Pfa porous sheet

A porous and sheet technology, applied in the direction of melt spinning, textiles, papermaking, non-woven fabrics, etc., can solve the problems that cannot be applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

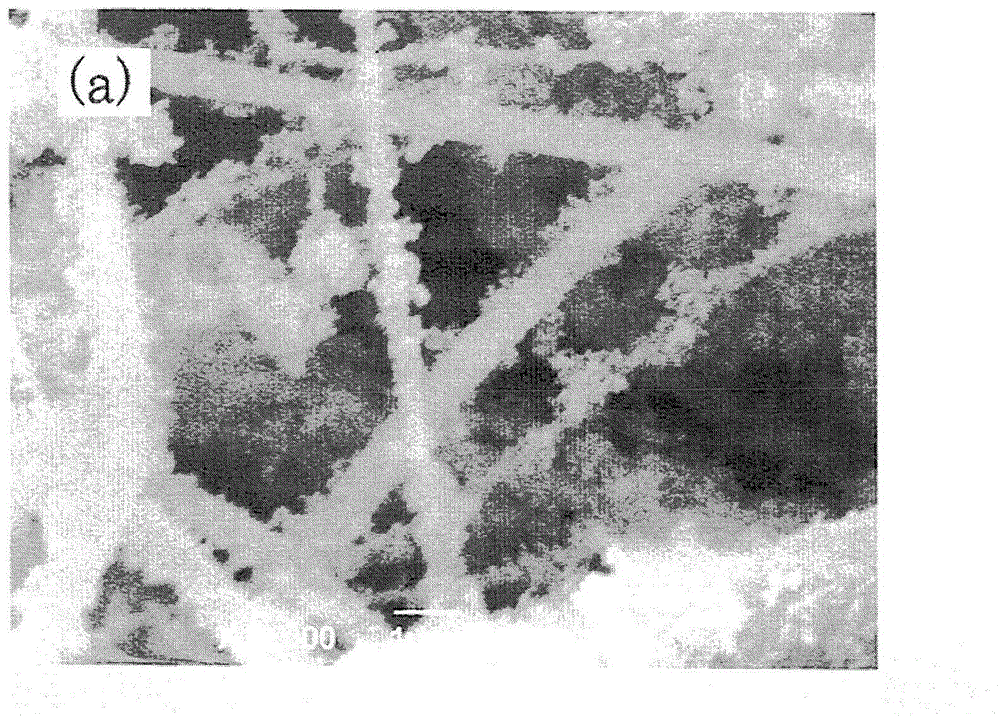

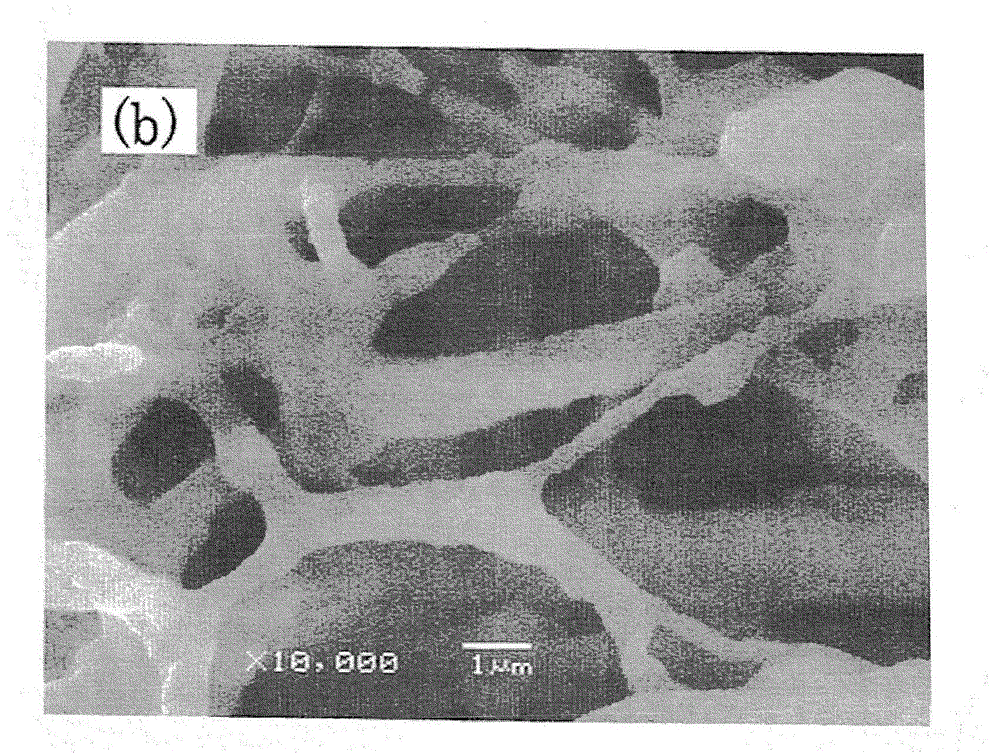

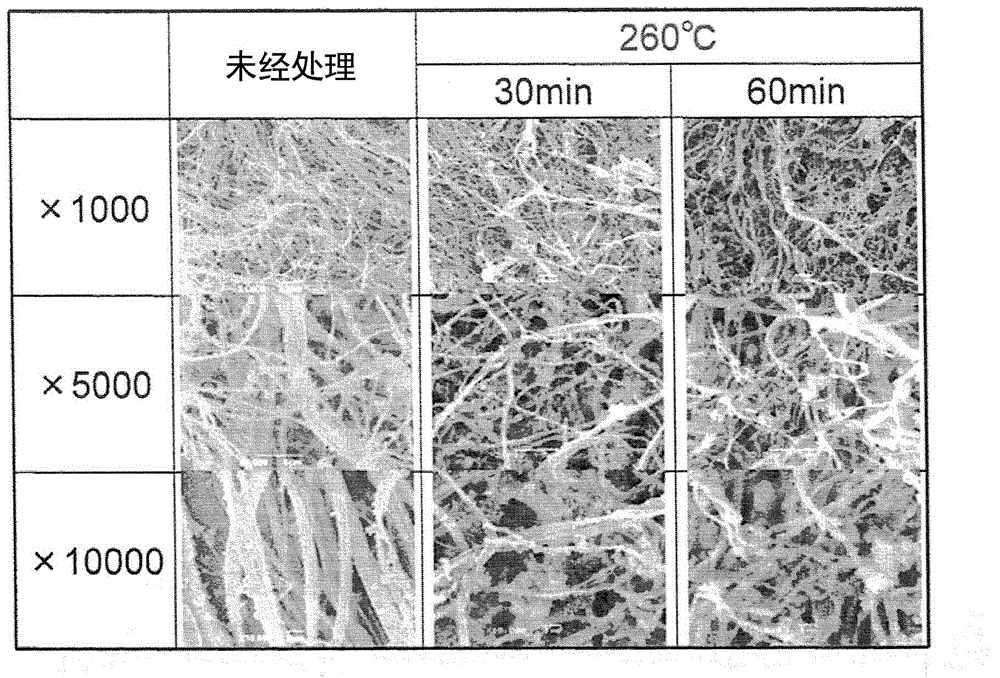

[0062] Hereinafter, examples of embodiments of the present invention will be described with reference to the drawings. figure 1 An electron micrograph (magnification: 10,000) shows a porous sheet of the present invention composed of PFA fibrils with a plurality of PFA fine particles. The many filaments in the figure represent the stretched PFA porous sheet accumulated on the conveyor net moving at 0.030 m / min. The dimensions shown in the figure are from 200 nm to 800 nm, and all the filaments are 10 μm or less. In addition, a plurality of microparticles are attached to each filament in the figure, and when observed, the particles are spherical and have a particle diameter of 100 nm or less, which is smaller than the diameter of the observed filament. Only the fine particles were collected and subjected to GPC measurement or DSC measurement, but no difference was found from the results of the porous sheet containing fibrils. For the porous sheet in this figure, the PFA fibri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com