Tea bag automatic box making device

An automatic tea bag making technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of uneven box tightness affecting the appearance, unfavorable large-scale production needs of enterprises, and low work efficiency, so as to achieve favorable The effect of large-scale production, reduction of manual operation error rate, and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

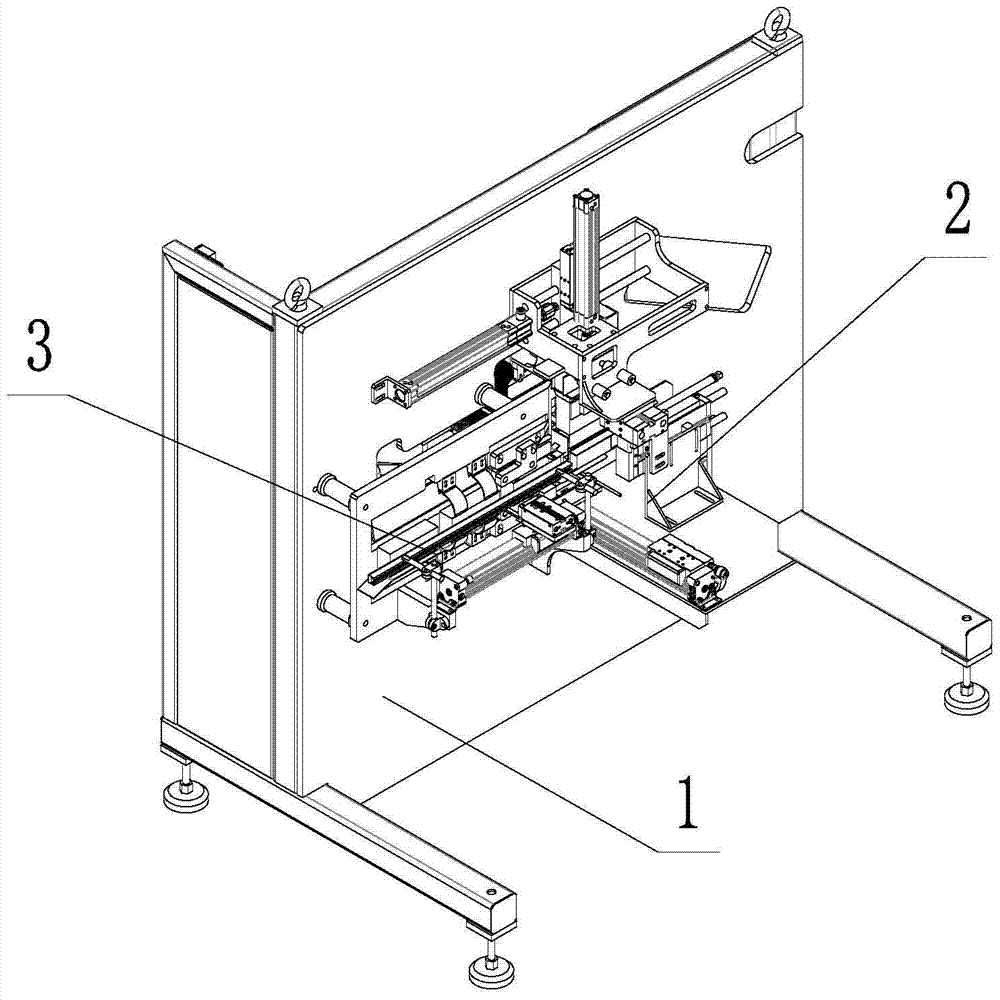

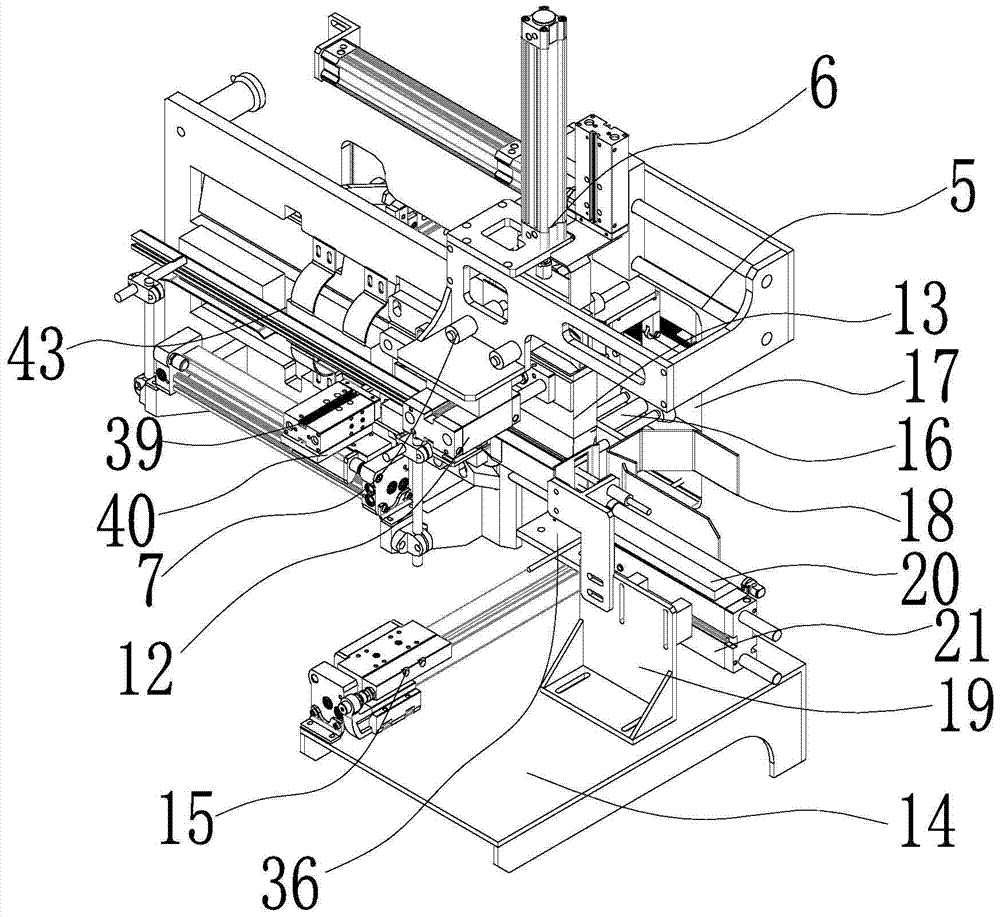

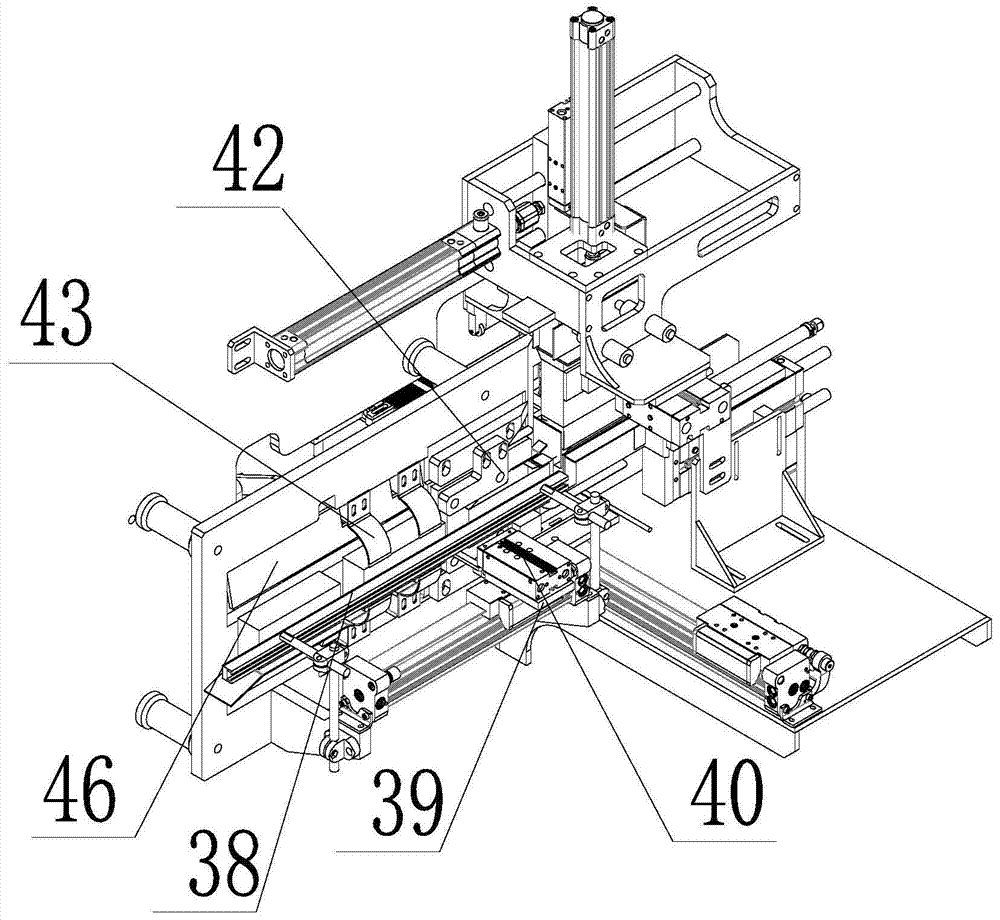

[0026] Referring to the accompanying drawings, the tea bag automatic box-making device includes a frame. The frame is provided with a box-making mechanism, a box-sealing mechanism, and a box-storage mechanism. The upper end of the frame is provided with a guide rail mounting frame. The guide rail mounting frame is provided with a bag pushing cylinder, and the inside two ends of the guide rail mounting frame are respectively provided with a raw material mounting frame, and the material mounting frames at both ends are provided with a raw material guide rail, and the described bag pushing cylinder is provided with a L Type pushing plate, the above-mentioned bag pushing cylinder is provided with an inductor, and the L-shaped pushing plate is vertically arranged above the raw material guide rail, the lower end of the raw material installation frame is provided with a support plate cylinder, and the support plate cylinder is provided with a support plate The board is arranged under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com