Self-regenerative continuous melt crystallization system and method

A melting crystallization, self-regenerating technology, applied in the direction of heat exchange cooling crystallization, solution crystallization, crystallization purification/separation, etc., can solve the problem that the growth rate of the crystal layer should not be too fast, the crystallization and sweating time is long, and the crystal bed suspension effect is poor, etc. problems, to achieve stable and continuous operation, improve heat and mass exchange efficiency, and increase the production capacity of equipment per unit volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

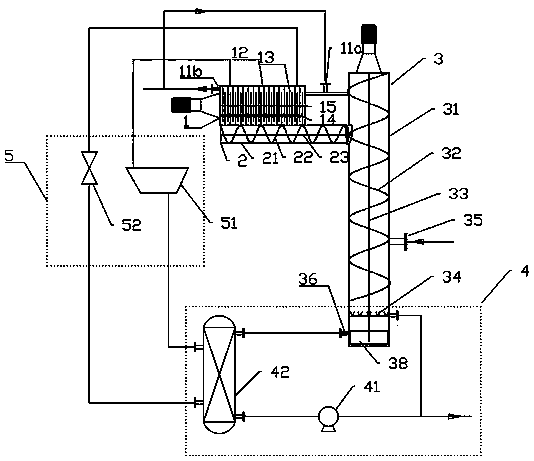

[0031]An external tube-plate heat exchanger is used to supply heat to the product recovery section, and the product with a high freezing point in the liquid phase is melted and recovered. Specifically, it is a self-reheating continuous melting crystallization system, which is characterized in that it includes crystallization section 1, crystal growth section 2, refining Section 3, product recovery section 4 and heat recovery system 5.

[0032] The crystallization section 1 includes a circulating feed inlet 11a, a discharge port 11b, a first cylinder body 12, a finned cooling fin 13 and a push scraper 14, wherein the finned cooling fin 13 is fixed on the first cylinder body 12, and the push scraper 14 is fixed On the first transmission shaft 15, the pushing scrapers 14 and the finned cooling fins 13 are alternately arranged at a certain angle, and the pushing scrapers 14 form an included angle of 15-75 degrees with the finned cooling fins along the material moving direction. Th...

Embodiment 2

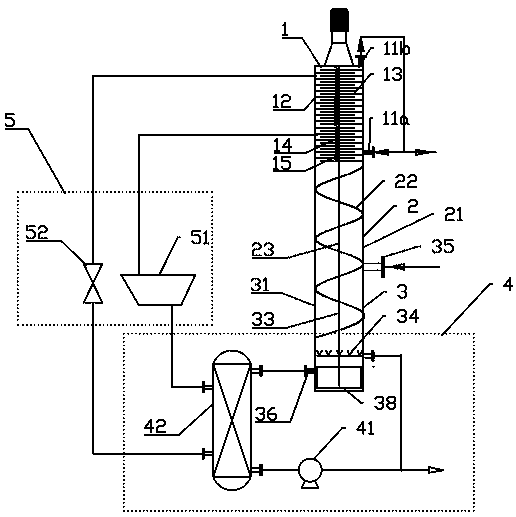

[0040] The inner-fin fin heat exchanger is used to supply heat to the product recovery section, and the liquid-phase high-freezing-point product is melted and recovered. Specifically, it is a self-reheating continuous melting crystallization system, which is characterized in that it includes a crystallization section 1 and a crystal growth section 2. , refining section 3, product recovery section 4 and heat recovery system 5.

[0041] The crystallization section 1 includes a circulating feed inlet 11a, a discharge port 11b, a first cylinder body 12, a finned cooling fin 13 and a push scraper 14, wherein the finned cooling fin 13 is fixed on the first cylinder body 12, and the push scraper 14 is fixed On the first transmission shaft 15, the pushing scrapers 14 and the finned cooling fins 13 are alternately arranged at a certain angle, and the pushing scrapers 14 form an included angle of 15-75 degrees with the finned cooling fins along the material moving direction. The finned ...

Embodiment 3

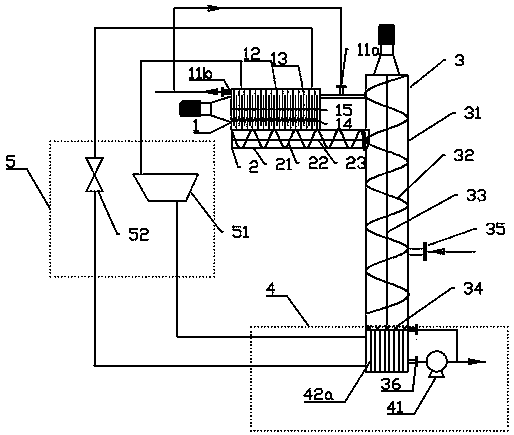

[0049] The product recovery section is heated by an inner-fin finned heat exchanger, and the product with a high freezing point in the liquid phase is melted and recovered. The specific implementation method is similar to that of Example 2. The component crystal particles melt when passing through the flow channel formed by the inner finned sheet 42a, part of the molten liquid is extracted as a product, and the remaining part of the molten liquid is reversed along the flow channel formed by the inner finned sheet 42a due to the extrusion of the solid particle settlement. Diffusion upwards to form a liquid phase countercurrent, and conduct heat and mass exchange with high melting point component crystal particles, so that the crystals complete the process of sweating and refining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com