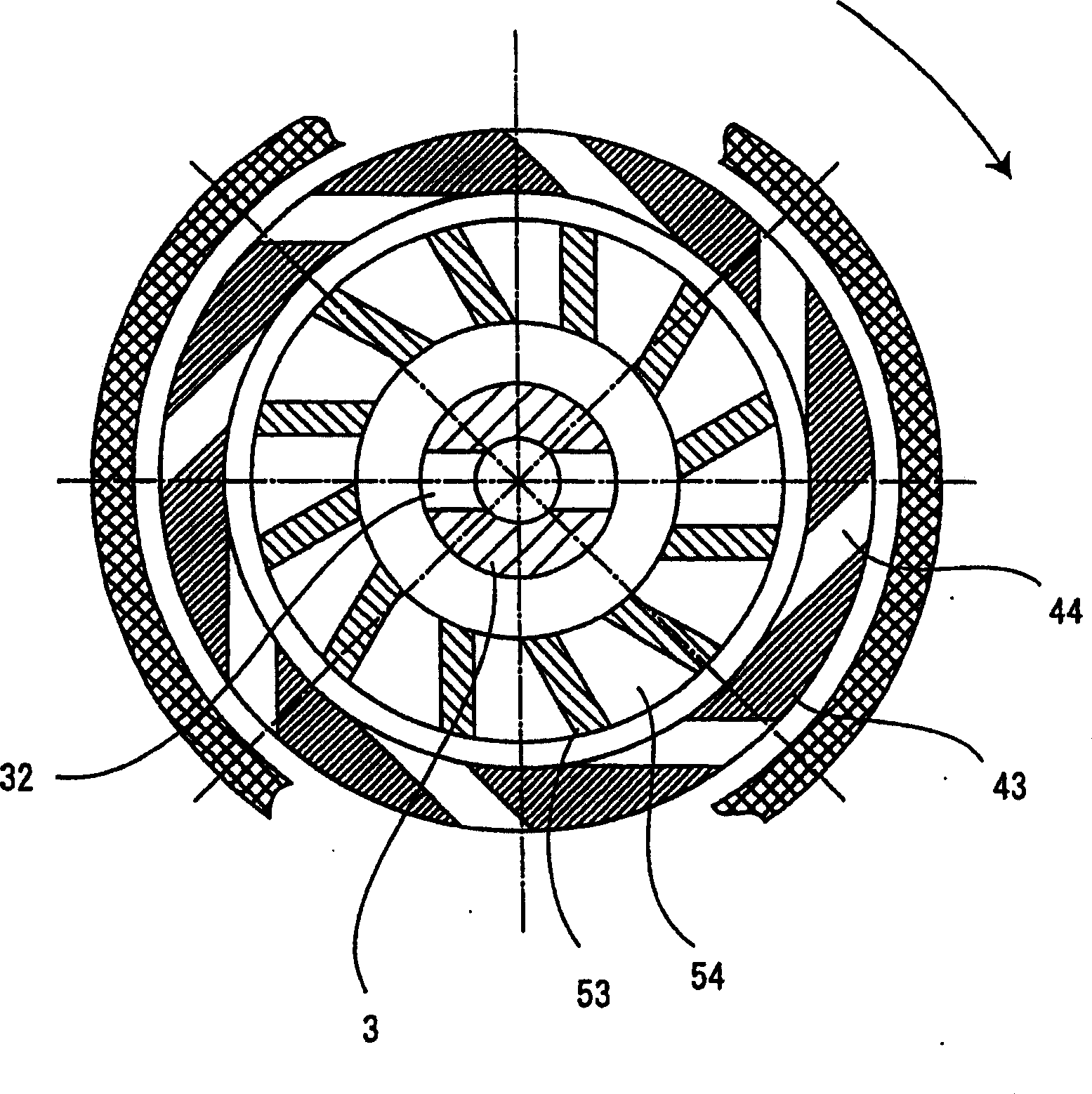

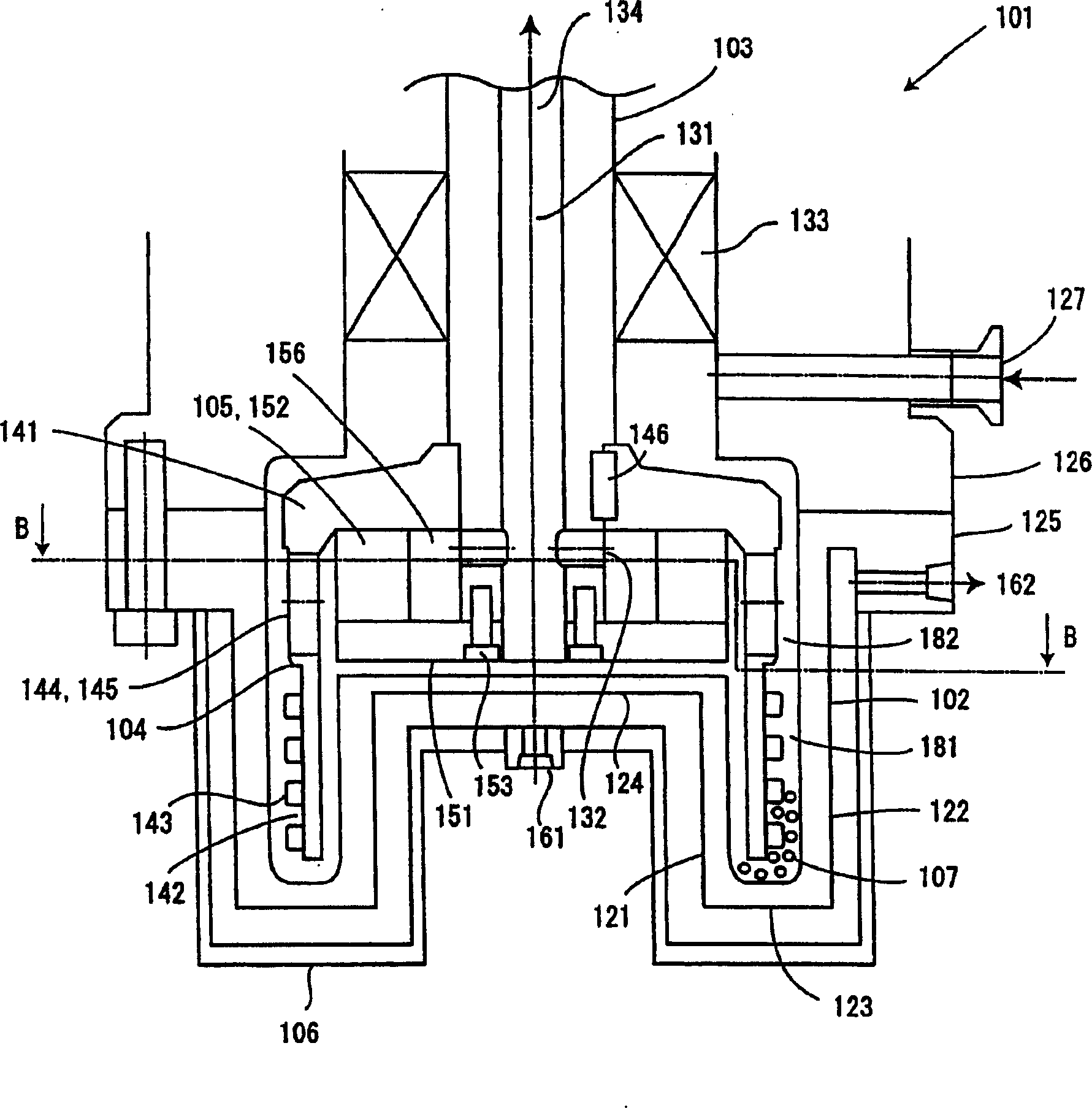

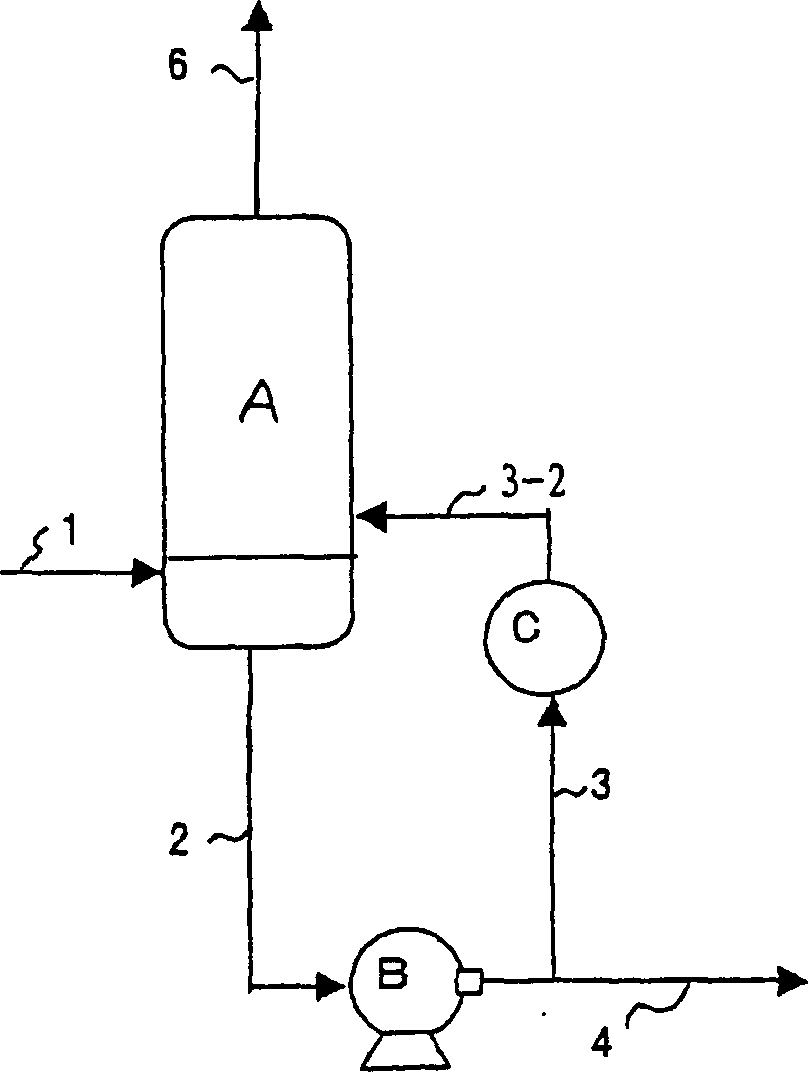

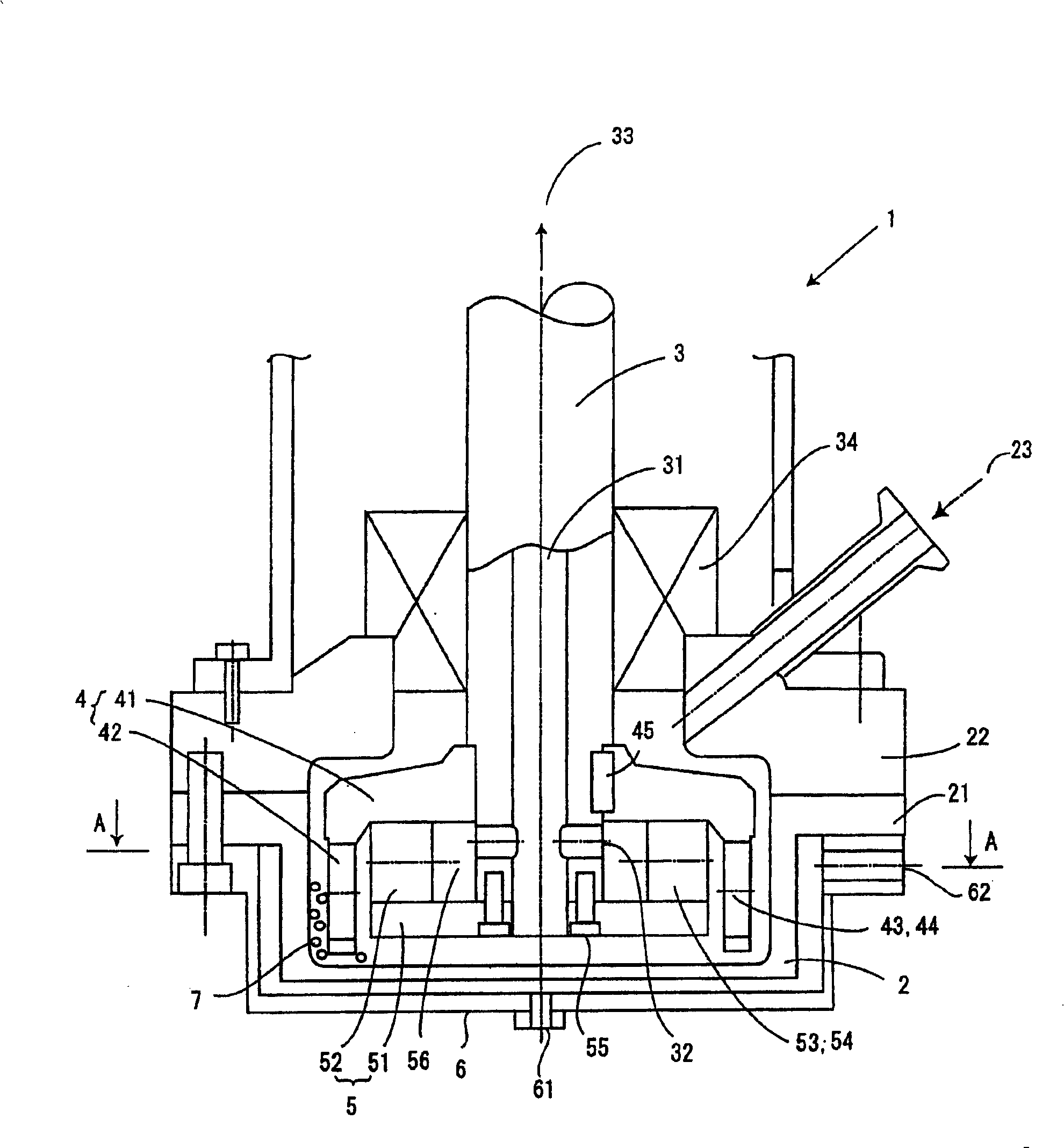

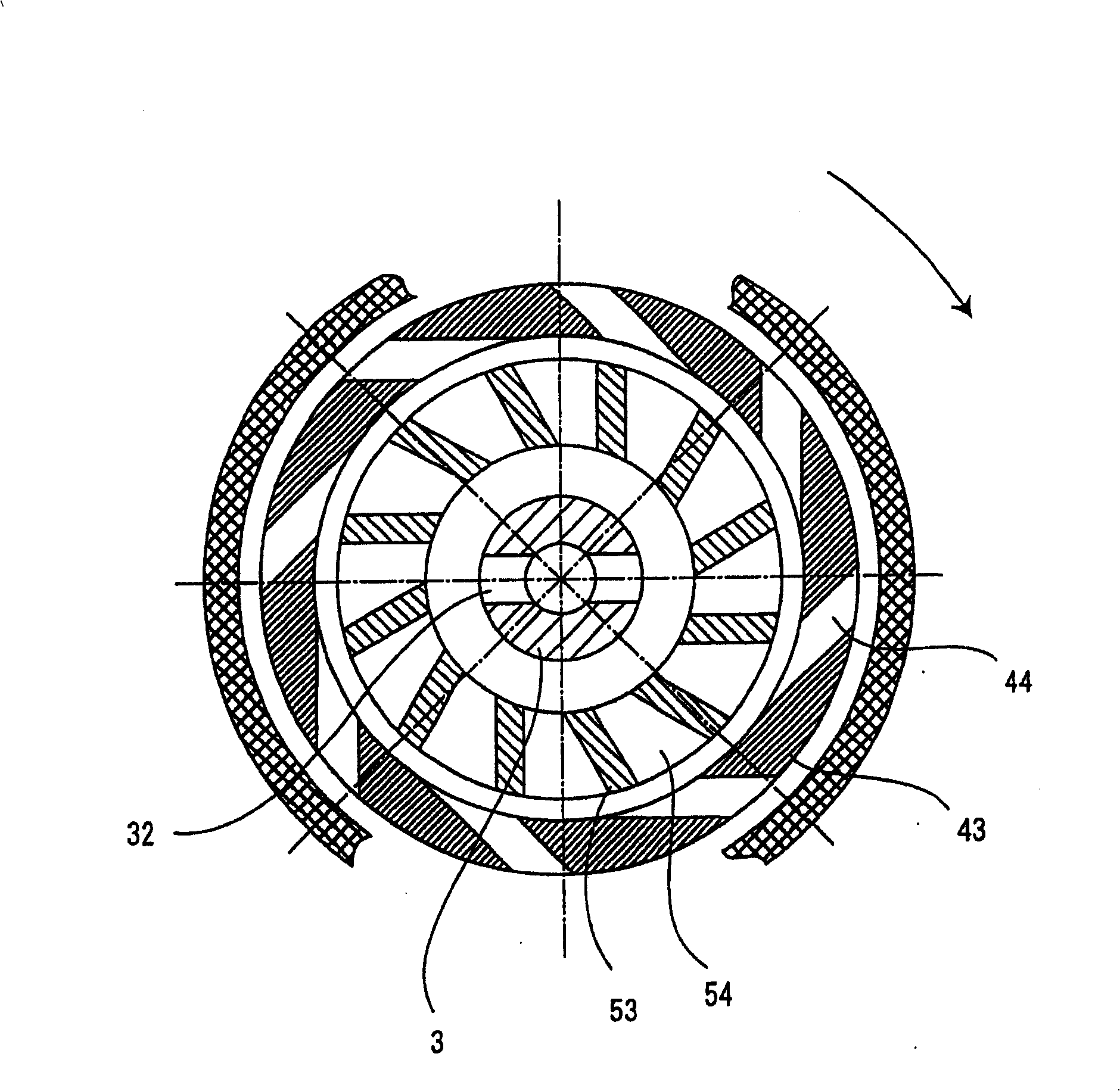

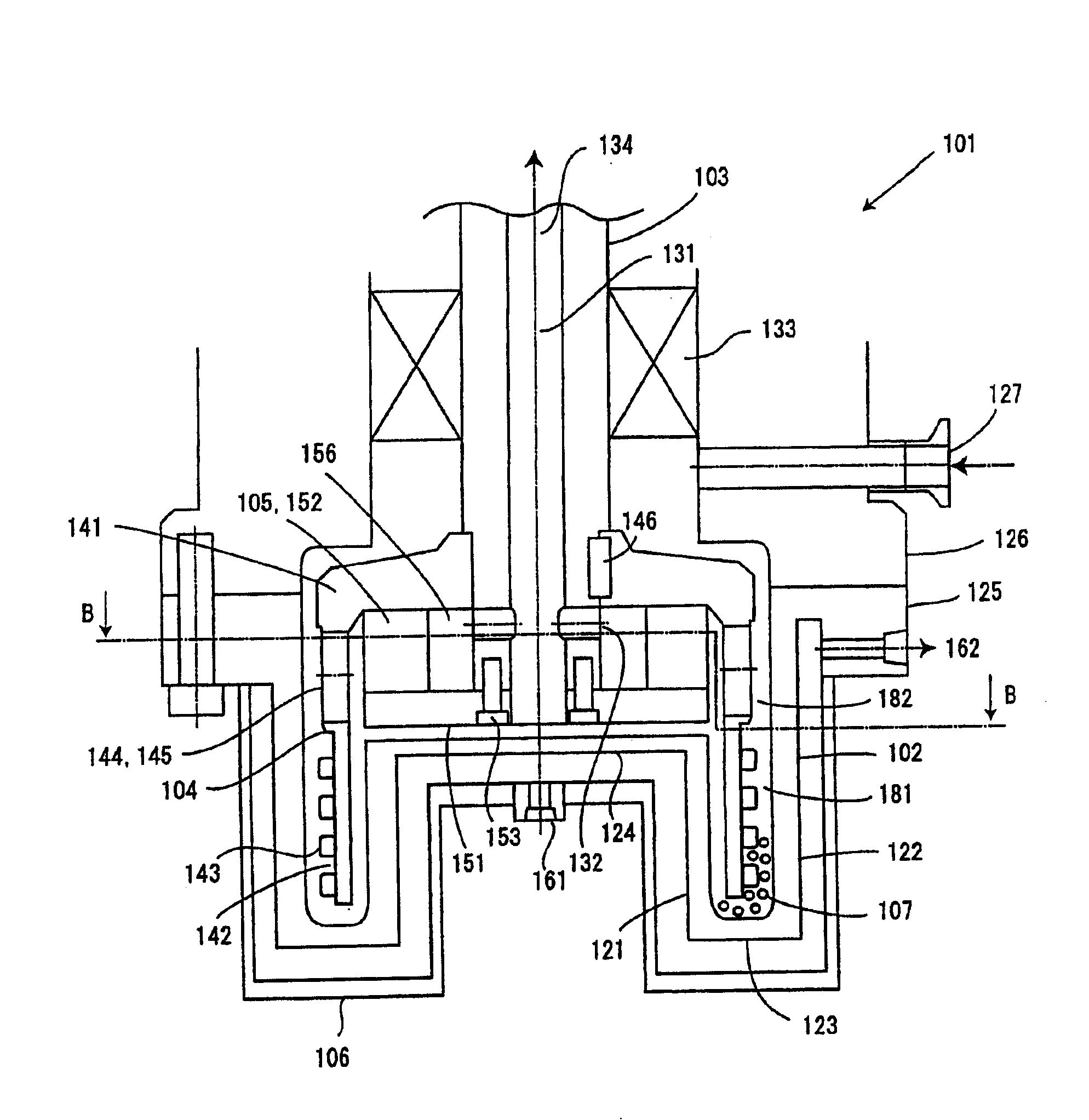

Medium mixing up of wet-type dispersion machine

ActiveCN1830570AStable and continuous operationImplement decentralized processingSublimationGrain treatmentsRotational axisDispersed media

The medium stirring wet dispersing machine has a cylindrical dispersing tank, a tubular rotation shaft, an outer rotor with blades arranged to form one cylinder for generating centrifugal force, and an inner rotor inside the outer rotor and with also blades arranged to form one cylinder for generating centrifugal force. The outer rotor possesses functions of crushing and dispersing particles, whereas the inner rotor possesses functions of separating and grading medium. Therefore, the present invention can disperse medium in nanometer level and has great capacity and excellent grading performance.

Owner:NIPPON COKE & ENG

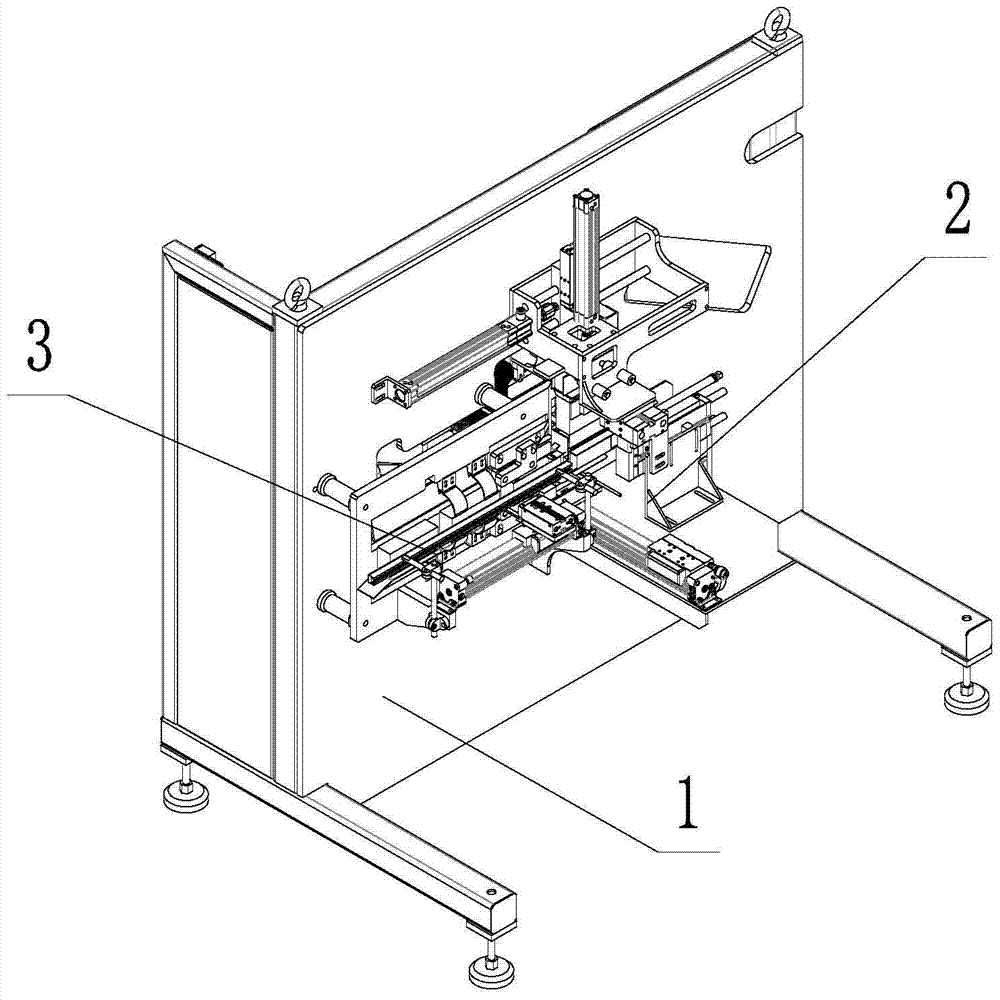

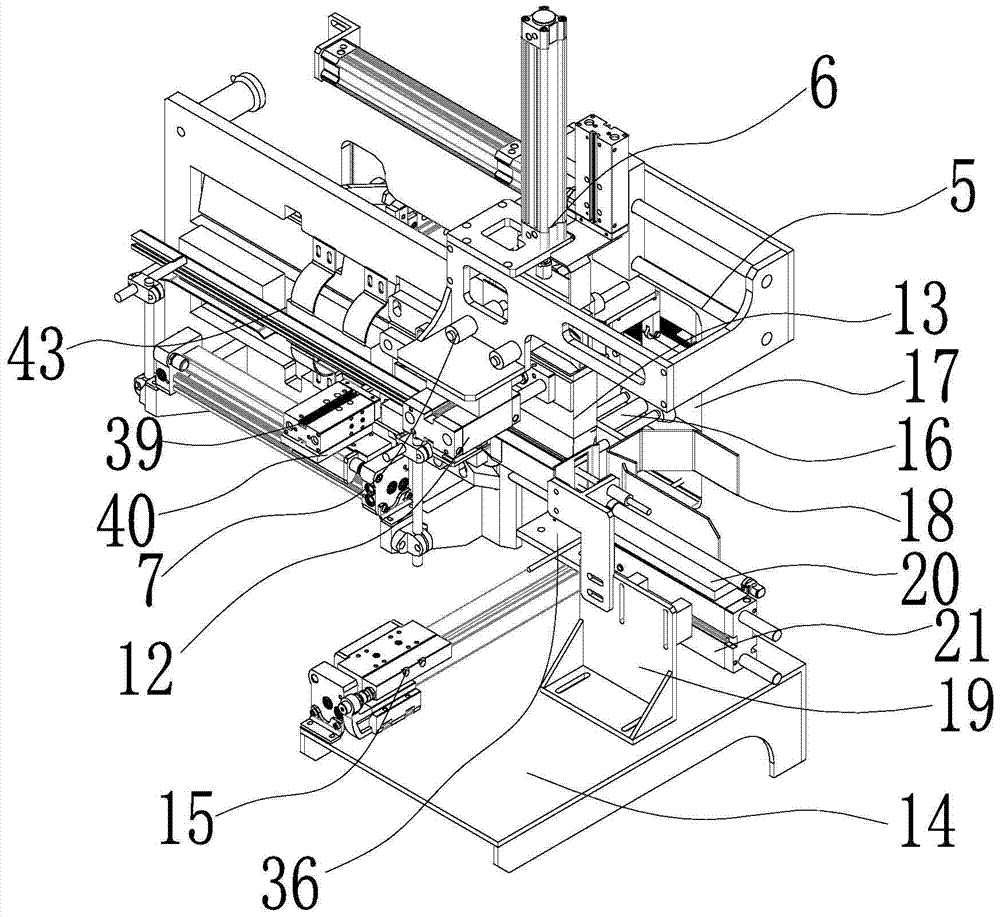

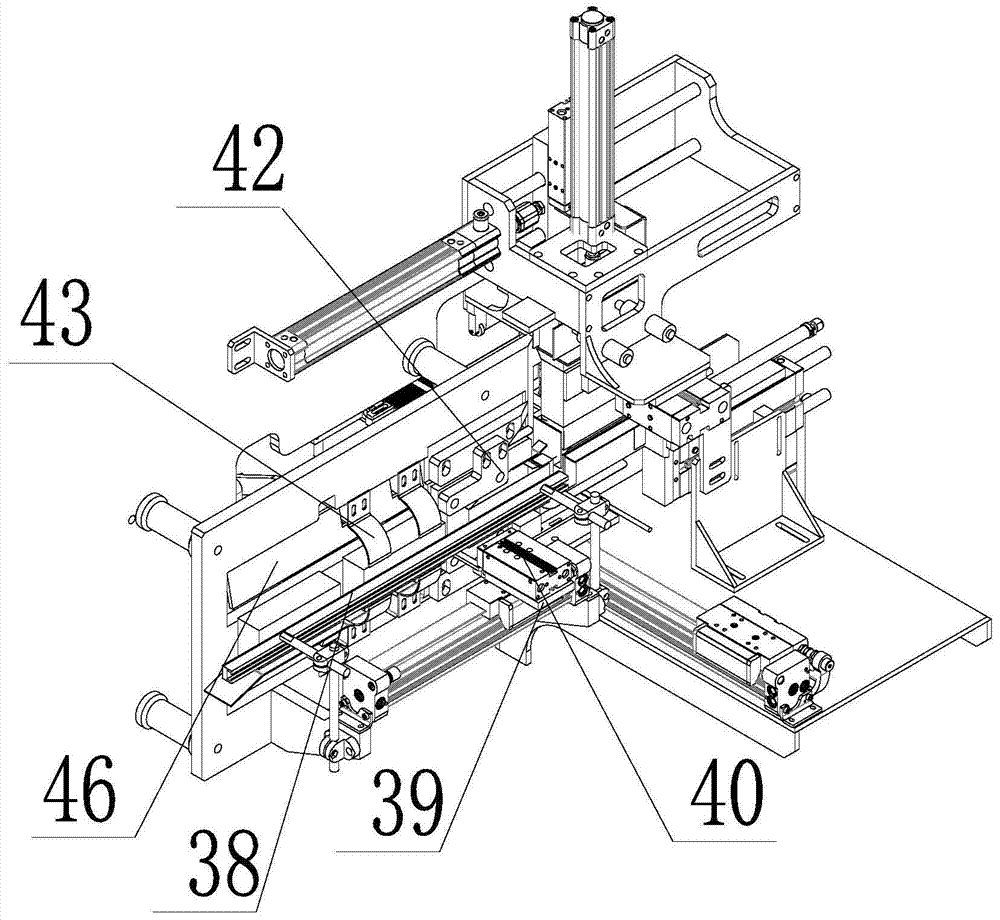

Automatic packaging unit for vacuum packaging of inner bag and outer bag

InactiveCN101837843BHigh degree of automationIncrease productivityPackaging by pressurising/gasifyingSolid materialEngineeringAutomation

Owner:李文峰

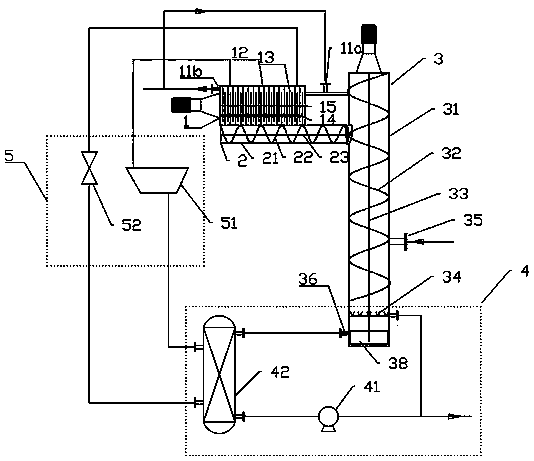

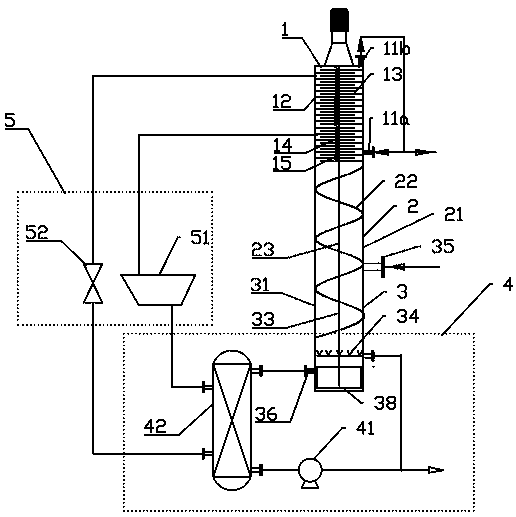

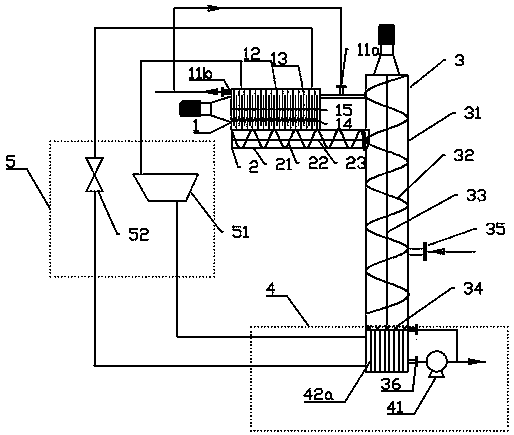

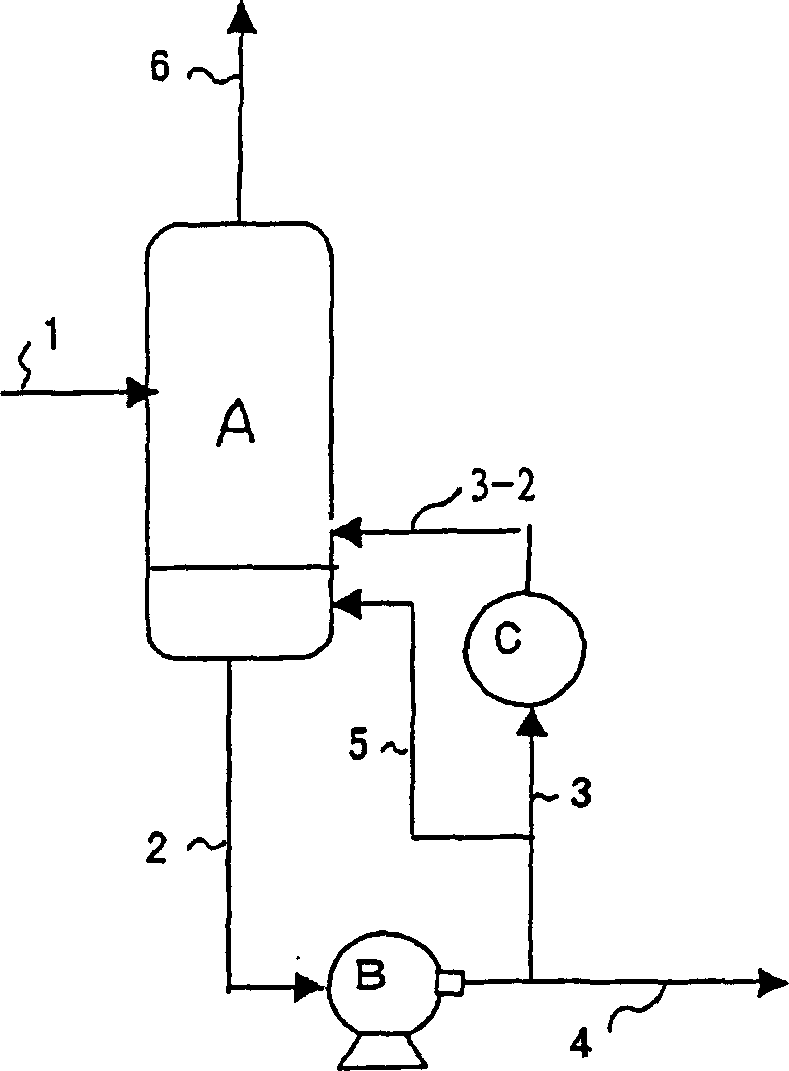

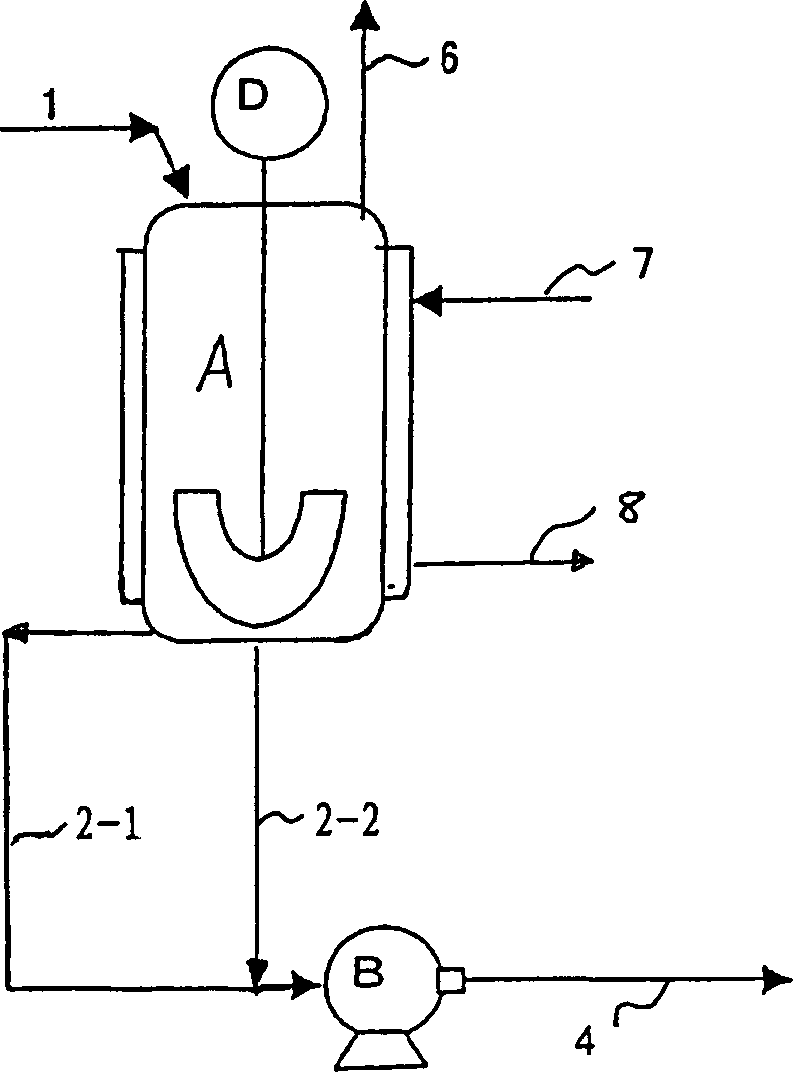

Self-regenerative continuous melt crystallization system and method

ActiveCN111544921AStable and continuous operationIncrease the heat exchange areaOrganic compound preparationCarboxylic acid esters preparationProcess engineeringEnergy consumption

The invention discloses a self-regenerative continuous melt crystallization system and method. The system comprises a crystallization section, a crystal growth section, a refining section, a product recovery section and a heat reuse system, wherein the crystallization section adopts a finned cooling fin structure to provide a cooling interface; a scraper is adopted to separate crystals generated on a cooling surface, so that the supercooled crystals enter a crystal growth section to grow, materials are conveyed to a refining section, crystal particles and high-melting-point product reflux flowreversely in the refining section to perform heat and mass transfer, and finally, high-purity and high-melting-point products are recovered through a product recovery section. The heat recycling system is connected with the finned cooling fins and the product recycling section heat exchanger, and heat recycling is achieved. The self-regenerative continuous melt crystallization system and method disclosed by the invention have the advantages of high production efficiency, high product purity, stable system operation, low energy consumption and the like, so that the defects of complex structure, low production efficiency and low energy utilization rate of the existing melt crystallization system are overcome.

Owner:天津乐科节能科技有限公司 +1

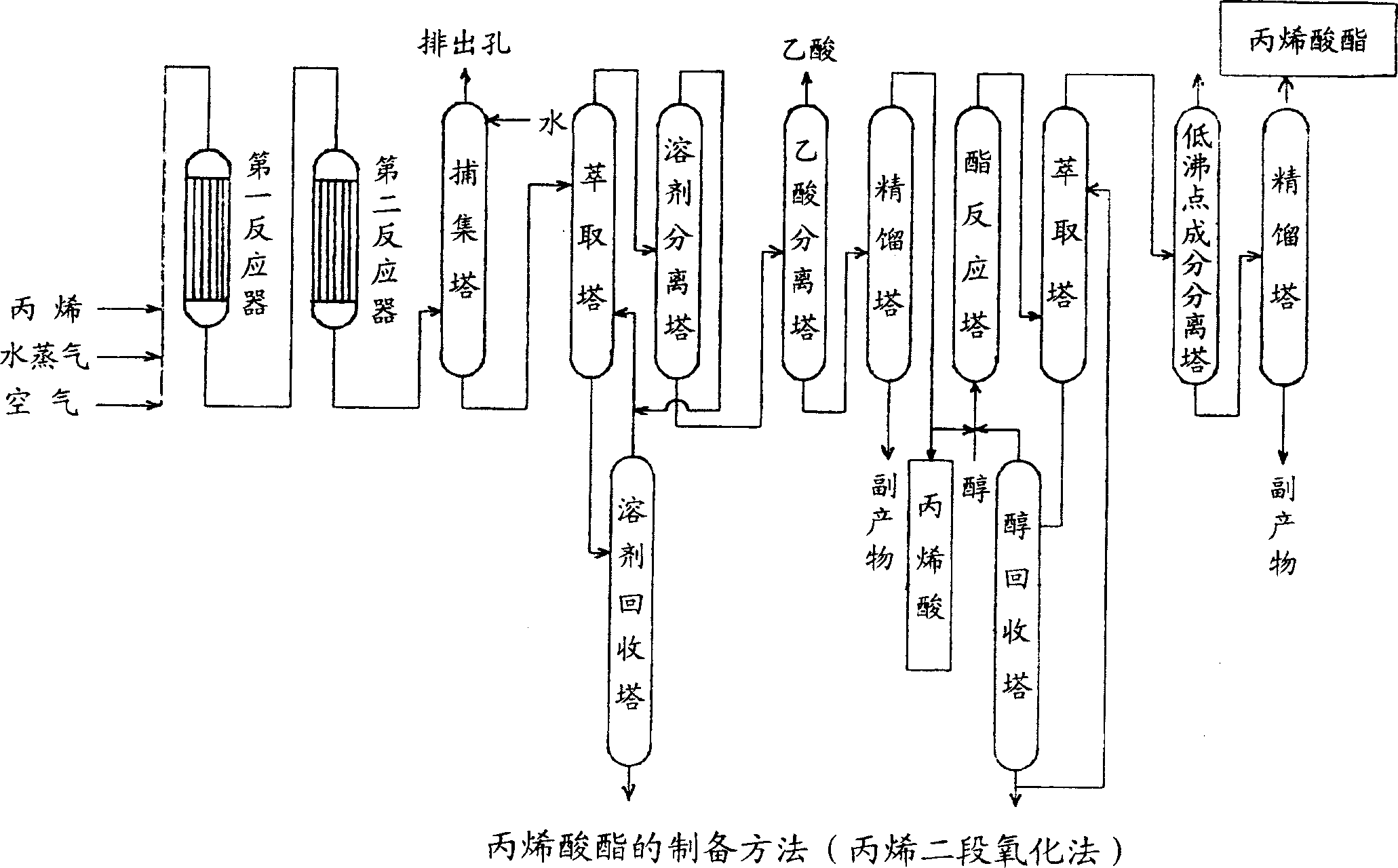

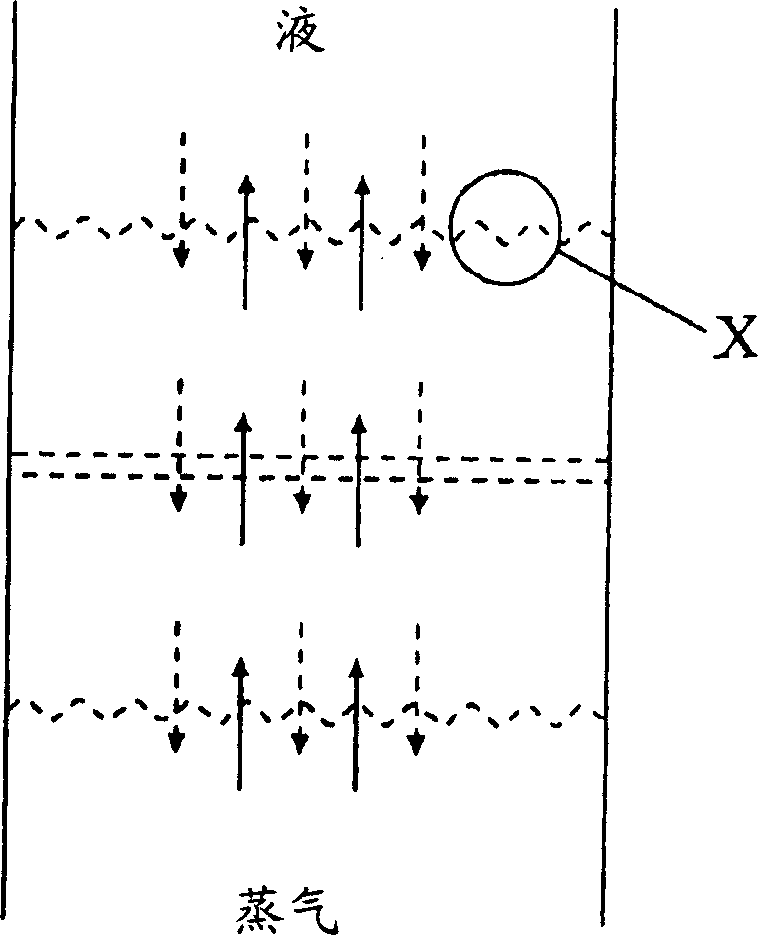

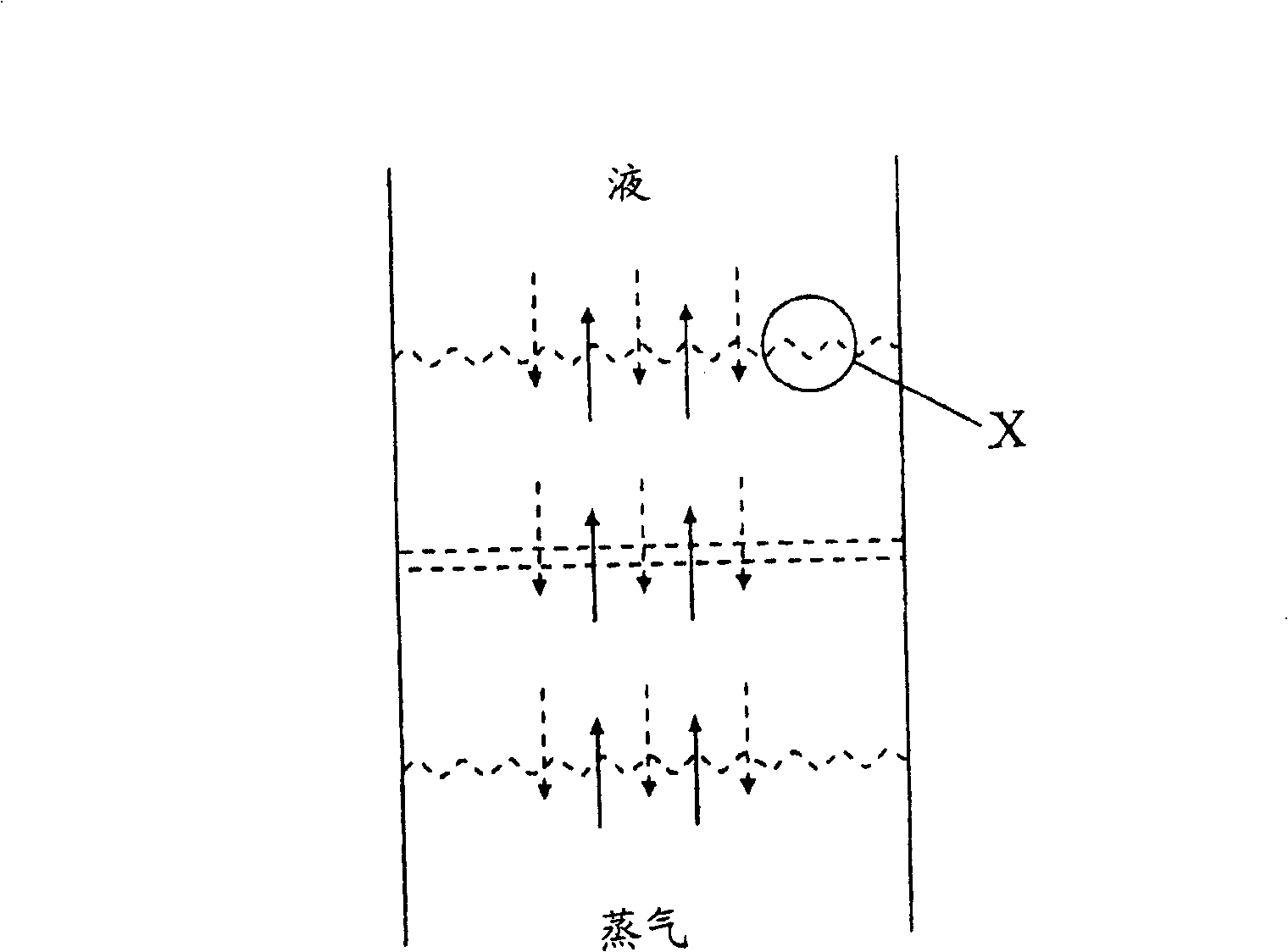

Process for producing (meth)acrylic acid or (meth)acrylic ester

InactiveCN1745055AReduce differential pressureStable and continuous operationOrganic compound preparationCarboxylic acid esters preparationMeth-Distillation

In the distillation purification of (meth)acrylic acid or a (meth)acrylic ester, attachment, deposition and accumulation of solid matter are prevented to thereby stably maintain a high recovery rate for (meth)acrylic acid or a (meth)acrylic ester, realizing stable continuous operation of the distillation column for a prolonged period of time. There is provided a method of distillation of a composition containing (meth)acrylic acid or a (meth)acrylic ester by means of a distillation column having multistage trays in its interior, wherein use is made of a distillation column packed with, as trays, corrugated-plate-type non-weir perforated plates each having a corrugated sectional configuration and multiple through-holes and flat-plate-type non-weir perforated plates each constituted of a flat plate having multiple through-holes.

Owner:MITSUBISHI CHEM CORP

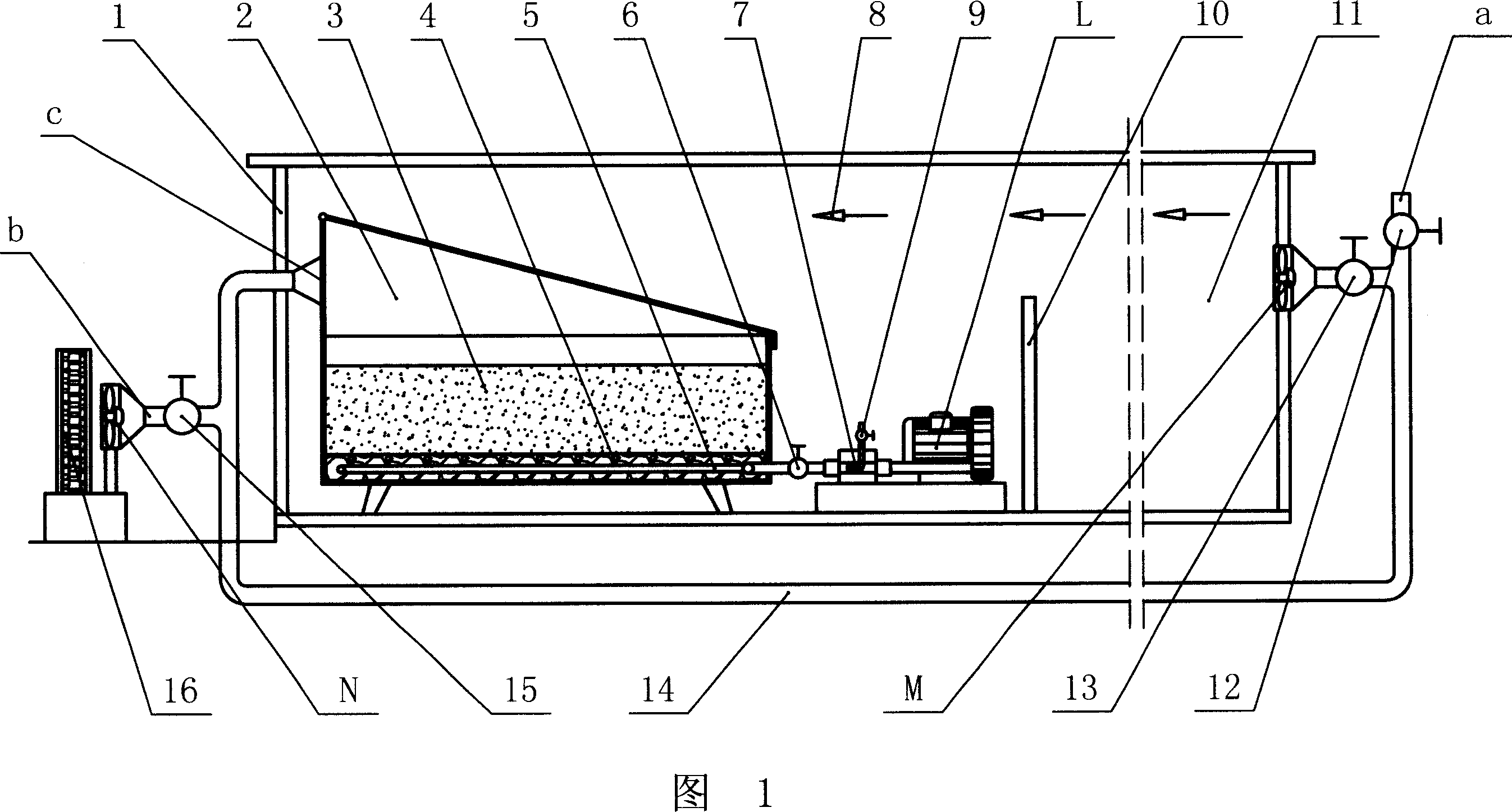

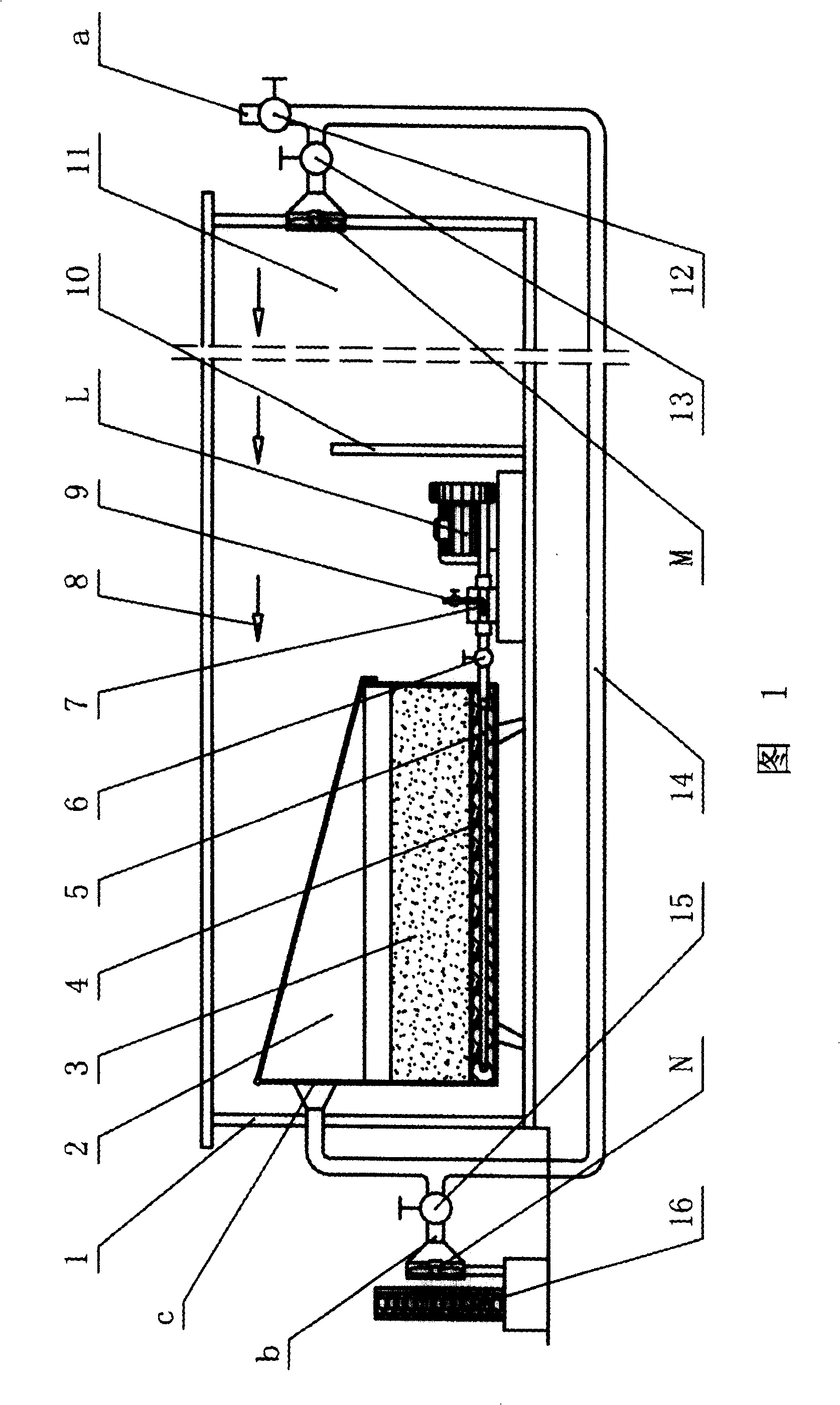

Biological filtering deodorizing device

InactiveCN1935330AStable and continuous operationLess investmentDispersed particle separationDeodrantsBio filtrationHazardous substance

The present invention provides a biological filter deodorization equipment. It includes a blower fan, said blower fan is connected with biological filter by means of humidifier; said biological filter includes air-permeable filter layer whose interior is filled up with filter filler for adsorbing microbe, under the air-permeable filter layer a gas distribution layer is set, in the gas distribution layer several gas distribution tubes with gas distribution holes are set, these air distribution tubes are connected with the above-mentioned humidifier; over the biological filter a gas outlet is set, and between the biological filter and controlled space a gas circulation pipeline is set.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

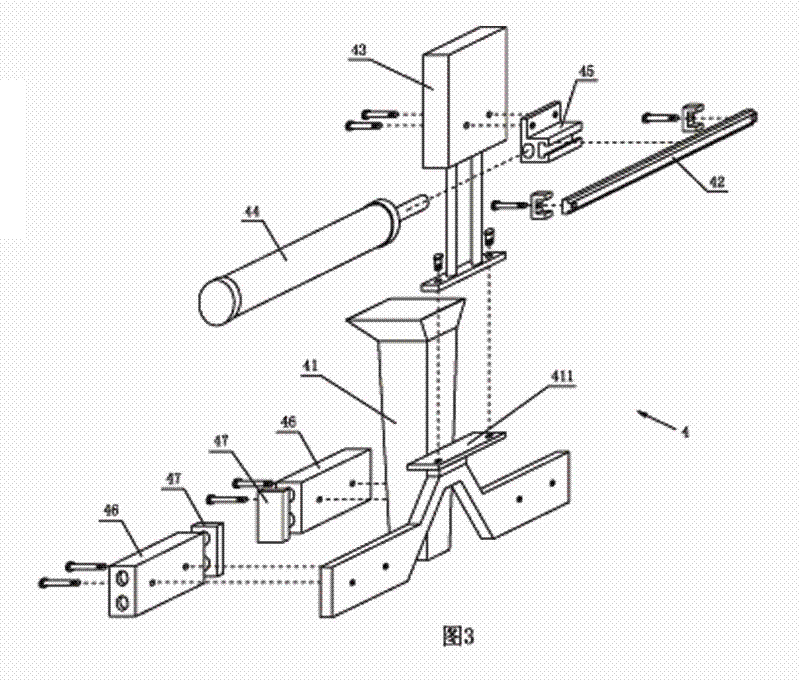

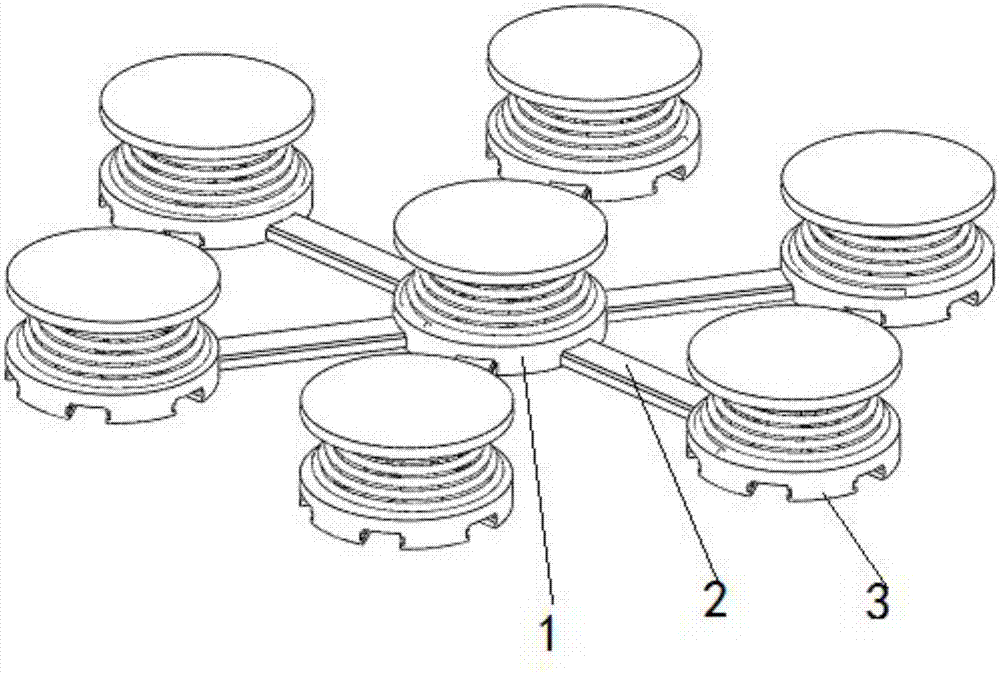

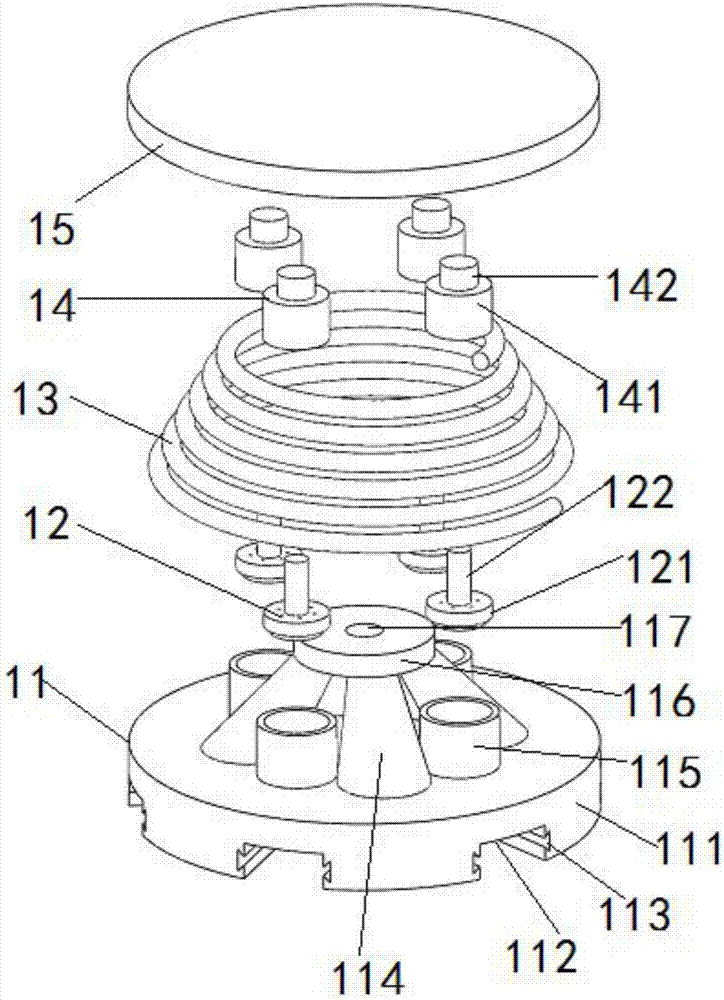

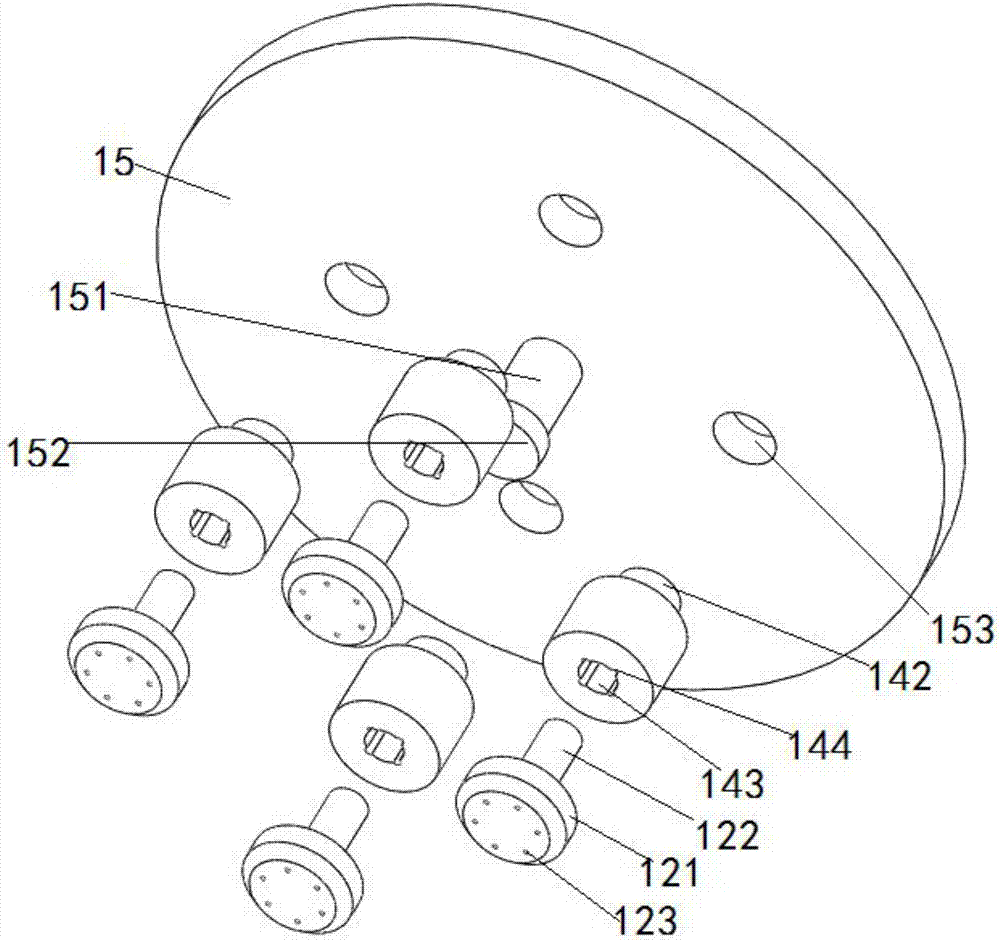

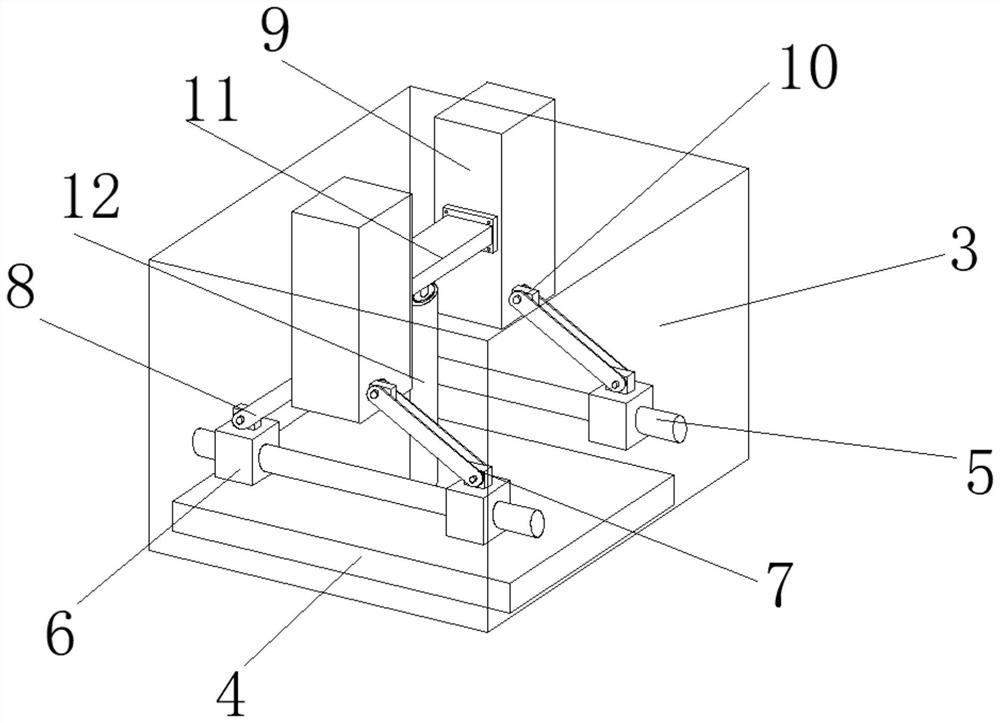

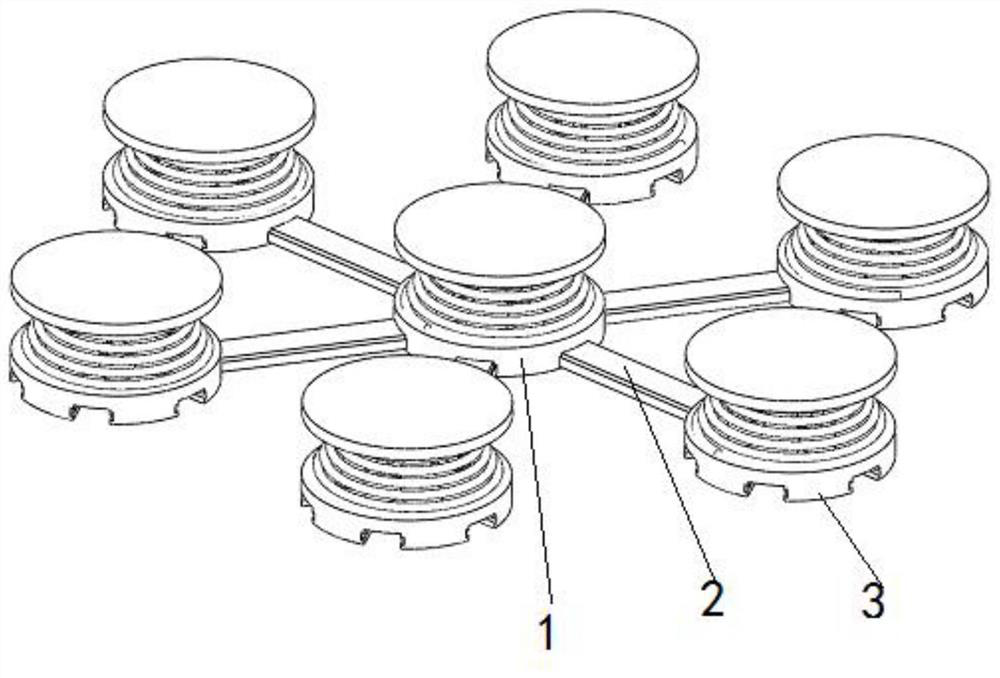

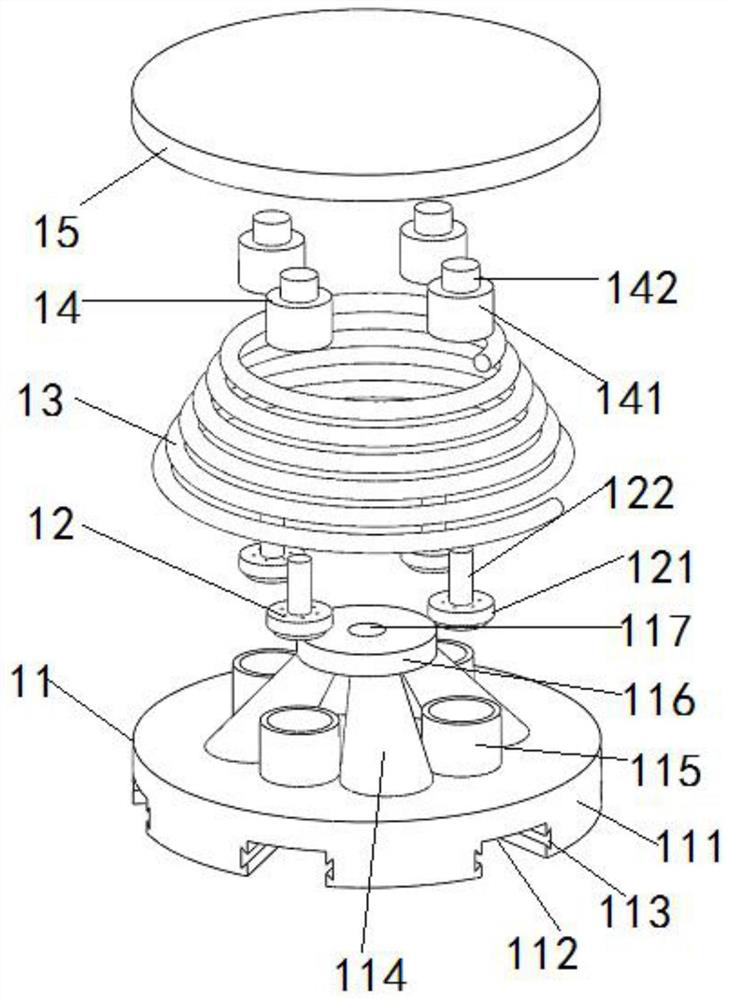

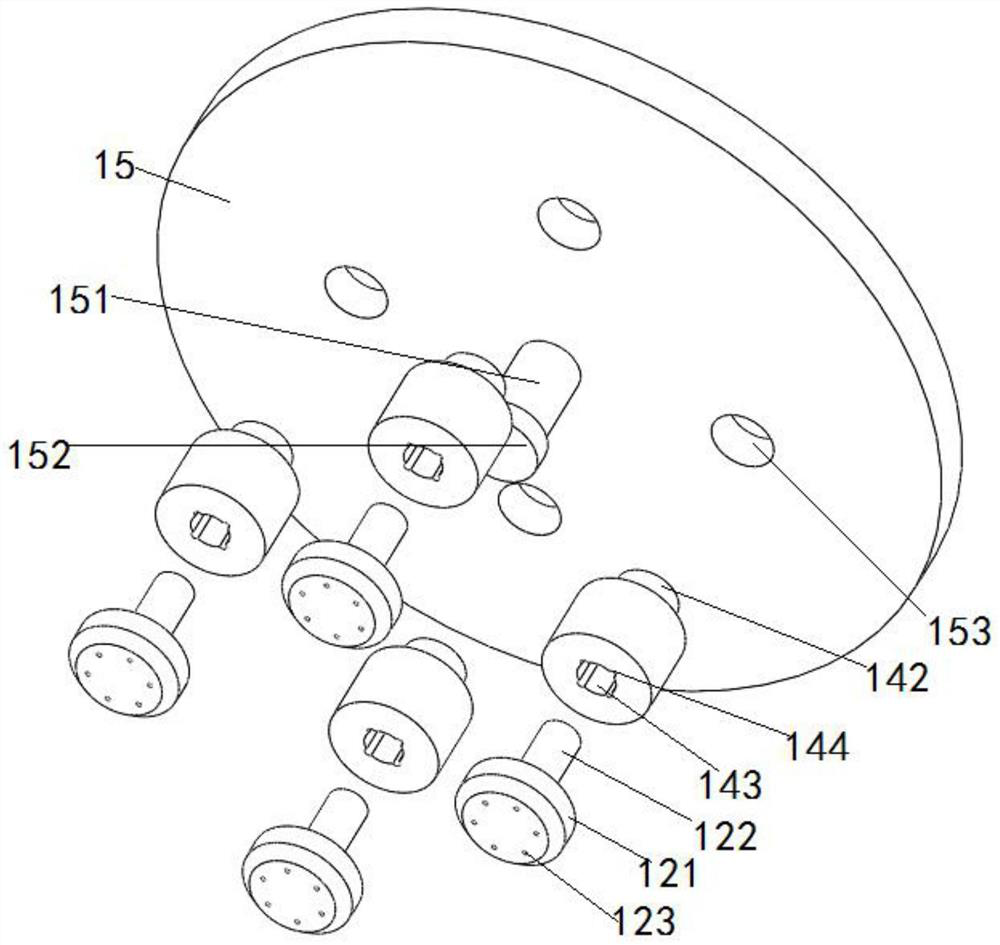

Buffer regulating technique based extractor control system

ActiveCN107096255AImprove the coordination effectImprove adaptabilitySolvent extractionTotal factory controlPistonEngineering

The invention discloses a buffer regulating technique based extractor control system. The buffer regulating technique based extractor control system comprises a support regulating mechanism distributed at the bottom of an extractor and is characterized in that the support regulating mechanism comprises six second buffer bases distributed circumferentially, a first buffer base is installed in the center of the second buffer bases and is connected with the same through fastening strips, and the first buffer base and the second buffer bases are identical in structure. By the arrangement that the six second buffer bases distributed circumferentially and the first buffer base located in the center of the second buffer bases, the base of the extractor can be well buffered and supported, impact force on the vertical direction can be effectively decomposed under mating reaction of pistons and piston barrels, good using effect is achieved, service life of the extractor is greatly prolonged as well, and steady and continuous running of the extractor in system is guaranteed.

Owner:合肥神马电气有限公司

Process for continuously producing calcium naphthenate

The invention discloses a process for continuously producing calcium naphthenate. The process comprises the following steps: (1) mixing naphthenic acid, methanol, dimethylbenzene and base oil to form a mixed oil raw material; (2) feeding the mixed oil raw material and a calcium hydroxide saturated solution in a first micro-tube type reactor, and carrying out neutralization reaction to obtain an intermediate product; (3) feeding the intermediate product and CO2 in a second micro-tube type reactor, and carrying out carbonation reaction to obtain a coarse product; and (4) directly feeding the coarse product into a coarse product tank from an outlet of the second micro-tube type reactor, distilling the coarse product and carrying out settling filtration on the coarse product to obtain the final product. The process has the beneficial effects that three-phase synthesis of high-base-number nano petroleum calcium naphthenate is carried out in a micro-reaction system, reaction materials can be micro-mixed uniformly instantaneously, the form and the particle size distribution of nanoparticles are controlled effectively, the production efficiency and the quality of products are improved, and stable continuous operation is realized.

Owner:XI'AN PETROLEUM UNIVERSITY

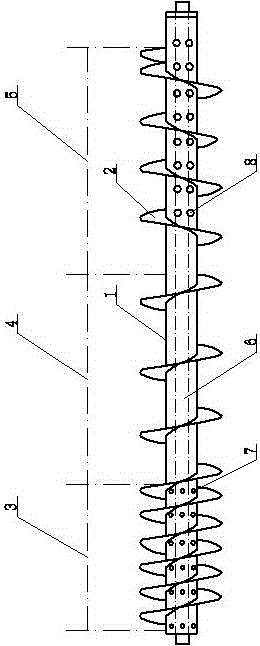

Hollow tube type variable-pitch spiral conveyor for potato pulp dewatering device

InactiveCN105115288AContinuous and even feedingImprove sealingDrying gas arrangementsDrying solid materialsHelical bladeEngineering

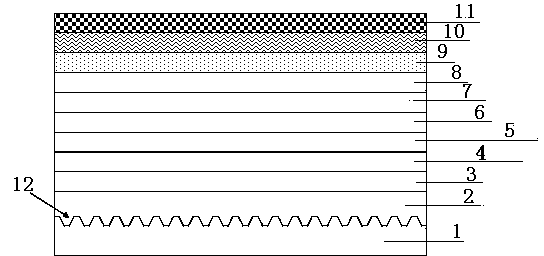

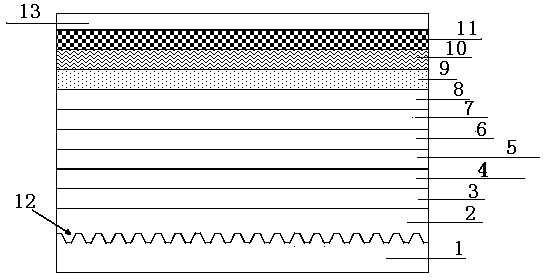

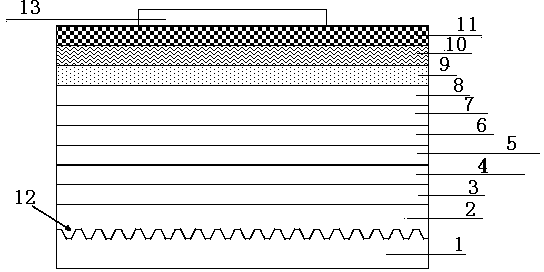

The invention belongs to the technical field of potato pulp dewatering devices, and particularly relates to a hollow tube type variable-pitch spiral conveyor for a potato pulp dewatering device. The spiral conveyor comprises a screw (1) and screw blades (2) arranged on the screw (1) and is mainly composed of a dense spiral section (3) located at the front end of the screw (1), a wide spiral section (4) located in the middle of the screw (1) and a reverse acting spiral section (5) located at the tail end of the screw (1). The spiral conveyor is characterized in that a hollow pipeline (6) is arranged in the screw (1), and the hollow pipeline (6) penetrates through the whole screw (1) and is connected with external equipment. The spiral conveyor has the advantages that bearing blocking is prevented, long-time stable and continuous spiral conveyance is guaranteed, and potato pulp is pressurized and heated to be dried through external hot air.

Owner:郑世奇

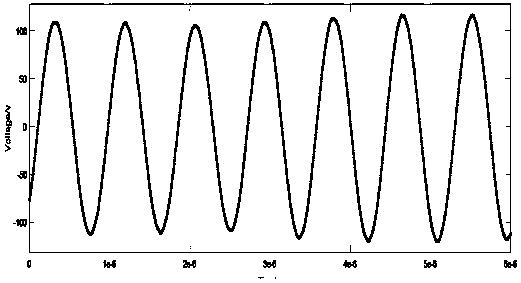

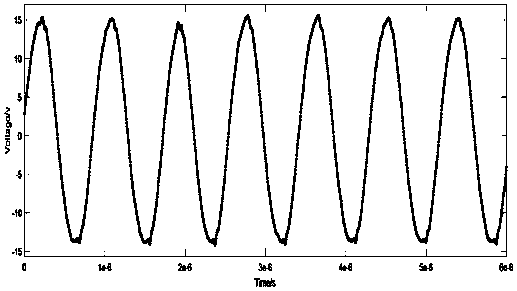

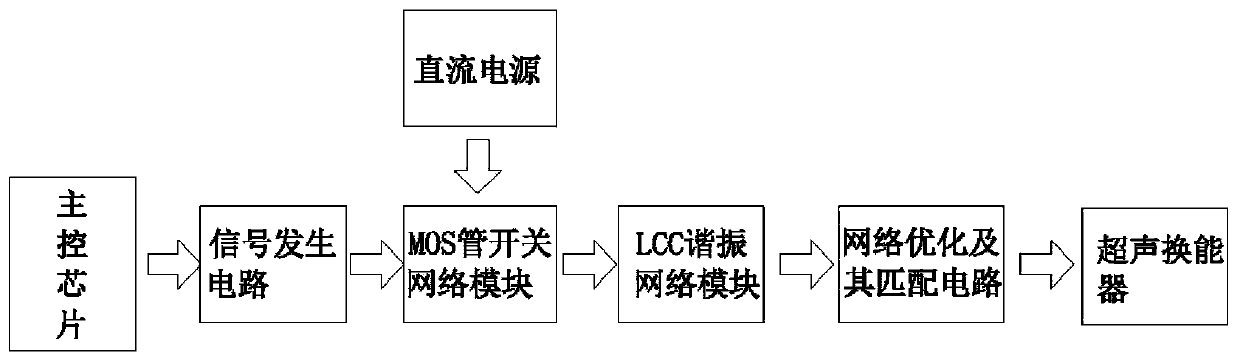

Physiotherapy driver system based on high frequency ultrasonic wave and driving method thereof

InactiveCN110354407AEfficient outputImprove reliabilityUltrasound therapyUltrasonic sensorEngineering

The invention discloses a physiotherapy driver system based on high frequency ultrasonic wave and a driving method thereof. The physiotherapy driver system comprises a main control chip, a signal generation circuit, a MOS tube switch network module, an LCC resonant network module, and network optimization and its matching circuit. The method adjusts the parameters of the LCC resonant network to match the loaded parameters of a corresponding ultrasonic transducer, so that the output of an entire system is optimized. the ultrasonic transducer operates in a resonant frequency range, so that the driver and the ultrasonic transducer are optimally matched, the energy conversion efficiency is effectively improved and the output of the ultrasonic amplitude is increased, the heat generation is small, the reliability and stability of a driver are effectively improved, the driver can continue to operate safely and stably, a more accurate optimization model is provided, the parameter design is relatively simple, the voltage amplification factor is further improved, the physiotherapy effect is improved, and the system facilitates widespread use.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

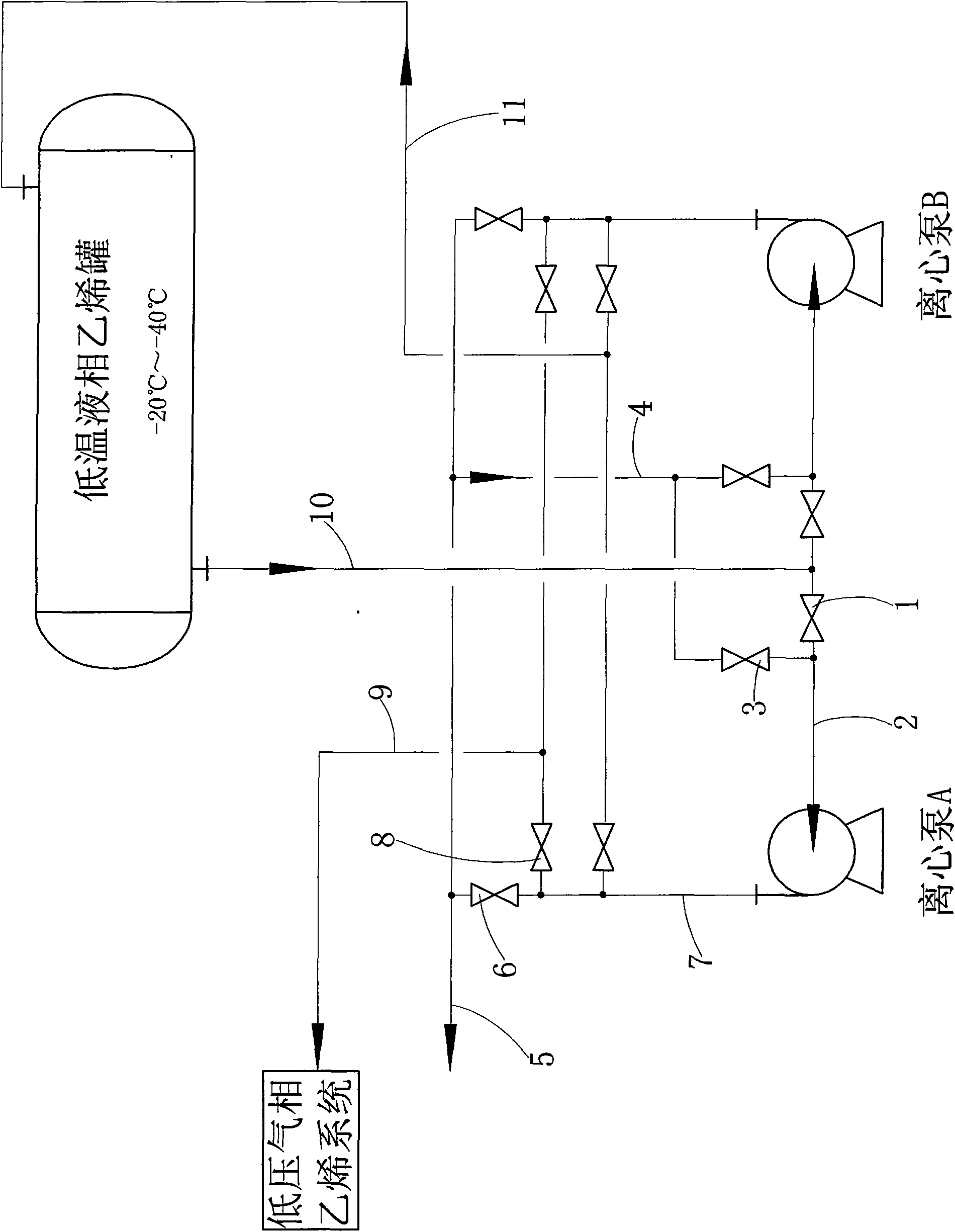

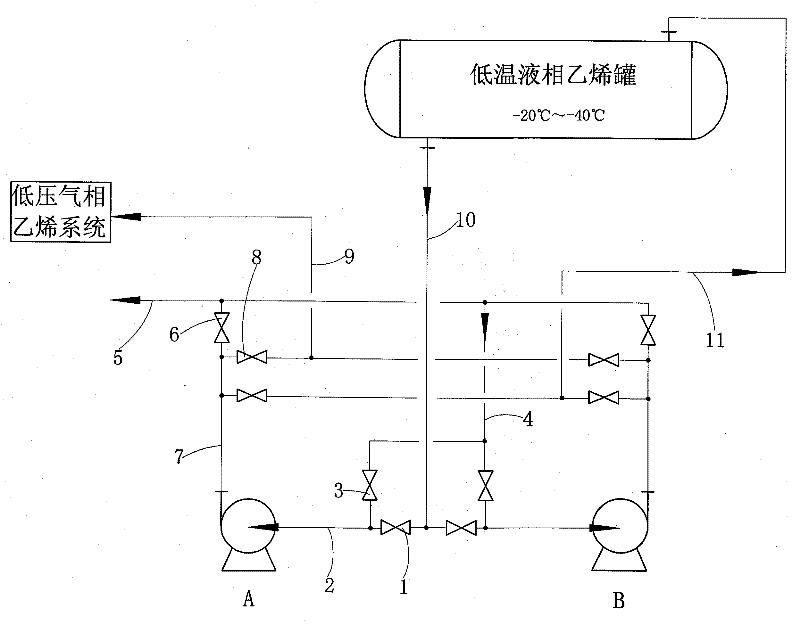

Method for precooling centrifugal pump used for transporting low temperature ethylene

ActiveCN101655103ANo thermal damageReduce manufacturing costSpecific fluid pumpsPump componentsGas phaseContinuous operation

The invention discloses a method for precooling a centrifugal pump which is used for transporting low temperature ethylene, comprising the following steps: using mini-flow low temperature liquid phaseethylene to constantly precool a back-up centrifugal pump, a liquid-in pipeline and a liquid-out pipeline and obtain gasified ethylene, constantly rolling the pump in the precooling and gasifying process, discharging gaseous phase ethylene into a low pressure gaseous phase ethylene system when the pressure of gaseous phase ethylene in the pump reaches 1.5-1.7Mpa, continuously discharging for 20-30min to lead the temperature of the pump and the liquid-in and liquid-out pipelines to be up to -40 to -20 DEG C, by now, closing corresponding hand stop valves of liquid phase ethylene entering pipeand gaseous phase ethylene discharge pipe and then opening corresponding hand stop valves on the liquid-in pipeline and the liquid-out pipeline, adopting liquid phase ethylene at the temperature of -40 to -20 DEG C to pour into the back-up centrifugal pump, successfully starting the back-up centrifugal pump by once, and closing the operation of the centrifugal pump at the moment. By adopting the method, the switchover of the centrifugal pump can be easily realized, the safe and stable continuous operation of an ethylene purification device can be ensured, and the production cost can be lowered.

Owner:SUZHOU COFCO BIOCHEM

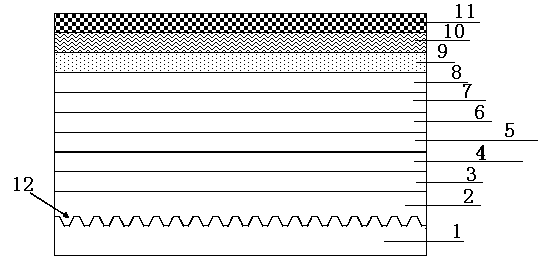

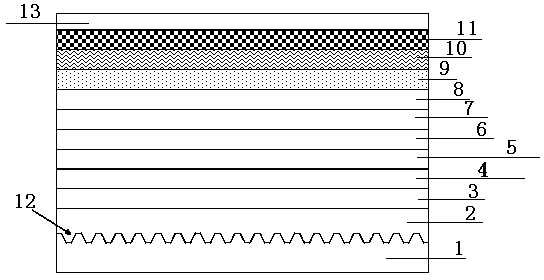

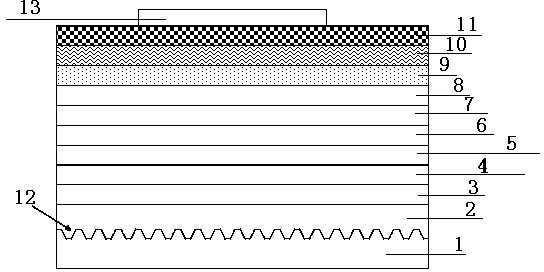

High-power LED lamp with heat radiated through ceramics

ActiveCN103943769AStable and continuous operationExtended service lifePoint-like light sourceSemiconductor devices for light sourcesLED lampHeat energy

The invention relates to a high-power LED lamp with heat radiated through ceramics. The high-power LED lamp comprises a ceramic radiating base (6), a circuit board is fixed to one face of the ceramic radiating base (6), a white light LED flip chip (5) is connected to the circuit board, a nontransparent lampshade is fixed to the position above the white light LED flip chip (5), outward-protruding radiating fins (61) are arranged on the other face of the ceramic radiating base (6), and the radiating fins (61) are made of ceramic materials. Due to the fact that the radiating fins and the ceramic radiating base are made of ceramic materials, heat produced by the white light LED flip chip can be rapidly absorbed and radiated through high conductivity and high radiation physical properties of the ceramic materials, it is ensured that the white light LED flip chip is in the constant low temperature state and can work stably and continuously, and therefore the service life of the LED lamp can be prolonged.

Owner:JIANGSU HOWELL TRANSPORTATION GRP CO LTD

Preparation of electrode-active material by using double-pipe type heat exchanger

InactiveCN103260742AStable and continuous operationExtend your lifeElectrode thermal treatmentChemical/physical/physico-chemical stationary reactorsPlate heat exchangerNuclear engineering

Owner:HANWHA CHEMICAL CORPORATION

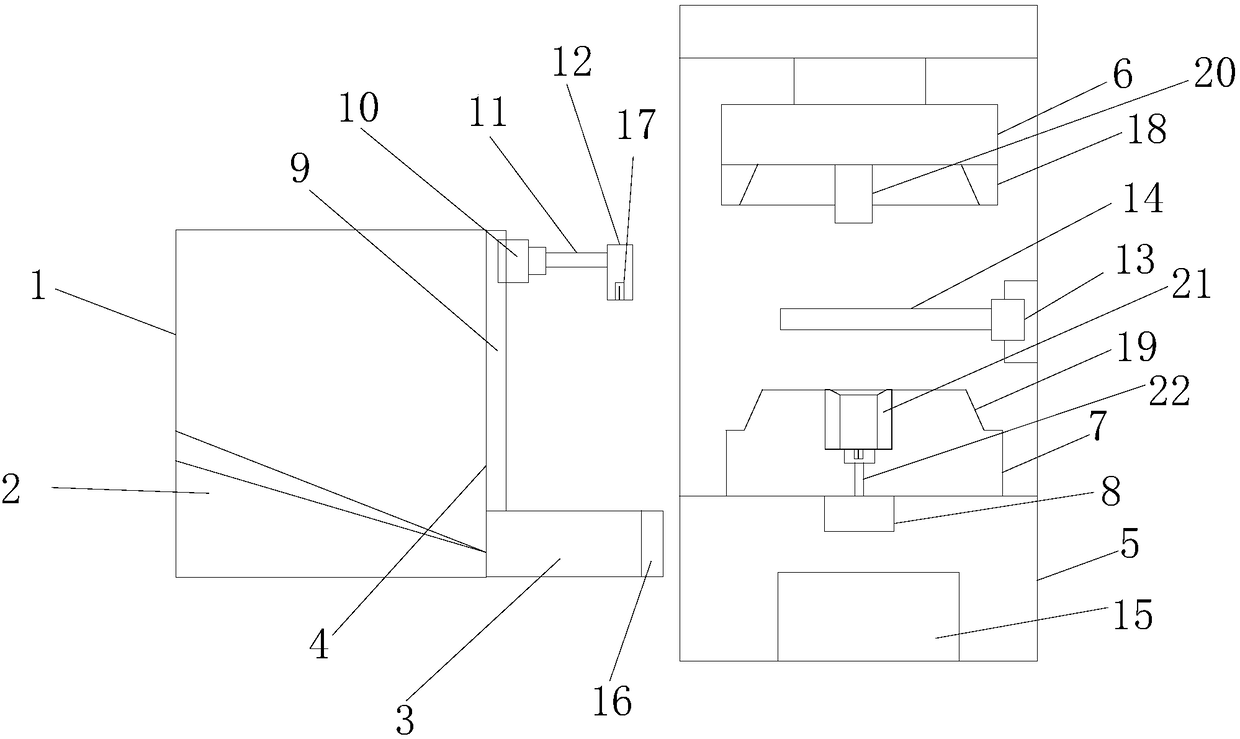

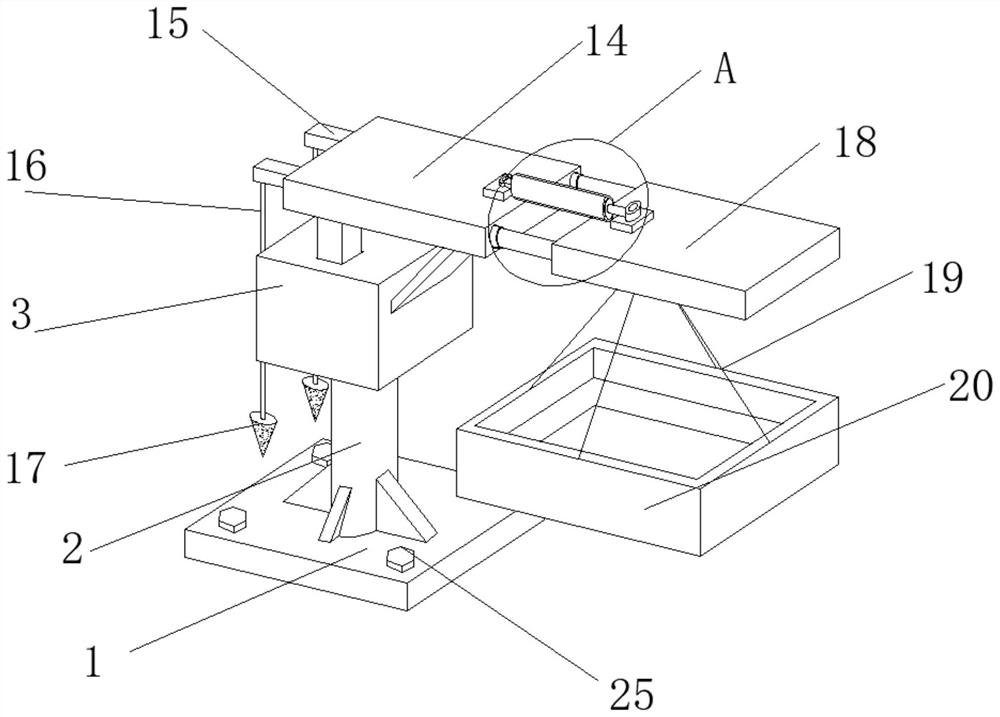

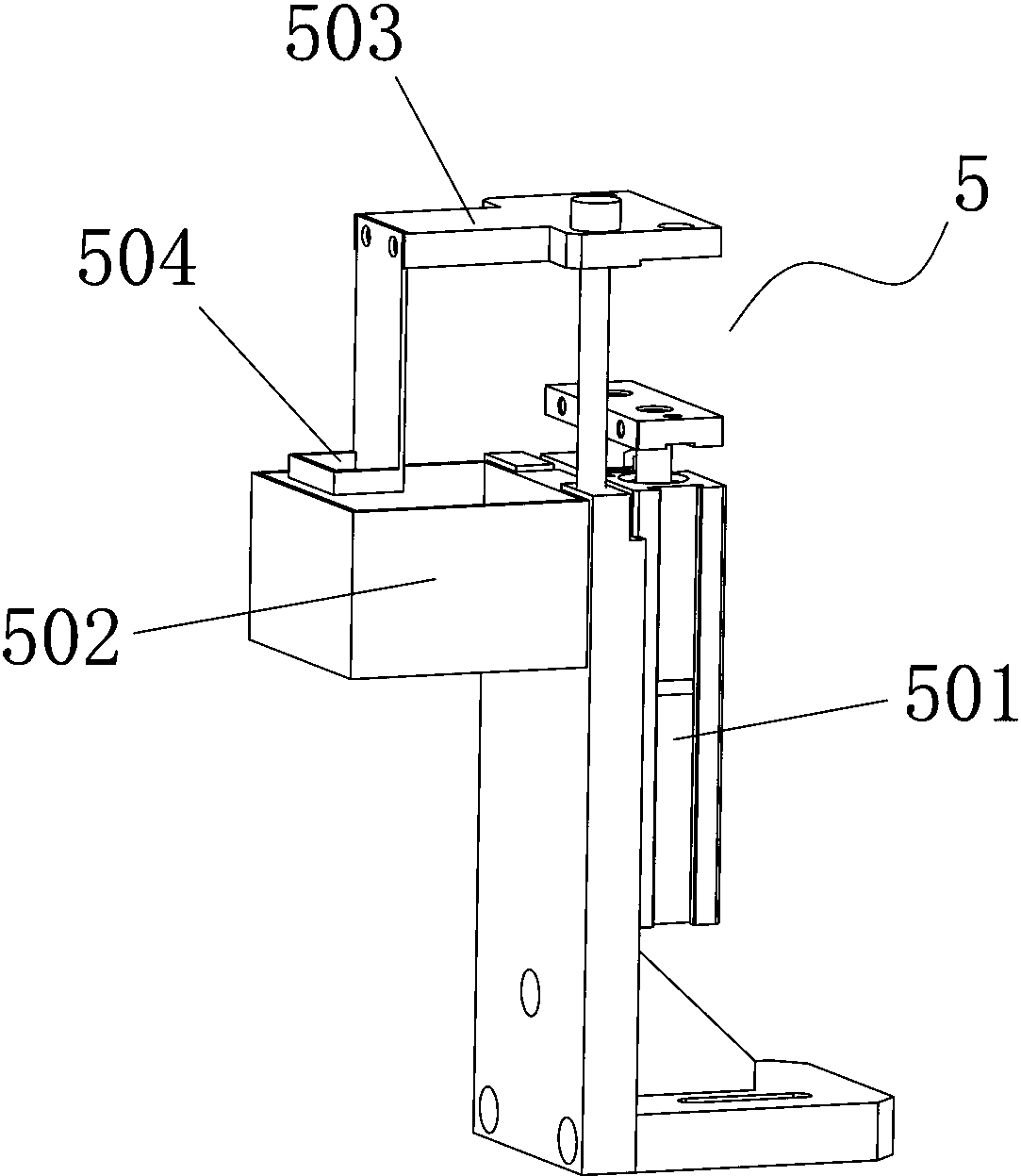

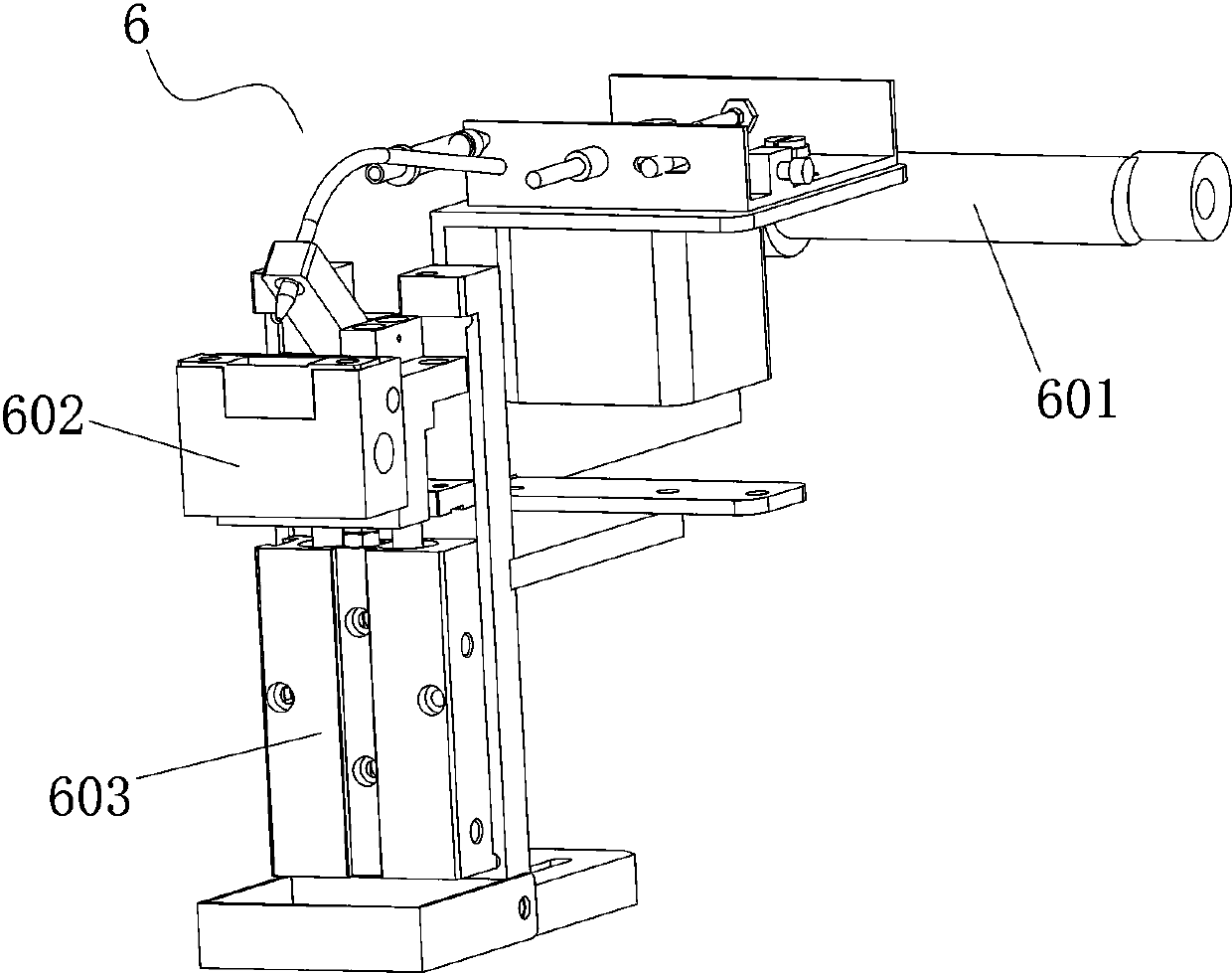

Automatic forming machine for auto parts

PendingCN108526340APrecise deliveryStable and continuous operationMetal-working feeding devicesVehicle componentsPunchingMolding machine

The invention discloses an automatic forming machine for auto parts. The automatic forming machine comprises a blanking bin, a material ordering bottom plate, a discharging groove, a feeding device, arack, an upper punching die, a lower jacking die and a discharging device. According to the automatic forming machine, by combing the blanking bin, the material ordering bottom plate, the discharginggroove, the feeding device, the rack, the upper punching die, the lower jacking die and the discharging device together, through experimental optimization, raw materials can be subjected to initial ordering output by matching the material ordering bottom plate with the discharging groove, the raw materials can be conveyed into a limiting jacking hole of the lower jacking die accurately and quickly through mutual matching of a lifting guiding rail, a lifting sliding block, a telescopic air cylinder arm and a material sucking block on the feeding device, workpieces are subjected to cold extruding through mutual matching of the upper punching die and the lower jacking die, the workpieces are jacked out by the discharging device, and the workpieces are shifted out of the rack range by a horizontal material pushing device. According to the automatic forming machine, the auto parts can be automatically subjected to cold extruding forming in the forming machine, operation is stable and continuous, the production efficiency is high, a formed product is high in strength and good in appearance, the manpower and cost are saved, and promotion is facilitated.

Owner:嘉兴晨飞科技有限公司

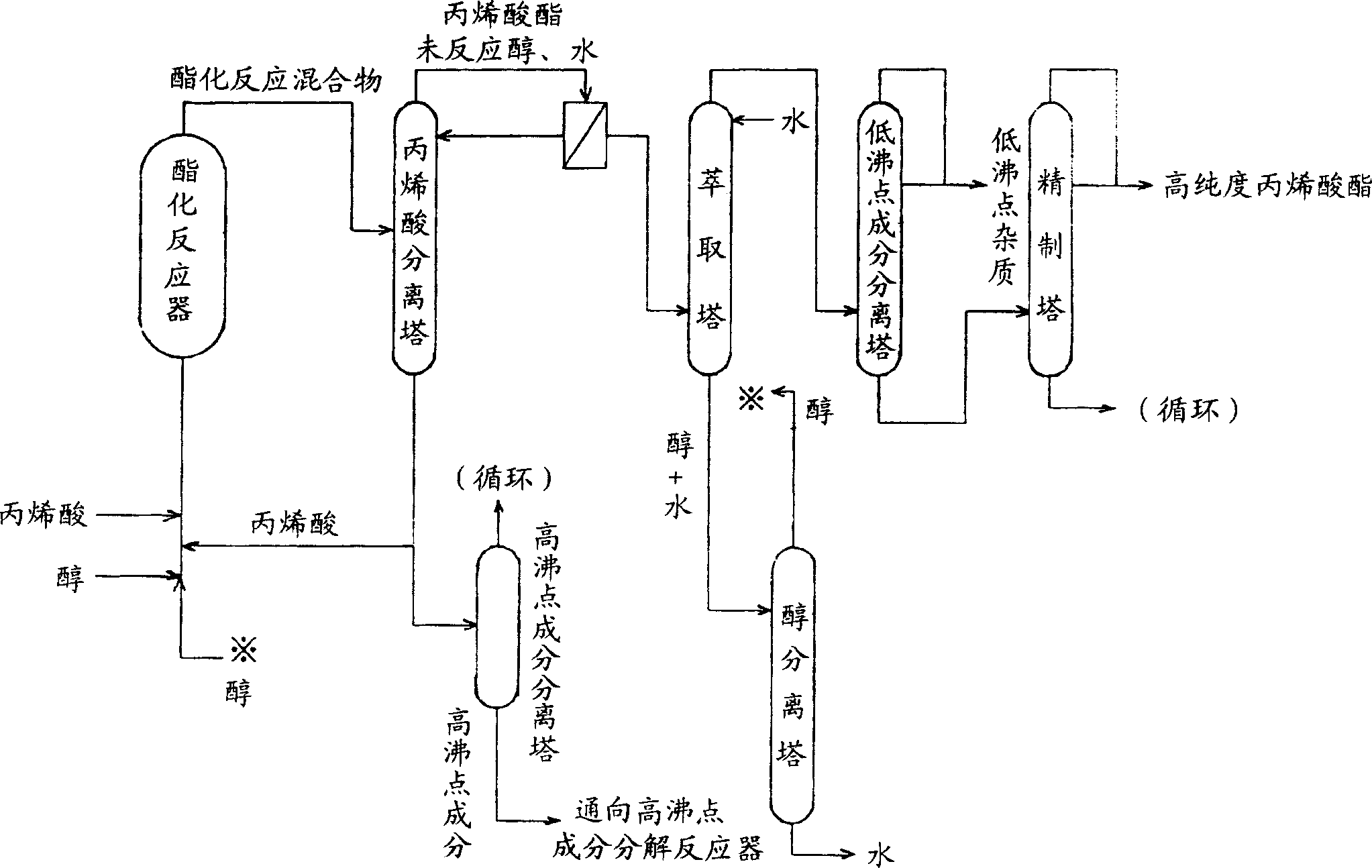

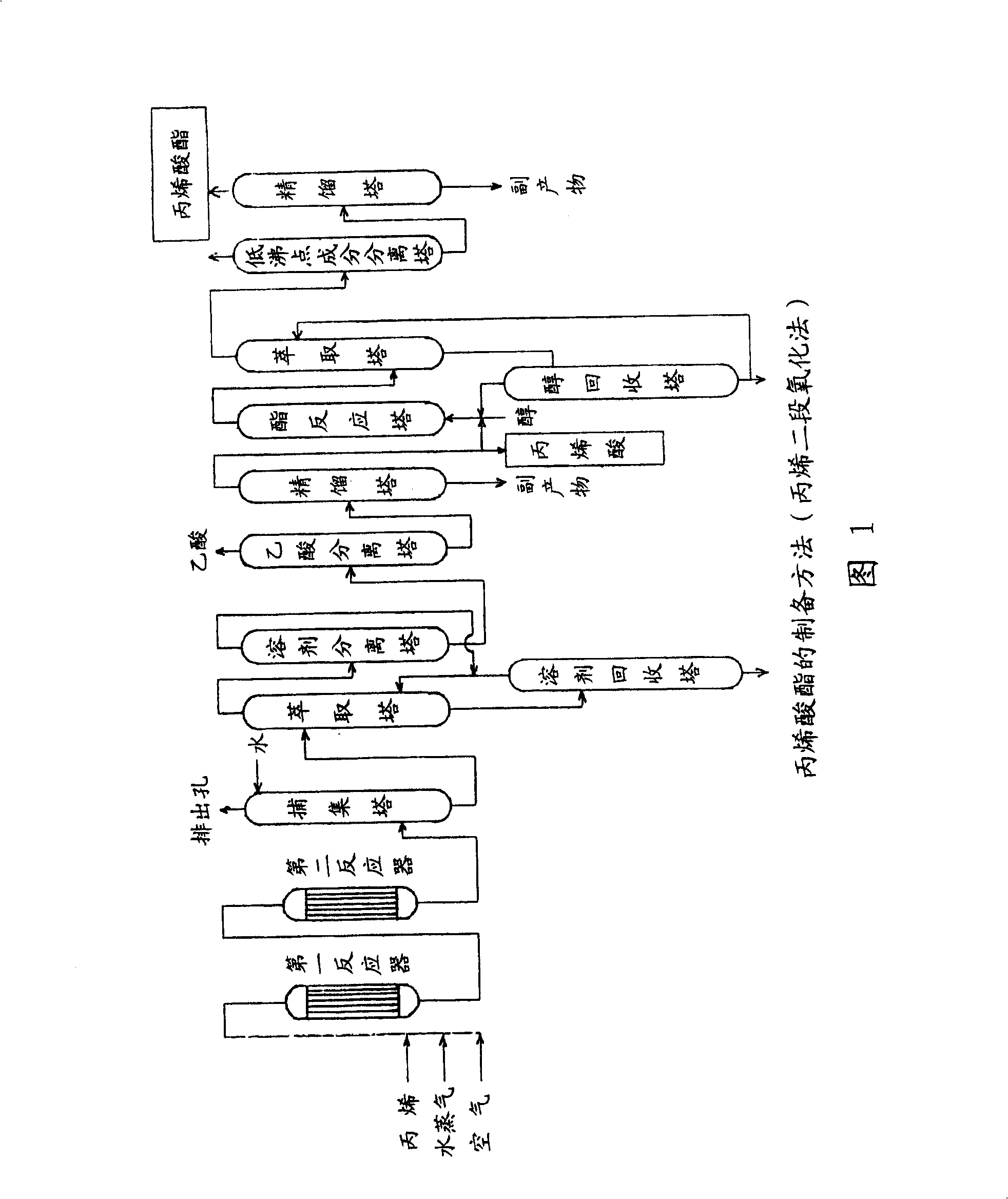

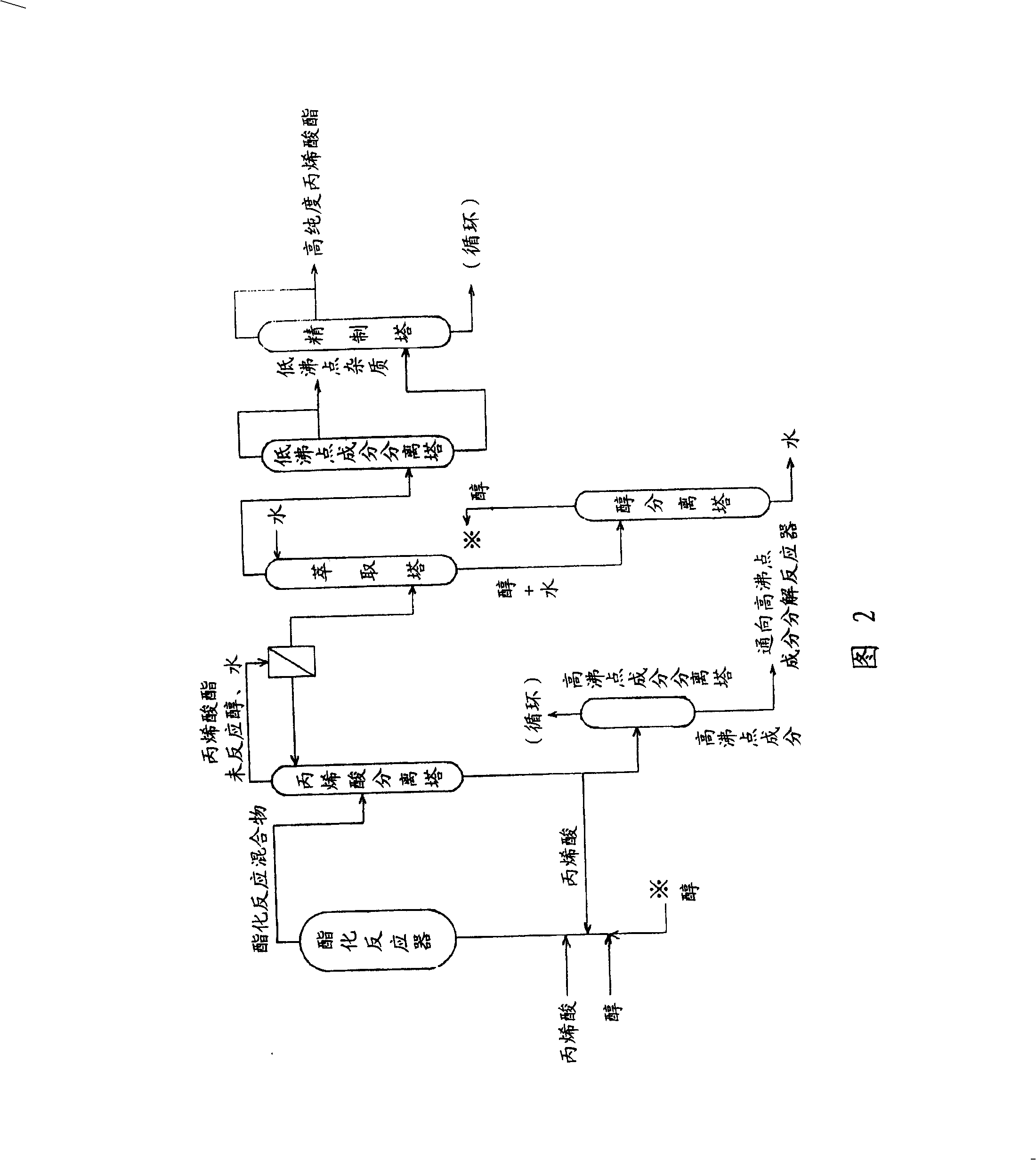

Process for producing (meth) acrylic acids

InactiveCN1562948AContinuous operationHigh recovery rateOrganic compound preparationCarboxylic acid esters preparationMeth-Gas phase

A process for producing (meth)acrylic acid or (meth)acrylic acid esters, which comprises a reaction step comprising vapor phase catalytic oxidation of propylene, propane or isobutylene and, if necessary, a reaction step comprising an esterification step, characterized in that at the time when a high boiling mixture (hereinafter referred to as a high boiling material) containing a Michael addition product, is decomposed in a decomposition reactor to recover (meth)acrylic acids, while forcibly imparting a liquid flow in the circumferential direction to a liquid reaction residue in the decomposition reactor, the liquid reaction residue is discharged. In a process for recovering a valuable substance by thermally decomposing the high boiling material containing the Michael addition product of (meth)acrylic acids, it is possible to transfer the decomposition residue from the decomposition reactor to the storage tank without clogging, whereby a long-term continuous operation is possible.

Owner:MITSUBISHI RAYON CO LTD

High-power LED lamp using ceramic for heat dissipation

ActiveCN103915557AStable and continuous operationExtended service lifePoint-like light sourceSemiconductor devices for light sourcesThermal energyLED lamp

The invention relates to a high-power LED lamp using ceramic for heat dissipation. The high-power LED lamp comprises a ceramic heat dissipation base (6), a circuit board is fixed on one surface of the ceramic heat dissipation base (6) and connected with a white-light LED flip chip (5), and a non-transparent lampshade is fixedly arranged above the white-light LED flip chip (5); heat dissipation fins (61) protruding outwards are arranged on the other surface of the ceramic heat dissipation base (6) and are also made of the ceramic. According to the high-power LED lamp, as the heat dissipation fins and the ceramic heat dissipation base are all made of the ceramic, heat produced by the white-light LED flip chip can be absorbed and dissipated rapidly by means of high-conductivity and high-radiation physical characteristics of the ceramic, it is guaranteed that the white-light LED flip chip is in a constant low-temperature state and can operate stably and continuously, and therefore service life of an LED can be prolonged.

Owner:永州菲斯特电子科技有限公司

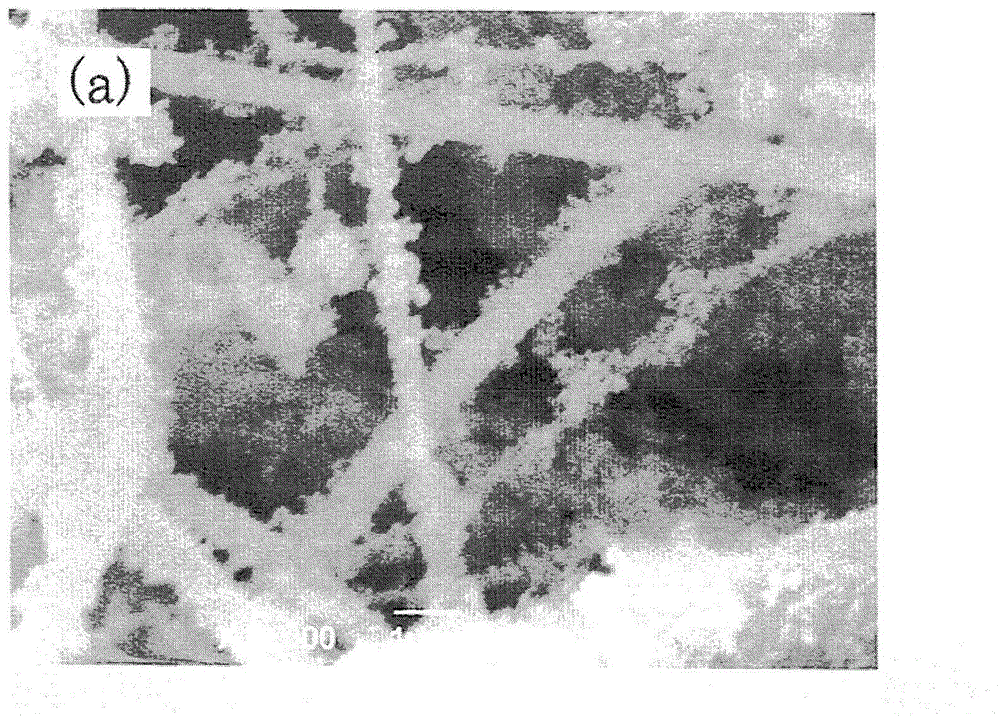

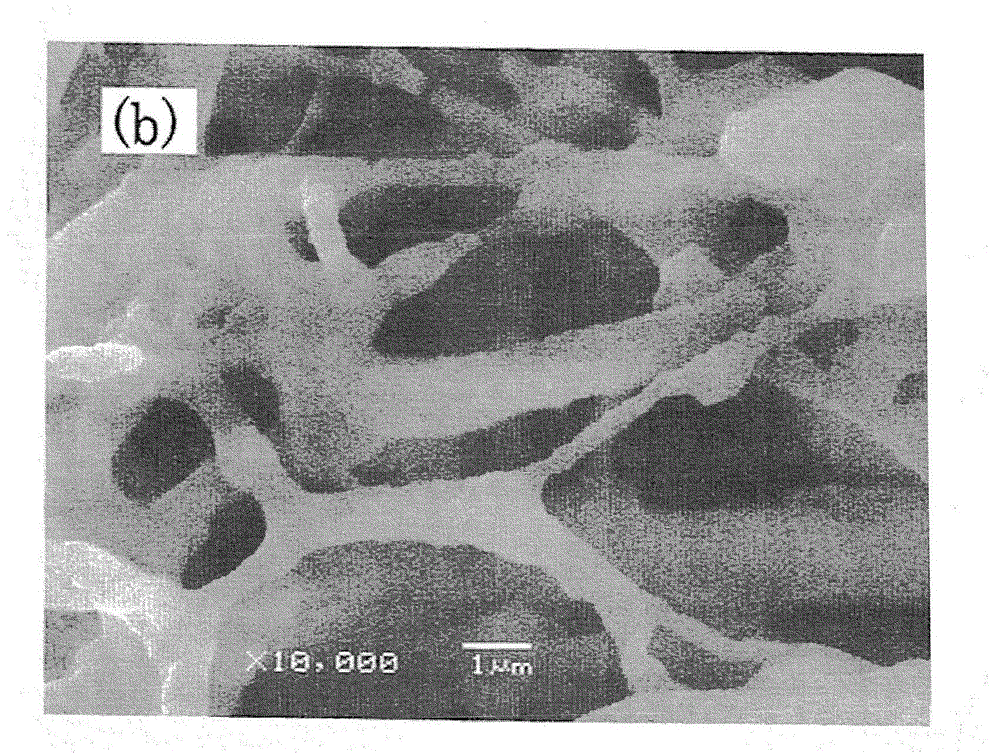

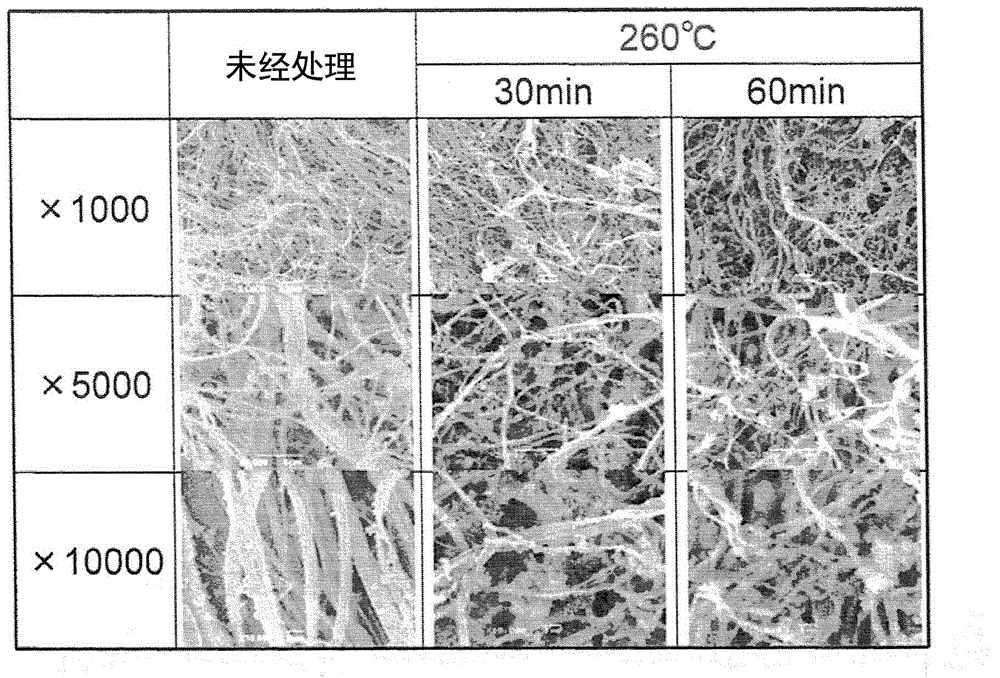

Pfa porous sheet

InactiveCN102753744ALarge specific surface areaSmall standard deviationMelt spinning methodsNon-woven fabricsVinyl etherTetrafluoroethylene

To provide a PFA porous sheet comprising a PFA (tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer) microfilament group and has enhanced tensile strength and a specific surface area. ; SOLUTION: There are provided the PFA porous sheet includes a filament group comprising PFA having an average filament diameter of not more than 10 [mu]m, and the filament contains many fine PFA particles having an average filament diameter or smaller, and a method for producing the same is further provided.

Owner:UNIVERSITY OF YAMANASHI +1

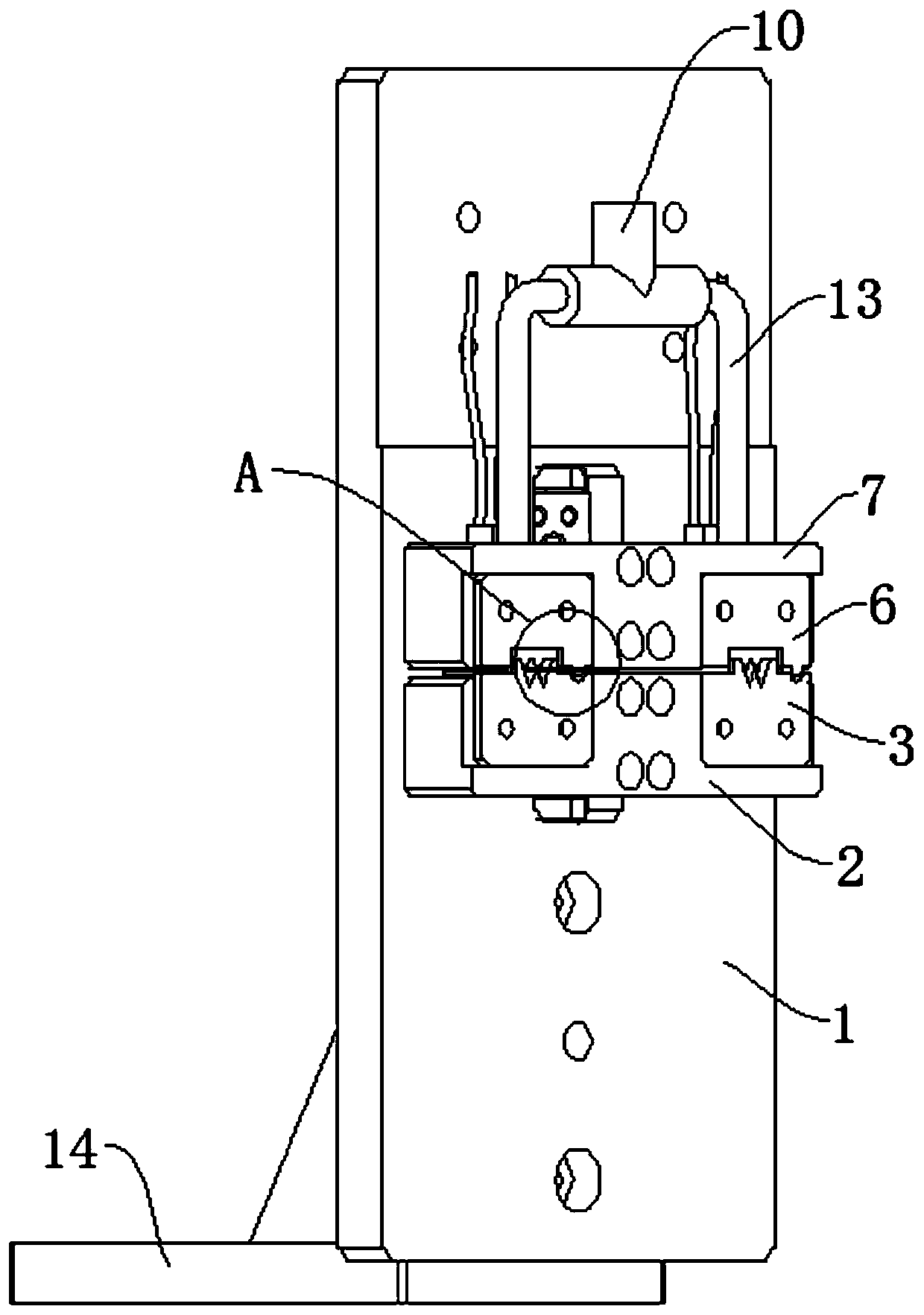

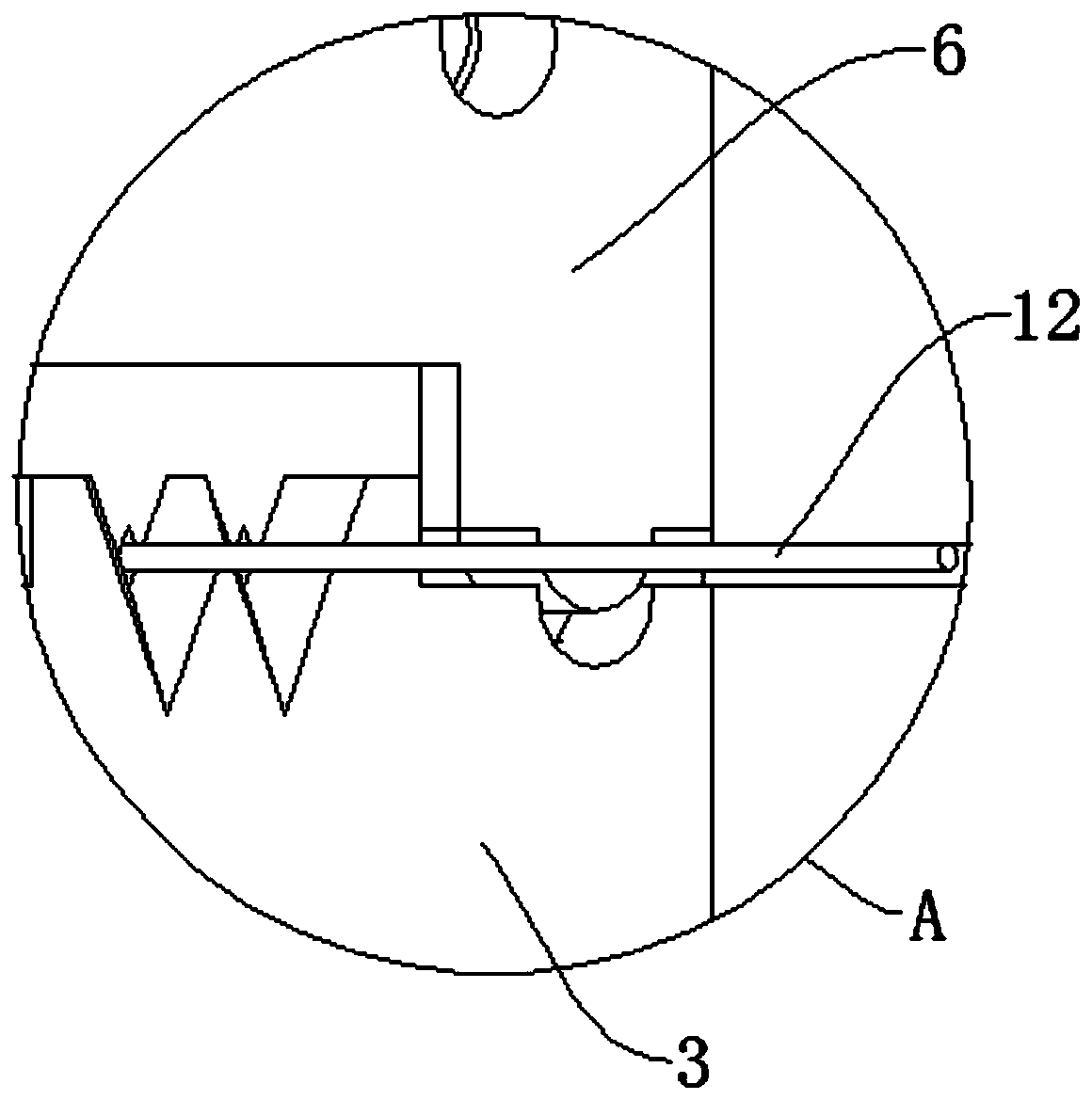

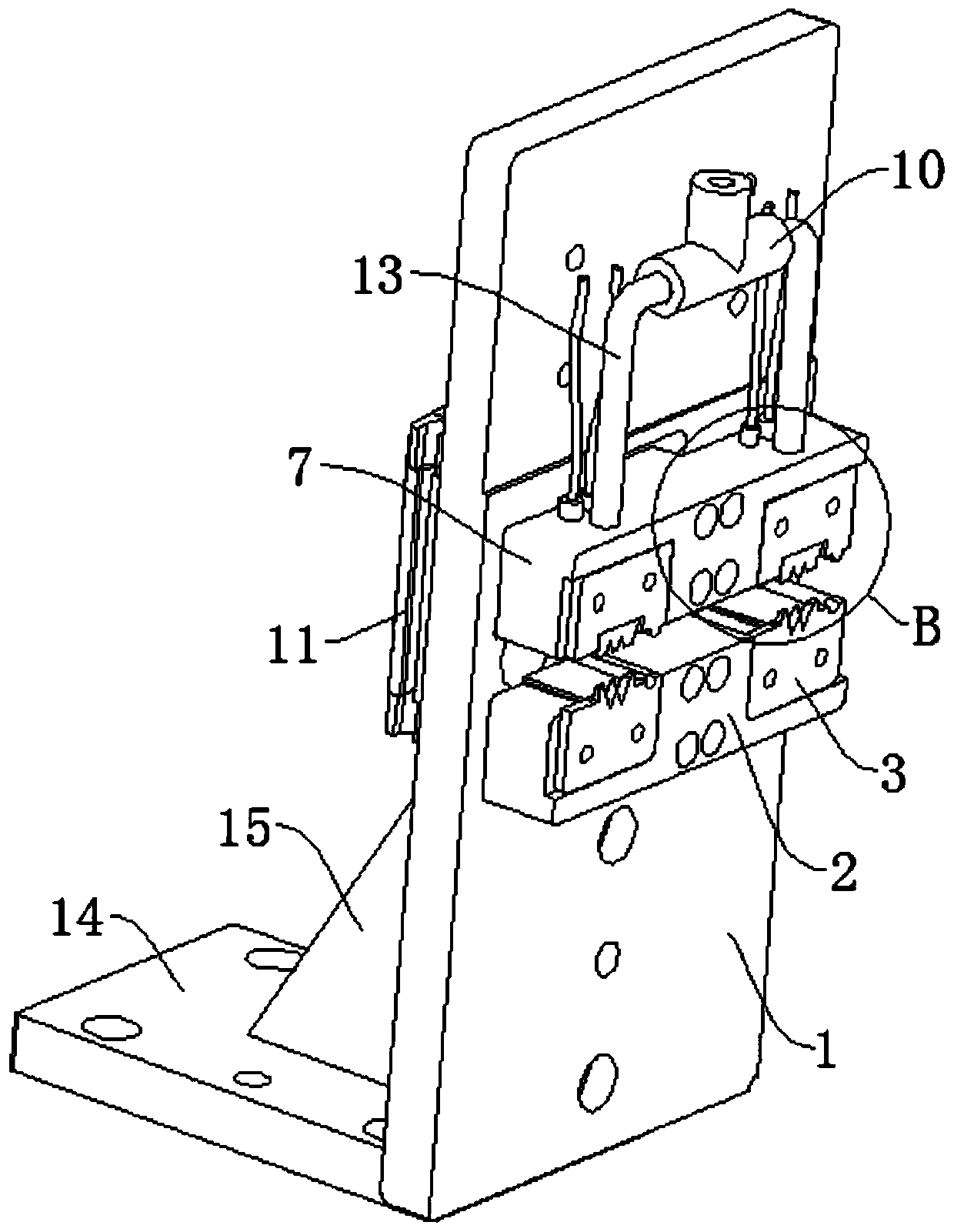

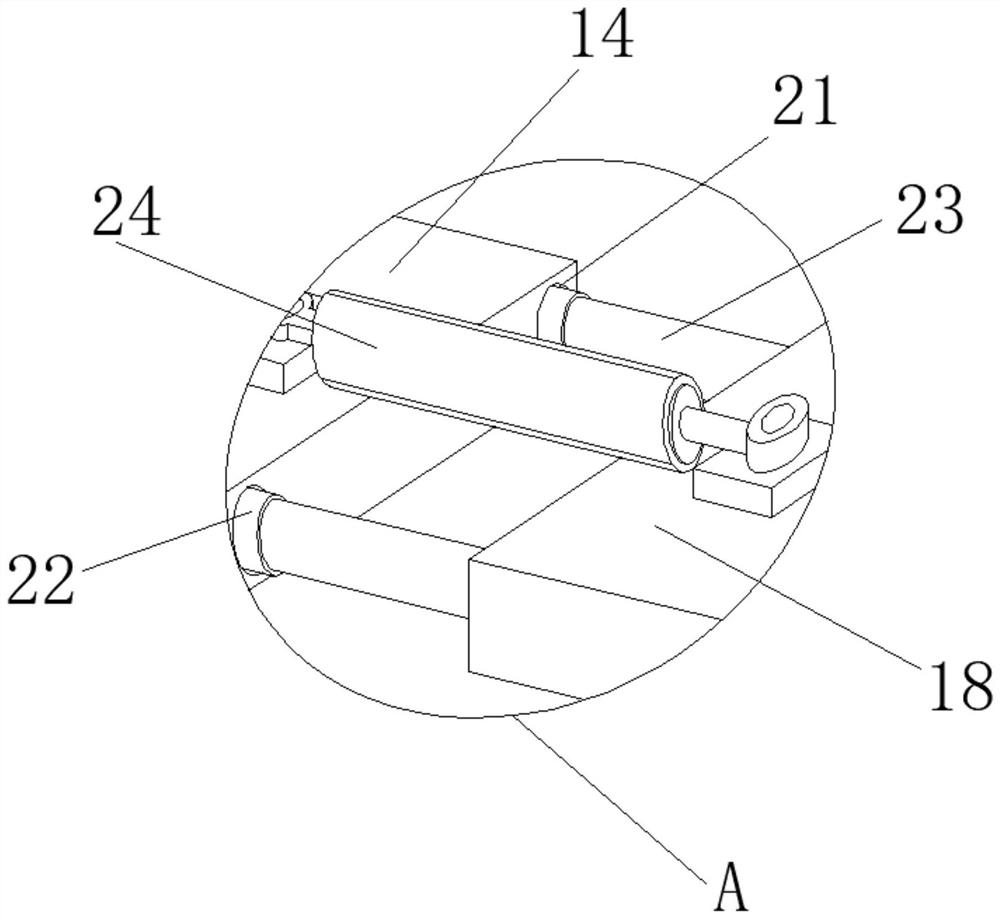

Micron-sized temperature control self-cleaning coating stripping mechanism

The invention discloses a micron-sized temperature control self-cleaning coating stripping mechanism, and relates to the technical field of optical fiber production equipment. The micron-sized temperature control self-cleaning coating stripping mechanism comprises a fixing frame, a pneumatic clamping mechanism, an upper pneumatic claw, a lower pneumatic claw, an upper peeling blade, a lower peeling blade, a heating piece, peeling flexible glue, a one-to-two air pipe, a temperature sensor, a high-speed airflow self-cleaning pipeline, a PLC, an air compressor and a heater. The rear side wall ofthe fixing frame is fixedly connected with the pneumatic clamping mechanism; the pneumatic clamping mechanism cylinder body and the piston rod are sequentially and fixedly connected with the lower pneumatic claw and the upper pneumatic claw respectively; upper peeling blades are fixedly connected to the side walls, away from the fixing frame, of the upper pneumatic claw through screws. An opticalfiber is synchronously clamped through the upper pneumatic claw and the lower pneumatic claw, temperature control is conducted through the heater and the heating piece, rapid peeling of the optical fiber can be achieved, after peeling, air blowing cleaning is conducted on coating layer residues of peeling stations on the two sides through the high-speed airflow self-cleaning pipeline, the workloadof workers is reduced, and the automation level is improved.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

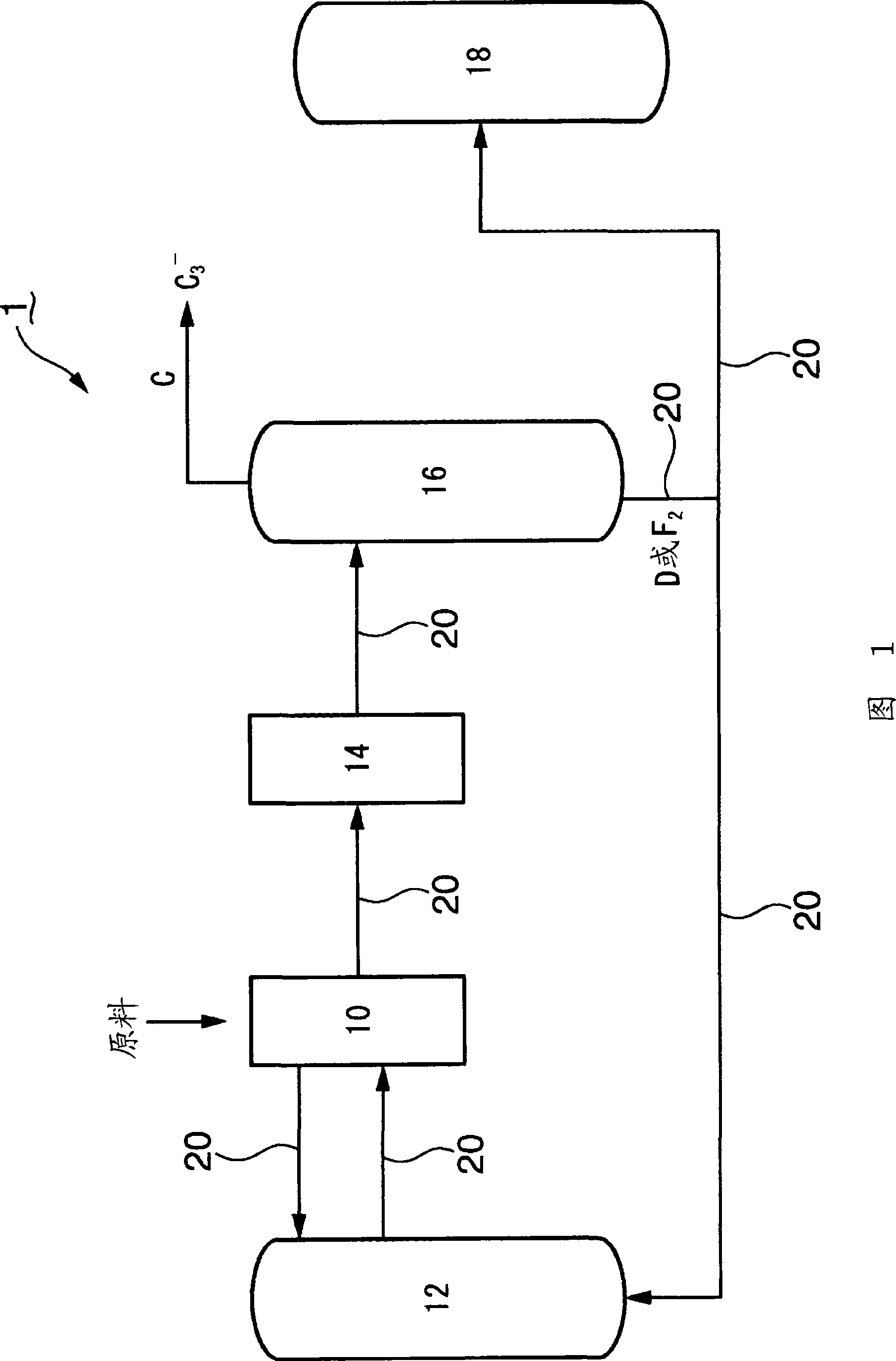

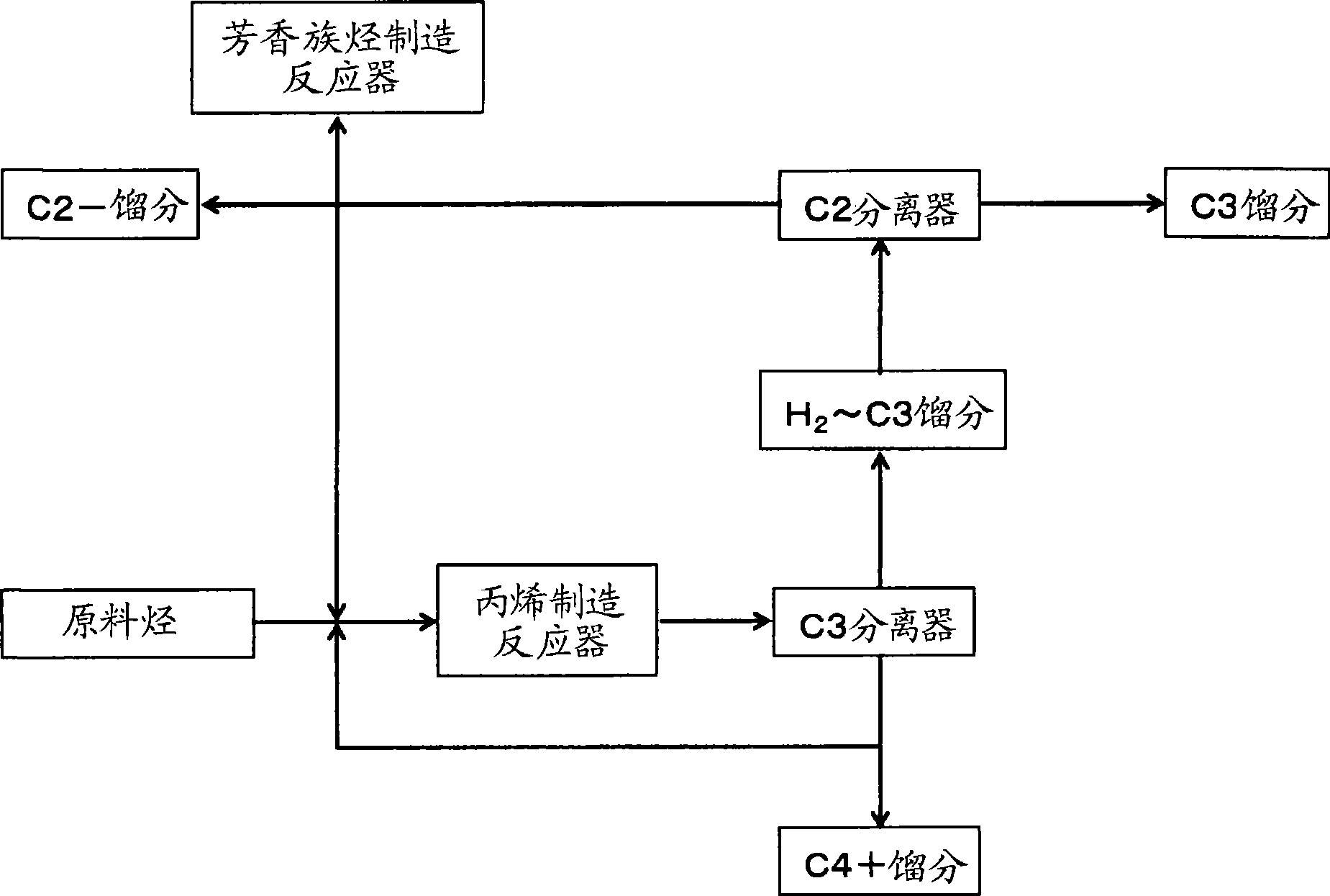

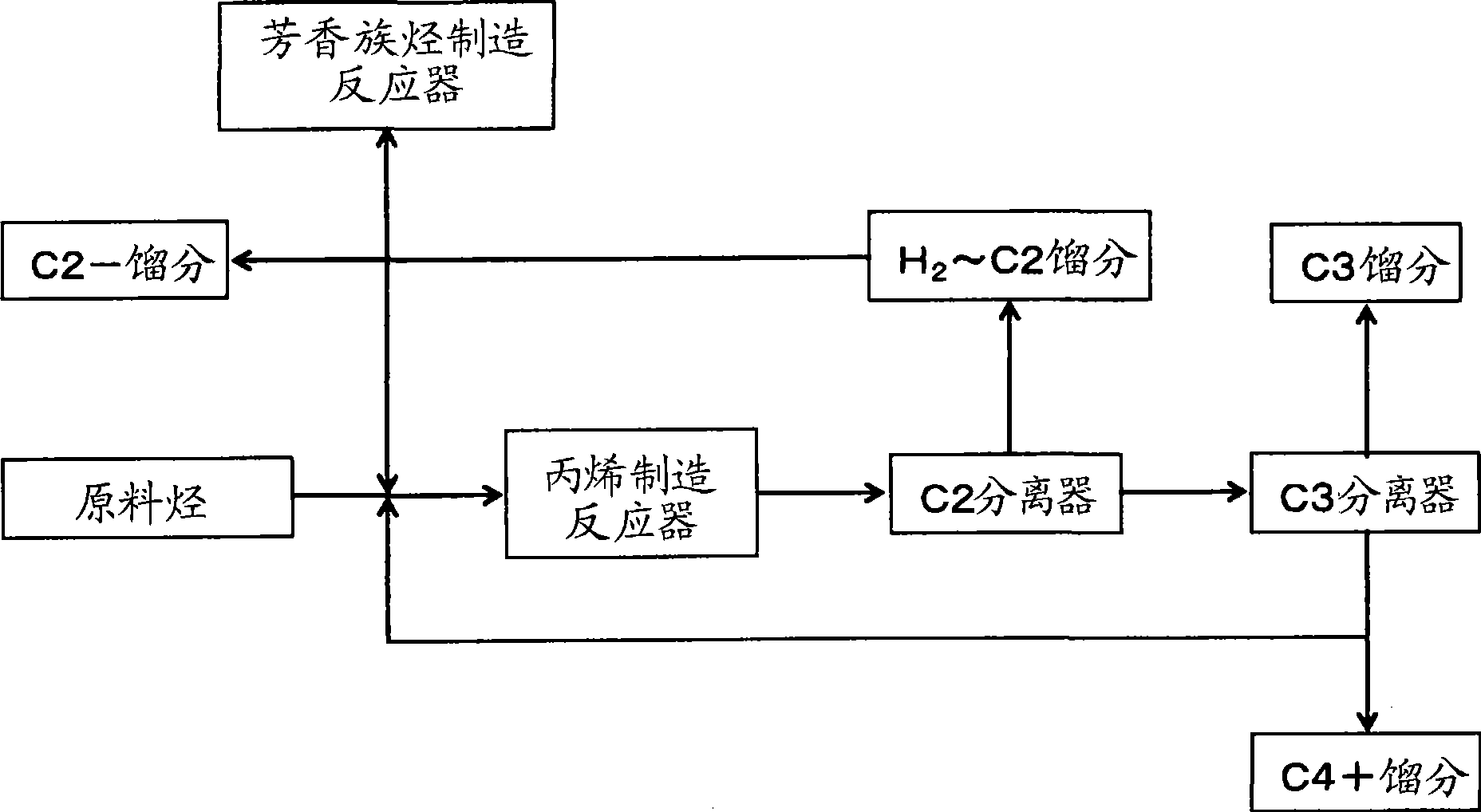

Process for production of propylene and aromatic hydrocarbon, and apparatus for the process

ActiveCN101370755AEfficient and stable manufacturingLess quantityCatalytic crackingOrganic chemistry methodsAlkeneAromatic hydrocarbon

Disclosed is an improved process for production of propylene and an aromatic hydrocarbon from a hydrocarbon raw material containing an olefin having 4 to 12 carbon atoms by using a catalyst containing a middle-pore zeolite, wherein the yields of the both products can be varied in a simple manner and the products can be produced stably and with good efficiency. The process comprises: a propylene production step for removing a hydrocarbon component having 4 or more carbon atoms from a reaction mixture by using a specific zeolite catalyst and, if required, recycling a part of the hydrocarbon component without any modification; and an aromatic hydrocarbon production step wherein the entire or a part of the hydrocarbon component having 4 or more carbon atoms is used as a starting material.

Owner:ASAHI KASEI KK

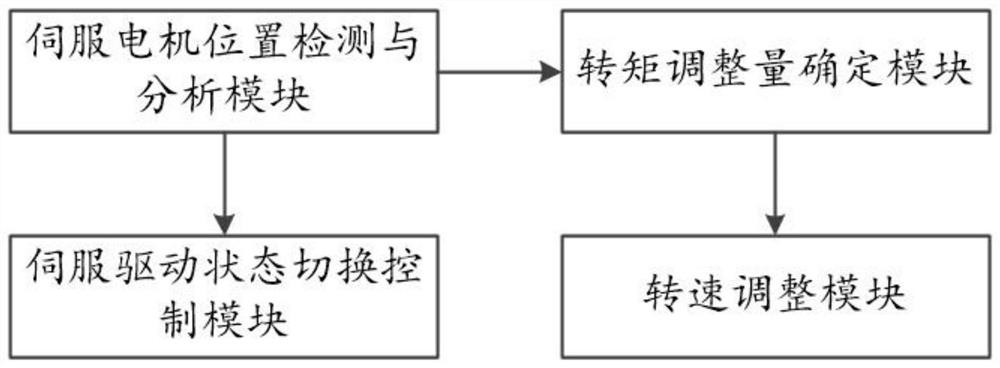

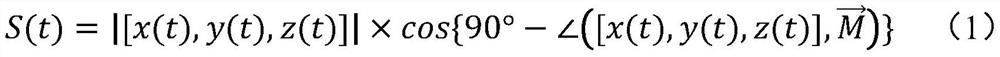

High-response servo driver

PendingCN114421821AStable and continuous operationClose in timeSingle motor speed/torque controlLoop controlControl engineering

The invention provides a high-response servo driver which determines corresponding operation position offset and torque adjustment amount output by a servo motor by detecting and analyzing real-time operation position information of the servo motor. According to the torque adjustment amount, a corresponding rotating speed adjustment instruction is generated so as to adjust the rotating speed of the servo motor; detecting and analyzing the real-time operation position information of the servo motor again so as to determine the secondary operation position offset of the servo motor after the rotating speed is adjusted; and finally, switching and controlling a switch working state of the servo motor according to the secondary operation position offset, so that closed-loop control can be carried out on the servo motor at three levels of operation position, torque and rotating speed, the torque and the rotating speed of the servo motor are adjusted by taking the operation position of the servo motor as a reference, and the control precision of the servo motor is improved. And the servo motor is closed under the condition that the offset of the operation position of the servo motor is too large, so that the driving control response speed of the servo driver to the servo motor is improved, and stable and continuous operation is ensured.

Owner:上海莘汭驱动技术有限公司

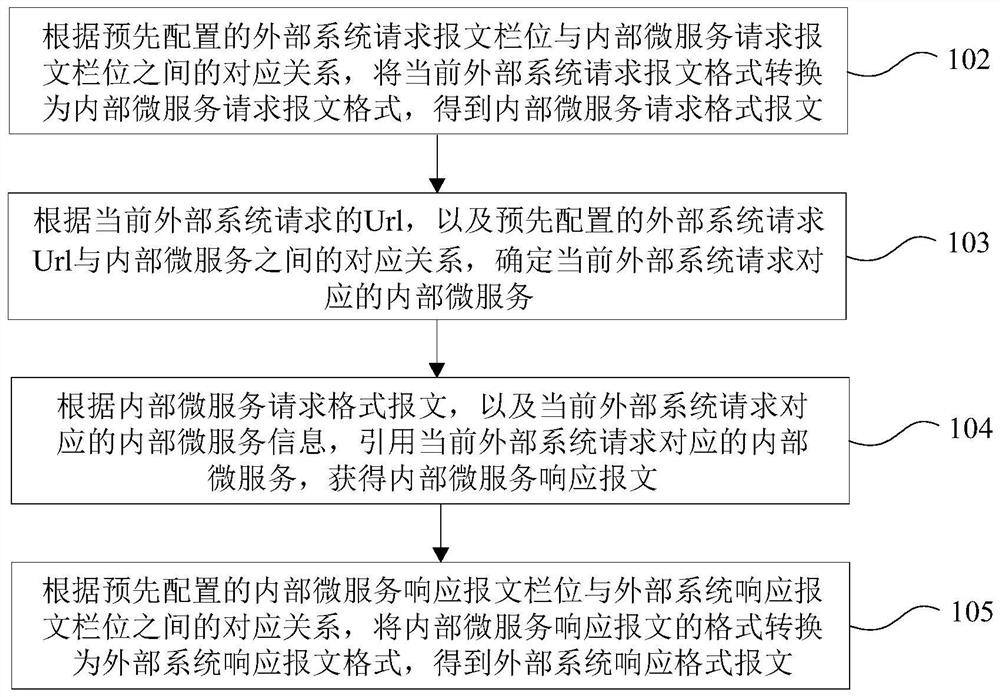

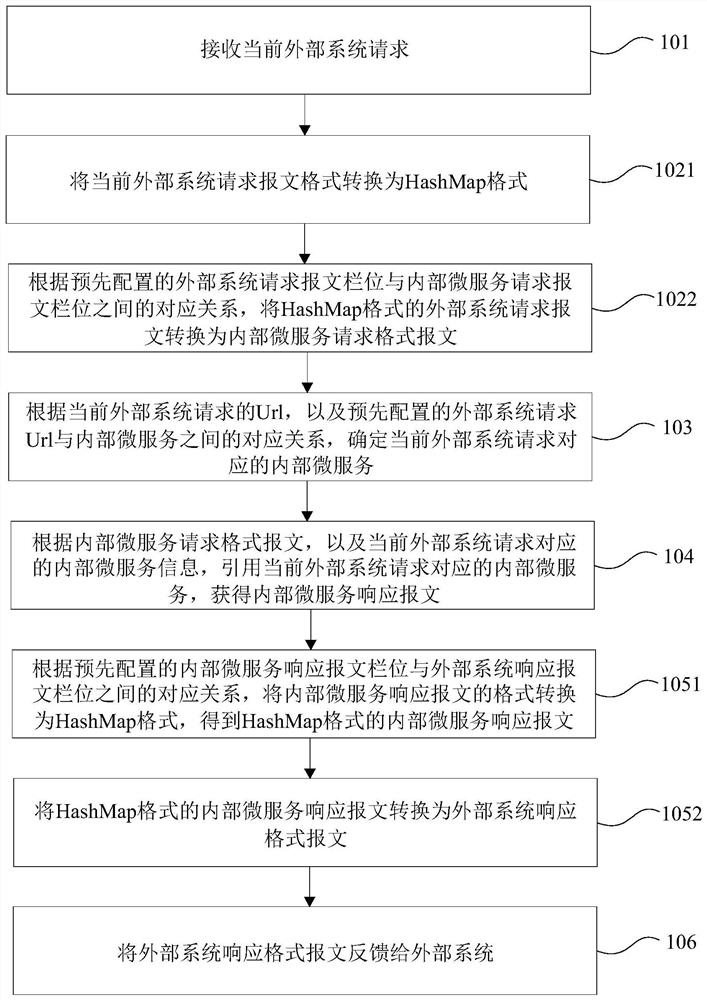

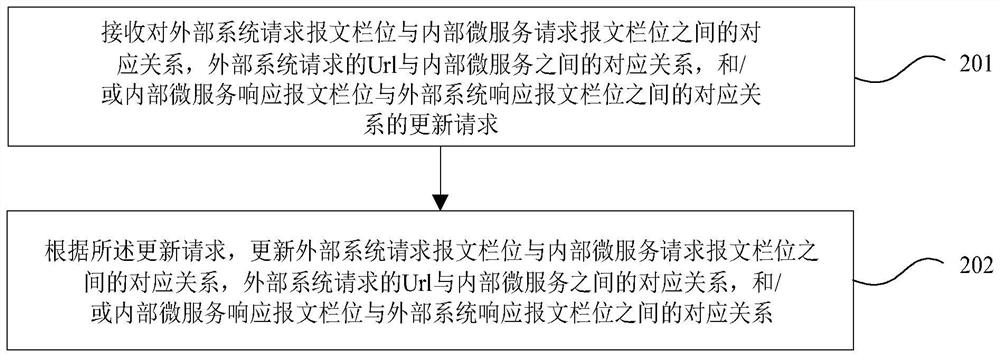

Gateway processing method and system based on database configuration in micro-service architecture

ActiveCN113472880AReduce workloadEasy to operateNetwork connectionsEnergy efficient computingService informationDatabase

The invention discloses a gateway processing method and system based on database configuration in a micro-service architecture, and relates to the field of network security, and the method comprises the steps: converting a current external system request into an internal micro-service request message format according to a pre-configured relationship between the external system request and an internal micro-service request message field; determining a current internal micro-service according to the current external system request Url and a pre-configured relationship between the external system request Url and the internal micro-service; obtaining an internal micro-service response message according to the internal micro-service request format message and the current micro-service information; and converting the obtained response message format into an external system demand format according to the pre-configured relationship between the internal micro-service response and an external system response message field. According to the invention, the gateway service in the micro-service architecture can be provided based on the corresponding relationship between the configured external system and the internal micro-service, the workload of development and test is reduced, and the continuity of external service of the gateway system is ensured.

Owner:BANK OF CHINA

Pneumatic lifting device used for hanging basket

PendingCN113526417AEasy to optimizeWork lessLifting devicesCranesHanging basketMechanical engineering

The invention belongs to the technical field of hanging basket lifting devices, and particularly relates to a pneumatic lifting device used for a hanging basket. The pneumatic lifting device comprises a fixed plate, a supporting column is fixedly connected to the middle position of the top of the fixed plate, a mounting box is arranged at the top of the supporting column, a transverse plate is transversely arranged at the position, close to the bottom wall, of the inner side of the mounting box, two sets of sliding columns are symmetrically arranged at the position, located between the two opposite inner side walls of the mounting box, above the transverse plate, two sets of sliding blocks are slidably connected to the surface of each set of sliding column, and first connecting blocks are fixedly connected to the tops of the sliding blocks. A lifting air cylinder is not affected by vibration, high temperature, electromagnetism, radiation and the like during working through the arranged mounting box, the lifting process of the hanging basket is quite convenient, long-time stable and continuous operation can be achieved through the pneumatic working mode of the arranged lifting air cylinder and an arranged telescopic air cylinder, and the problems that when a common hanging basket is lifted, an electric climbing type structure is often adopted, and long-time full-load continuous operation cannot be realized are solved.

Owner:WUXI ANSHENG CONSTR MACHINERY CO LTD

Method for precooling centrifugal pump used for transporting low temperature ethylene

ActiveCN101655103BEasy to switchSolve gasification problemsSpecific fluid pumpsPump componentsGas phaseContinuous operation

The invention discloses a method for precooling a centrifugal pump which is used for transporting low temperature ethylene, comprising the following steps: using mini-flow low temperature liquid phase ethylene to constantly precool a back-up centrifugal pump, a liquid-in pipeline and a liquid-out pipeline and obtain gasified ethylene, constantly rolling the pump in the precooling and gasifying process, discharging gaseous phase ethylene into a low pressure gaseous phase ethylene system when the pressure of gaseous phase ethylene in the pump reaches 1.5-1.7MPa, continuously discharging for 20-30min to lead the temperature of the pump and the liquid-in and liquid-out pipelines to be up to -40 to -20 DEG C, by now, closing corresponding hand stop valves of liquid phase ethylene entering pipe and gaseous phase ethylene discharge pipe and then opening corresponding hand stop valves on the liquid-in pipeline and the liquid-out pipeline, adopting liquid phase ethylene at the temperature of -40 to -20 DEG C to pour into the back-up centrifugal pump, successfully starting the back-up centrifugal pump by once, and closing the operation of the centrifugal pump at the moment. By adopting the method, the switchover of the centrifugal pump can be easily realized, the safe and stable continuous operation of an ethylene purification device can be ensured, and the production cost can be lowered.

Owner:SUZHOU COFCO BIOCHEM

Biological filtering deodorizing device

InactiveCN100453150CMaintain humidityStable and continuous operationDispersed particle separationDeodrantsBio filtrationHazardous substance

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

An extractor control system based on buffer adjustment technology

ActiveCN107096255BExtended service lifeGood cushion supportSolvent extractionTotal factory controlMachine controlControl system

The invention discloses an extraction machine control system based on buffer adjustment technology, comprising a support adjustment mechanism distributed at the bottom of the extraction machine, characterized in that: the support adjustment mechanism comprises six second buffer bases evenly distributed along the circumferential direction , a first buffer base is installed in the center of the six second buffer bases, the first buffer base and the six second buffer bases are connected by clips, and the first buffer base and the second buffer base have the same structure . The present invention can provide good buffer support to the bottom of the extractor through the six second buffer bases evenly distributed along the circumferential direction and the first buffer base in the center. The impact force on the machine can be effectively decomposed, which has a good use effect, greatly improves the service life of the extractor, and ensures the stable and continuous operation of the extractor system.

Owner:合肥神马电气有限公司

Process for continuous production of calcium naphthenate

Owner:XI'AN PETROLEUM UNIVERSITY

Medium mixing up of wet-type dispersion machine

ActiveCN100448546CFunctionalWith grading functionSublimationGrain treatmentsRotational axisDispersed media

The medium stirring wet dispersing machine has a cylindrical dispersing tank, a tubular rotation shaft, an outer rotor with blades arranged to form one cylinder for generating centrifugal force, and an inner rotor inside the outer rotor and with also blades arranged to form one cylinder for generating centrifugal force. The outer rotor possesses functions of crushing and dispersing particles, whereas the inner rotor possesses functions of separating and grading medium. Therefore, the present invention can disperse medium in nanometer level and has great capacity and excellent grading performance.

Owner:NIPPON COKE & ENG

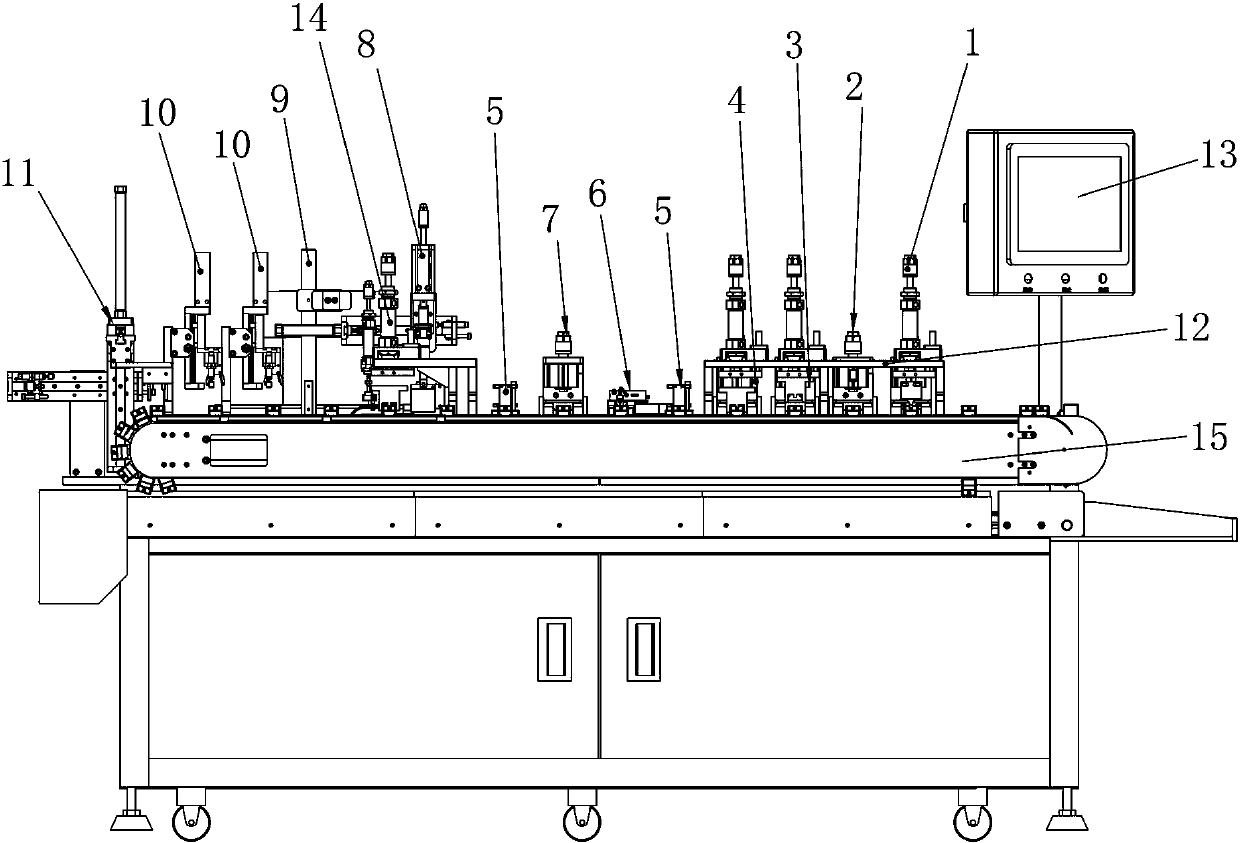

A usb3.1 Type‑C welding assembly line equipment

ActiveCN105798416BGuaranteed tin effectSimple structureMetal working apparatusSoldering auxillary devicesButt jointAssembly line

Owner:DONGGUAN ZHEN SHI HAO ELECTRONICS TECH

Process for producing (meth)acrylic acid or (meth)acrylic ester

InactiveCN100427451CReduce differential pressureStable and continuous operationOrganic compound preparationCarboxylic acid esters preparationMeth-Distillation

In the distillation purification of (meth)acrylic acid or a (meth)acrylic ester, attachment, deposition and accumulation of solid matter are prevented to thereby stably maintain a high recovery rate for (meth)acrylic acid or a (meth)acrylic ester, realizing stable continuous operation of the distillation column for a prolonged period of time. There is provided a method of distillation of a composition containing (meth)acrylic acid or a (meth)acrylic ester by means of a distillation column having multistage trays in its interior, wherein use is made of a distillation column packed with, as trays, corrugated-plate-type non-weir perforated plates each having a corrugated sectional configuration and multiple through-holes and flat-plate-type non-weir perforated plates each constituted of a flat plate having multiple through-holes.

Owner:MITSUBISHI CHEM CORP

Tea bag automatic box making device

ActiveCN104803050BReasonable structural designRapid continuous operationWrapper twisting/gatheringEngineeringContinuous operation

The invention discloses a tea bag automatic box suction and bag feeding device. A guide rail mounting frame is arranged at the upper end of a machine frame; a bag pushing air cylinder is arranged on the guide rail mounting frame; raw material mounting frames are respectively arranged at the two ends of the inner side of the guide rail mounting frame; a raw material guide rail is arranged on each raw material mounting frame; a material pushing plate is arranged on the bag pushing air cylinder; a box making mounting frame is arranged at the lower end of the machine frame; a box suction mounting frame is arranged at one end of the box making mounting frame; a vacuum suction disc is arranged on the box suction mounting frame; a passage is arranged at the part, penetrating through a mounting plate, of the vacuum suction disc and is connected with a box storage mechanism; a shaping folding plate is arranged at one side of the passage. The tea bag automatic box suction and bag feeding device has the advantages that the structure design is reasonable; a box can be automatically and correctly sucked and opened by different air cylinders and sensors, and a packaging bag is quickly pushed into the box; multiple procedures are sequentially linked, the quick and stable continuous operation is realized, the automation degree is high, the error rate of manual operation is reduced, the working efficiency is improved, and the device is suitable for large-scale production.

Owner:HEFEI SANGUAN PACKING SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com