Medium mixing up of wet-type dispersion machine

A stirring and dispersing machine technology, which is applied in separation methods, grain processing, chemical instruments and methods, etc., can solve the problems that it is difficult to balance the crushing function and grading function, and the functions of both cannot be fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Using the medium agitation type wet disperser of the present invention described in the first embodiment, a test for dispersing secondary agglomerated titanium oxide was performed under the conditions shown below to confirm its performance.

[0089] Put the prepared slurry into the holding tank, and introduce it to the supply port of the disperser with a quantitative pump, return the slurry discharged from the discharge port of the disperser to the holding tank again to form a circulation system, and start in this state The disperser was tested.

[0090] After the disperser is started, samples are taken from the outlet of the disperser at regular intervals. Particle size analyzer (Nikkiso (Co., Ltd.) ) MKIIDRA, measured by laser diffraction and light scattering method.

[0091] processing conditions

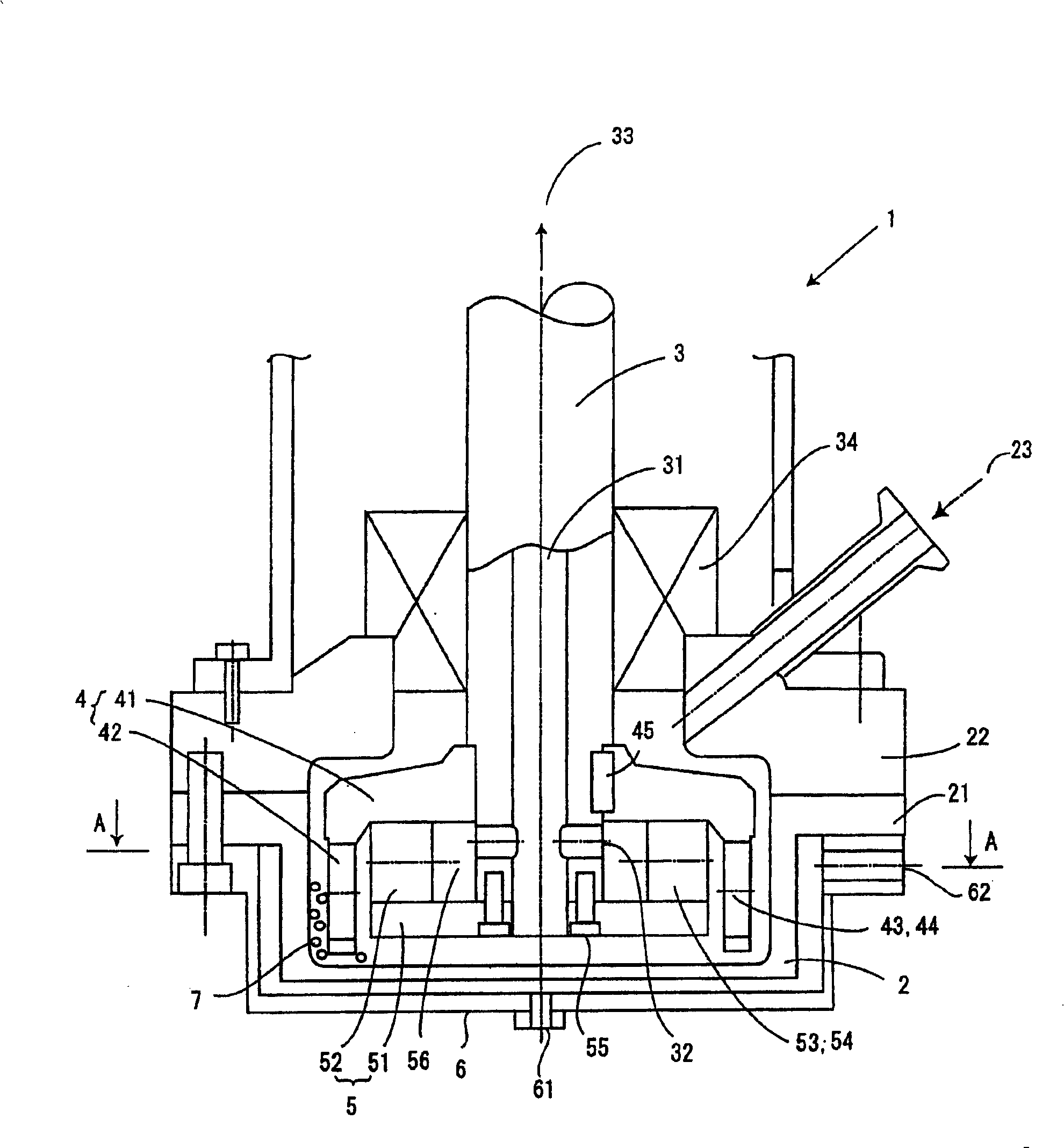

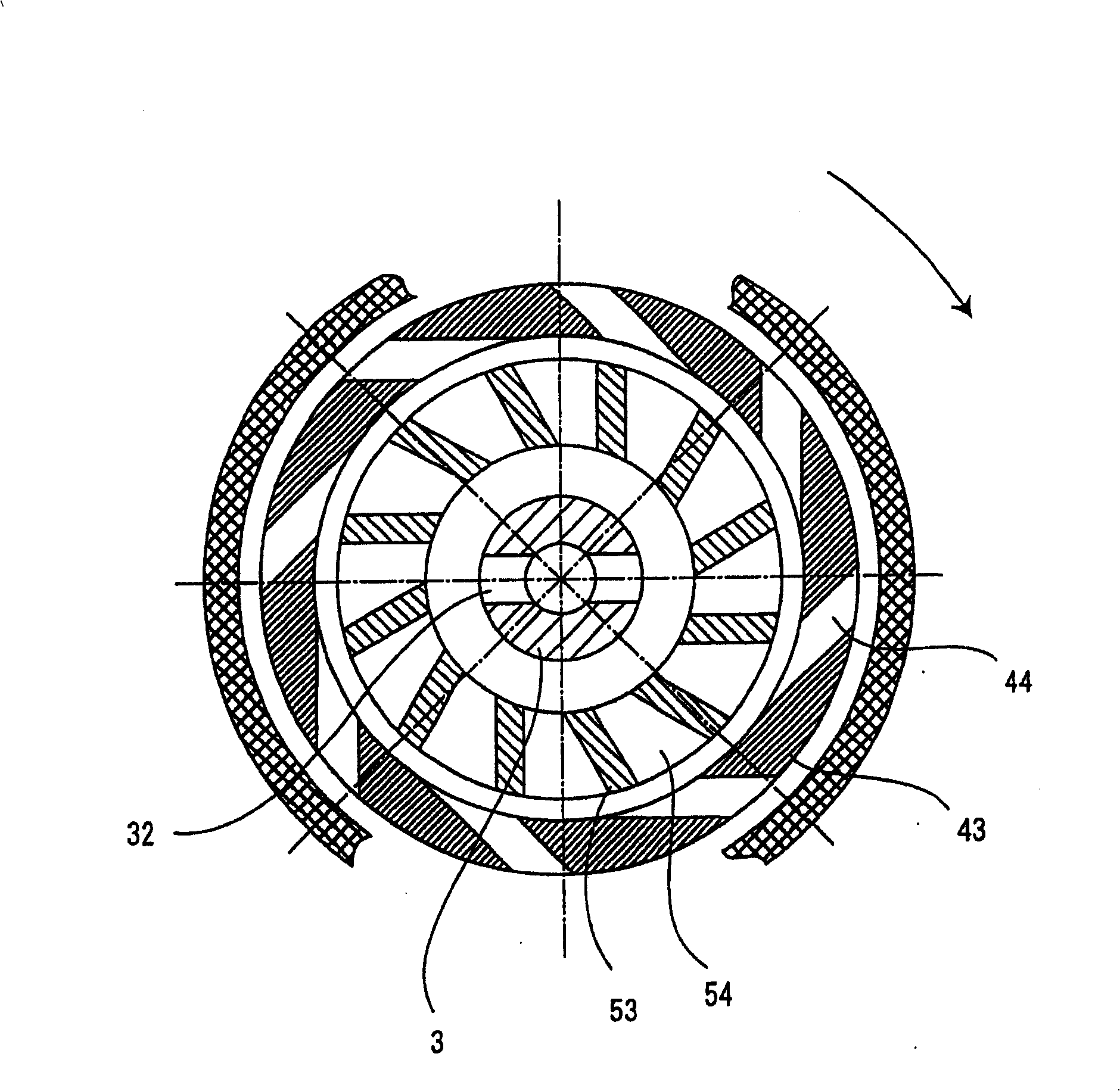

[0092] Dispersing machine: such as figure 1 and 2 For the disperser shown, the outer diameter of the outer rotor is 120mm

[0093] Motor: 3.7kw, maximum speed 3,600...

Embodiment 2

[0103] The rotational speeds of the two rotors were changed to 1600 rpm, and other conditions were the same as in Example 1. 90 minutes after the operation was started, a dispersion liquid having an average particle diameter of 24.1 nm was obtained. In the dispersion liquid, no medium was mixed.

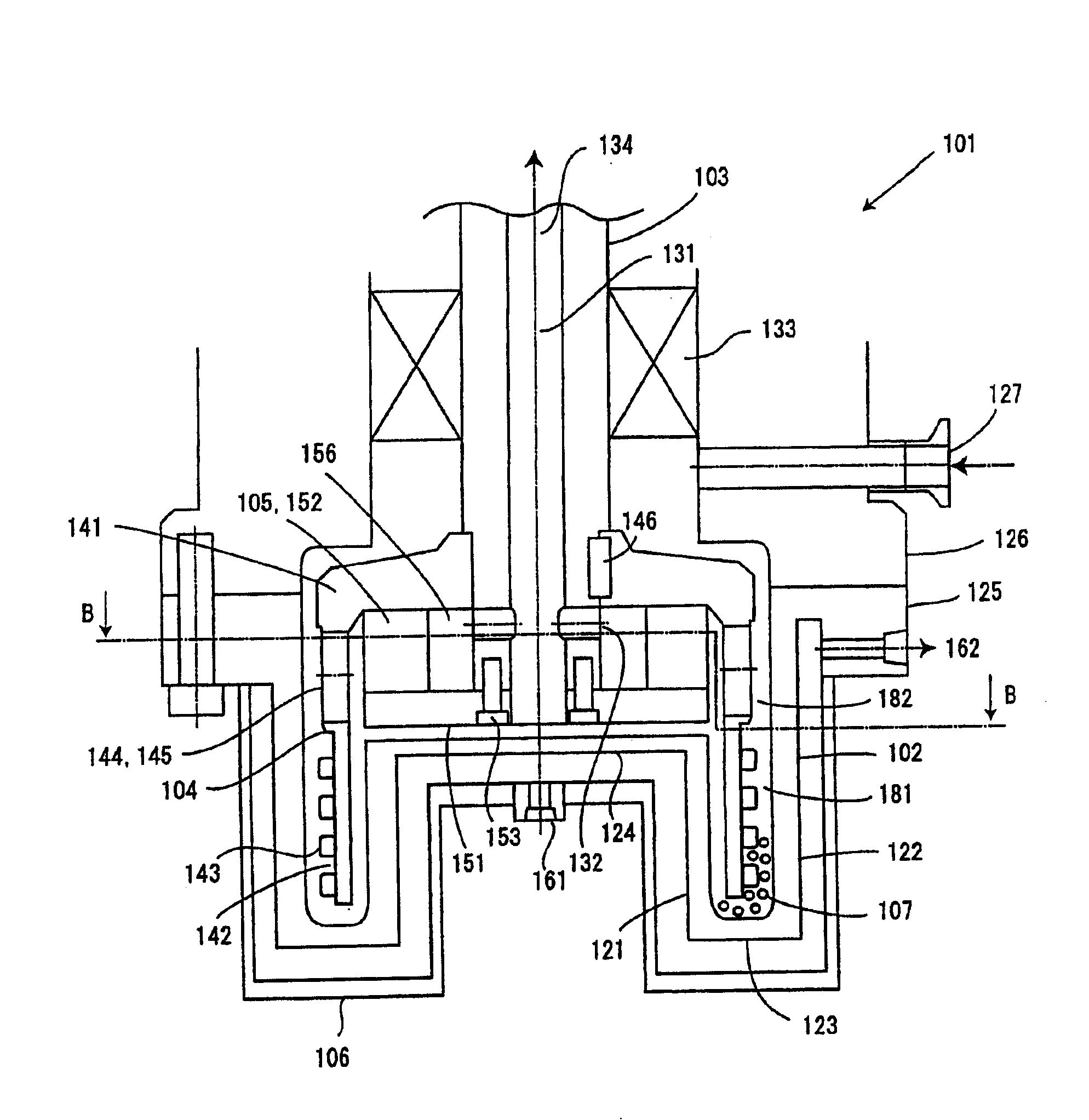

[0104] Next, a test for dispersing the titanium oxide (average particle diameter: 2.4 μm) was performed under the conditions shown in Table 1 using the medium agitation type wet disperser of the present invention shown in the second embodiment to confirm its performance.

[0105] Put the prepared slurry into the holding tank, introduce it to the supply port of the disperser with a quantitative pump, return the slurry discharged from the discharge port of the disperser to the holding tank again, form a circulation system, and start in this state The disperser was tested.

[0106] Table 1

[0107]

Embodiment 3

[0109] After the disperser is started, samples are taken from the discharge port of the disperser at predetermined intervals. During the determination of the particle size, the particle size analyzer ( ) MKIIDRA, measured by laser diffraction and light scattering method.

[0110] Zirconia beads with a particle diameter of 0.03 mm were used as a medium, and the dispersion test was performed by filling 53.7% of the volume of the dispersion tank with the rotational speed of the rotor at 1600 rpm. As a result, 90 minutes after the start of the operation, the average particle size of the processed product was 24.1 nm, and no medium was mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com