A usb3.1 Type‑C welding assembly line equipment

A welding assembly line and assembly line technology, applied in the direction of welding equipment, metal processing equipment, auxiliary devices, etc., can solve the problems of workers' health hazards, uneven solder spot size, inaccurate solder positioning, etc., and achieve stable and continuous workability, soldering High positioning accuracy and guaranteed tinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

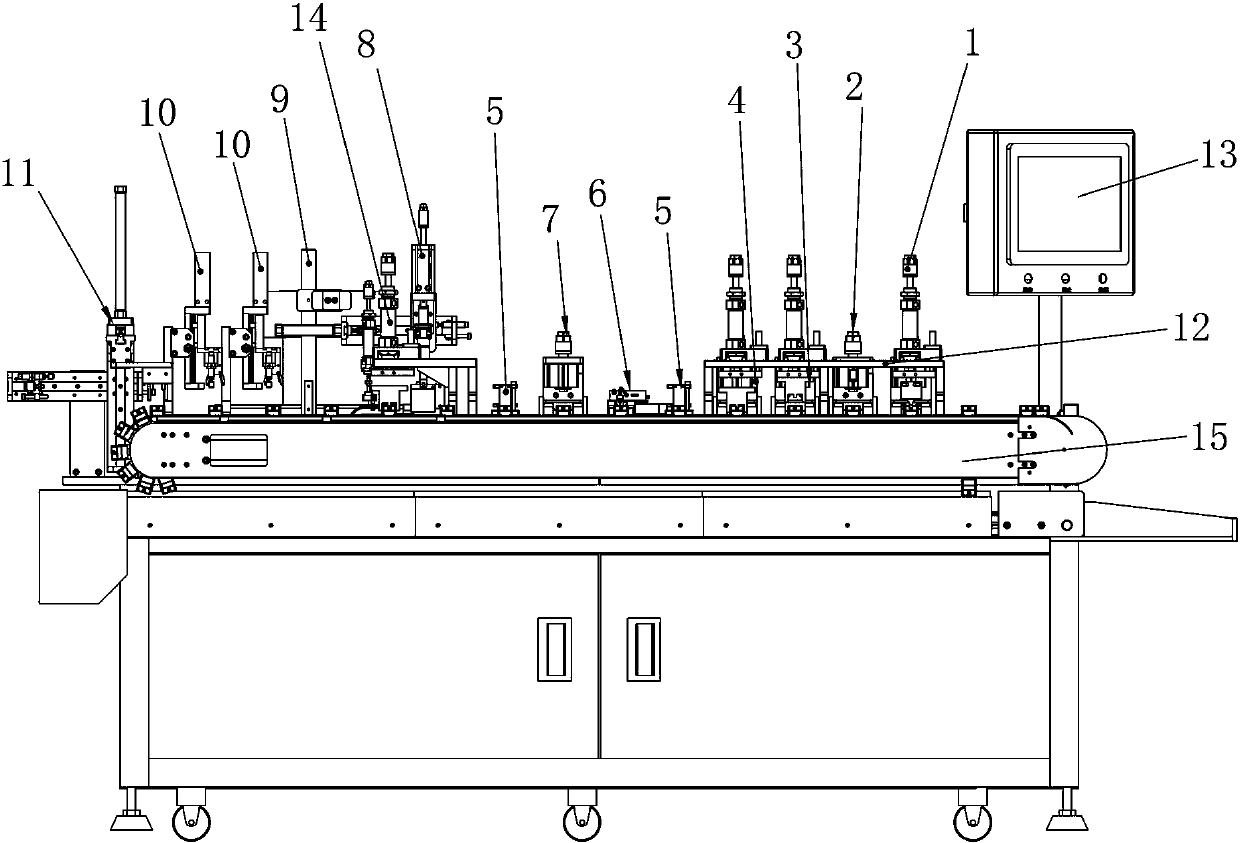

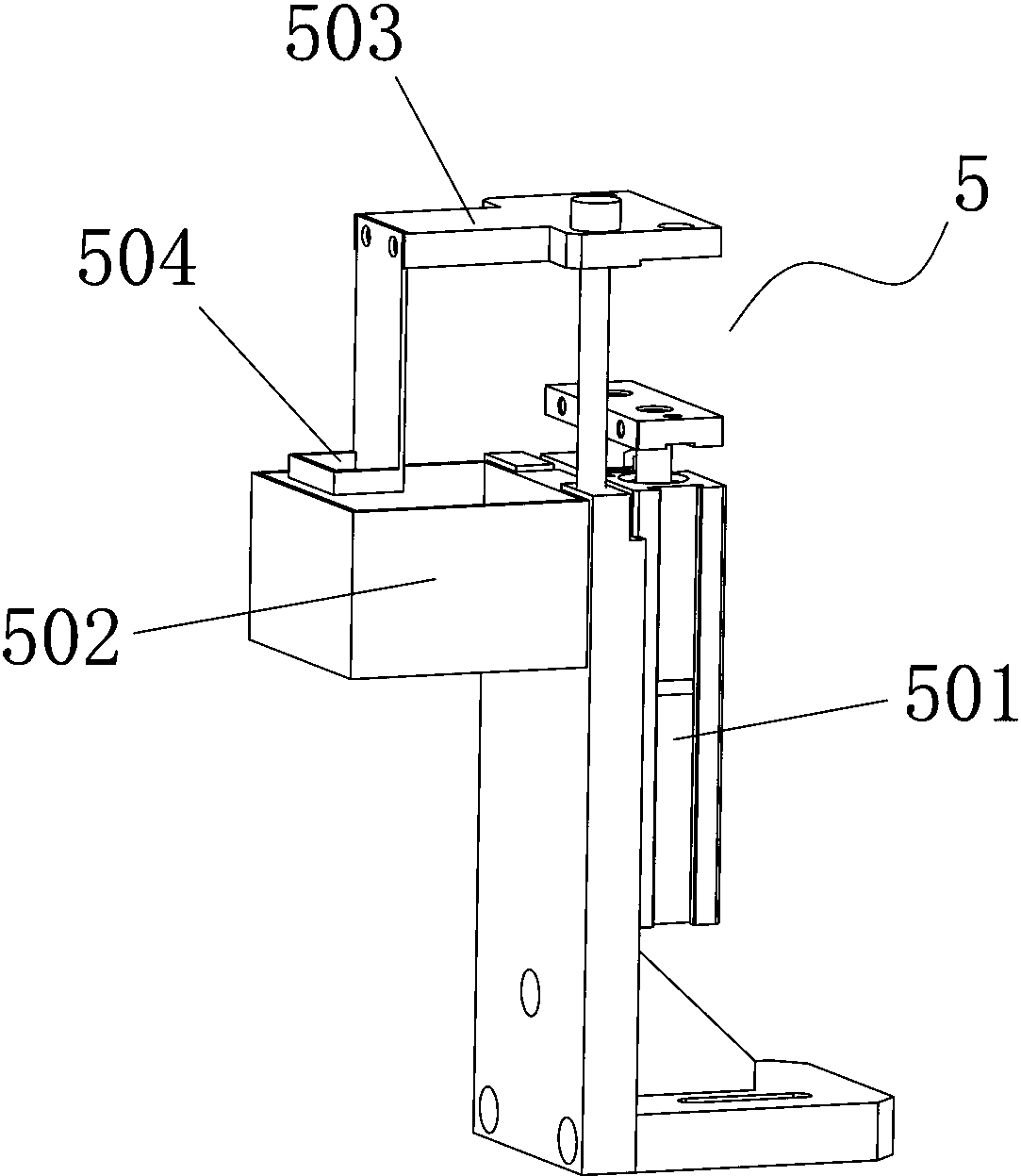

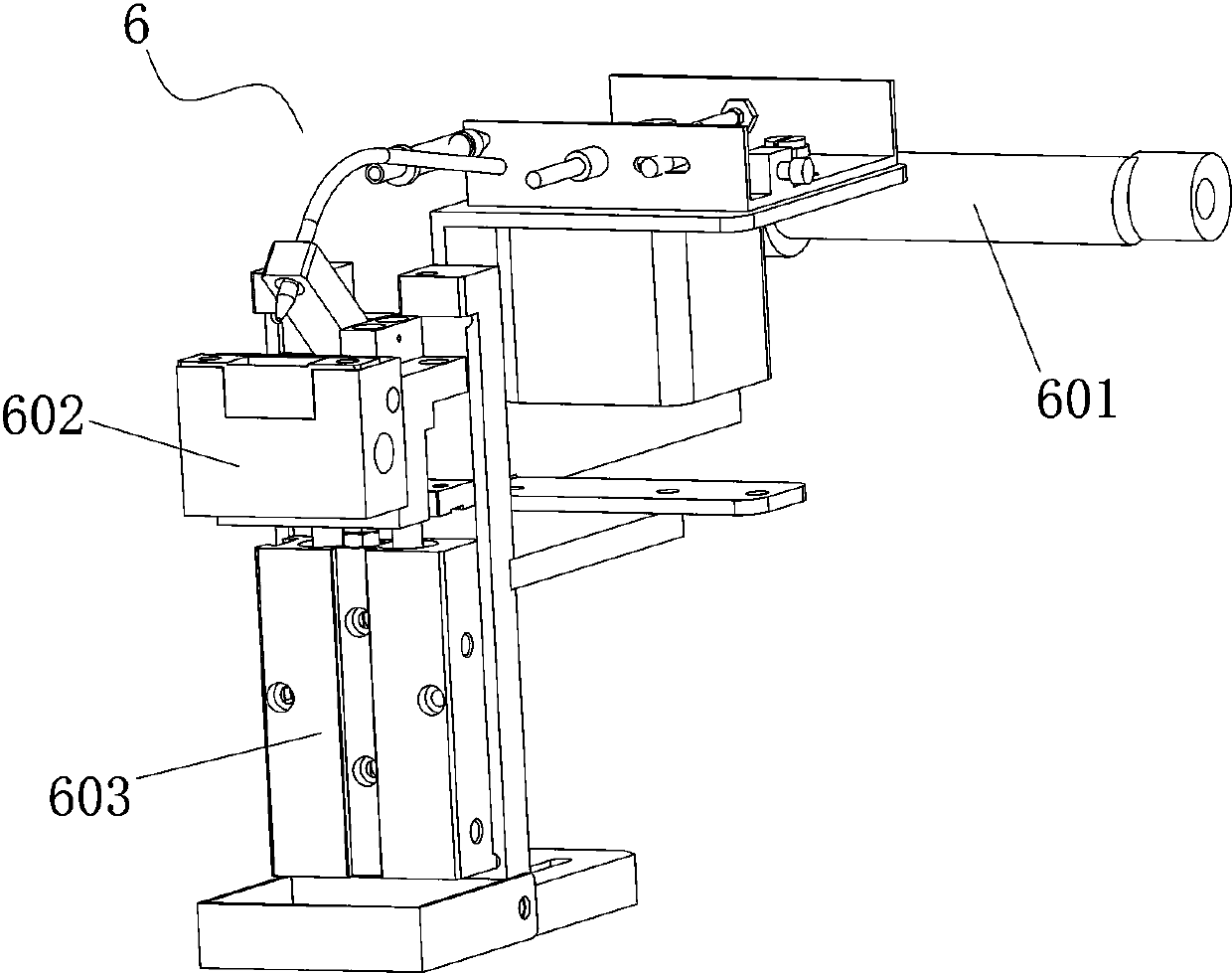

[0020] Such as Figure 1-5 As shown, a USB3.1 Type-C welding assembly line equipment includes a wire pulling device 1, a wire cutting device 2, a peeling device, a fluxing device 5, a tin dipping device 6, and a wire core cutting device in sequence from the beginning of the assembly line to the end of the assembly line. Device 7, fluxing device 5, welding device 8, CCD detection device 9, blanking device 10 and gripping fixture device 11, and each of the aforementioned devices is arranged along the fixture circulation device 15; the peeling device includes thin wire peeling The device 3 and the thick wire stripping device 4 are used for wires with inconsistent wire sizes, and the wires are placed on the jig circulation device 15; a vibrating plate is provided to connect with the jig 151 that flows to the welding device 8 through the terminal circulation chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com