Patents

Literature

64results about How to "Stable continuous operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

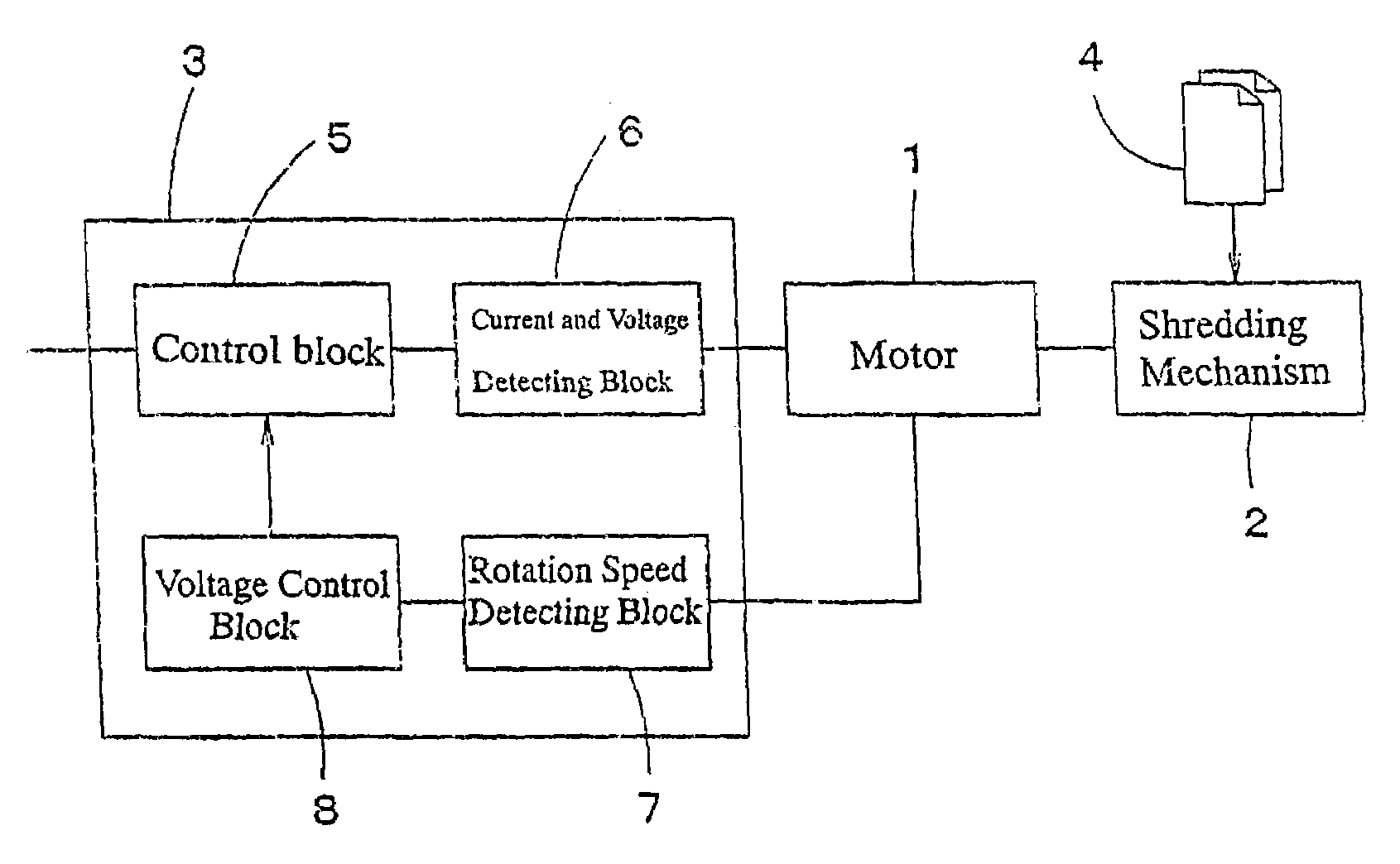

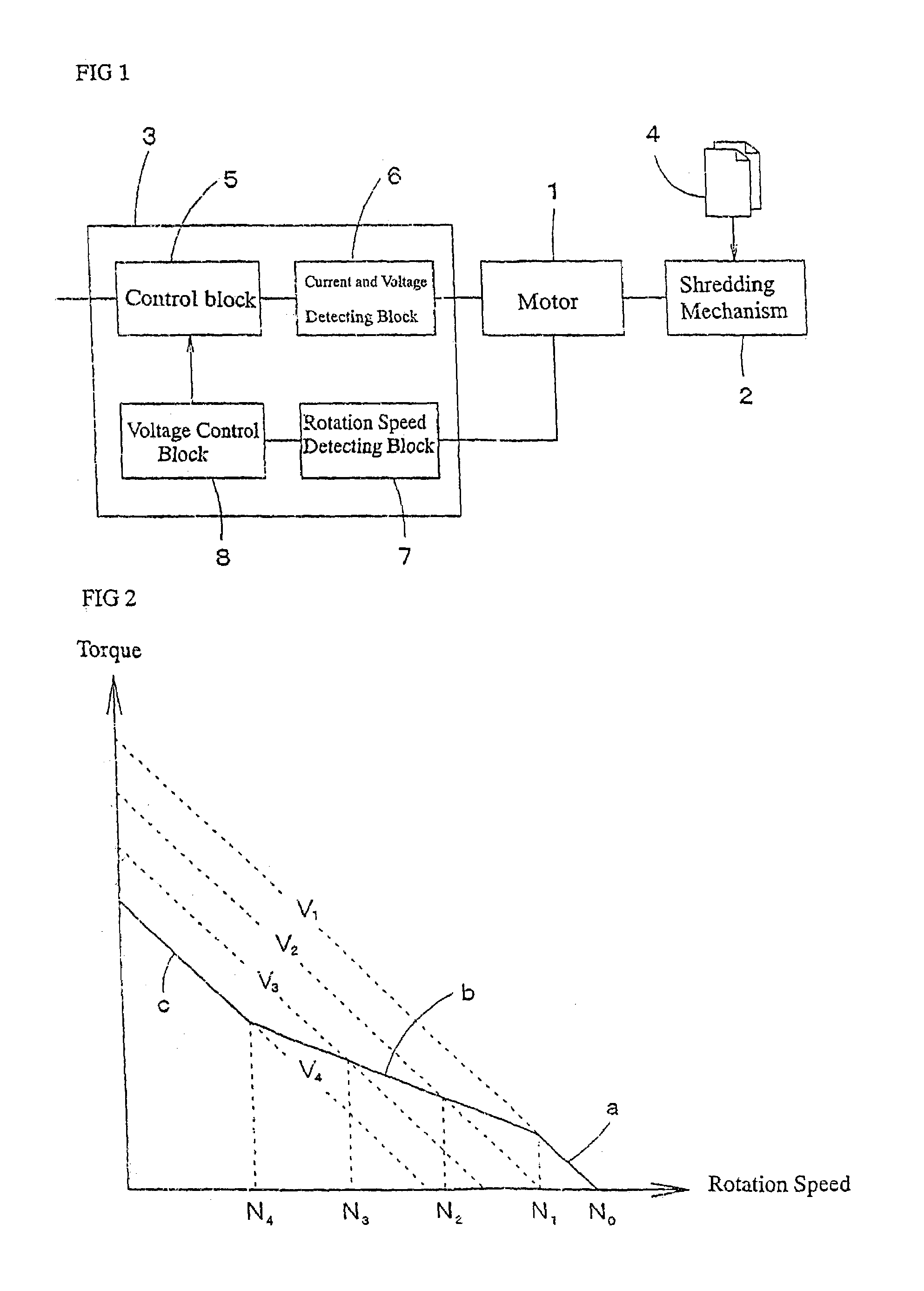

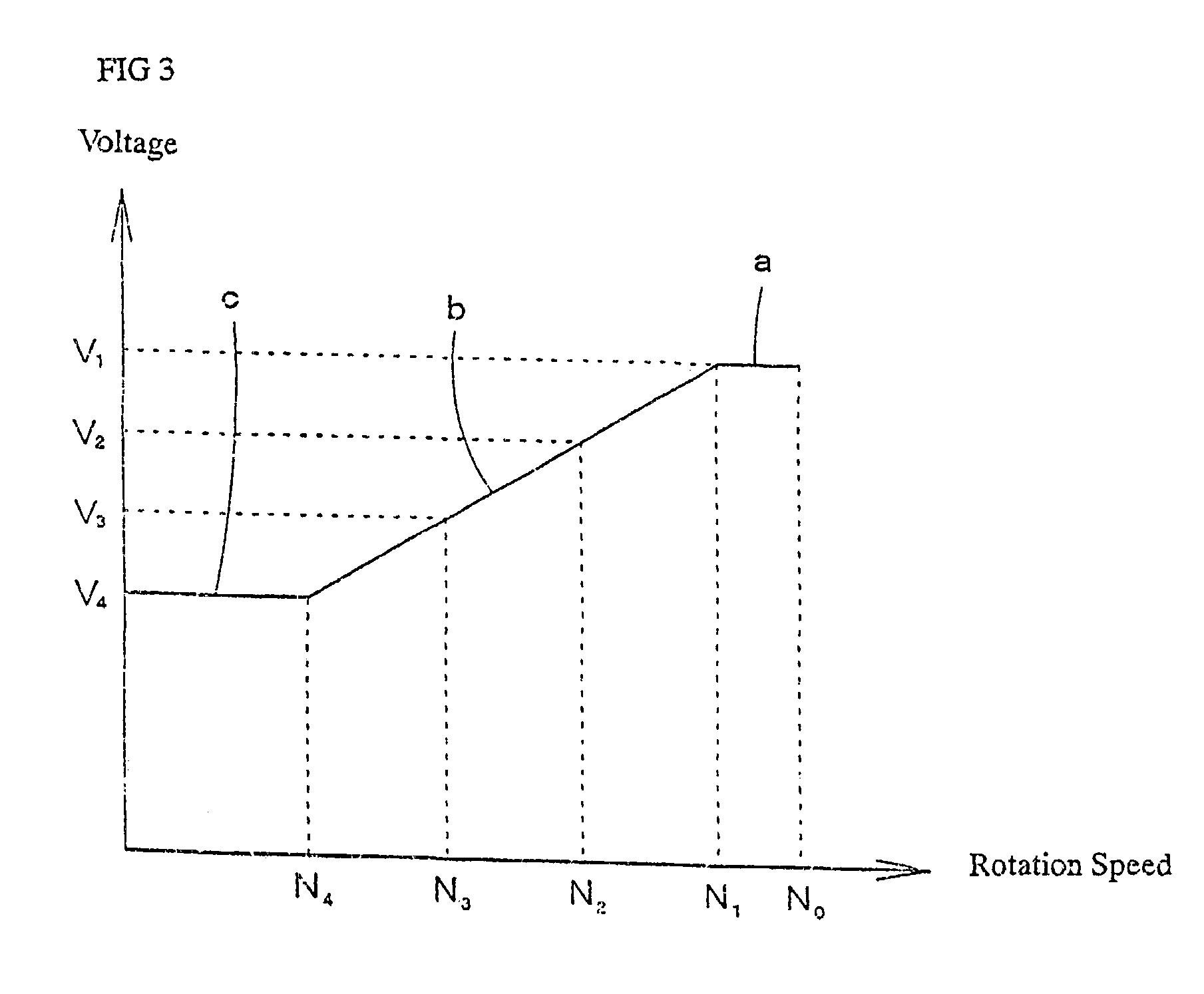

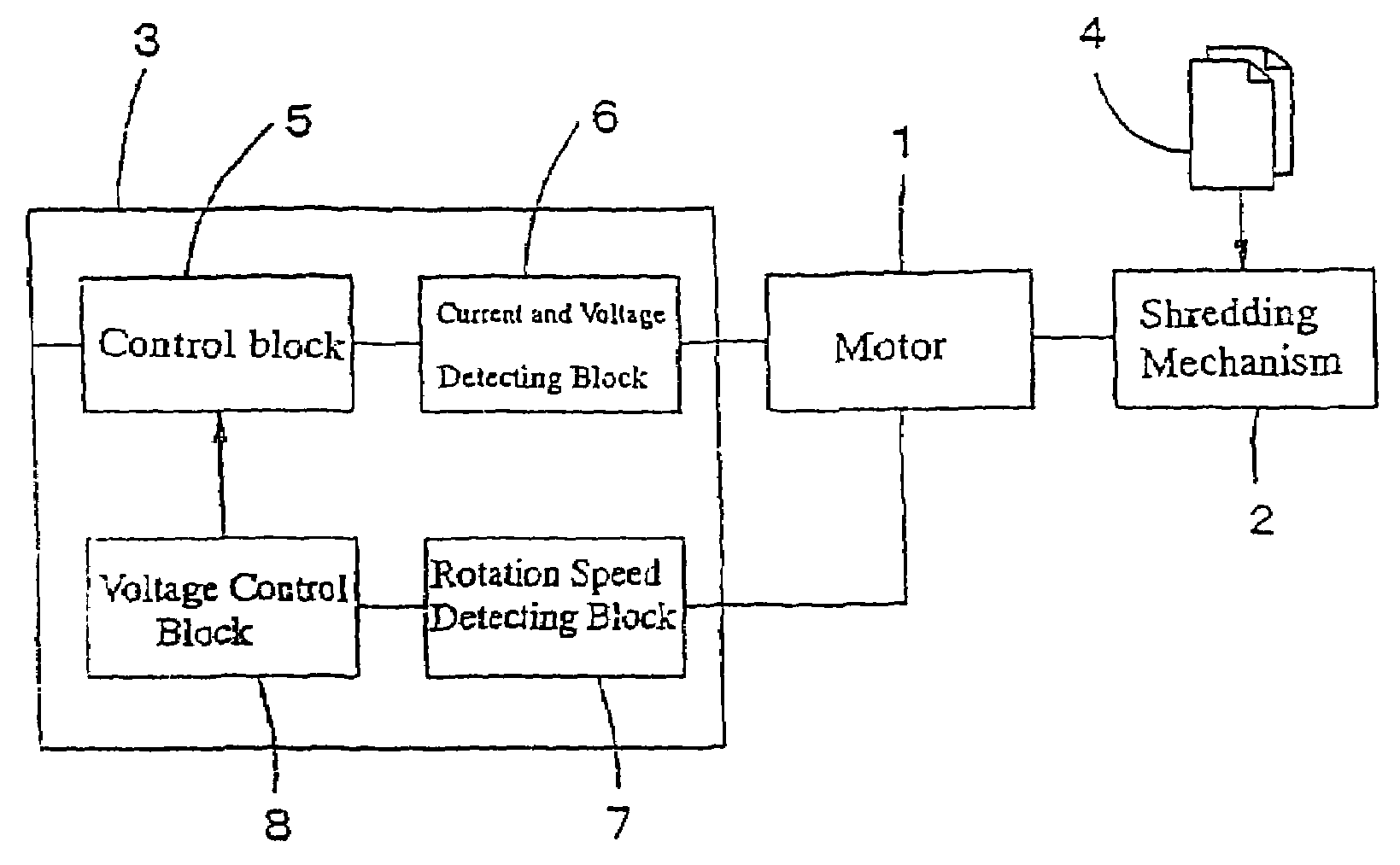

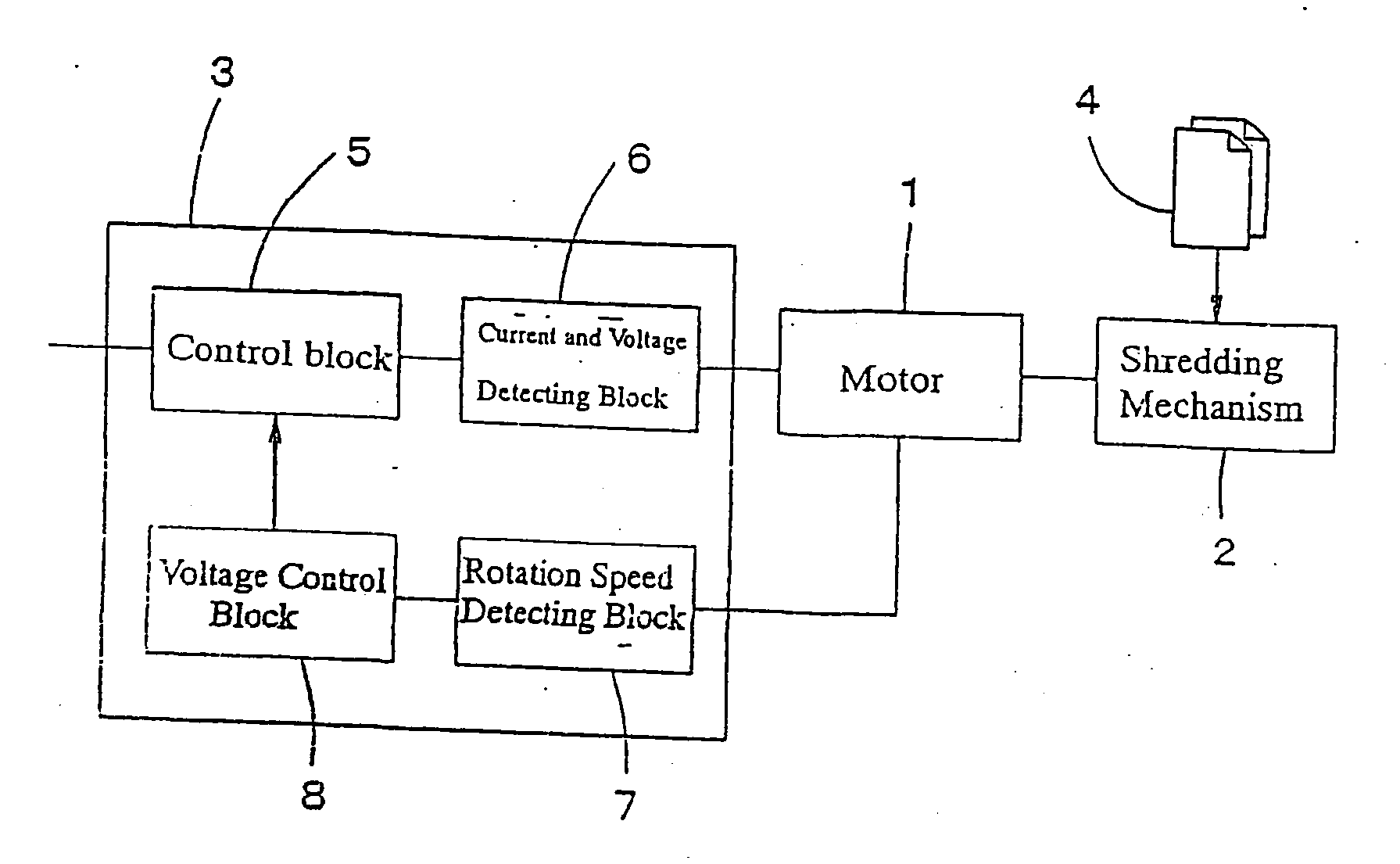

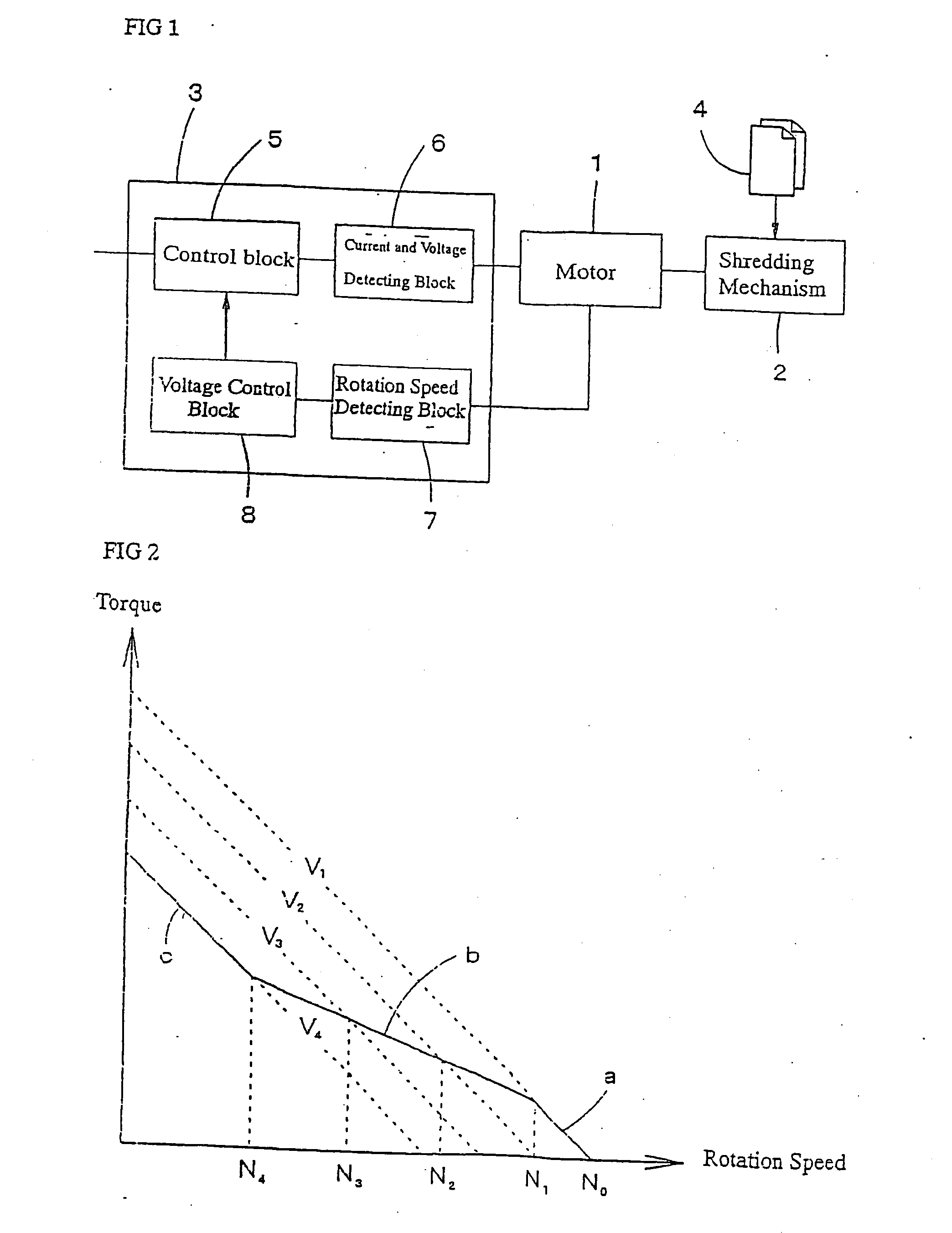

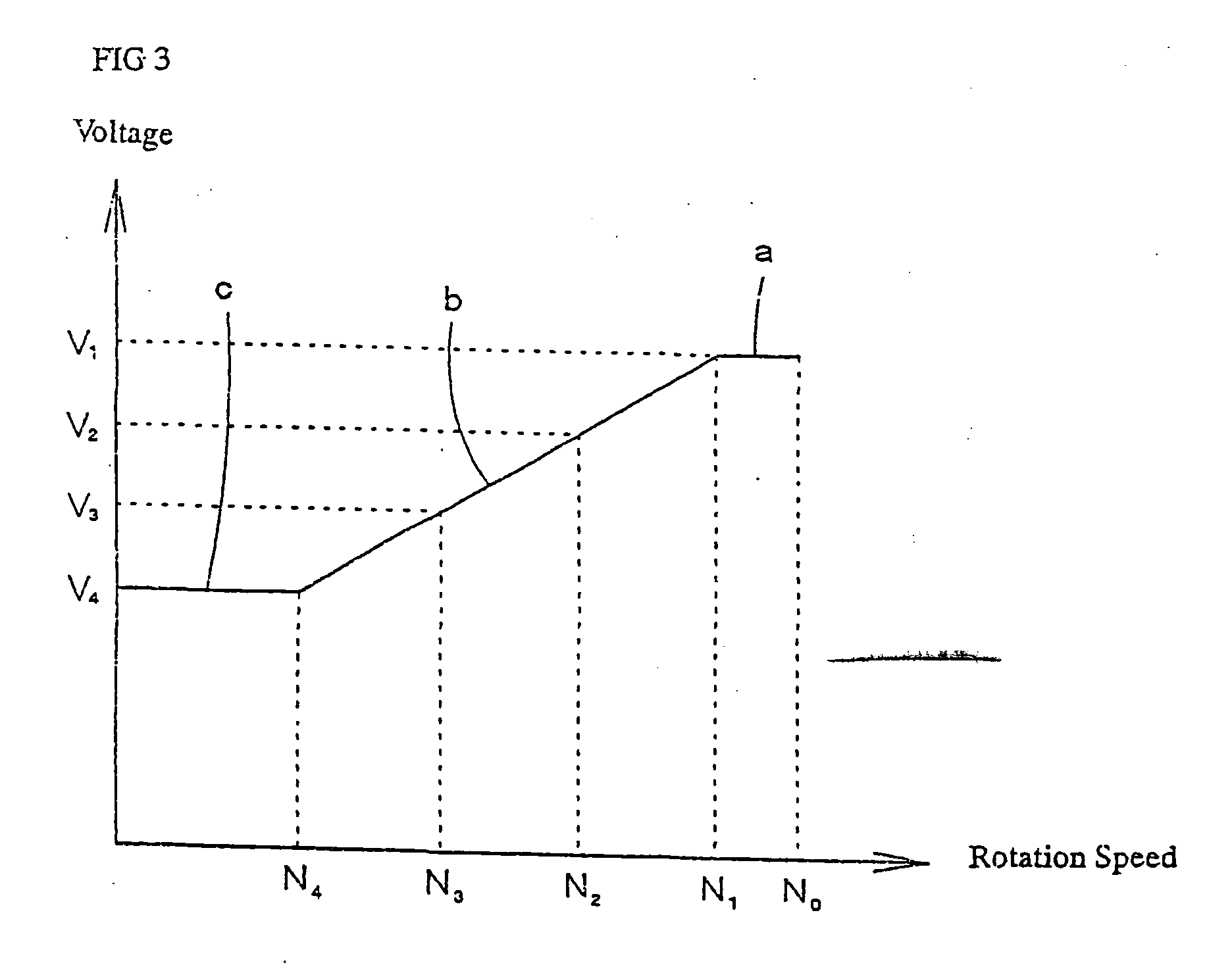

Motor control circuit for paper shredders

InactiveUS6997408B2Control power consumptionImprove energy savingElectric motor controlEnergy industryLow speedControl power

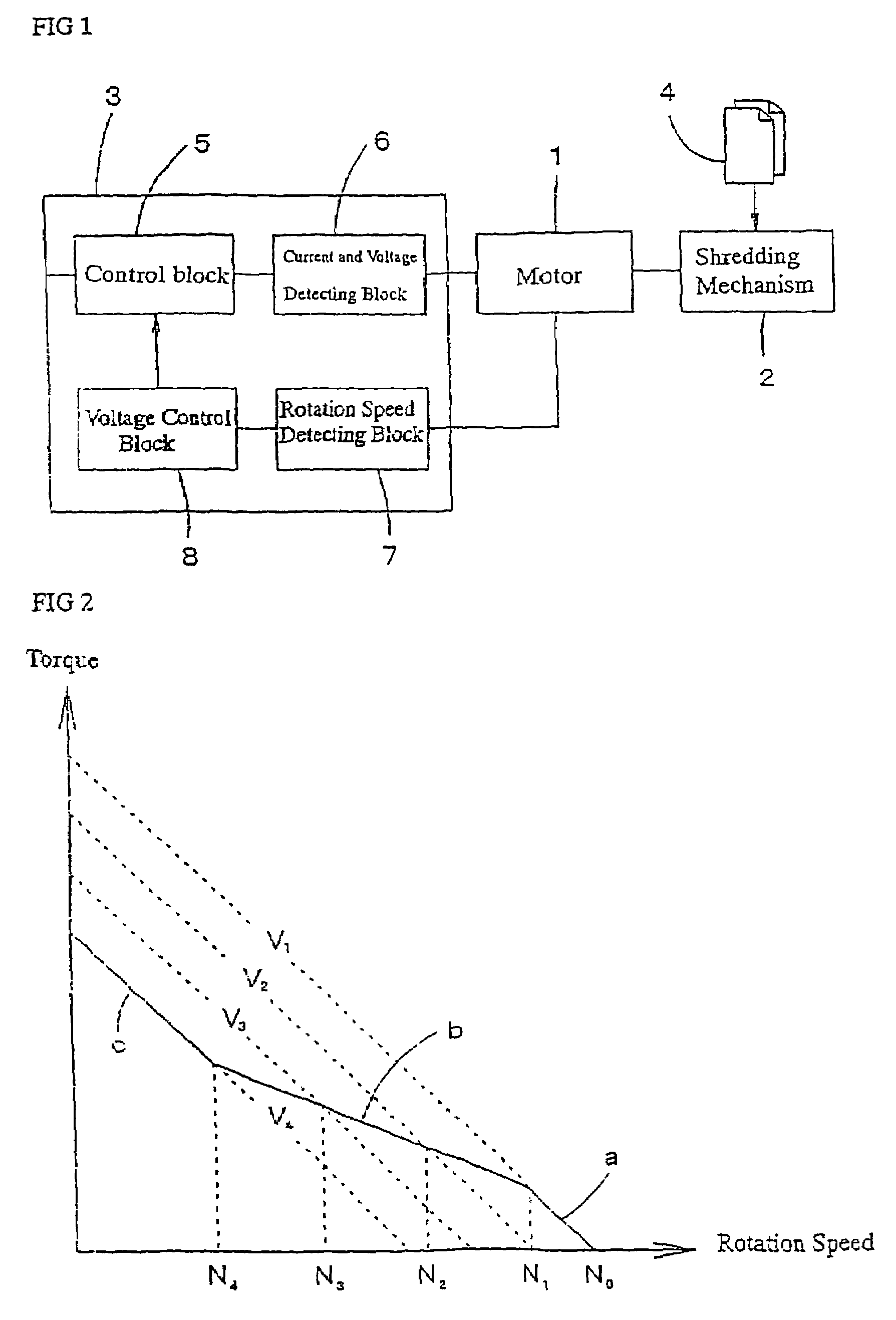

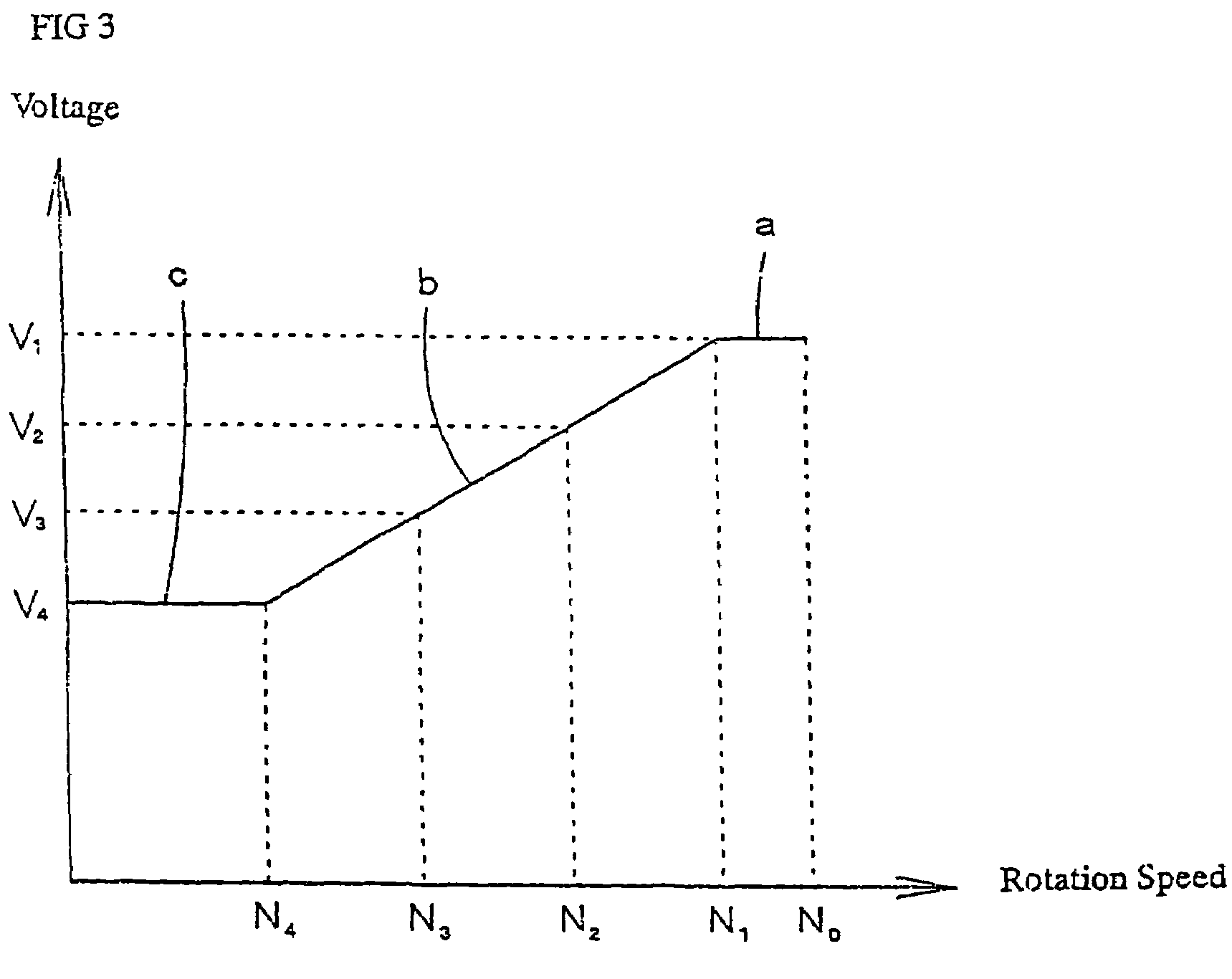

A paper shredder enables to control power consumption and achieve energy saving by realizing a torque characteristic of low torque at high speed or high torque at low speed keeping an output of a motor within a steady level. This circuit adopts a paper shredder structured with a driving motor for a rotary cutter having an inverted linear flow characteristic between rotation speed and torque and a control circuit composed of a detecting block for said rotation speed of said motor, a voltage control block for restricting a voltage output of said motor within a certain range in accordance with said rotation speed, and a current and voltage detecting block for monitoring a current flow of said motor. While a voltage is decreased on account of motor rotation speed which correlates negatively with a torque increase of said motor in shredding papers, when a voltage is restricted to a minimum by said voltage control block, an operation of said motor is to be suspended or reversed in the case that a current detected by said current and voltage detecting block exceeds a certain level. If a motor current detected by said current and voltage detecting block exceeds a certain level, a motor operation is to be suspended or reversed by a delaying circuit.

Owner:NAKABAYASHI CORP +1

Motor control circuit for paper shredders

InactiveUS7520452B2Stable continuous operationImprove shredding efficiencyCocoaGrain treatmentsLow speedEngineering

Owner:NAKABAYASHI CORP +1

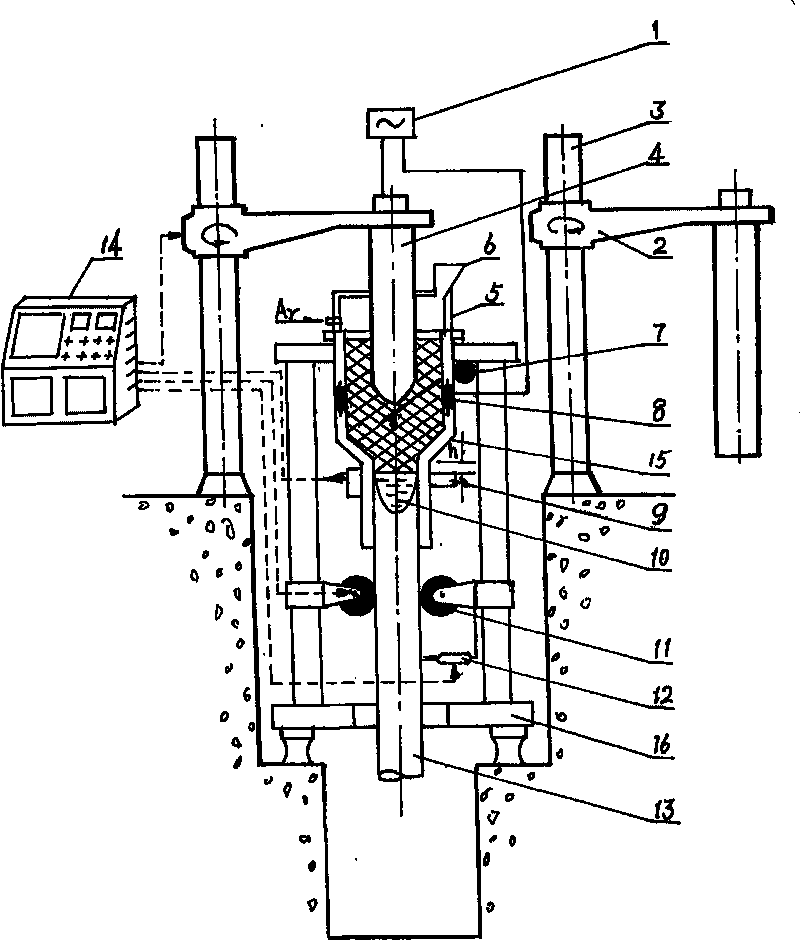

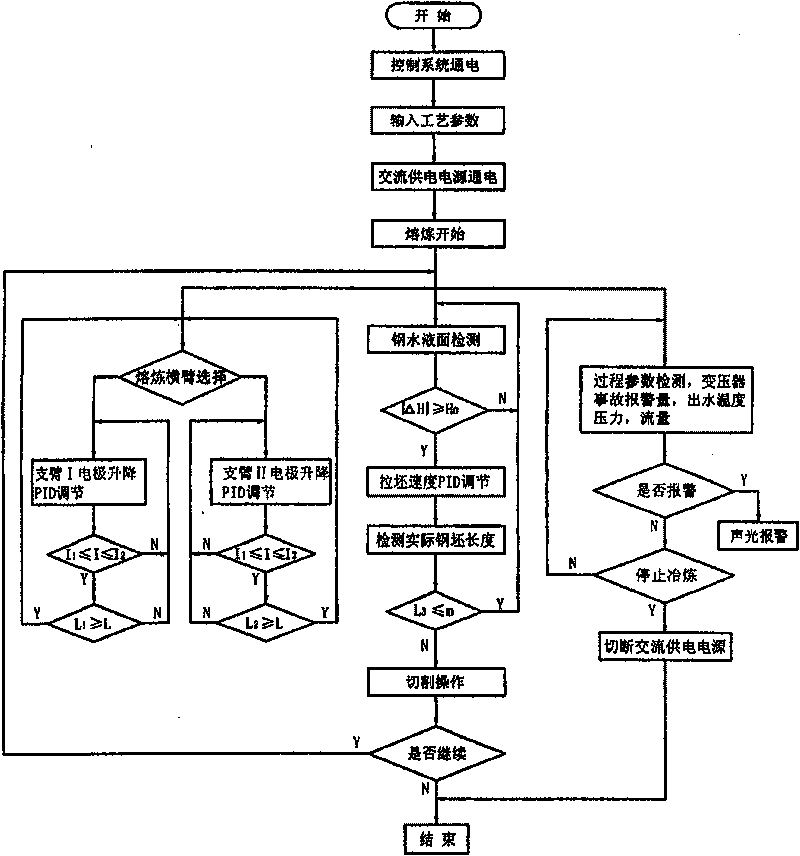

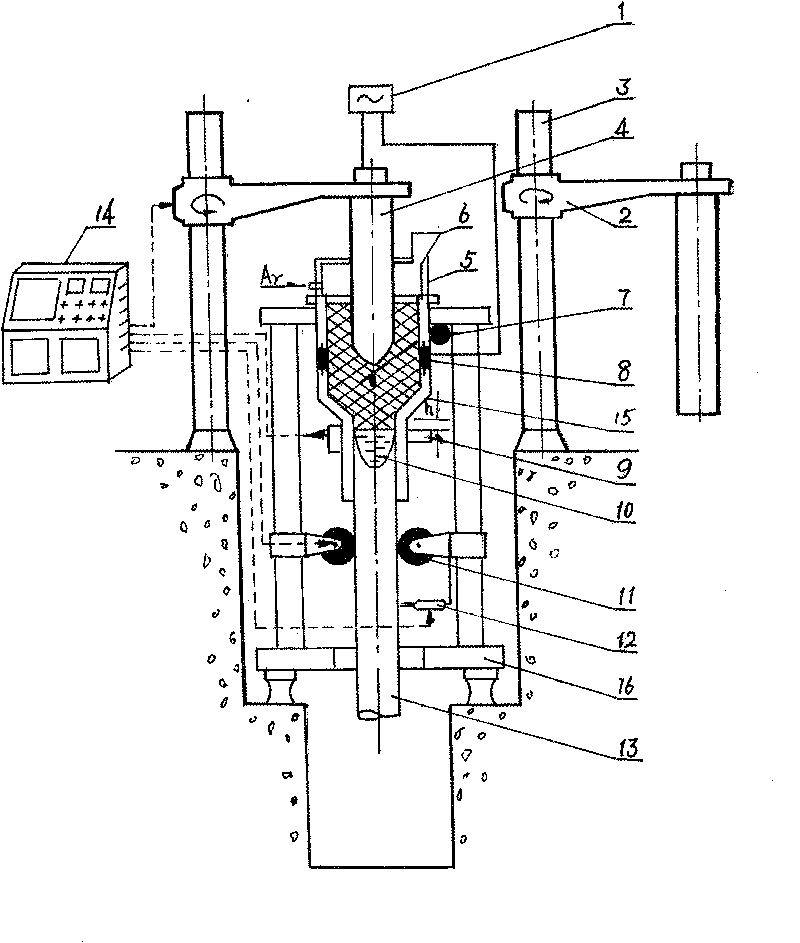

Protective atmosphere electro-slag continuous casting furnace

The invention discloses a protective atmosphere electro-slag continuous casting furnace, which belongs to metal electro-slag re-melting equipment. The furnace comprises an alternating current power supply, electrode lifting mechanisms, a consumable electrode, a conductive crystallizer, a supporting mechanism, a molten steel liquid level detection device, an argon protective cover, a vibration mechanism, a throwing mechanism, a cutting device and a control system. The electrode lifting mechanisms are fixed on two sides of the conductive crystallizer; one end of the consumable electrode is fixed on a cross arm of the electrode lifting mechanism and is connected with the alternating current power supply, while the other end passes through the argon protective cover and is placed inside the conductive crystallizer; the conductive crystallizer is a jacket type water-cooled crystallizer with combined upper and lower parts, a conductive ring is embedded at the upper wall, and the conductive ring is connected with the alternating current power supply through a cable so that a loop is formed from the alternating current power supply, the consumable electrode, furnace slag, the conductive ring to the alternating current power supply; the vibration mechanism is fixed on the supporting mechanism, and a cam of the vibration mechanism is tightly contacted with a shell of the conductive crystallizer; the joint of upper and lower cavities of the conductive crystallizer is provided with the molten steel liquid level detection device; the throwing mechanism and the cutting device are fixed under an ejection port of the conductive crystallizer in turn; and the control system is electrically connected with the cross arm of the electrode lifting mechanism, the molten steel liquid level detection device, the drawing mechanism and the cutting device respectively. The protective atmosphere electro-slag continuous casting furnace can realize electro-slag continuous casting.

Owner:SHENYANG HUASHENG METALLURGICAL TECH & INSTALLATION

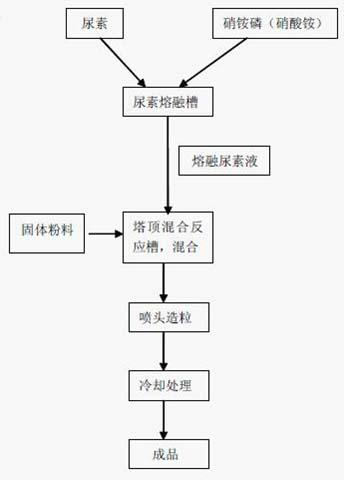

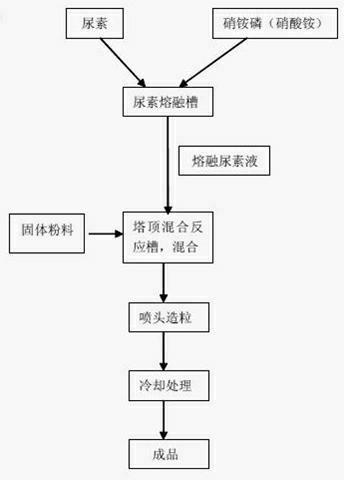

Method for producing urea-based compound fertilizer by high tower granulation

ActiveCN102584395AImprove liquidityReduce the presence of air bubblesFertiliser formsFertilizer mixturesFertilizerChemistry

The invention discloses a method for producing a urea-based compound fertilizer by high tower granulation. The method comprises the following steps of: (1) adding a fluxing agent and urea into a melting tank, melting the urea at low temperature, and adding into a mixing reaction tank on the top of a tower; (2) adding other raw materials into the melted urea solution in the mixing reaction tank on the top of the tower, and mixing and stirring to obtain mixed and melted slurry; and (3) spraying the mixed and melted slurry by using a granulation nozzle in the high tower, and granulating in the tower. The method has the advantages that operating temperature and energy consumption are low, the liquidity of the slurry is high, a few bubbles exist in the mixed slurry, a small amount of biuret is generated, the operating environment is good, and the like; and high tower granulation production can be stably, normally and continuously performed.

Owner:WENGFU (GRP) CO LTD

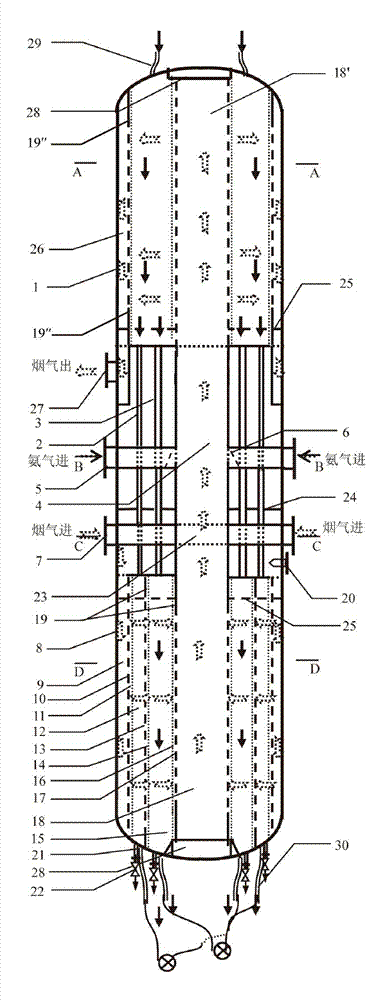

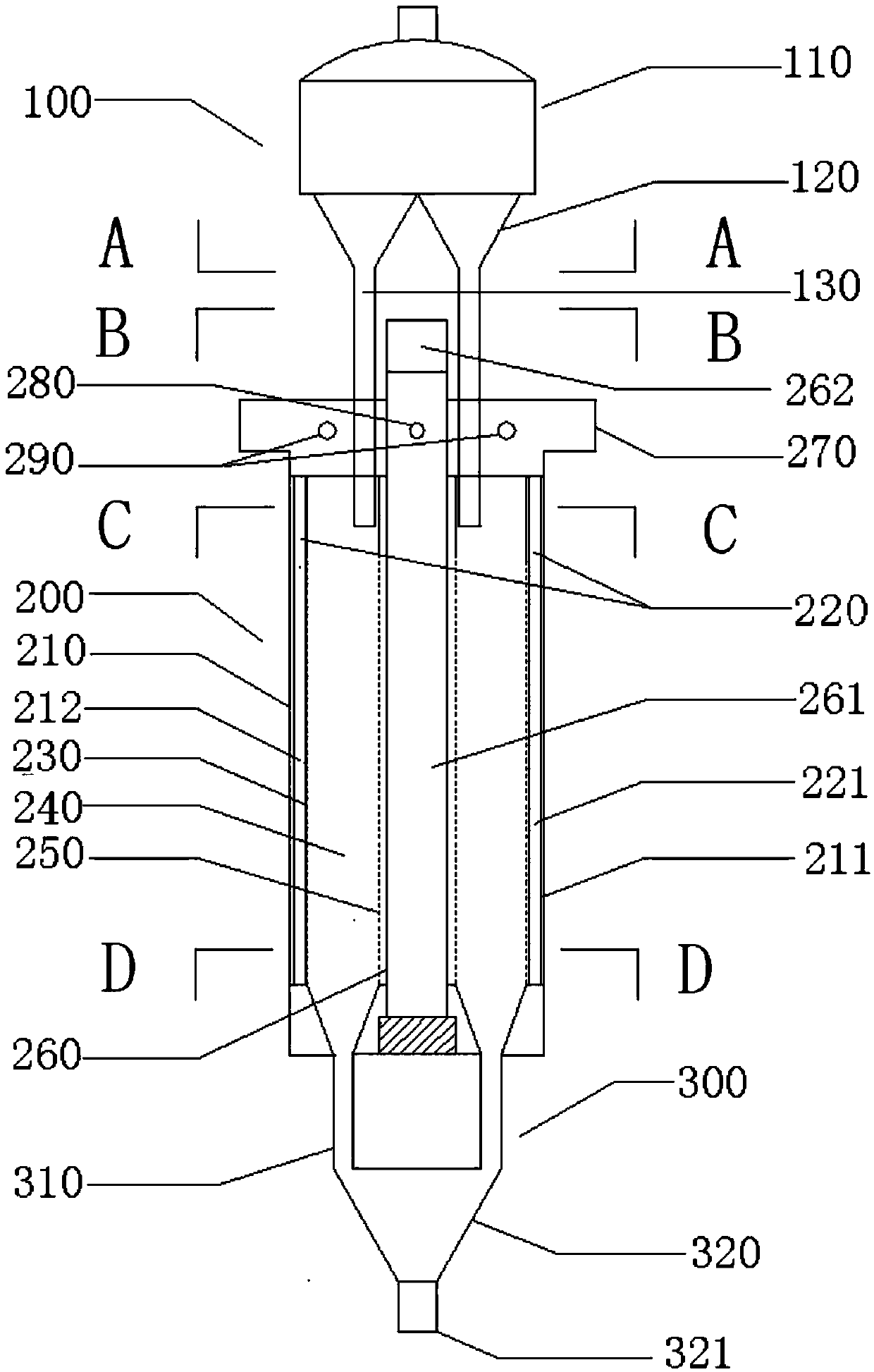

Axial and radial cross flow moving bed reactor and activated coke flue gas desulfurization and denitration technology thereof

ActiveCN102824846ACombined removalAchieve efficient utilizationDispersed particle separationAir quality improvementThermodynamicsFlue gas

An axial and radial cross flow moving bed adsorption reactor and an activated coke flue gas desulfurization and denitration technology thereof are used for realizing the purposes that SO2, NOx, mercury, dioxin and other pollutants in flue gas are unitedly removed and integrally purified in an adsorption reactor, and belong to the technical field of comprehensive waste flue gas treatment. The adsorption reactor is a combined type double-section double-inverse U-type axial and radial cross flow moving bed, awherein desulfurization area is arranged at a lower section of the axial and radial cross flow moving bed, an annular internal activated coke particle layer and an annular external activated coke particle layer are arranged, and the desulfurization area is divided into a coarse desulfurization area and a fine desulfurization area; a denitration area is arranged at an upper section of the axial and radial cross flow moving bed, and an activated coke particle layer is arranged; an ammonia spray pipe is arranged between the upper section and the lower section; and flue gas is filled along a double-port counter annular gas flow channel structure, the flue gas of the lower section centripetally flows to be desulfurized, and the flue gas of the upper section centrifugally flows to be denitrated. According to the reactor and the technology, desulfurization and denitration are realized in one adsorption reactor, so the adsorption reactor has the advantages of efficient utilization of activated coke, uniform flue gas mixing, sufficient gas-solid contact, stability and reliability in operation, operation cost saving and the like.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

Device for producing coarse titanium tetrachloride by low-temperature fluidizing chlorination

ActiveCN102701274AReduce vibration intensityReduce static pressureTitanium halidesSlagDiffusion resistance

The invention discloses a device for producing coarse titanium tetrachloride by low-temperature fluidizing chlorination. The device comprises a furnace top, a furnace body and a furnace bottom, wherein the furnace bottom is provided with a gas distributor which is communicated with a gas inlet pipe and comprises a chassis and a plurality of gas nozzles uniformly distributed on the chassis; a gas outlet of each gas nozzle is upward; the furnace body is in a straight cylinder shape; the side wall of the furnace body is provided with a charging opening and a slag discharging opening; the charging opening is positioned at the bottom of the furnace body and is arranged opposite to the slag discharging opening; the arrangement position of the slag discharging opening is higher than that of the charging opening; and the vertical distance of the slag discharging opening to the charging opening is 1.2-2.2m. With the adoption of the device, production large scale is easily realized, static pressure and diffusion resistance in the furnace are reduced, the vibration strength of the furnace body is reduced; reverse backmixing of the gas is inhibited, the mass transfer and heat transfer rate are improved, the contact time and contact surface of carbide slag and chlorine are ensured, the transformation rate of TiC is improved; and the device is beneficial to continuous operation of a chlorination furnace and is convenient in manufacturing, transformation and maintenance compared with the traditional chlorination furnace.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Motor control circuit for paper shredders

InactiveUS20060027689A1Control power consumptionImprove energy savingCocoaGrain treatmentsLow speedControl power

A paper shredder enables to control power consumption and achieve energy saving by realizing a torque characteristic of low torque at high speed or high torque at low speed keeping an output of a motor within a steady level. This circuit adopts a paper shredder structured with a driving motor for a rotary cutter having an inverted linear flow characteristic between rotation speed and torque and a control circuit composed of a detecting block for said rotation speed of said motor, a voltage control block for restricting a voltage output of said motor within a certain range in accordance with said rotation speed, and a current and voltage detecting block for monitoring a current flow of said motor. While a voltage is decreased on account of motor rotation speed which correlates negatively with a torque increase of said motor in shredding papers, when a voltage is restricted to a minimum by said voltage control block, an operation of said motor is to be suspended or reversed in the case that a current detected by said current and voltage detecting block exceeds a certain level. If a motor current detected by said current and voltage detecting block exceeds a certain level, a motor operation is to be suspended or reversed by a delaying circuit.

Owner:NAKABAYASHI CORP +1

Method and equipment for treating ammonia-nitrogen wastewater

InactiveCN106277419AEasy to handleSimple processMultistage water/sewage treatmentSludgeSmall footprint

The invention discloses a method and equipment for treating ammonia-nitrogen wastewater. The method for treating the wastewater comprises the following steps of a pH regulating stage, an air stripping reaction stage, a struvite settling reaction stage, a deep treatment stage and a sludge discharging stage in sequence. The equipment mainly comprises a regulating tank, an air stripping tower, a struvite settling reactor, a zeolite filter and a water producing tank which are sequentially connected in series. The method and equipment for treating the ammonia-nitrogen wastewater have the advantages that through pH value regulation, ammonia and nitrogen in the wastewater are converted into a free state and then are stripped through air introduced into the wastewater, and ammonia and nitrogen remaining in the wastewater are removed and recycled through a struvite settling reaction method; finally, a zeolite adsorption tower is used for adsorption, ammonia and nitrogen in the wastewater are deeply removed, and it is ensured that produced water is discharged up to the standard; the method and equipment for treating the ammonia-nitrogen wastewater are stable in treatment effect, simple in technological process, high in ammonia-nitrogen removing rate, short in reaction time, small in occupied area and the like.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

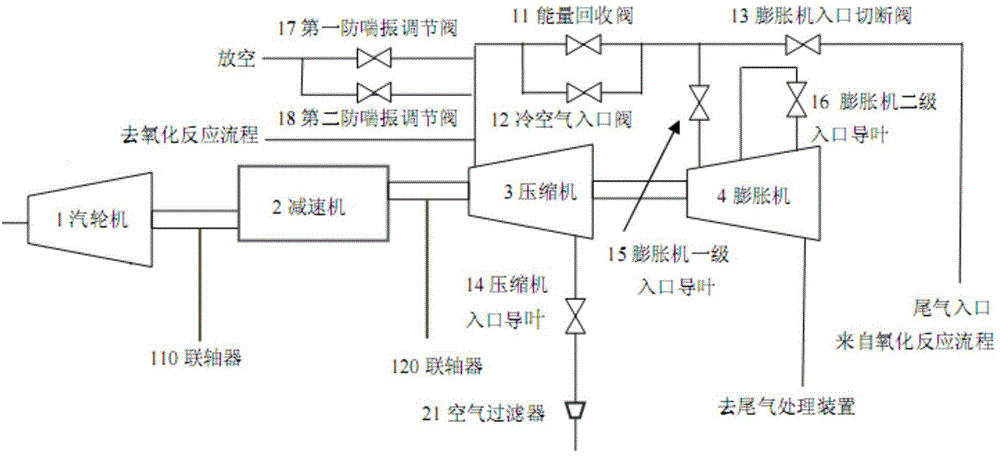

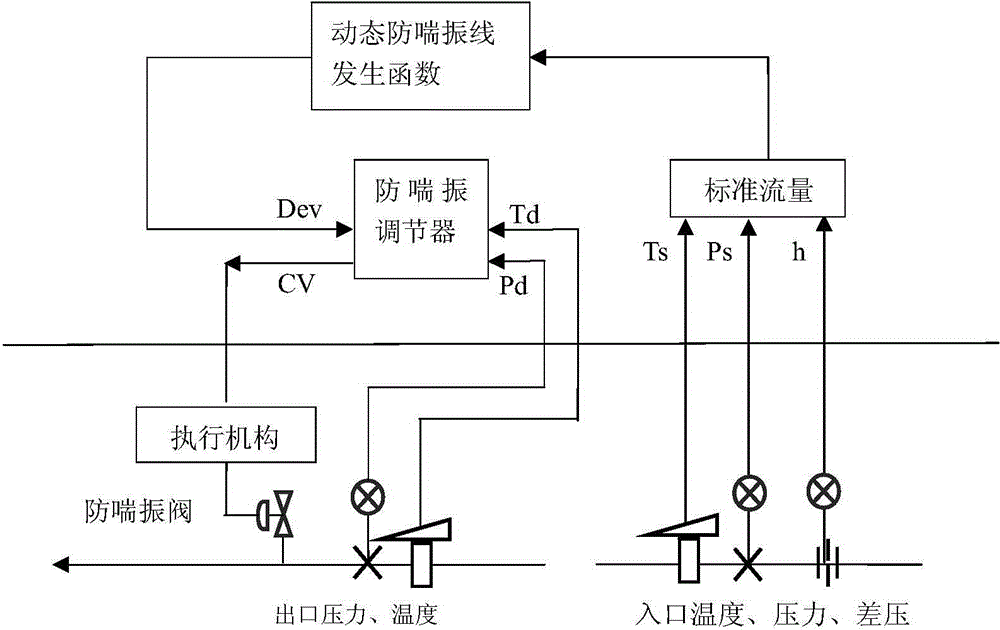

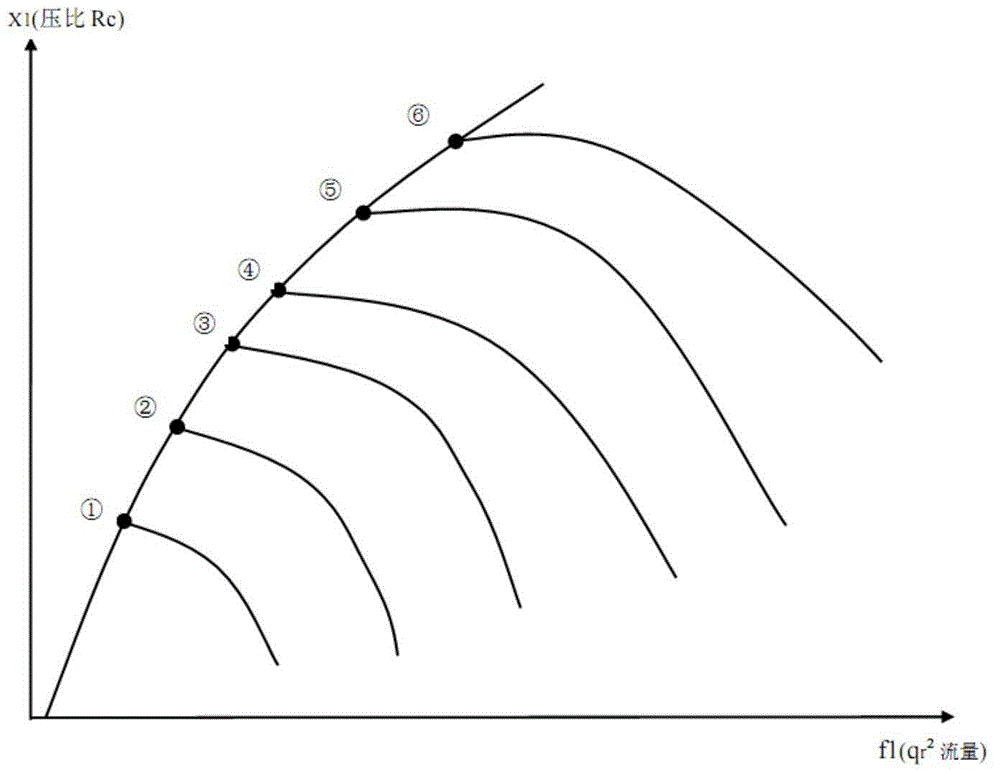

Energy recycling control method for PTA device

ActiveCN105370629AGuaranteed uptimeAnti-surge control implementationPump componentsPump controlDifferential pressureInlet pressure

The invention relates to an energy recycling control method for a PTA device. The energy recycling control method is characterized by comprising the following steps that the inlet temperature and the outlet temperature of a compressor, the inlet pressure, the outlet pressure and the outlet flow are measured; the pore plate differential pressure is converted into the square of the inlet flow qr<2> to serve as the transverse coordinate of an anti-surge curve; the outlet pressure and the inlet pressure of the compressor are converted into the pressure ratio Rc to serve as the longitudinal coordinate of the anti-surge curve; a dynamic anti-surge control curve is obtained according to the square of the inlet flow qr<2> and the pressure ratio Rc; the distance d between a working point and a surge point is obtained according to the dynamic anti-surge control curve; the DEV value, namely DEV=d-2b, is obtained according o the set safety margin b; and an energy recycling valve is controlled according to the DEV value. The energy recycling valve is controlled through an anti-surge control method, the requirement for reliable operation of the compressor is met, and the extremely-high stability performance is achieved. The working point of the compressor is near the anti-surge curve in a following manner, the unit efficiency is achieved to the maximum degree, the valve is usually in a completely-closed state, and it is ensured that the energy is not lost during use.

Owner:SHENYANG BLOWER WORKS GRP AUTOMATIC CONTROL SYST ENG

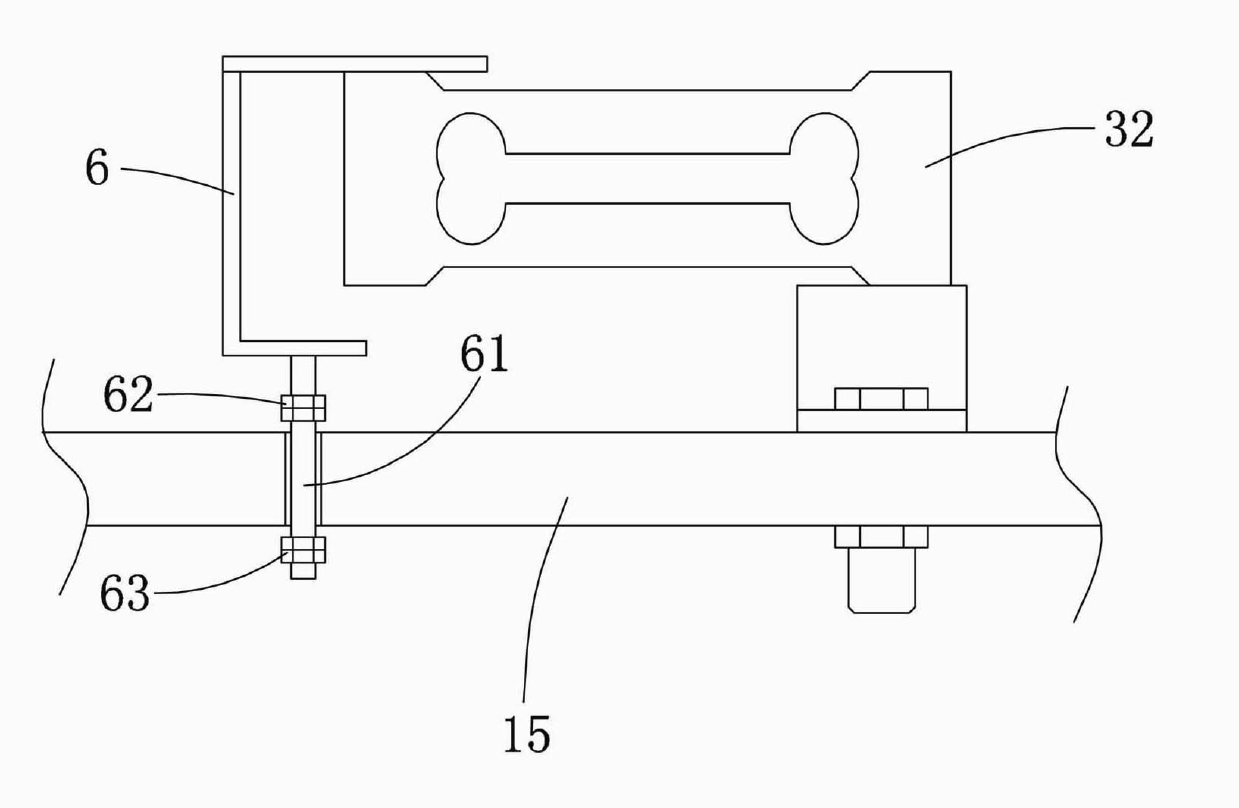

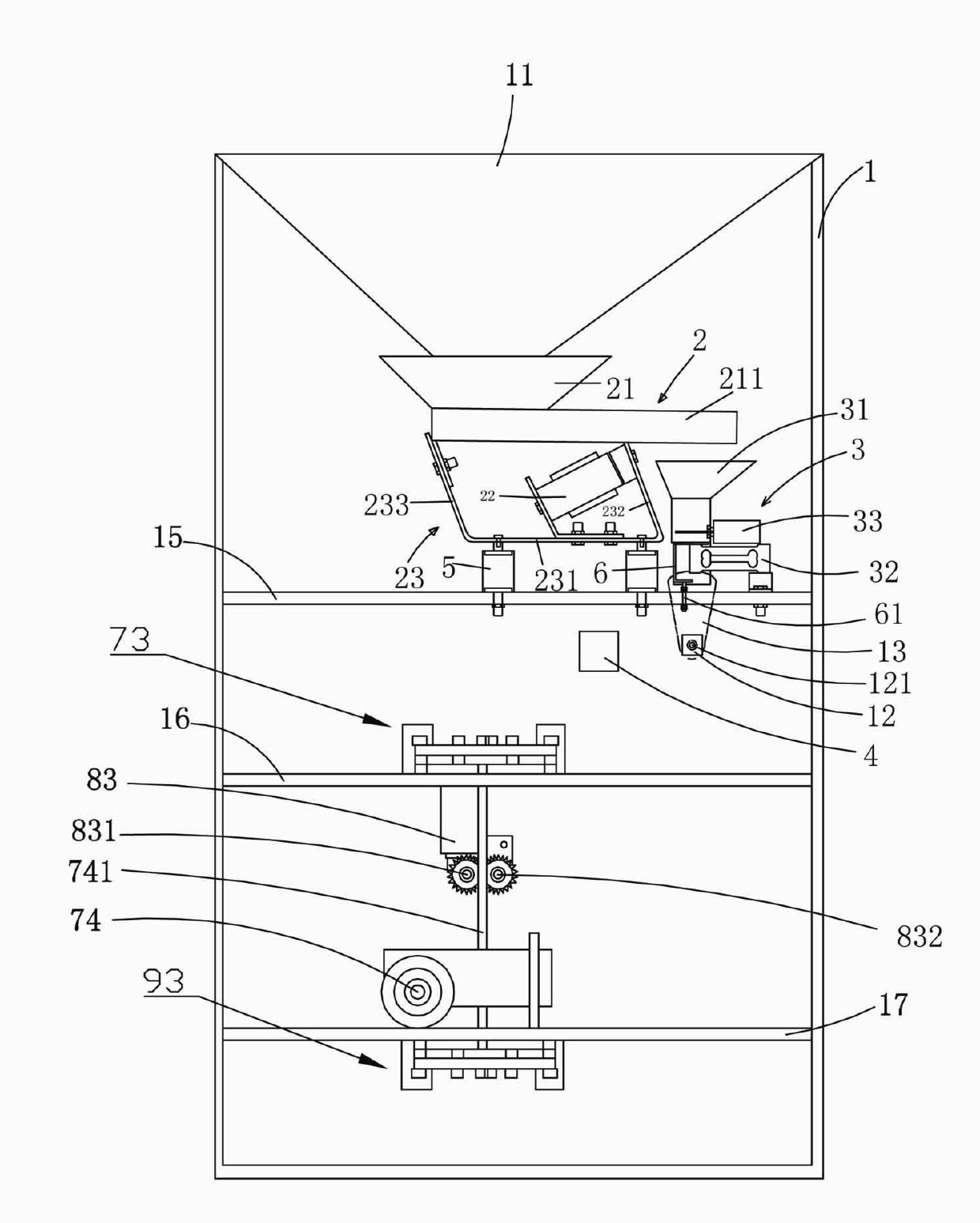

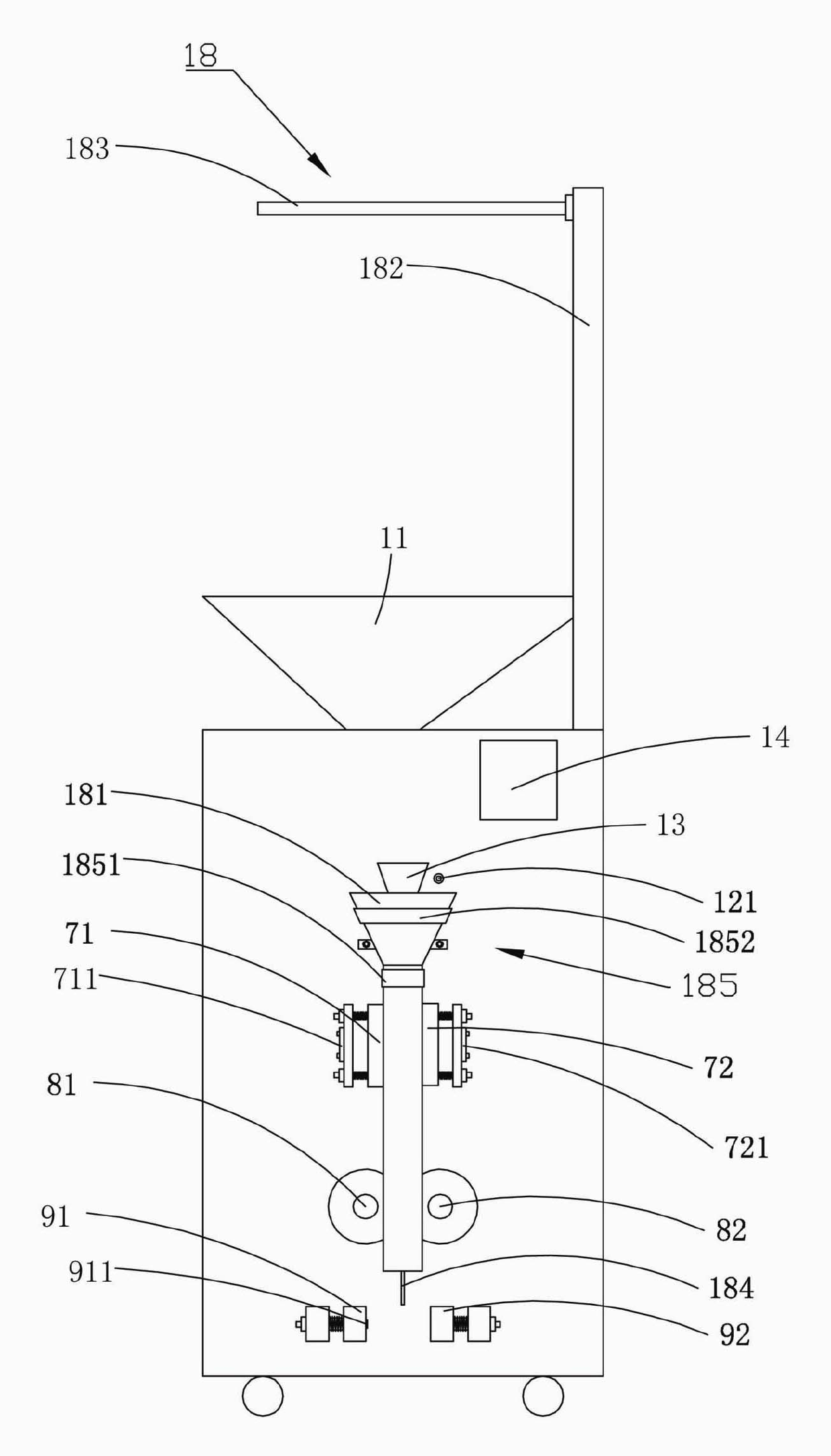

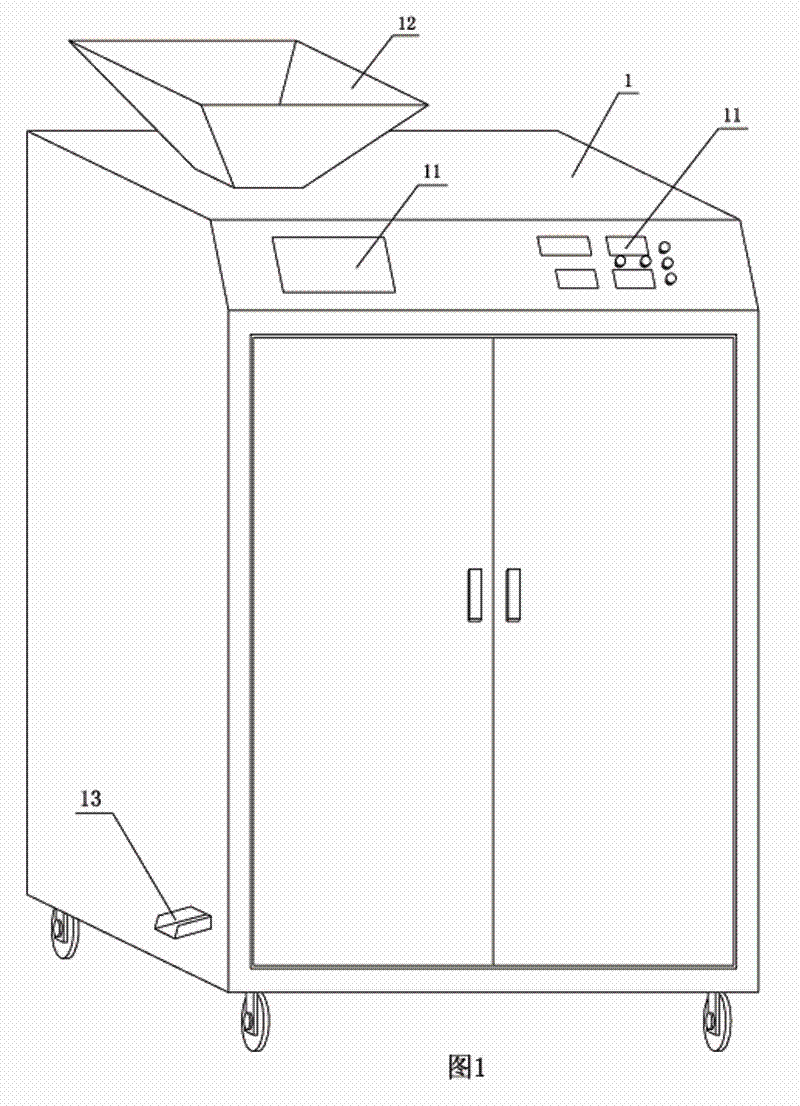

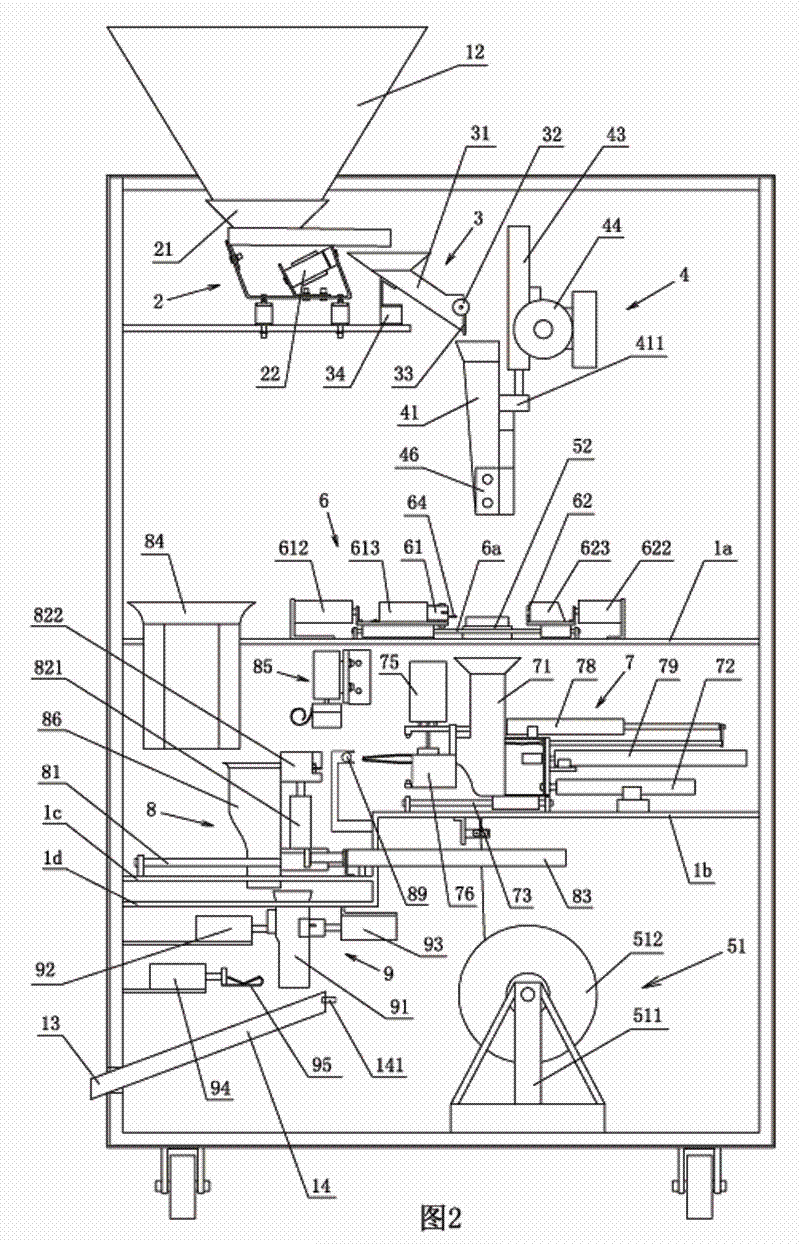

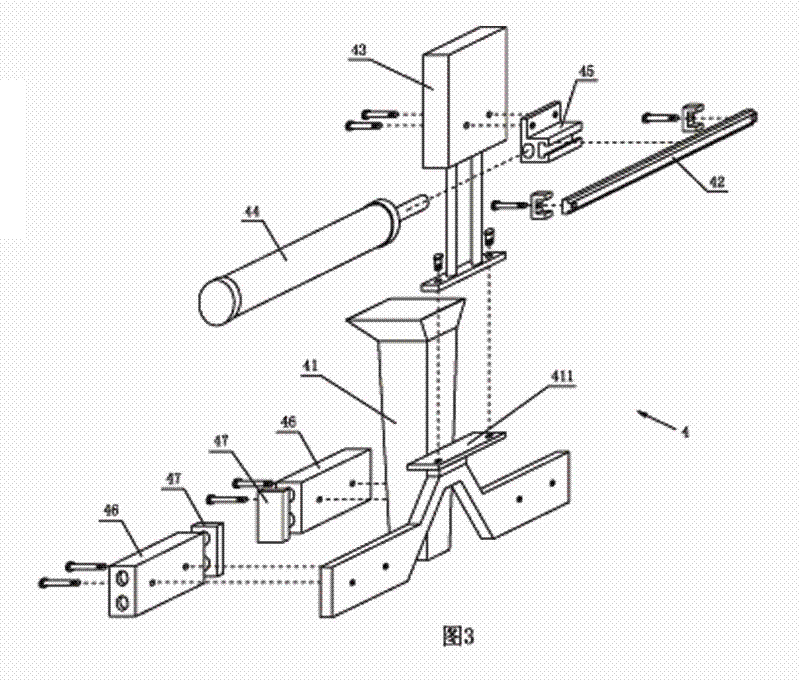

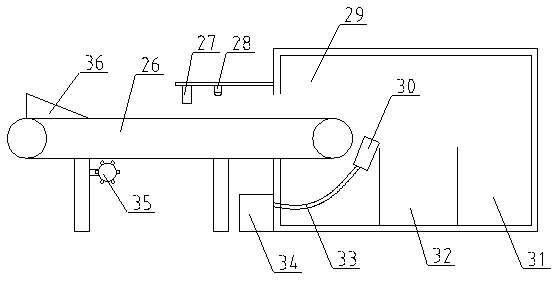

Machine integrating tea weighing with film inner bag making and loading

InactiveCN102001457AHigh degree of automationIncrease productivityWrapping material feeding apparatusWrapper twisting/gatheringEngineering

The invention provides a medicine integrating tea weighing with film inner bag making and loading, which comprises a casing, a reel device fixed on the casing and used for installing a film reel for making an inner bag, and a precise automatic tea weighing device and a film inner bag making and loading device which are arranged on the casing from top to bottom. Through reasonably integrating the tea weighing, the film inner bag making and the tea bagging together, the machine is more convenient and practical for use, improves the production efficiency and is more beneficial to massive production.

Owner:李文峰

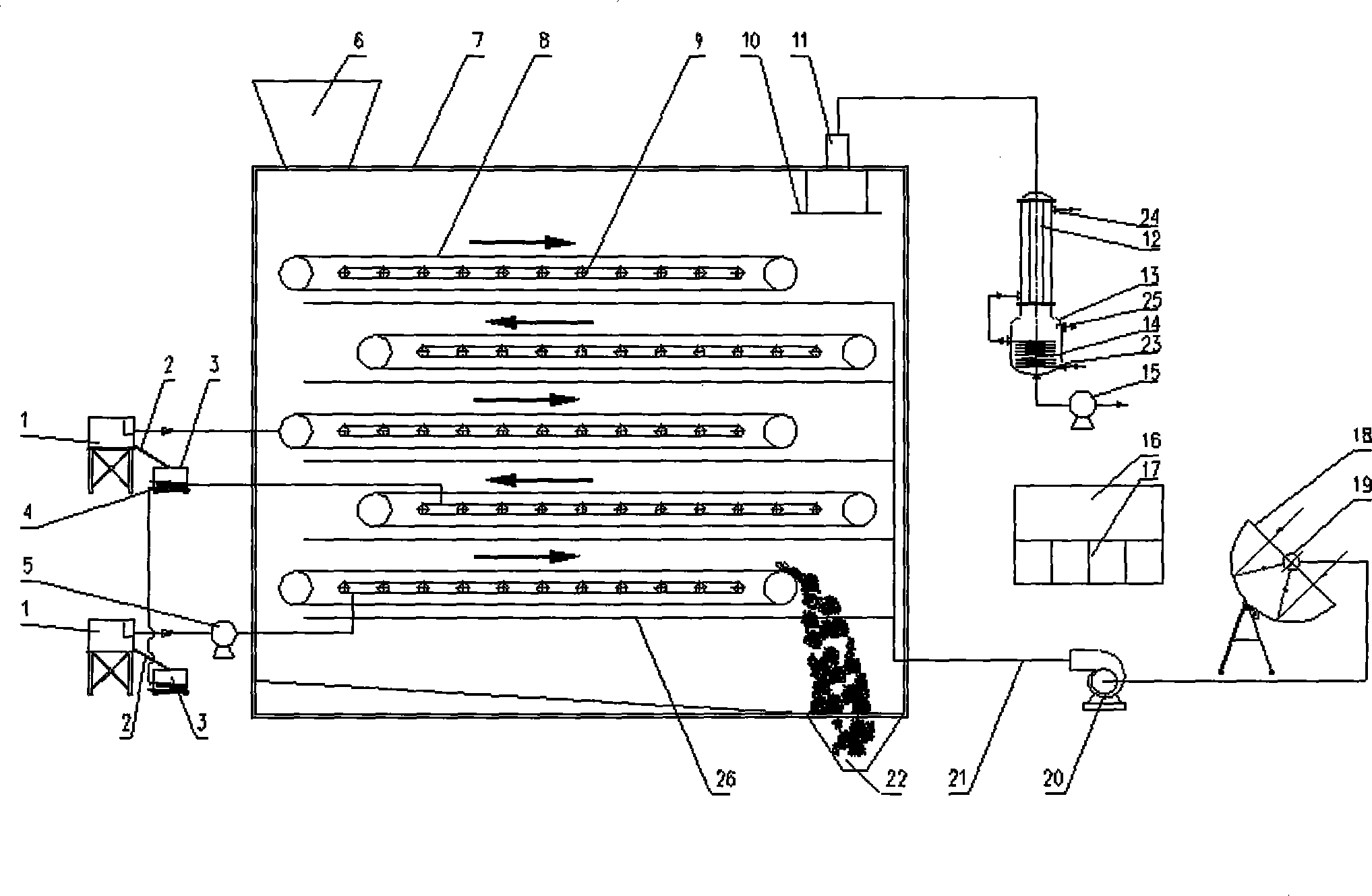

Novel compound solar sludge drying equipment

InactiveCN103319062ASimple structureEasy to installSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentSludgeSolar power

The invention discloses novel compound solar sludge drying equipment which belongs to the technical field of deep dehydration of sludge. In comparison with present sludge dehydration equipment, the equipment provided by the invention has the following advantages: a solar heat collector and a solar power system are additionally added; a crawler belt and a heating pipe are used to dry sludge; the structure is simple; and efficiency is high. According to the invention, a renewable clean energy, solar energy, is used as the main energy, thus saving a lot of energy. The solar heat collector has a simple structure and is convenient to install. The equipment is simple to operate. Water content of dried sludge is about 20-30%. The dried sludge can be used as a raw material of a novel energy to be recycled.

Owner:KANGTAI JIANGSU ENVIRONMENTAL PROTECTION LTD BY SHARE LTD

Automatic packaging unit for vacuum packaging of inner bag and outer bag

InactiveCN101837843BHigh degree of automationIncrease productivityPackaging by pressurising/gasifyingSolid materialEngineeringAutomation

Owner:李文峰

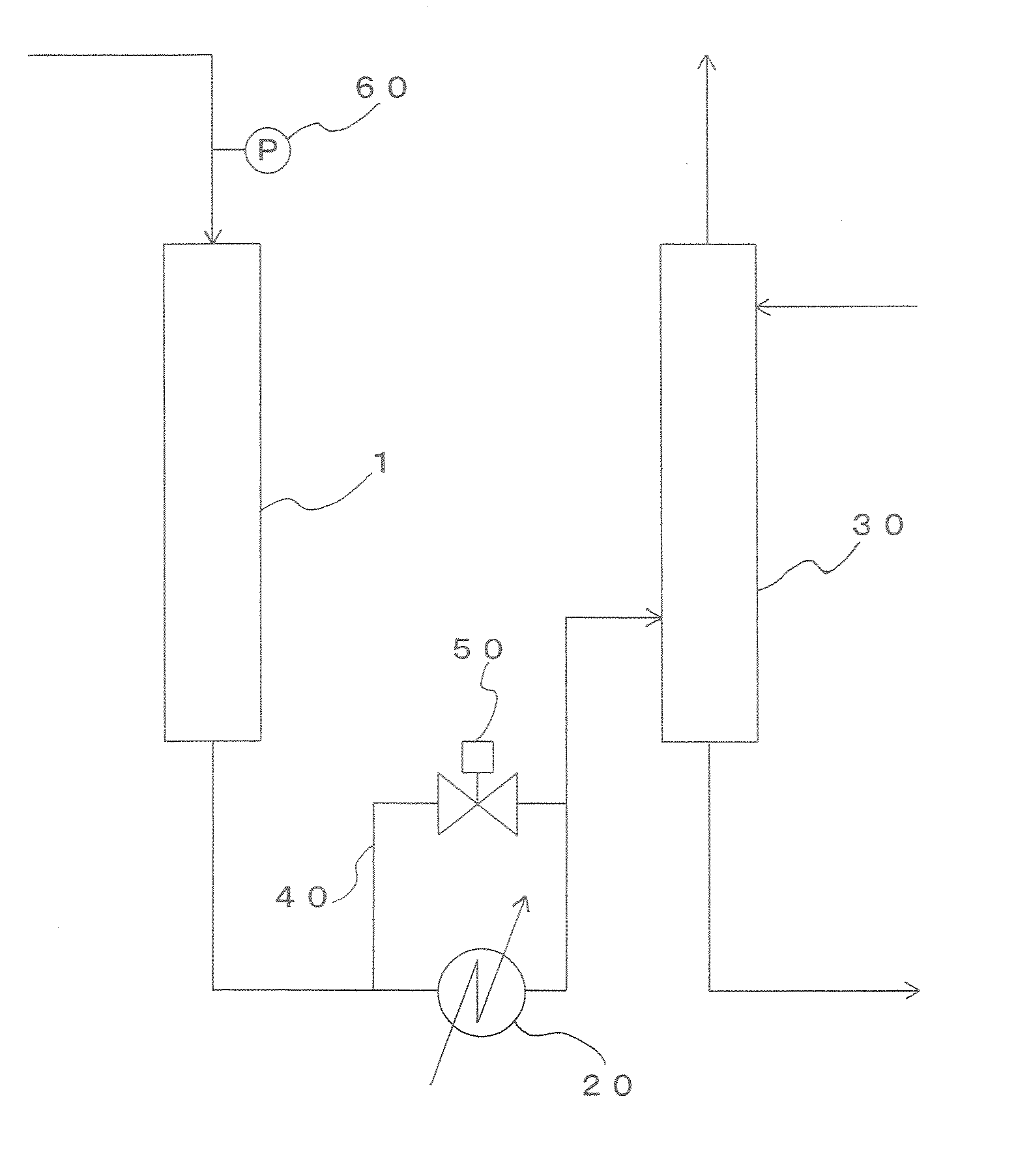

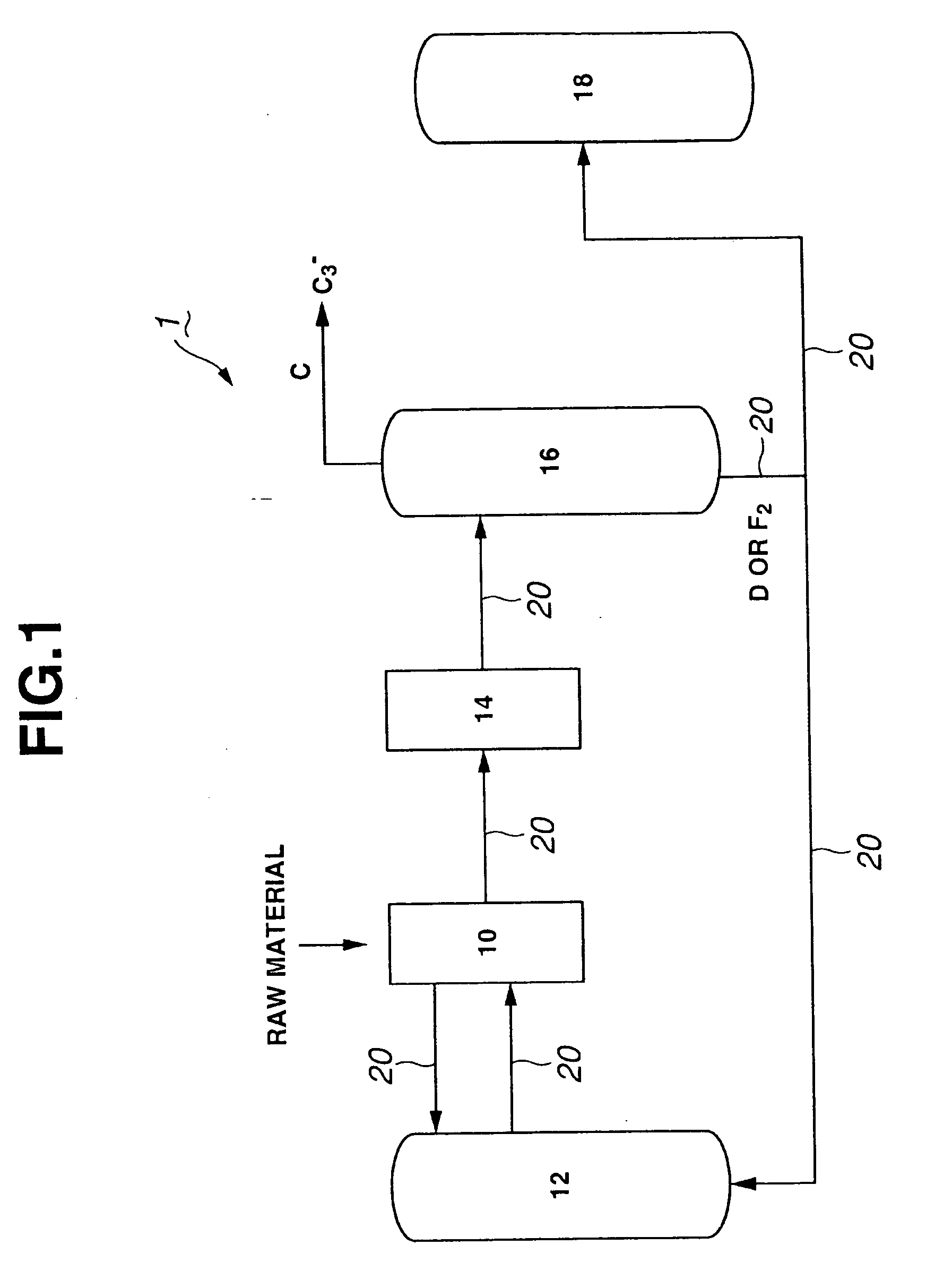

Apparatus For (Meth) Acrylic Acid Production And Process For Producing (Meth) Acrylic Acid

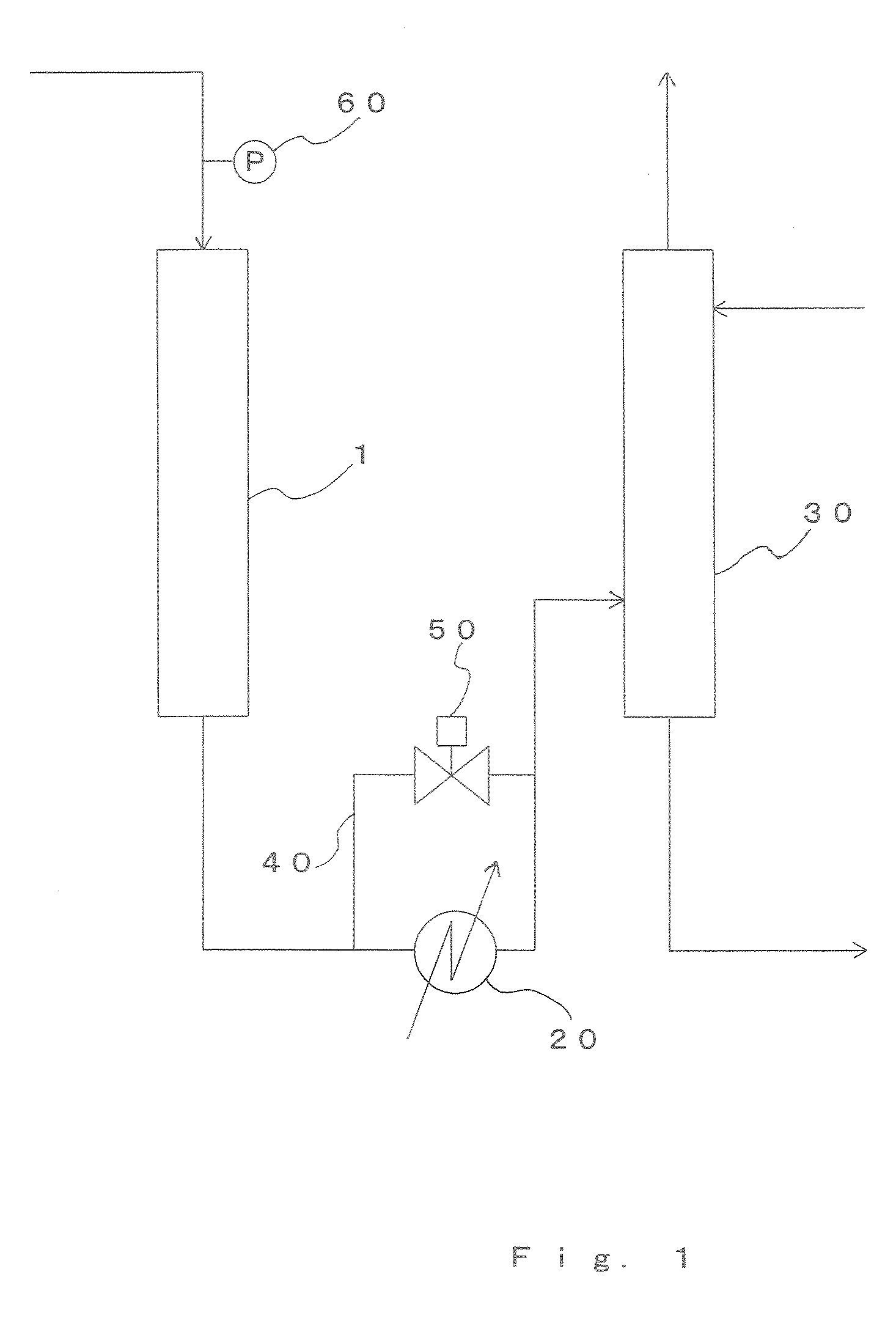

InactiveUS20080021238A1Stable continuous operationOrganic compound preparationOrganic chemistry methodsMeth-Gas phase

(Meth)acrylic acid is produced using a reactor (1) through a vapor-phase catalytic oxidation reaction of propane or the like in a raw material gas, and the obtained reaction gas is distributed to a heat exchanger (20) and an absorption tower (30). Heat energy is recovered from the reaction gas supplied to the heat exchanger (20), and the reaction gas cooled in the heat exchanger (20) and the reaction gas distributed to the absorption tower (30) are supplied to the absorption tower (30). (Meth) acrylic acid is recovered from the reaction gas in an absorbing liquid, to thereby produce (meth) acrylic acid. The reaction gas is distributed to the heat exchanger (20) and the absorption tower (30) according to a pressure of the raw material gas at an inlet of the reactor (1). The present invention allows heat recovery from the reaction gas and a stable and continuous operation even when the heat exchanger for heat recovery is clogged.

Owner:YAMAGISHI MASAHIKO +2

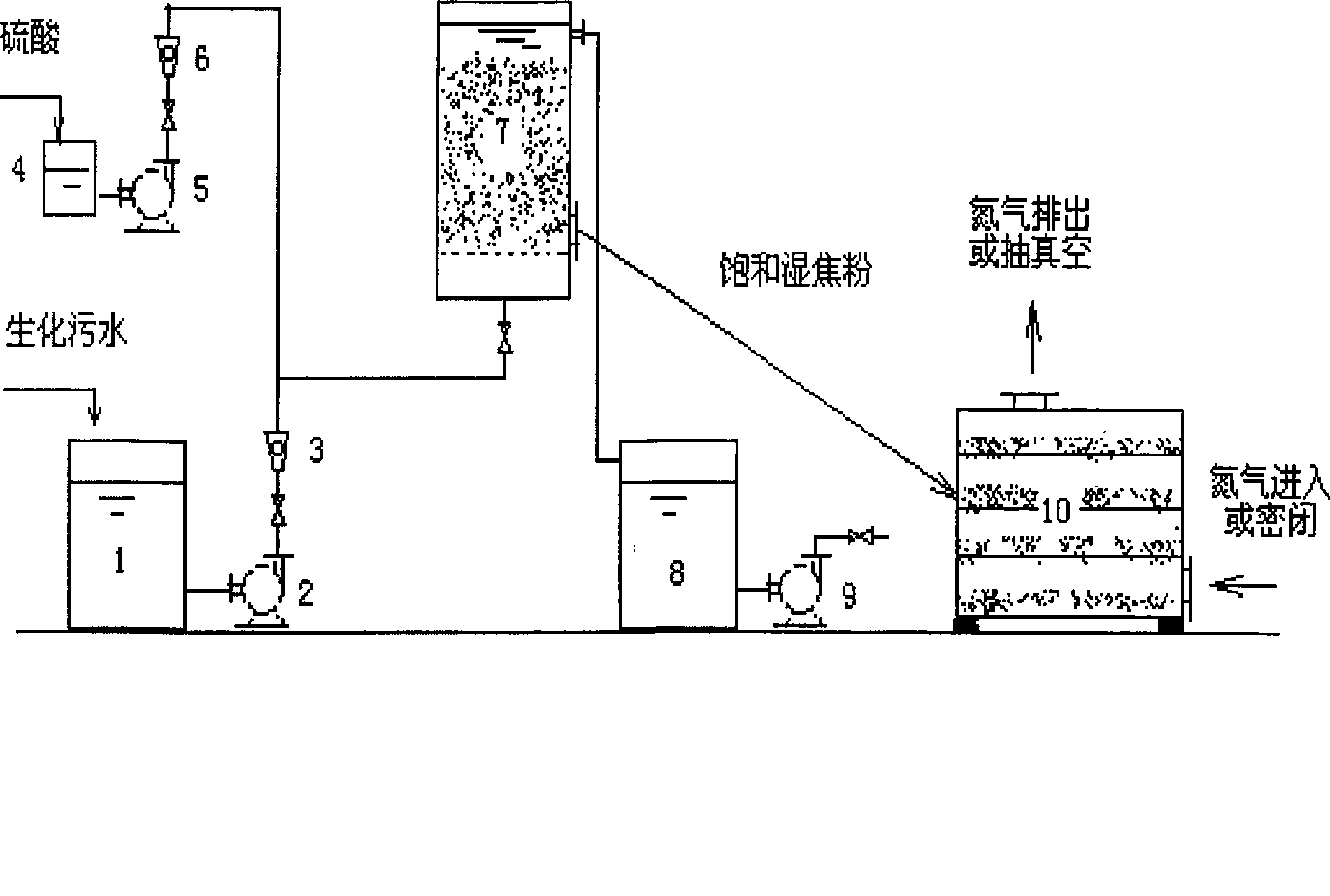

Method for treating coking wastewater by using industrial pulverized coke instead of active carbon

ActiveCN101439891ASimple processEasy to handleWater/sewage treatment by sorptionWater qualityCarbonization

The invention relates to a method for treating carbonization wastewater through industrial fine coke instead of activated carbon. The method comprises the following three steps: (A) carrying out the acidizing of the carbonization wastewater; (B) carrying out the absorption treatment of the wastewater in an absorption tower through the industrial fine coke; and (C) carrying out the regeneration and reclamation of the absorption saturated wet industrial fine coke through oxygen insulated high temperature heating or directly using the wet industrial fine coke to replace common fine coke and be doped into iron making sintering raw material without regeneration. Therein, during the step A, sulfuric acid or industrial waste sulfuric acid is used to regulate the pH value of the wastewater to 2.0 to 3.0; during the step B, fresh fine coke which is directly produced by a coke plant and has the grain size of 10 to 80 meshes is arranged in the industrial fine coke absorption tower or absorption trough; and during the step C, the absorption saturated wet industrial fine coke is regenerated and reclaimed through oxygen insulated high temperature heating at 300 to 450 DEG C or directly replaces common fine coke to be doped into iron making sintering raw material without regeneration. After the treatment, the removal rates of the chromaticity and COD value in the outputted water reach 65 percent and 85 percent respectively, thereby reaching the first level emission standard in Integrated Wastewater Discharge Standard (GB8978-96).

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

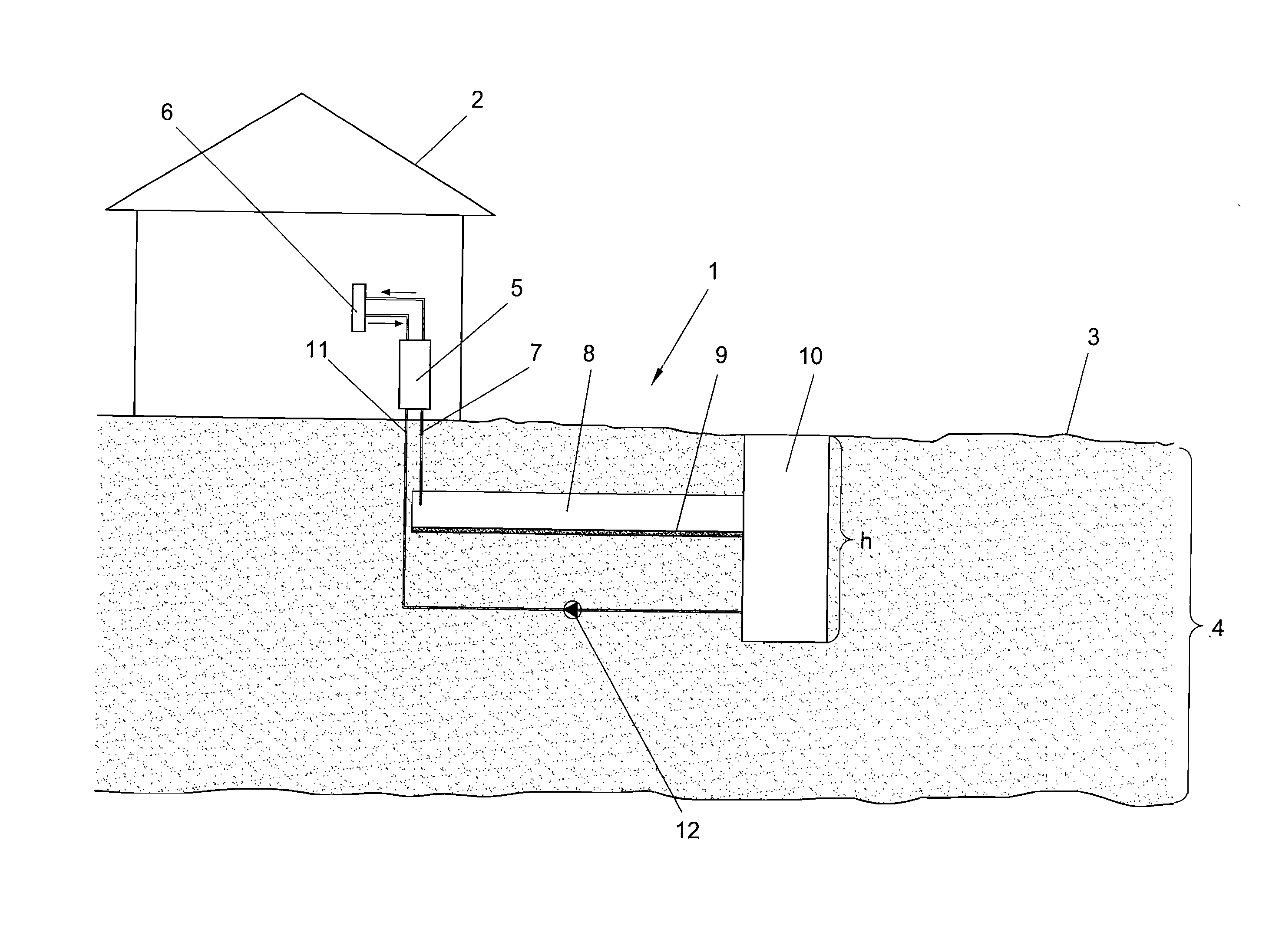

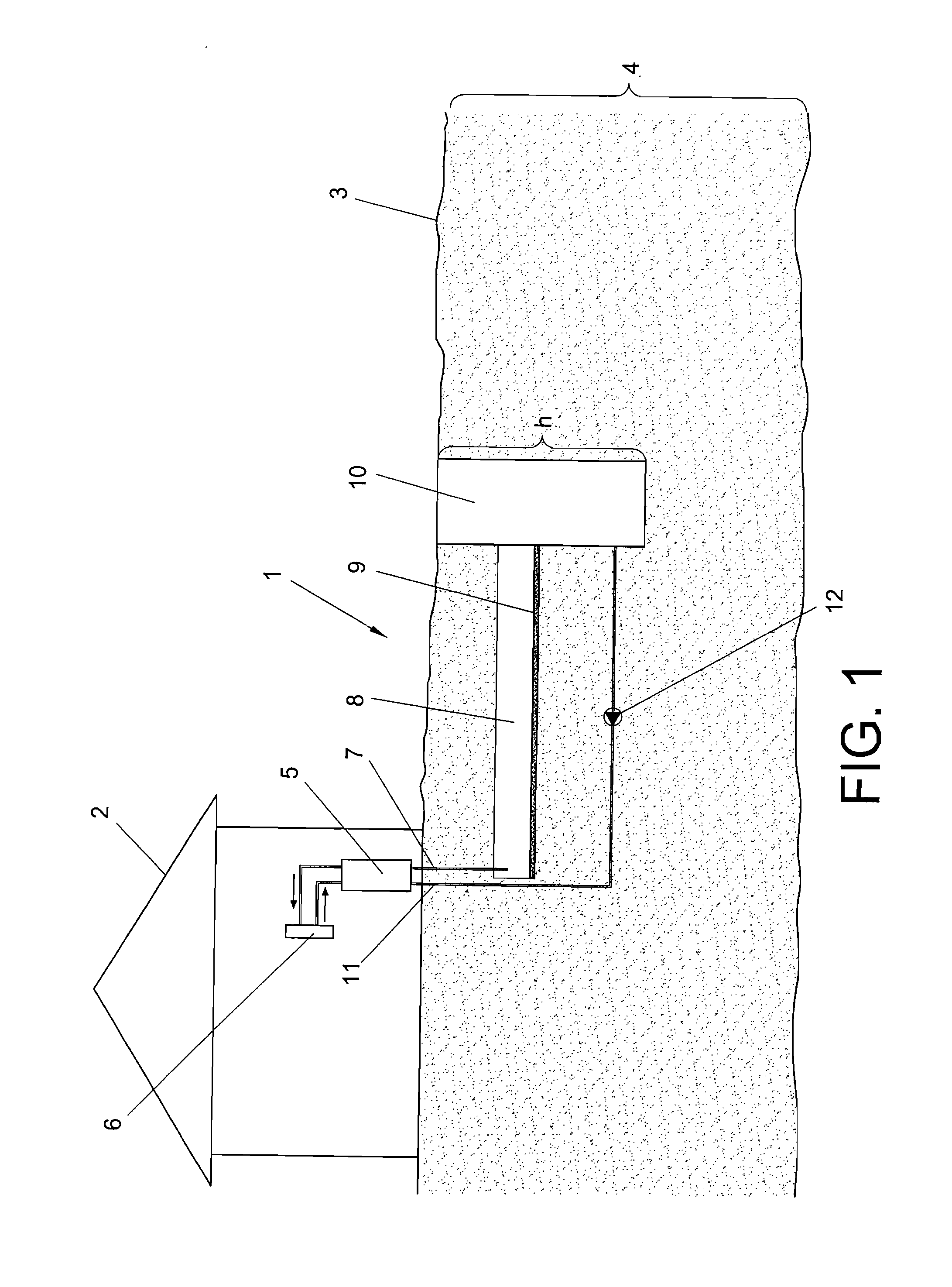

System for utilizing renewable geothermal energy

InactiveUS20100251710A1Reduce installation costsDrawback can be obviatedCentral heating with accumulated heatOther heat production devicesEngineeringEnergy exchange

In the system there is a geothermal facility (1) including an outer circuit of heat-carrying water or fluid which exchanges heat energy with a terrain (3) to be applied in at least one dwelling unit (2) by means of its connection to a heat pump (5) which in turn connects to an inner distribution equipment or circuit (6). The referred outer circuit is placed buried in a renewable geothermal zone (4) of the terrain (3) and is made up of a closed / semiclosed circuit which connects to the heat pump (5) via a pulse pipe (7) and a return pipe (11); being arranged in that outer circuit a special channel (8) wherein the energy exchange is performed, so that the heat-carrying water or fluid is thermally regenerated as it passes through this channel (8) to be used again in the system.

Owner:TECNICA & INSTALACIONES DE FLUIDOS

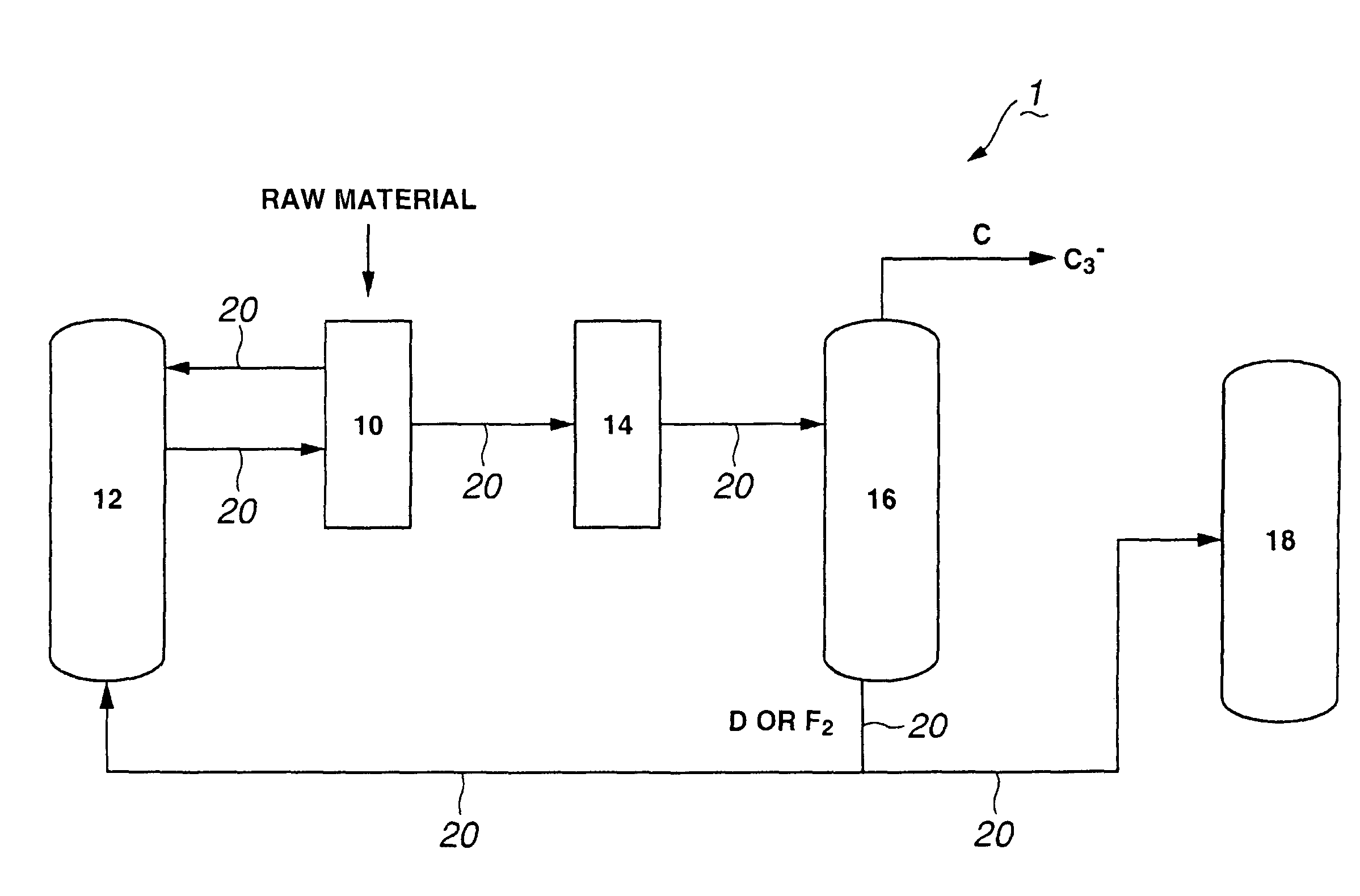

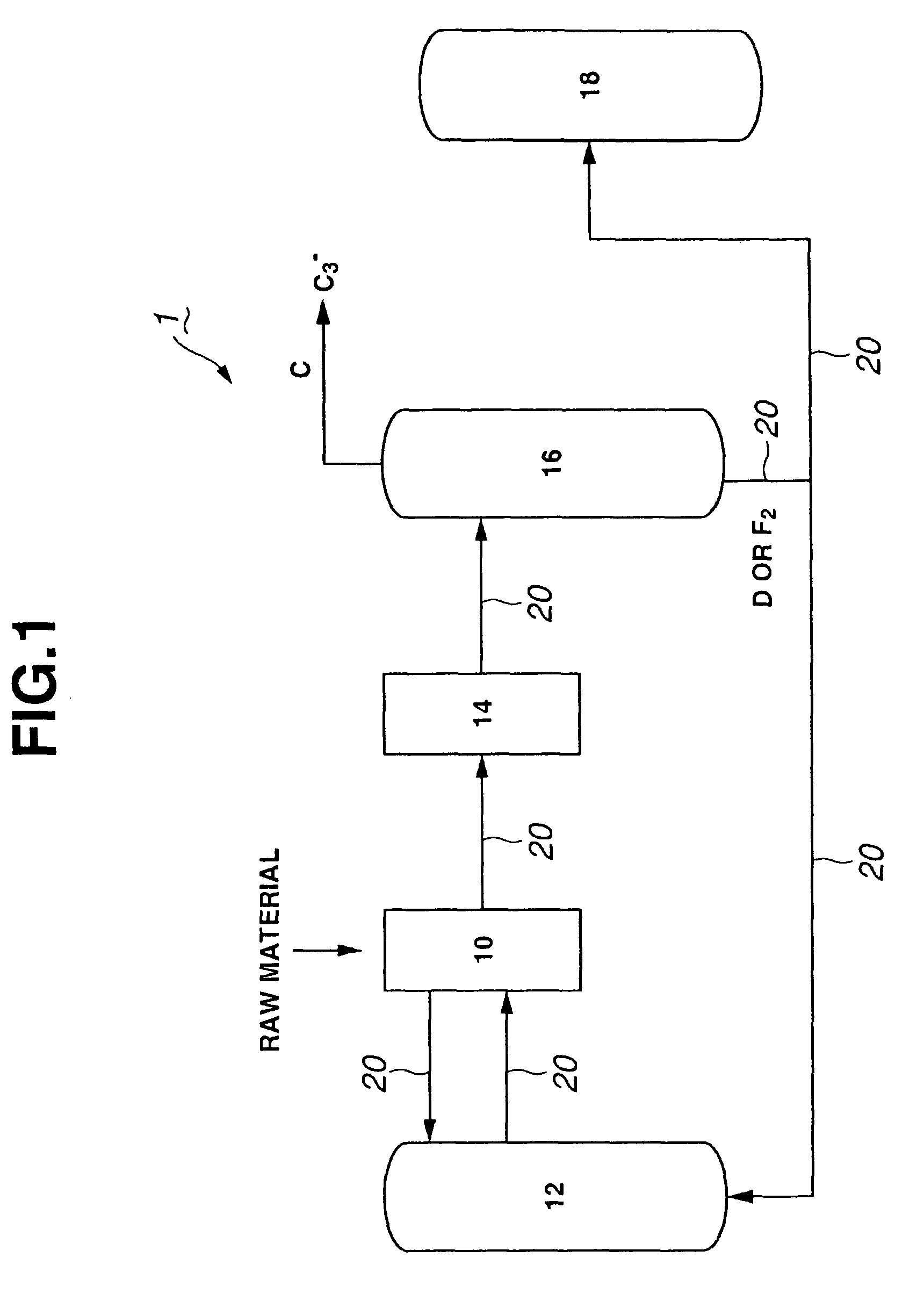

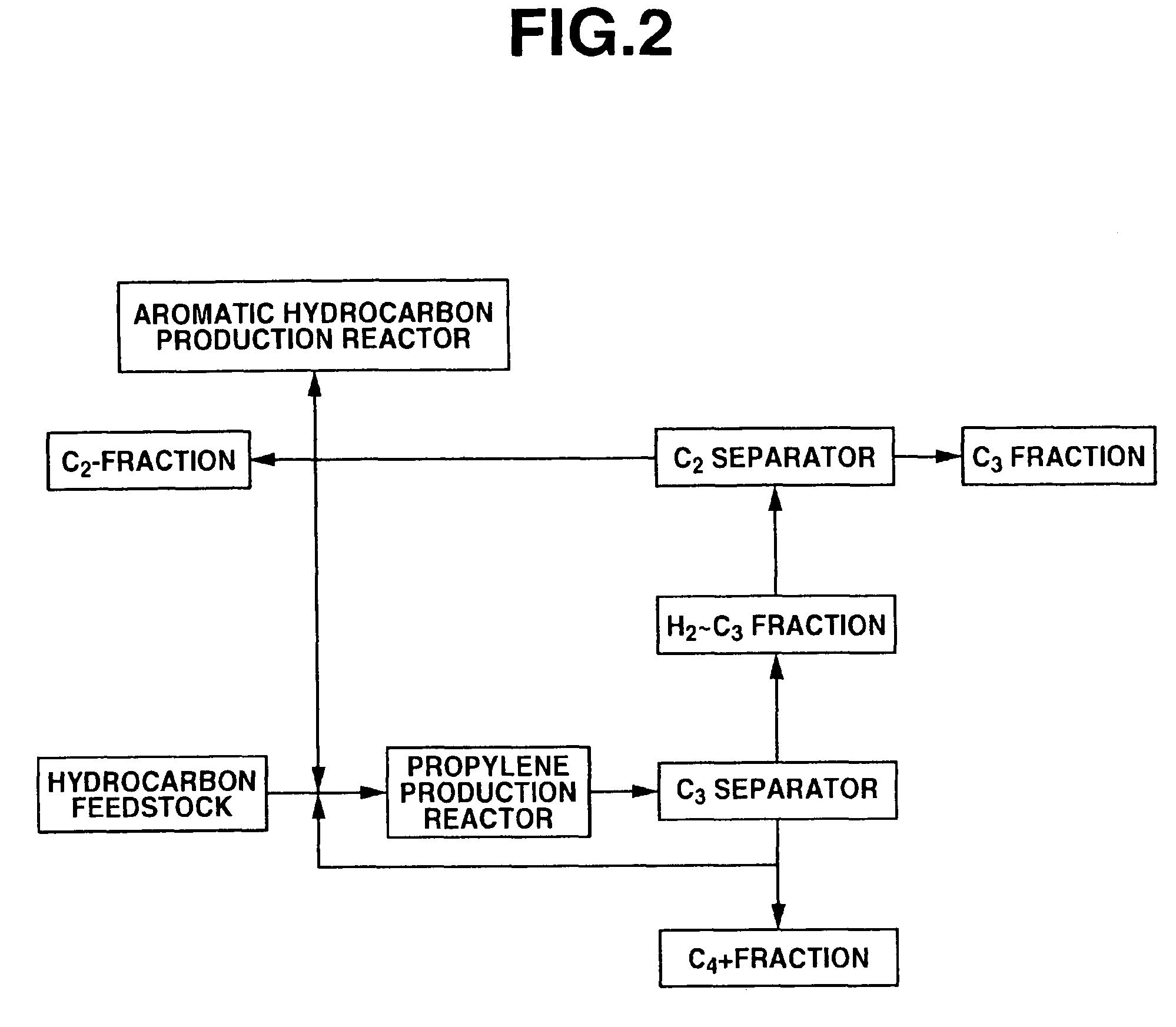

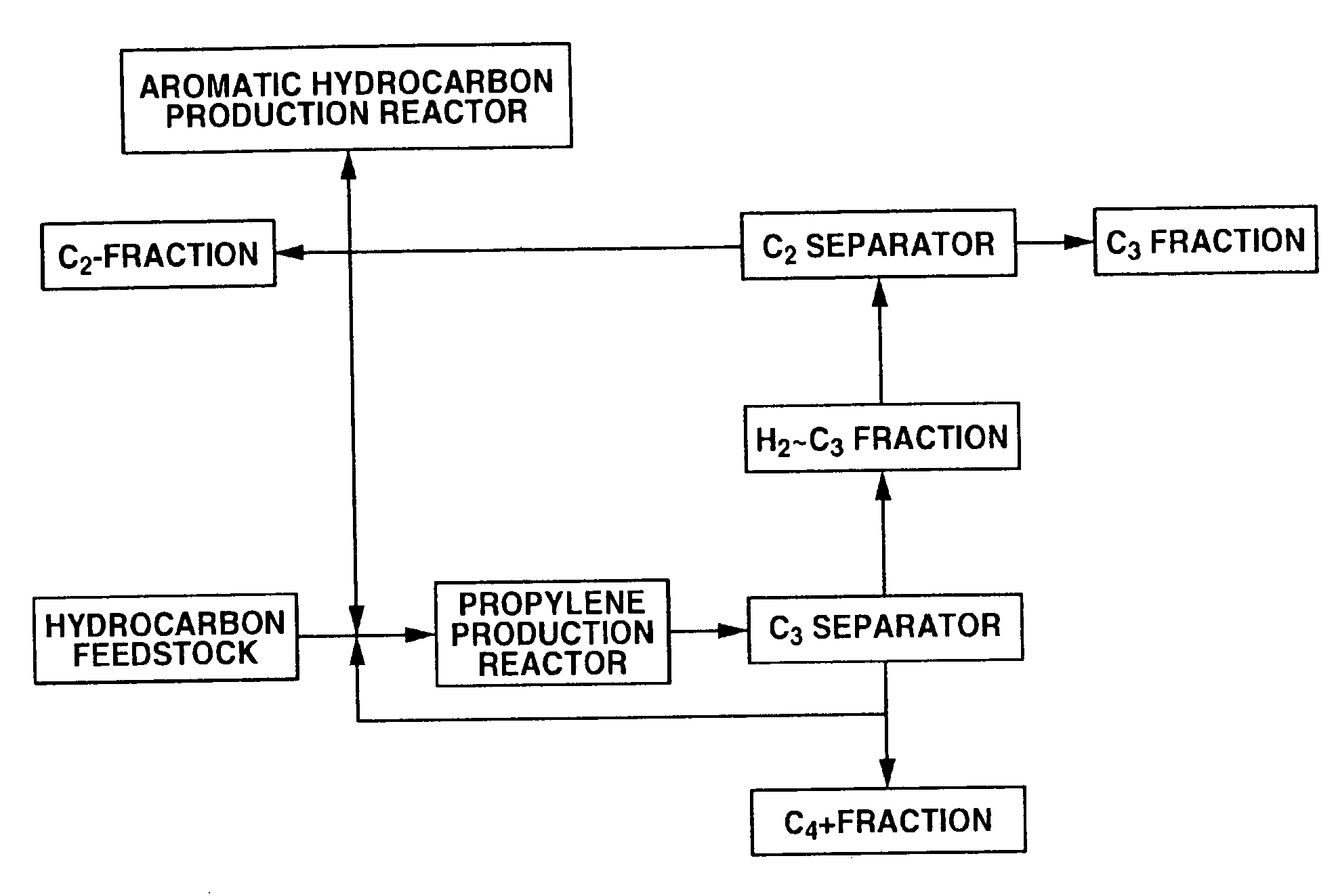

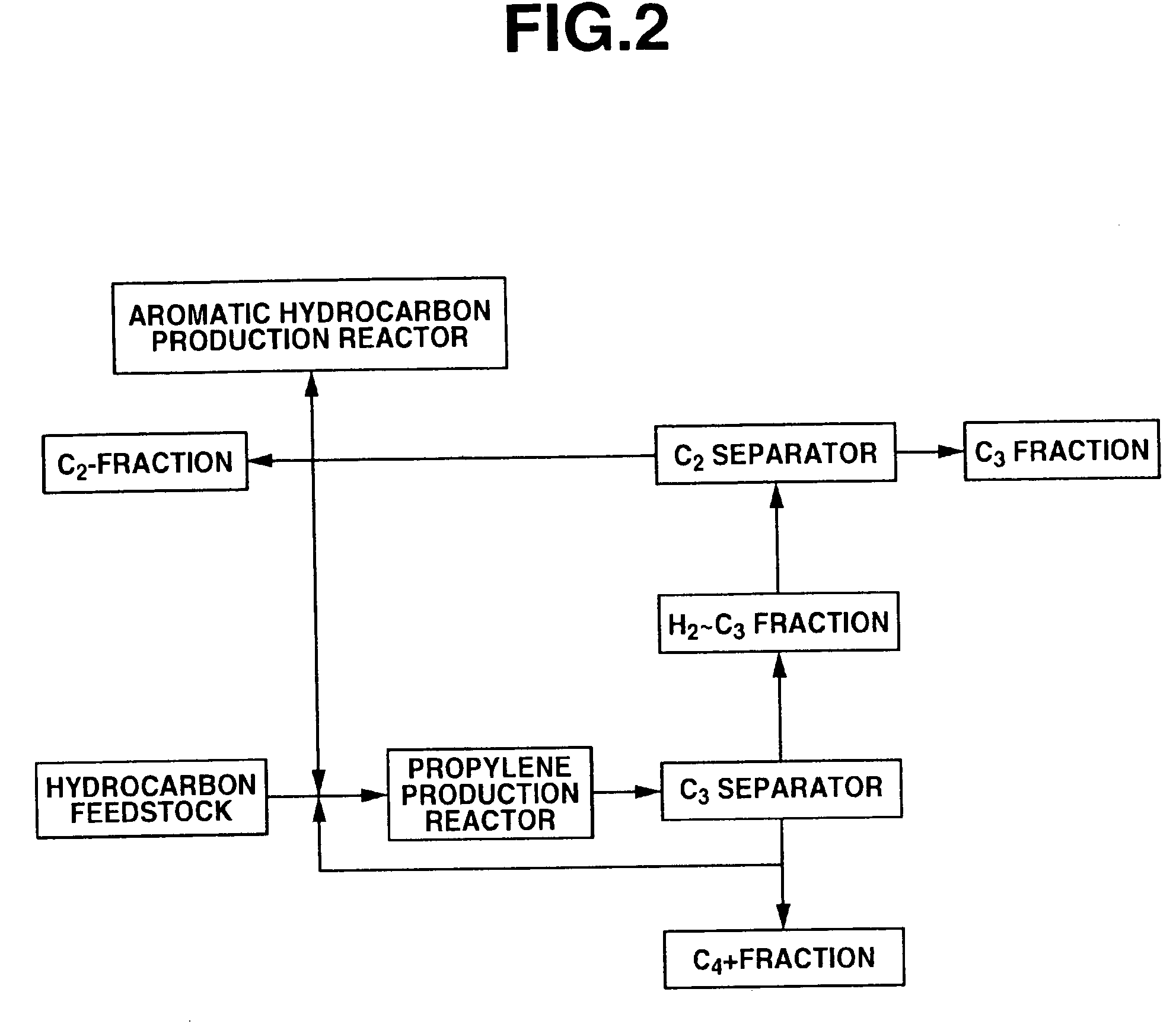

Process for producing propylene and aromatic hydrocarbons, and producing apparatus therefor

ActiveUS8034987B2Efficient and stable productionRatio can be easilyCatalytic crackingOrganic chemistry methodsPore diameterAromatic hydrocarbon

It is an object of the present invention to provide an improved process whereby the yield structure of the components can be varied by a simple method, and the products can be produced stably and efficiently in a process for producing propylene and aromatic hydrocarbons from a hydrocarbon feedstock containing C4-12 olefins using a medium pore diameter zeolite-containing catalyst. A process for producing is disclosed which comprises a propylene production step wherein a specific zeolite catalyst is used to remove a C4+ hydrocarbon component from a reaction mixture, and part of the hydrocarbon component is recycled as necessary without modification, and an aromatic hydrocarbon production step wherein all or a part of the C4+ hydrocarbon component is used as the raw material.

Owner:ASAHI KASEI KK

Process for Producing Propylene and Aromatic Hydrocarbons, and Producing Apparatus Therefor

ActiveUS20100022810A1Efficient and stable productionRatio can be easilyCatalytic crackingOrganic chemistry methodsPore diameterAromatic hydrocarbon

It is an object of the present invention to provide an improved process whereby the yield structure of the components can be varied by a simple method, and the products can be produced stably and efficiently in a process for producing propylene and aromatic hydrocarbons from a hydrocarbon feedstock containing C4-12 olefins using a medium pore diameter zeolite-containing catalyst. A process for producing is disclosed which comprises a propylene production step wherein a specific zeolite catalyst is used to remove a C4+ hydrocarbon component from a reaction mixture, and part of the hydrocarbon component is recycled as necessary without modification, and an aromatic hydrocarbon production step wherein all or a part of the C4+ hydrocarbon component is used as the raw material.

Owner:ASAHI KASEI KK

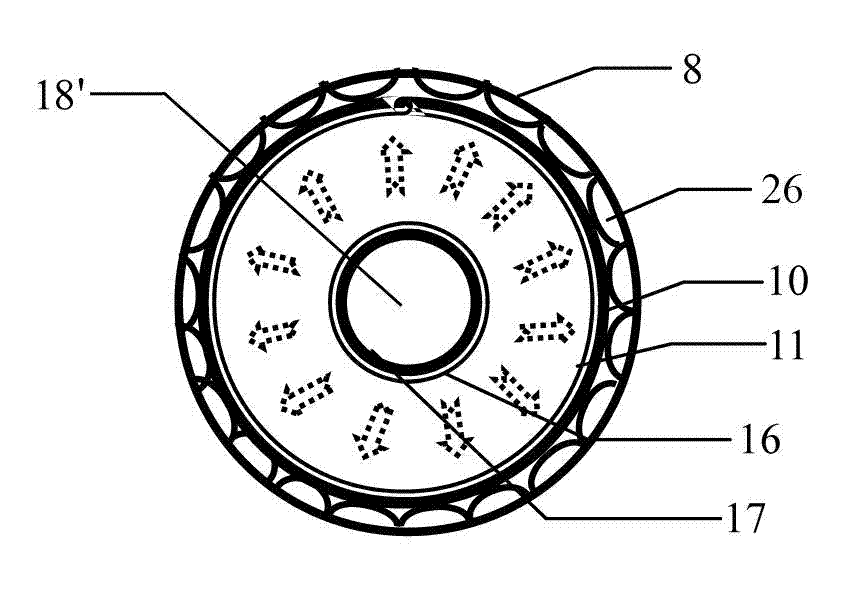

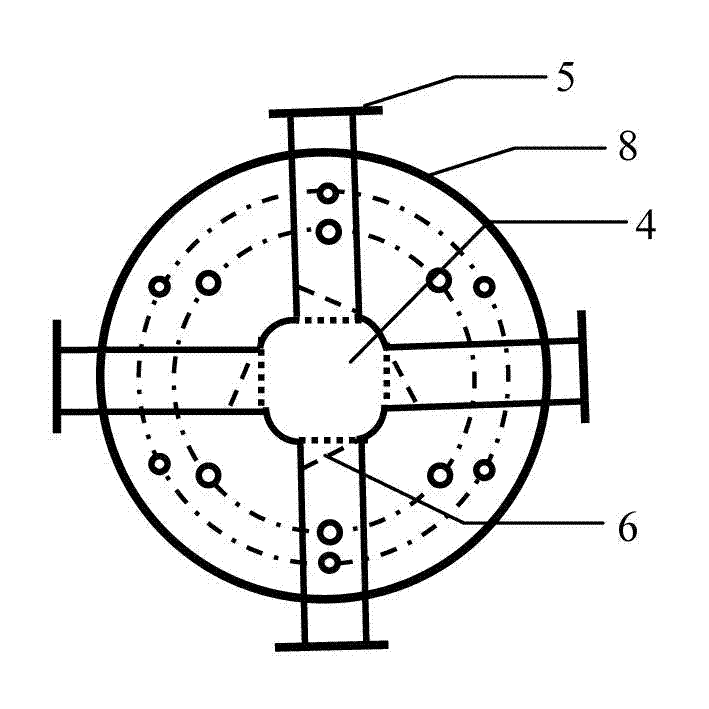

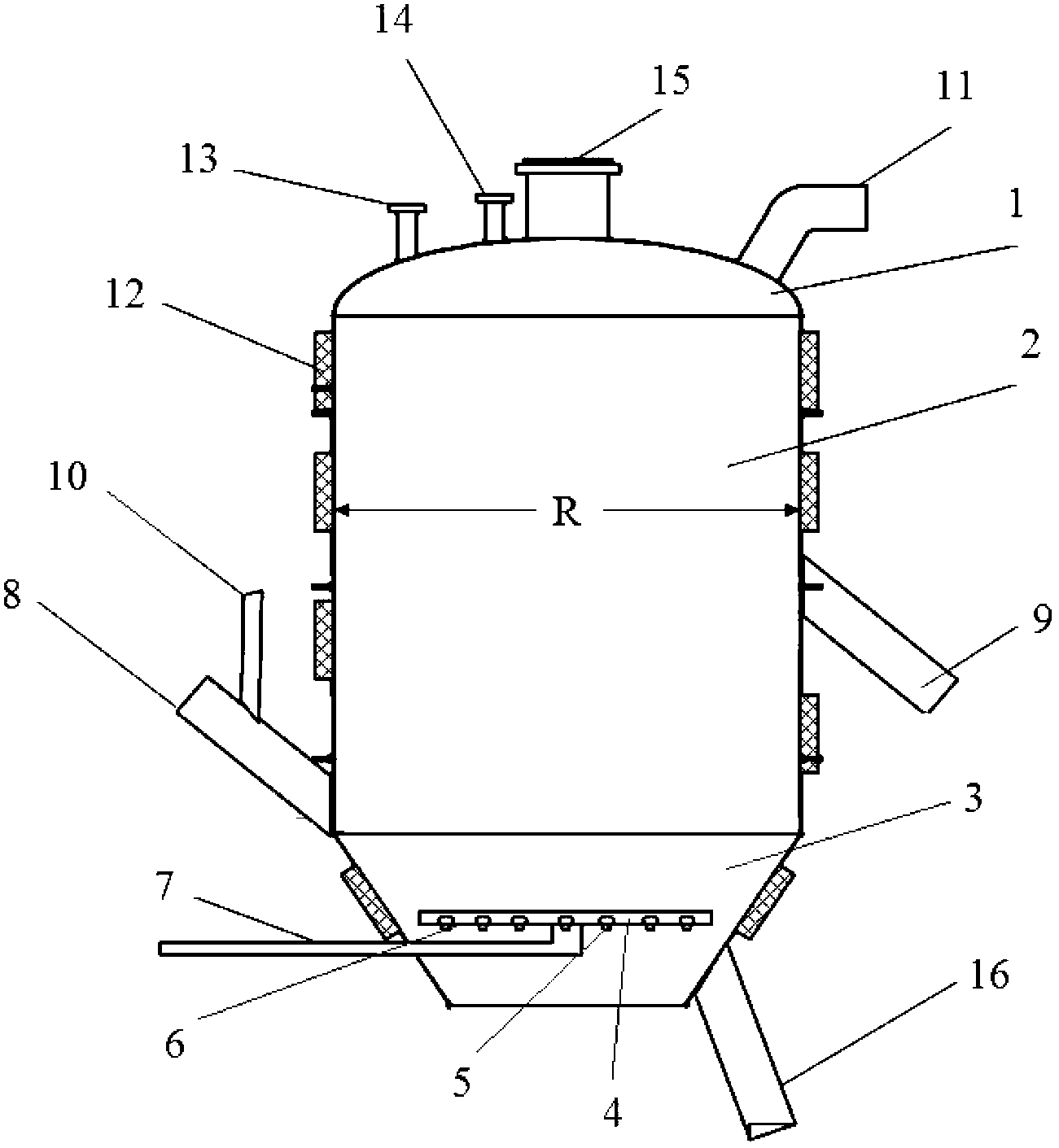

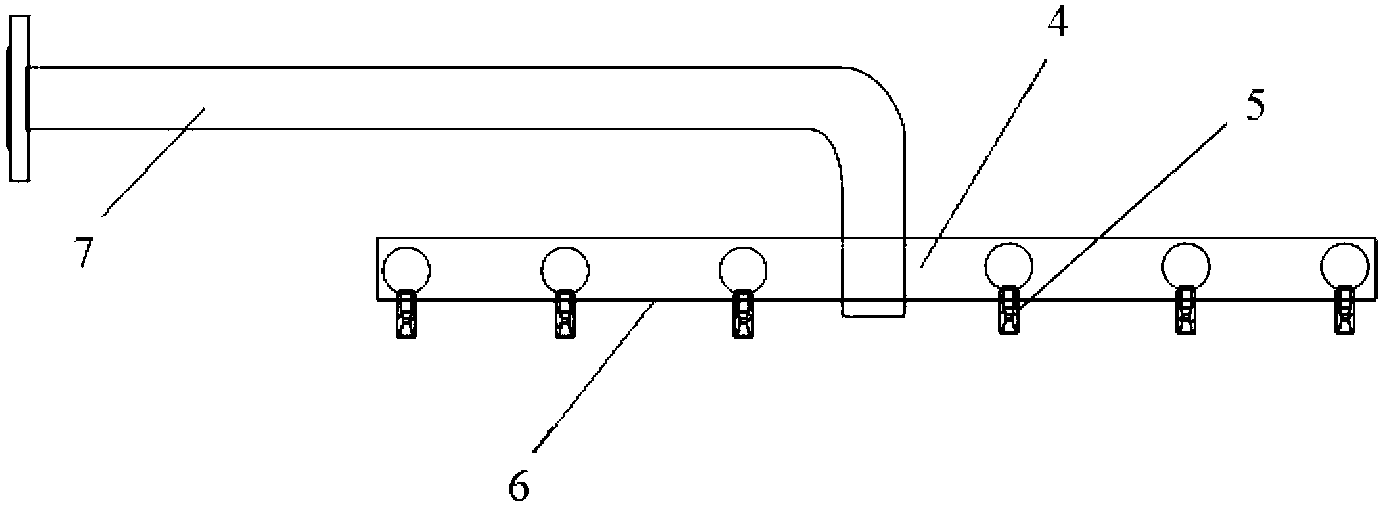

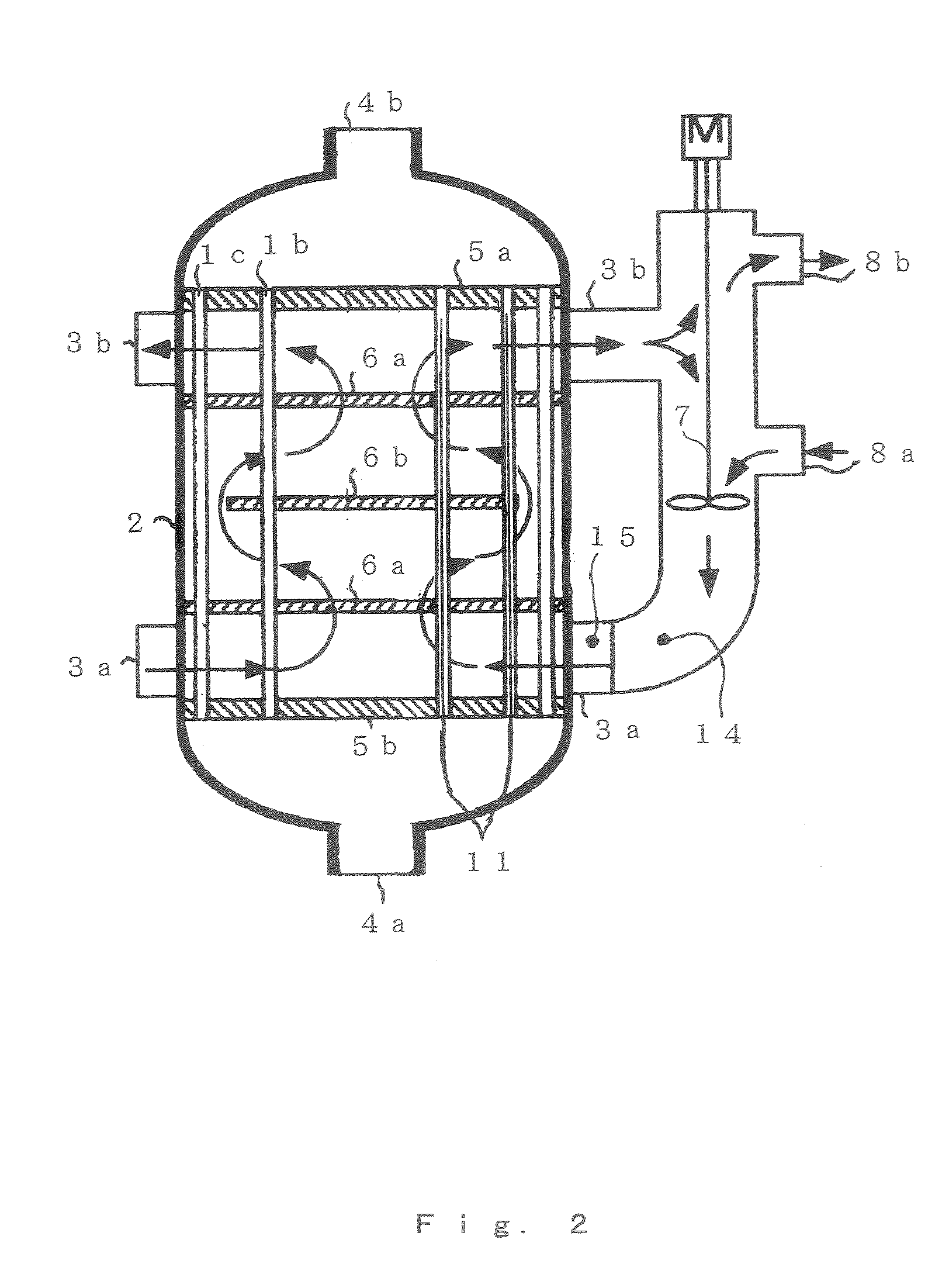

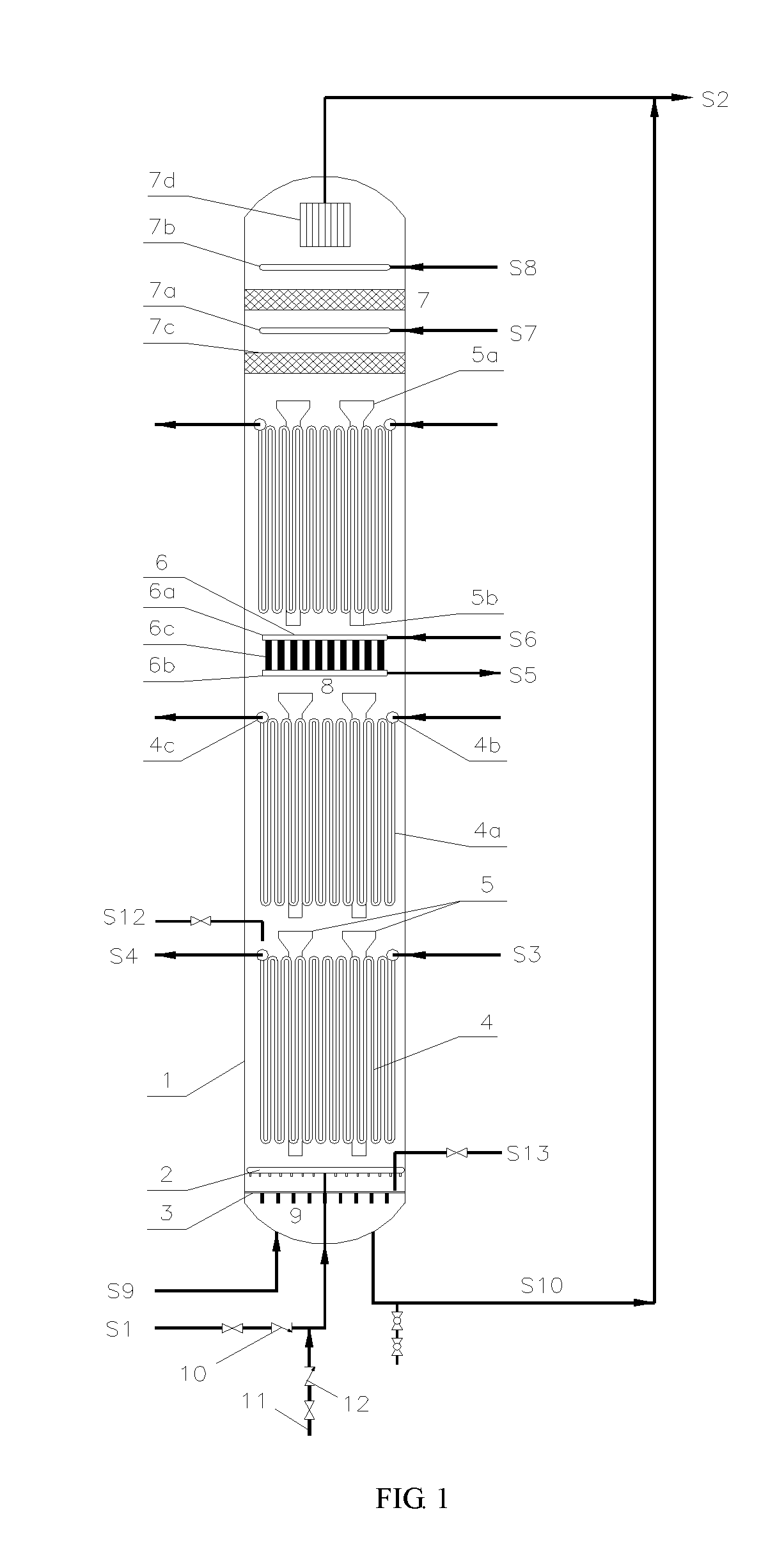

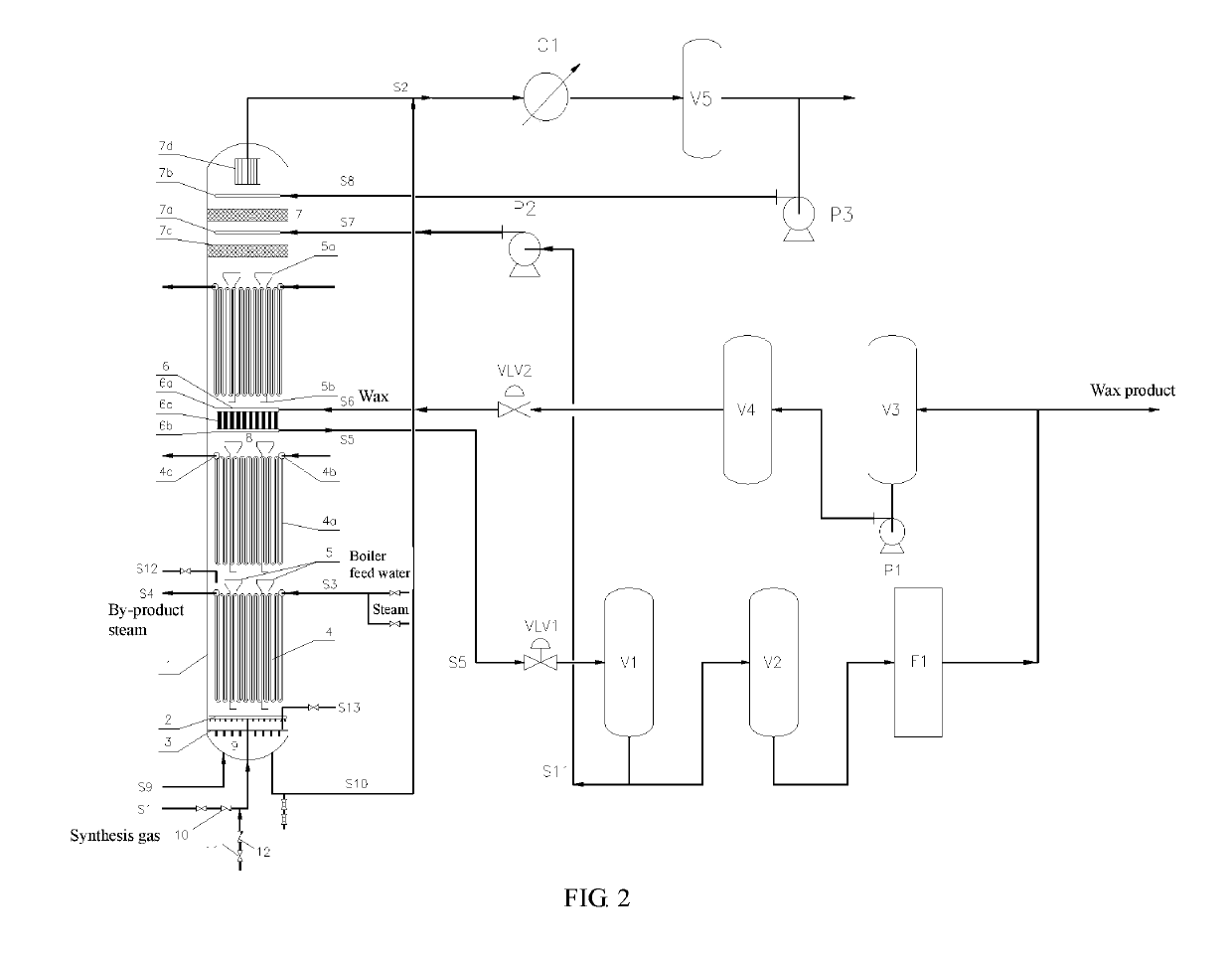

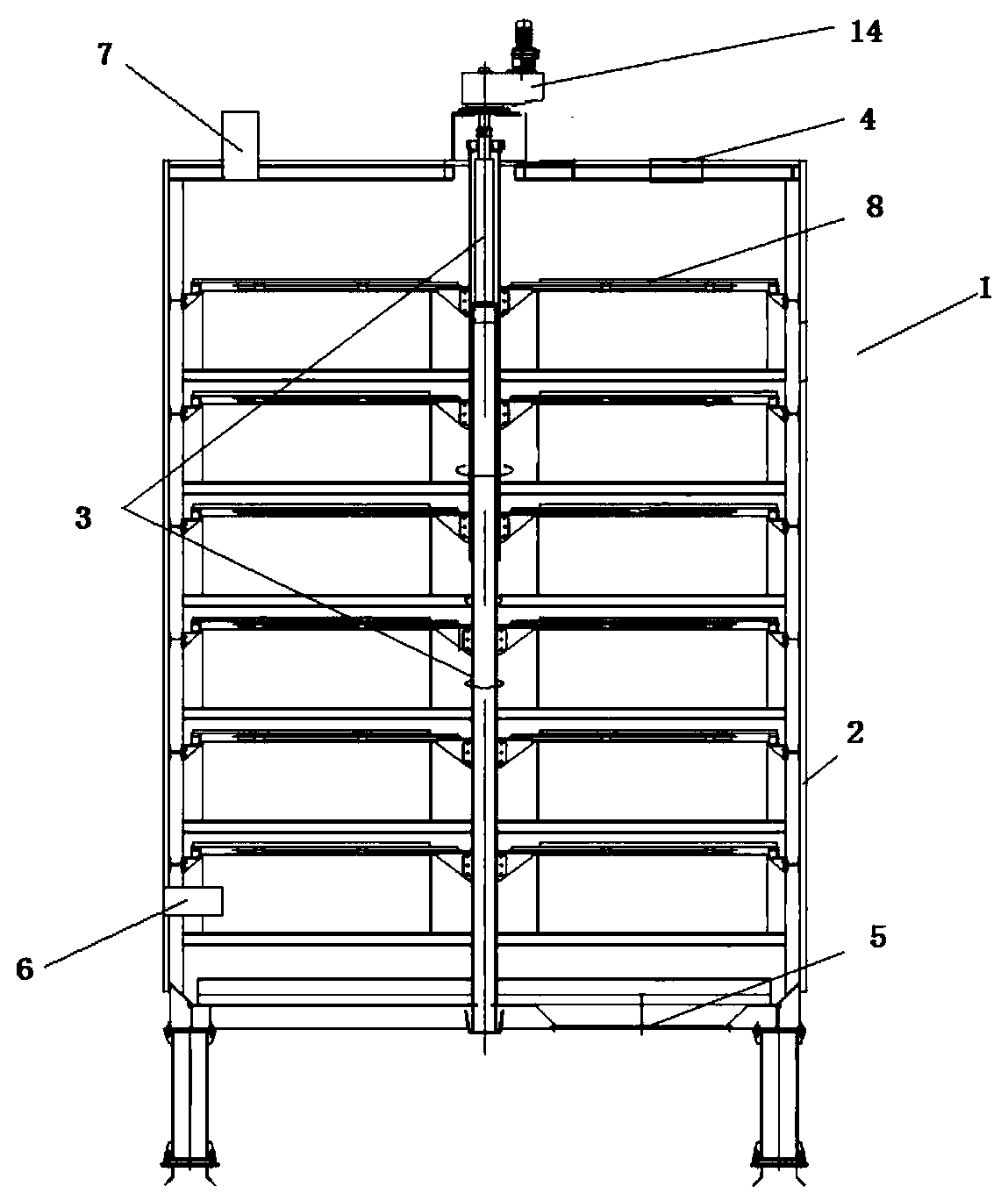

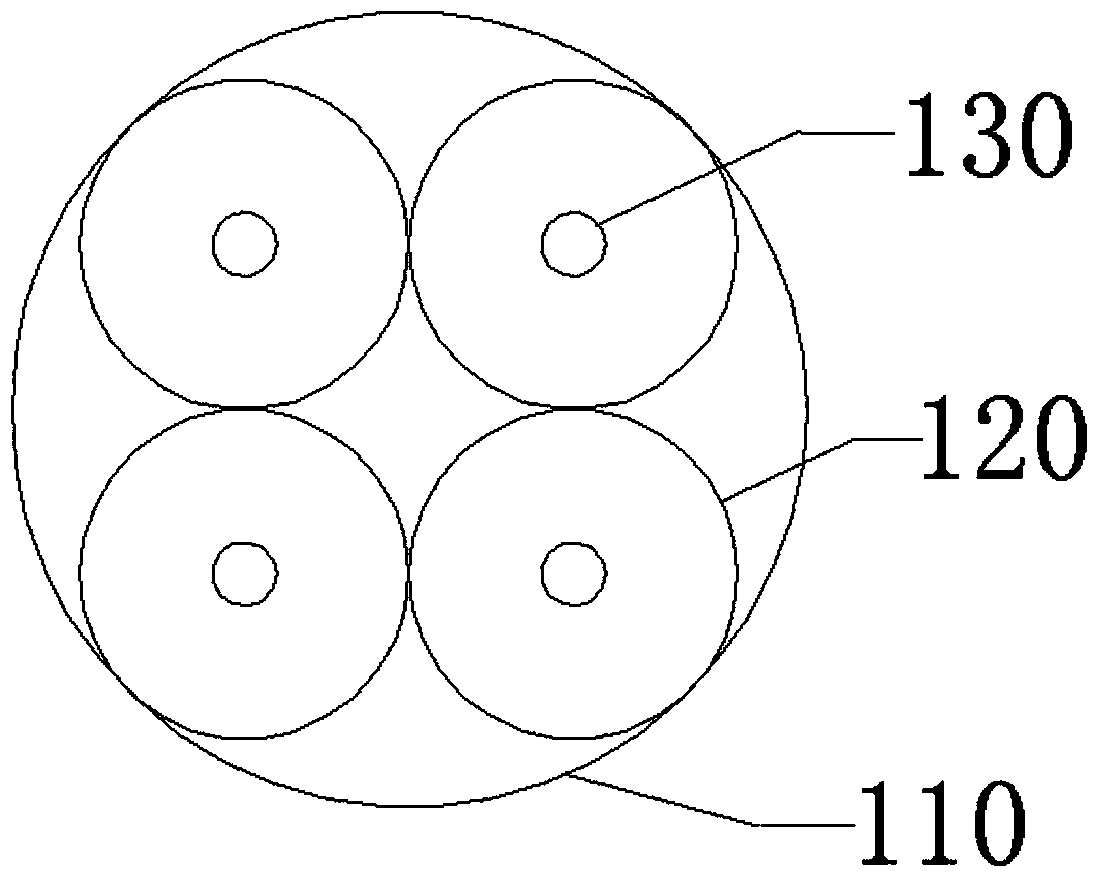

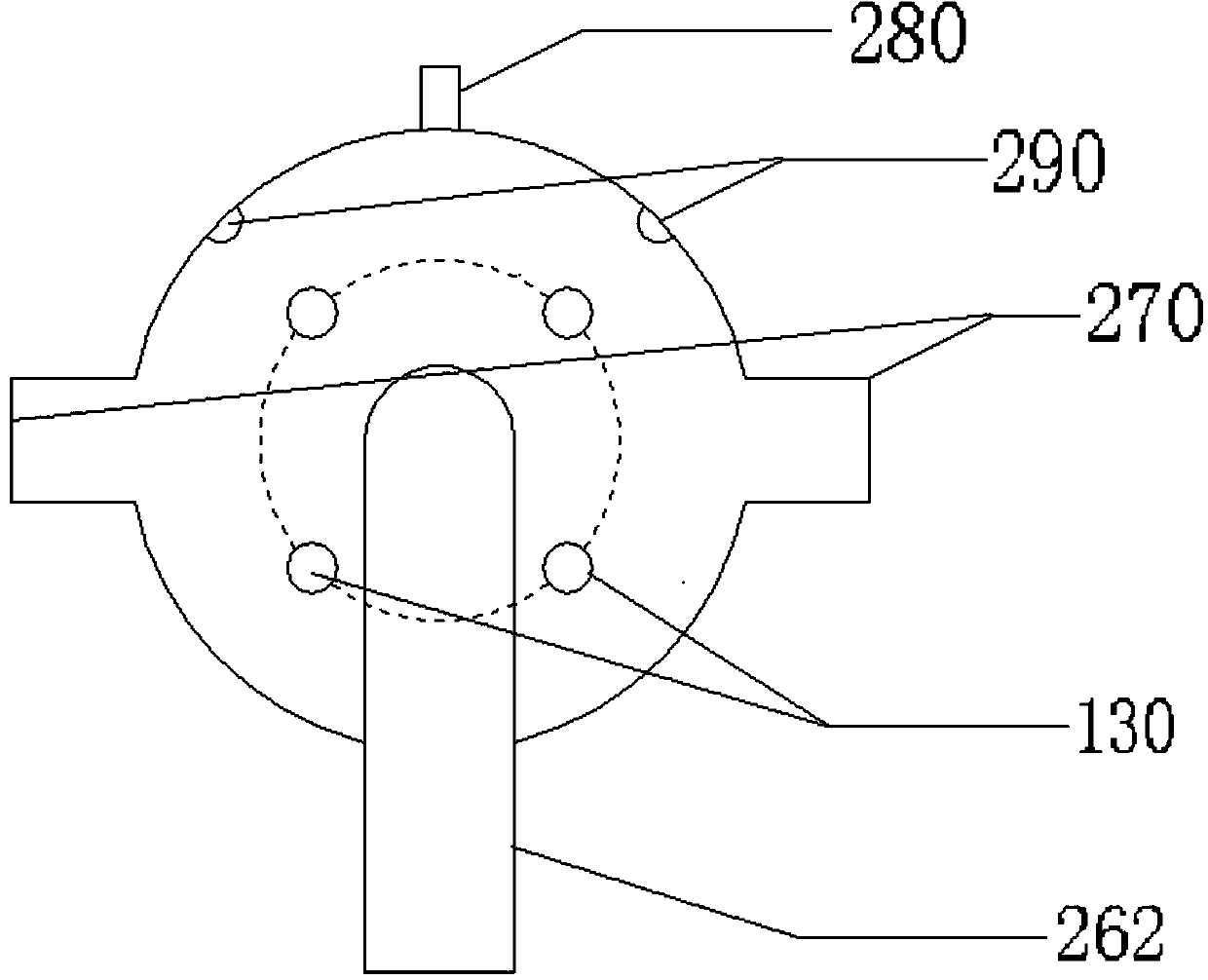

Gas-liquid-solid three-phase slurry bed industrial reactor capable of achieving continuous operation

ActiveUS10363535B1Stable and continuous industrial operationStable continuous operationLiquid hydrocarbon mixture productionChemical/physical processesConcentration gradientSlurry

A gas-liquid-solid three-phase slurry bed industrial reactor capable of achieving continuous operation comprises an inlet gas distribution component composed of a false bottom and inlet gas distribution tubes, one or more layers of heat exchange tube components used for heating / cooling the bed, one or more layers of liquid-solid separator components capable of being cleaned automatically, an outlet gas-liquid-solid entrainment separation component located in the upper portion of the interior of the reactor and used for removing liquid foam and solid entrainments, a plurality of layers of solid concentration uniform distribution devices used for reducing the catalyst concentration gradient and the inlet-outlet temperature difference of the reactor, a flow guiding device located on a component support beam and used for preventing catalyst accumulation, and auxiliary systems including a filter-backflush system and a washing system. Compared with the prior art, the reactor is low in energy consumption and solves the problems of blockage, backflow and dead zones, the temperature and liquid level are well controlled, catalysts can be easily added and discharged online, and stable and continuous operation of the reactor is achieved. The reactor is suitable for being applied to the Fischer-Tropsch synthesis process on an industrial scale.

Owner:SHANGHAI YANKUANG ENERGY R&D

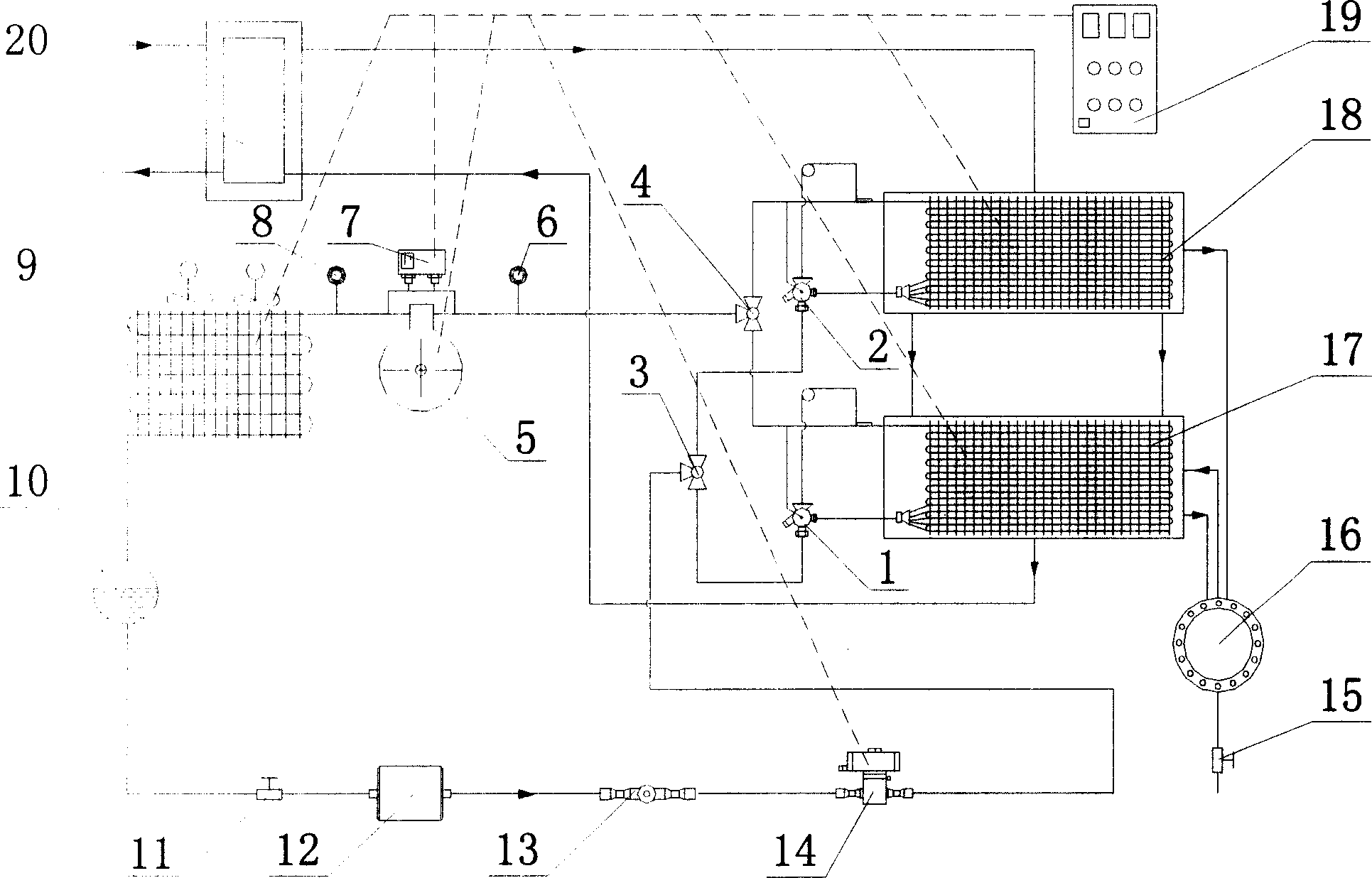

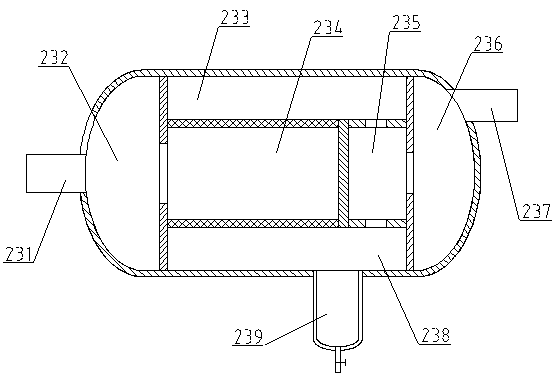

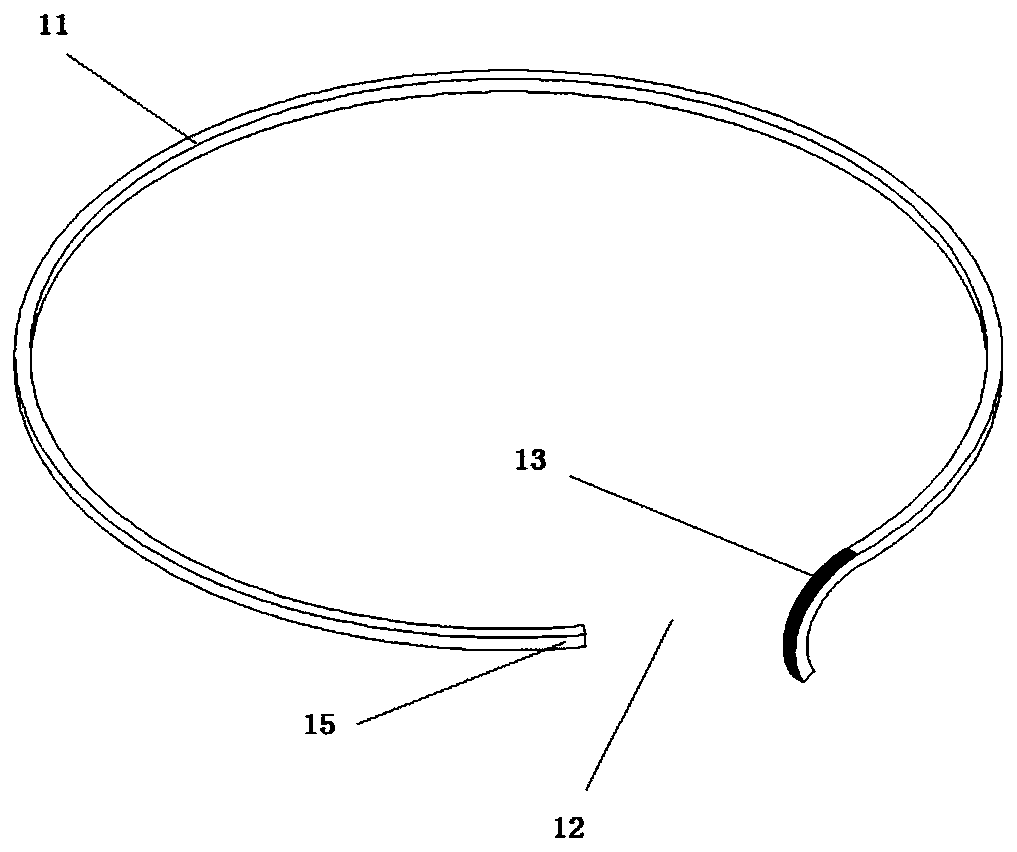

Environmental protection refrigerating hydrogen drying unit

InactiveCN1669620AIncrease heat transfer areaIncrease contact timeSolidificationLiquefactionThermal expansionEngineering

The invention relates to a hydrogen drying device through refrigerating which can protect the environment. Said device primarily comprises a deep cooling thermal expansion valve 1, an original cooling thermal expansion valve 2, a supporting triple valve 3, a air venting triple valve 4, a refrigerant compressor 5, a low pressure gage 6, a pressure controller 7, a high pressure gage 8, an air condenser 9, a liquid tanker 10, a cut-off valve 11, a drying filter 12, a liquid visible glass 13, a magnetic valve 14, a draw-off valve 15, a tank 16, a deep cooling desiccating dryer 17, an original cooling desiccating dryer 18, electrical controller 19, circle heat exchanger 20. Said invention can eliminate the water in the hydrogen effectively, and the drying degree of the hydrogen can reach to the dew-point below the required.

Owner:SOUTH CHINA UNIV OF TECH

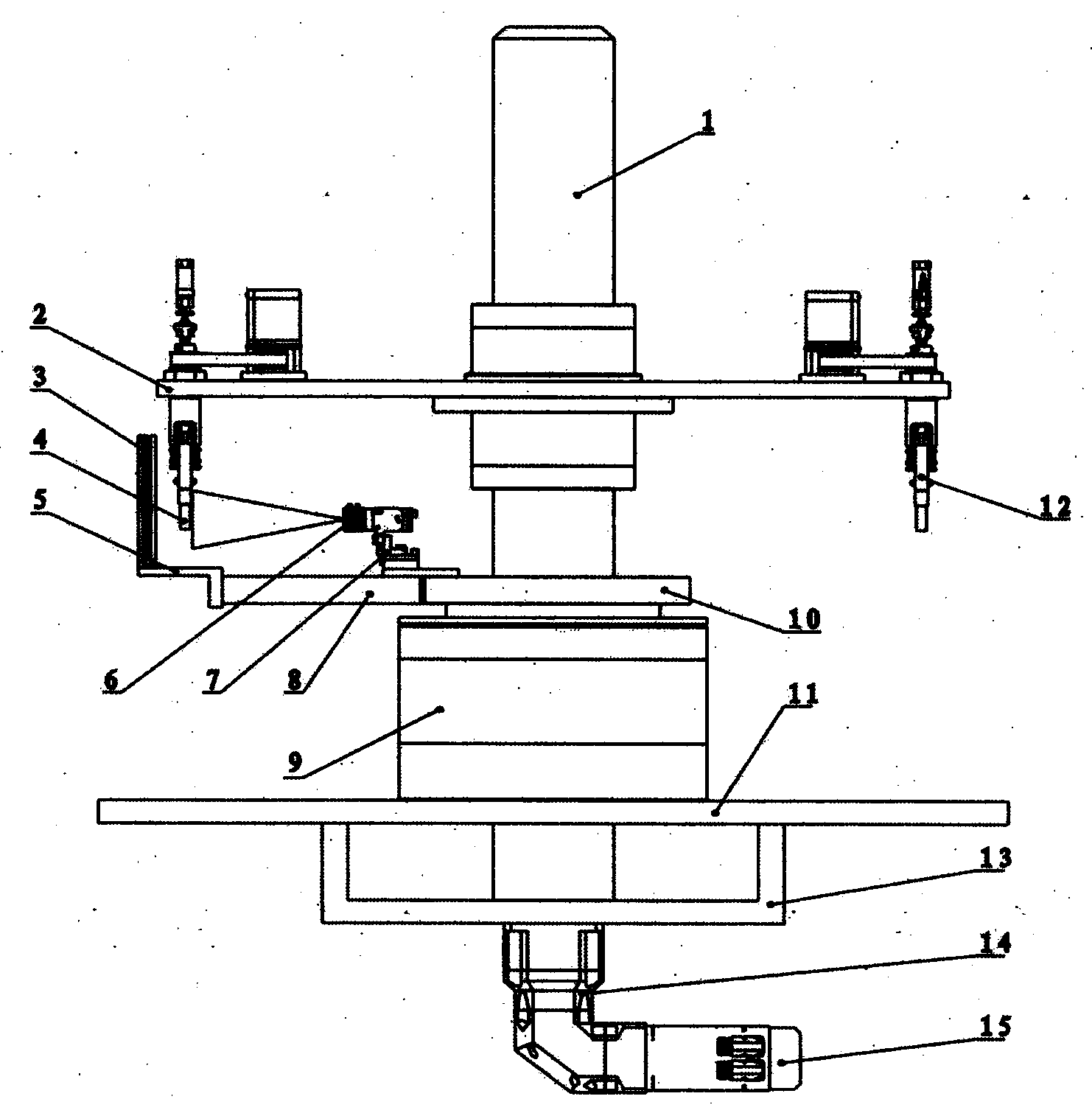

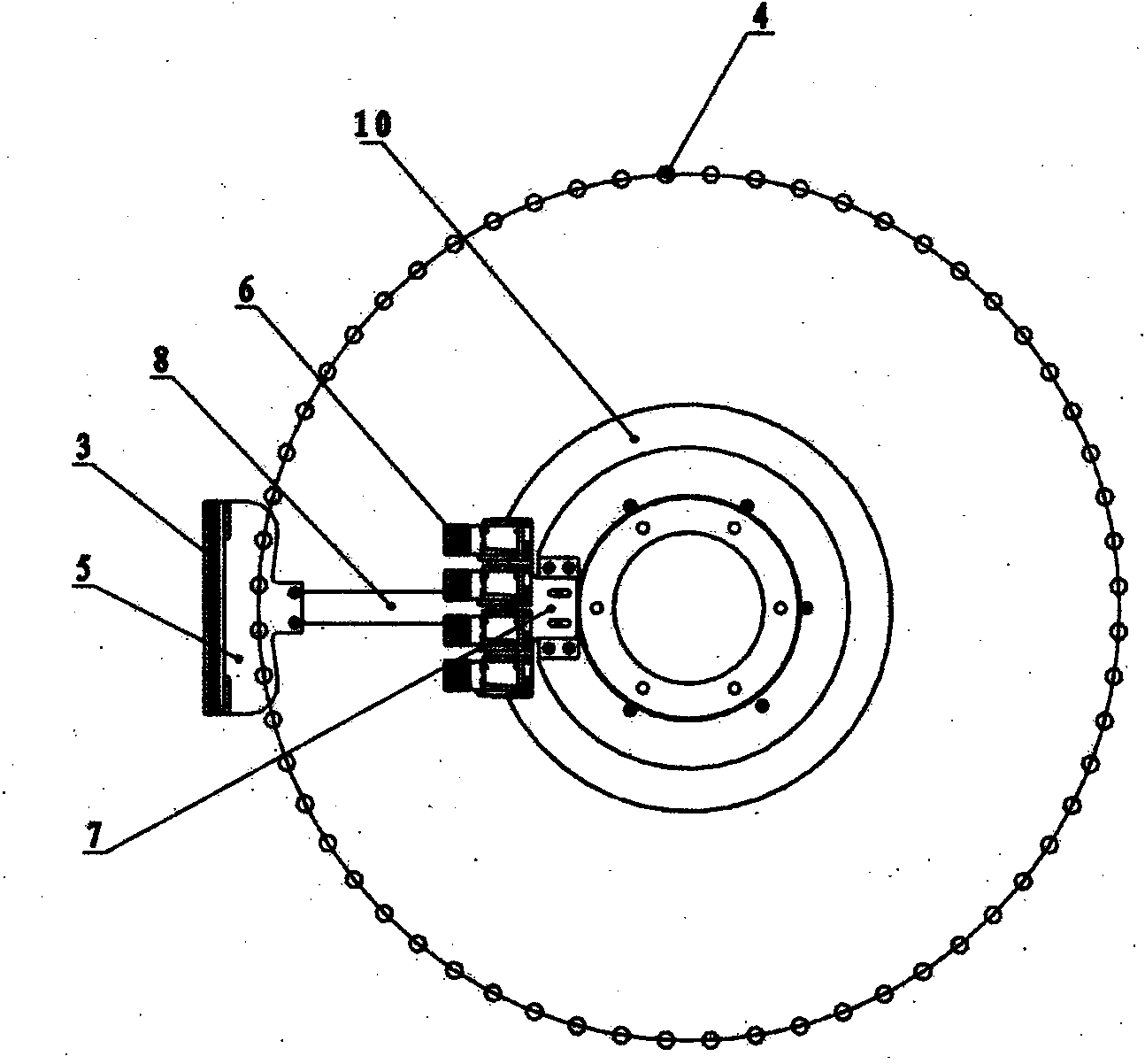

Image synchronous following acquisition device of ampoule bottle light inspection device adopting backlight

ActiveCN103512898AImprove detection efficiencyImprove detection accuracyOptically investigating flaws/contaminationEngineeringReducer

The invention provides an image synchronous following acquisition device of an ampoule bottle light inspection device adopting a backlight. The device is characterized by comprising a spindle, wherein the spindle is rotatably arranged in the central hole of a hollow direct-drive servo motor; the spindle is concentric with the hollow direct-drive servo motor; one end of the spindle is connected with a reducer; the reducer is connected with a main motor; the other end of the spindle is arranged in the center of a light inspection plate and fixedly connected with the light inspection plate; clamping jaws are arranged at the periphery of the light inspection plate; a to-be-inspected ampoule bottle is fixed on the clamping jaws; a hollow direct-drive servo motor output flange is fixed on the hollow direct-drive servo motor; the hollow direct-drive servo motor output flange is connected with a rocker arm; the rocker arm is fixedly connected with a backlight mounting plate and an industrial camera mounting plate; the backlight is arranged on the backlight mounting plate; an industrial camera is arranged on the industrial camera mounting plate; the to-be-inspected ampoule bottle is arranged between the backlight and the industrial camera. The device can complete image acquisition without halting, so that the inspection efficiency of the device is greatly improved.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

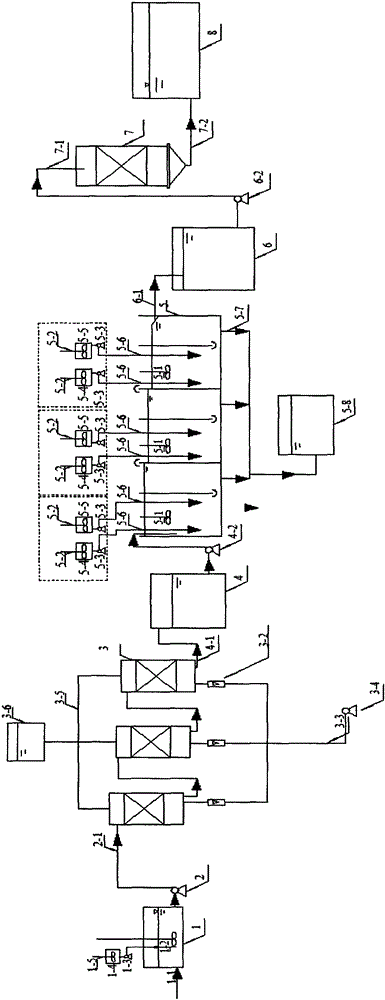

Garbage refinement pretreatment system and method for garbage incineration power plant

InactiveCN109489043AHigh fuel valueRealize sortingMagnetic separationIncinerator apparatusPower stationMagnetic separator

The invention discloses a garbage refinement pretreatment system and a method for a garbage incineration power plant, comprising a garbage storage pool and a sorting system, wherein the sorting systemcomprises a bag breaking machine, an intelligent sorting platform, a crusher and an extruder; a slurry outlet of the extruder is sequentially connected with a slurry pool and an oil-water separator;a solid outlet of the extruder is connected with a bouncing sieving machine; an oversize product outlet of the bouncing sieving machine is sequentially connected with a first magnetic separator, a first sorting machine, a disc sieving machine and a second sorting machine; the combustible material outlet of the second sorting machine is connected with a combustible storage bin; a screen underflow outlet of the bouncing sieving machine is sequentially connected with a second magnetic separator and a star disc sieving machine, and the combustible material outlet of the star disc sieving machine is connected with the combustible material storage bin. The pretreatment technology adopted by this system has advanced principle, good sorting effect; the sorting combustible material has high heat value and high single-line treatment capacity; therefore the pretreatment technology is a more optimized, more suitable, more economical and more reliable garbage refinement pretreatment technology.

Owner:QUJING YUNDIAN TOUXIN ENERGY POWER GENERATION

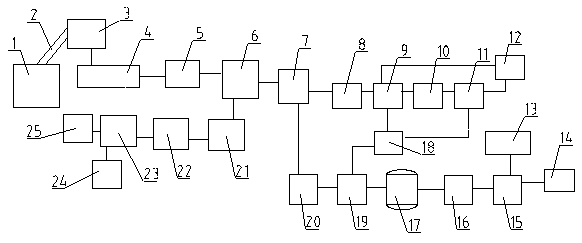

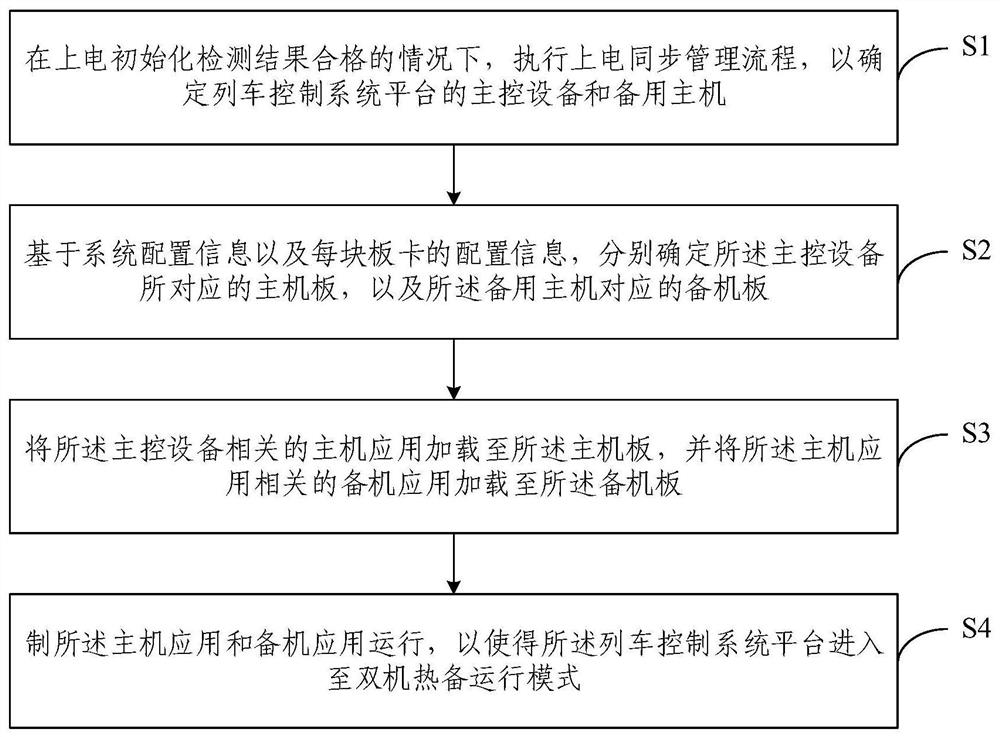

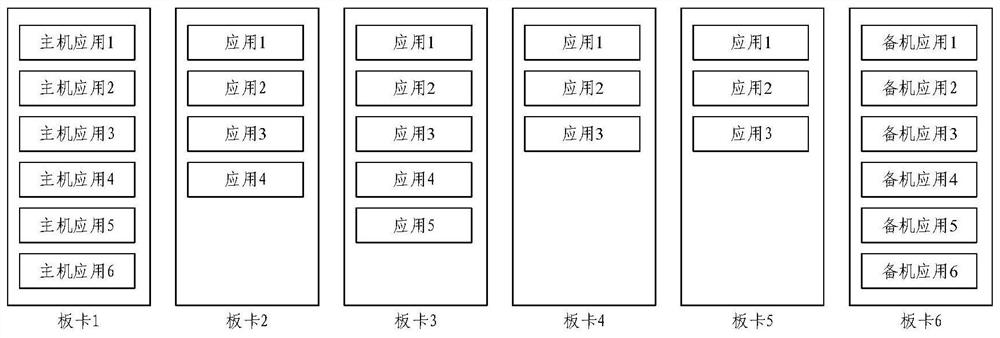

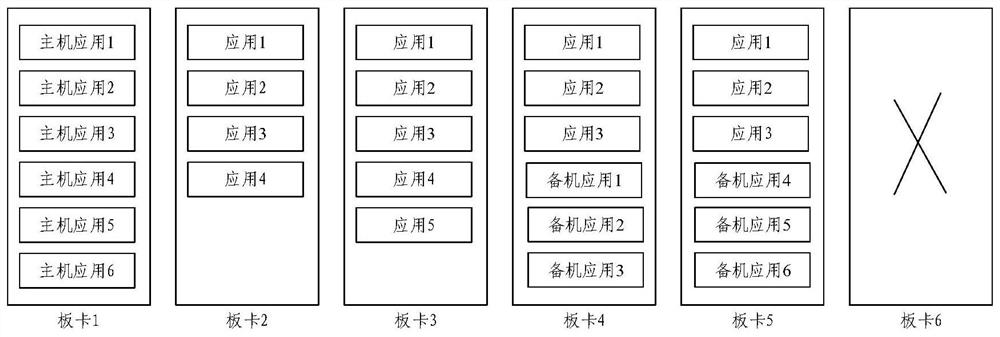

Dynamic redundancy backup method and system suitable for train control system platform

ActiveCN112477919AStable continuous operationMeet the design requirementsSignalling indicators on vehicleControl systemControl engineering

The invention provides a dynamic redundancy backup method and system suitable for a train control system platform, and the method comprises the steps: executing a power-on synchronization management flow under the condition that a power-on initialization detection result is qualified, so as to determine main control equipment and a standby host of the train control system platform; on the basis ofthe system configuration information and the configuration information of each board card, respectively determining a mainboard corresponding to the main control equipment and a standby board corresponding to the standby host; loading a host application related to the main control equipment to the mainboard, and loading a standby application related to the host application to the standby board; and controlling the host application and the standby application to operate to enable the train control system platform to enter a dual-computer hot standby operation mode. The invention provides a setof redundant backup processing logic, and the spare board card is dynamically utilized to deploy the backup application, so that the stable and continuous operation of the host and the spare machinecan be ensured, hardware resources are integrated and utilized to the greatest extent, the design requirements on main and spare redundancy are met, and higher safety and reliability are achieved.

Owner:TRAFFIC CONTROL TECH CO LTD

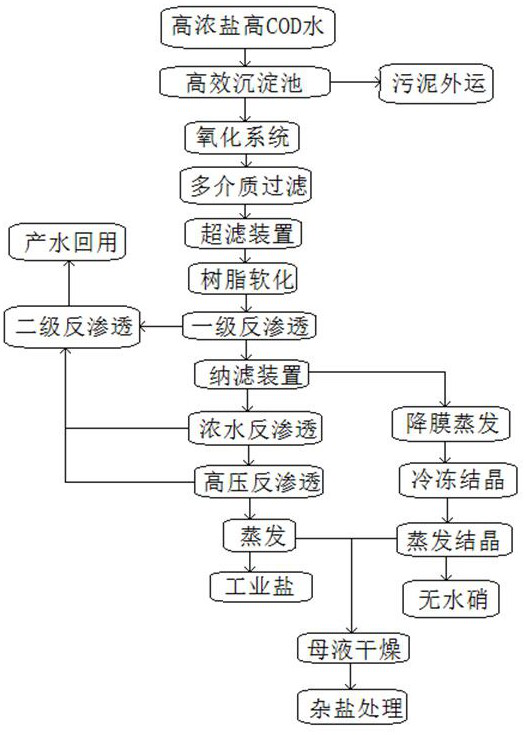

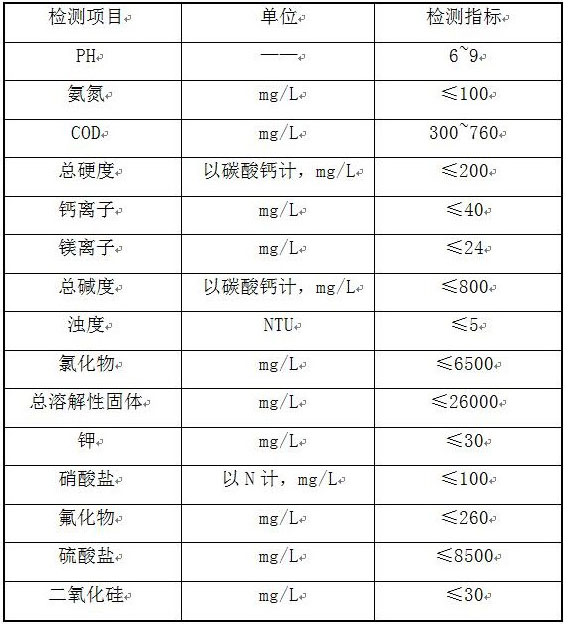

Integrated treatment system for recycling strong brine in coking wastewater and process thereof

PendingCN113955888AOvercoming large amount of sewageOvercome substandard salt contentWater treatment compoundsAlkali metal nitratesUltrafiltrationFiltration

The invention provides an integrated treatment system for recycling strong brine in coking wastewater and a process thereof. The integrated treatment system comprises an efficient sedimentation tank system, an advanced oxidation system, a multi-medium filtration system, an ultrafiltration system, a resin softening system, a primary reverse osmosis system, a nanofiltration system, a concentrated water reverse osmosis system, a high-pressure reverse osmosis system, an industrial salt evaporative crystallization system and a mother liquor drying system which are connected in sequence; the nanofiltration system is also connected with a nitrate evaporative crystallization system, and the nitrate evaporative crystallization system is also connected with the mother liquor drying system; the primary reverse osmosis system, the concentrated water reverse osmosis system and the high-pressure reverse osmosis system are respectively connected with a secondary reverse osmosis system; by adopting the scheme, the problems that COD / silicon dioxide is high in content and difficult to remove, the quality of crystal salt is low, the amount of impurity salt is large and the like can be effectively solved, water for a coking production process, a sodium chloride product and a sodium sulfate product are finally formed, and the purposes of zero emission and recycling after coking wastewater treatment are effectively achieved.

Owner:蓝星工程有限公司

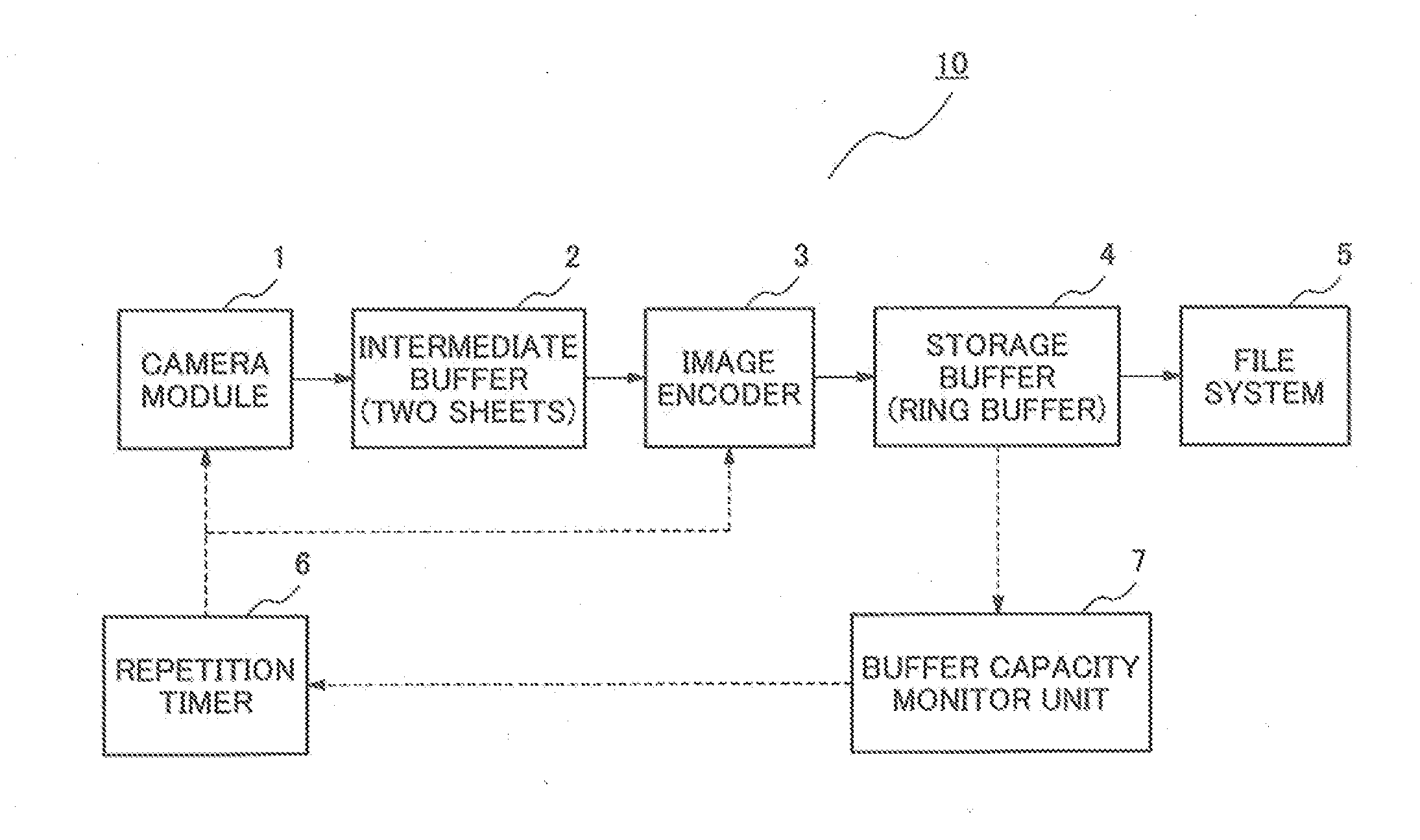

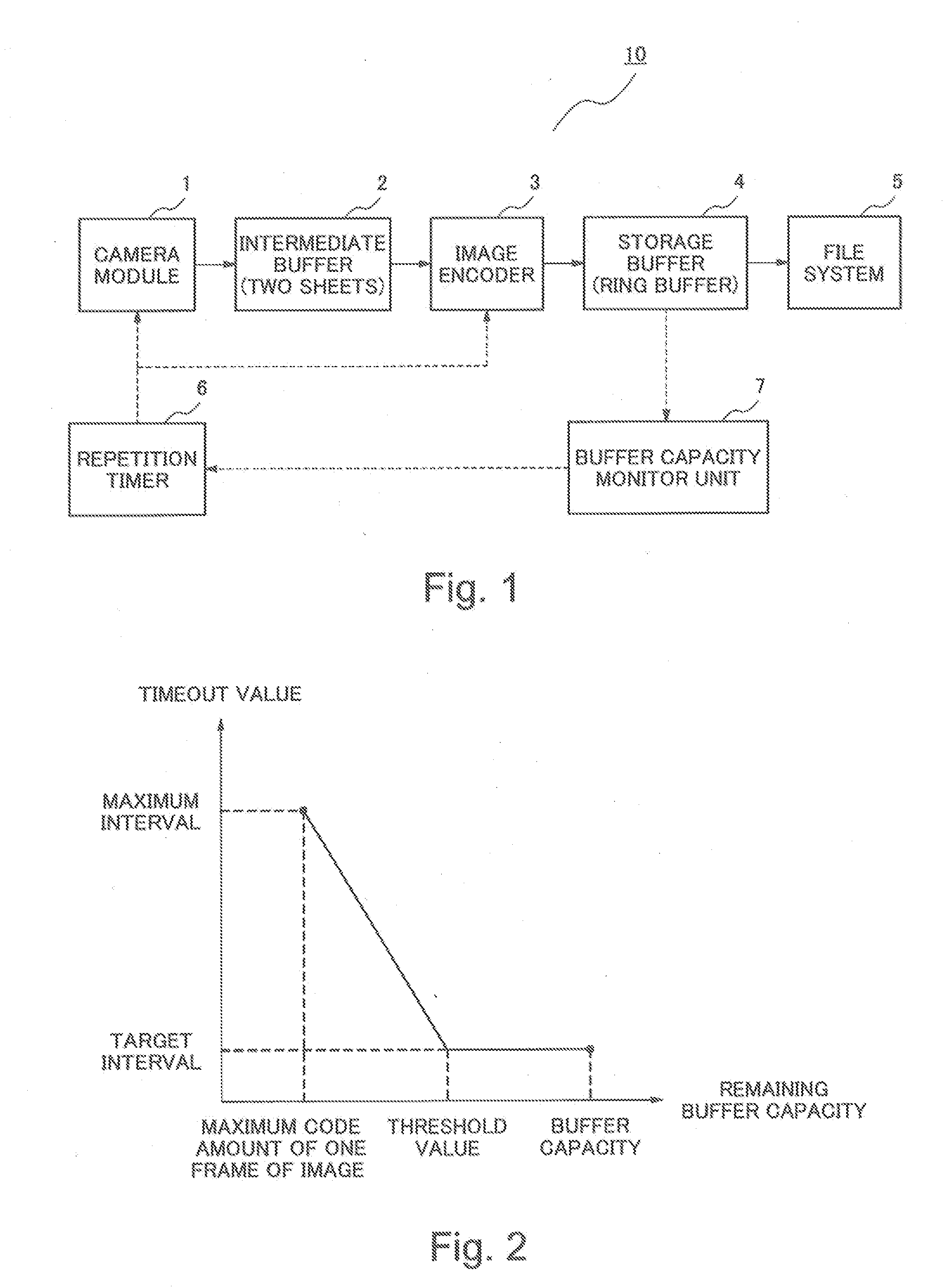

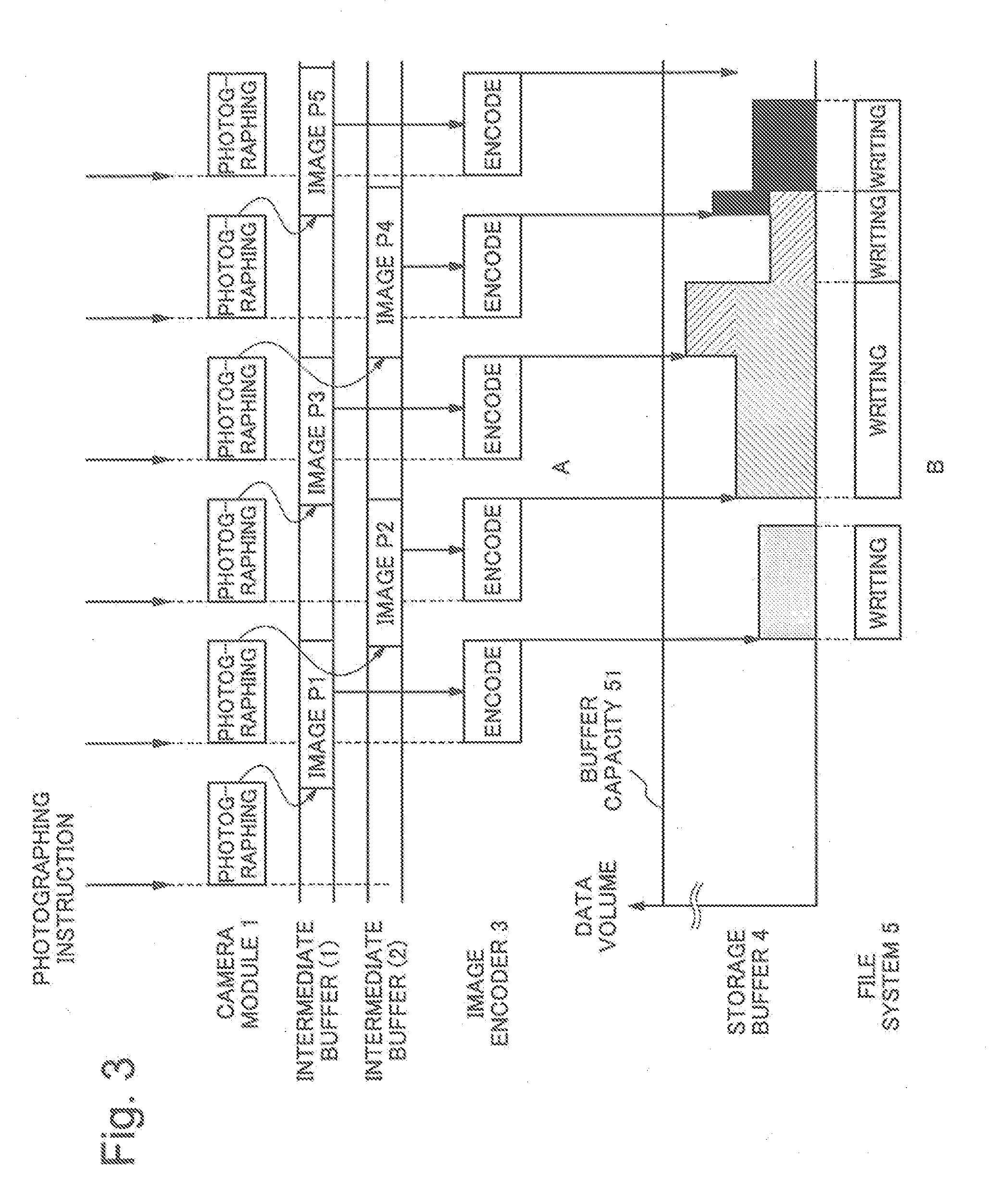

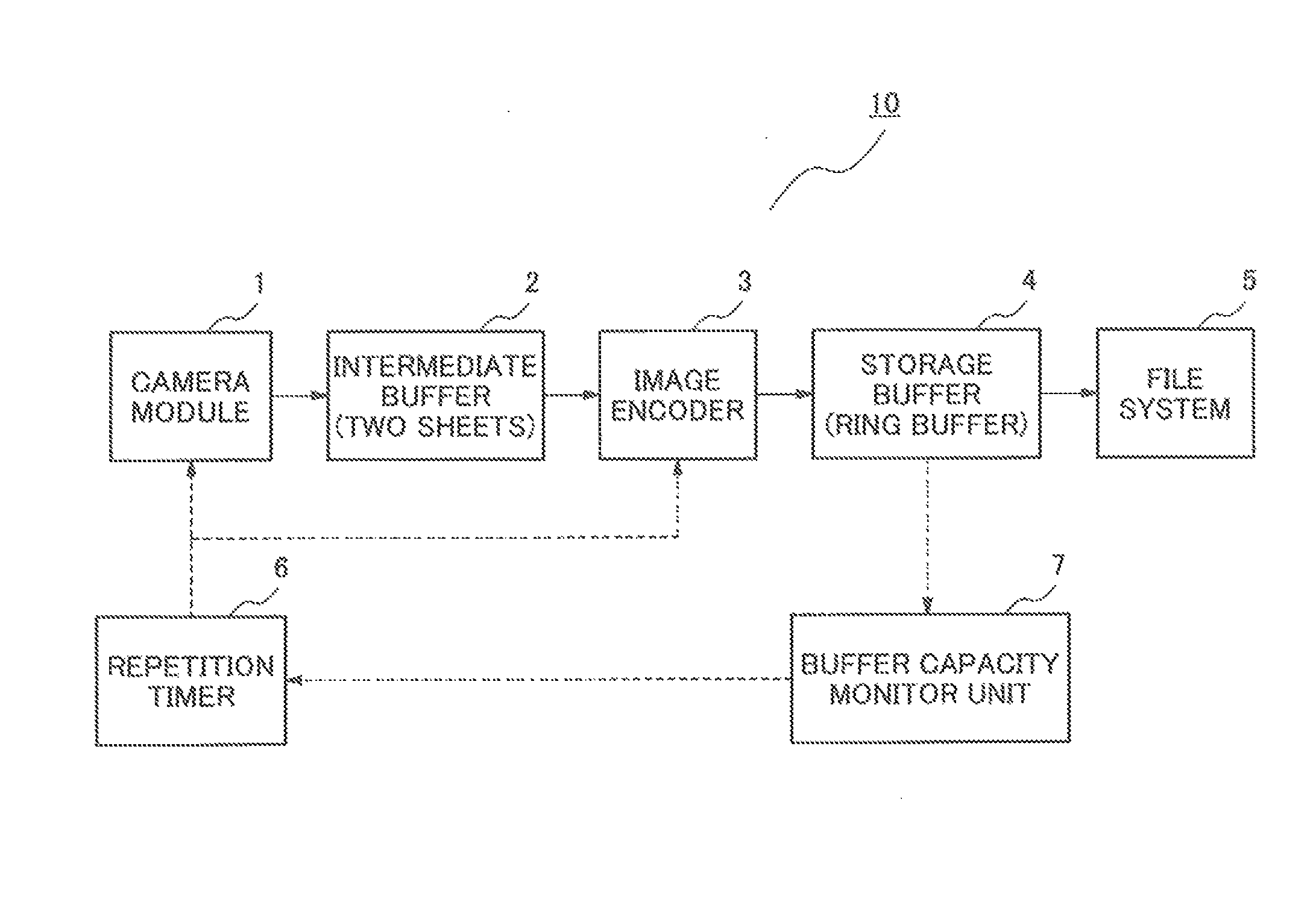

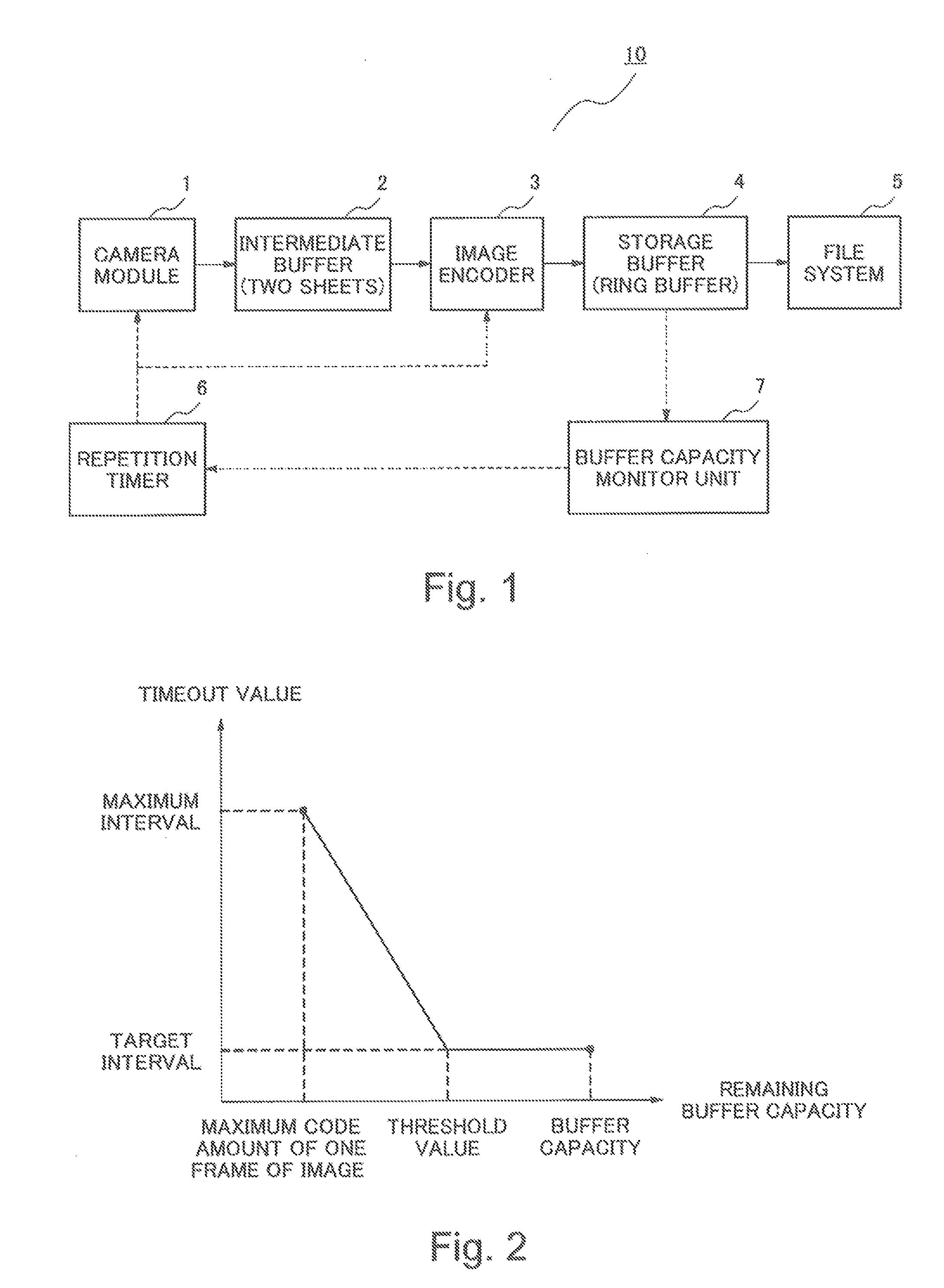

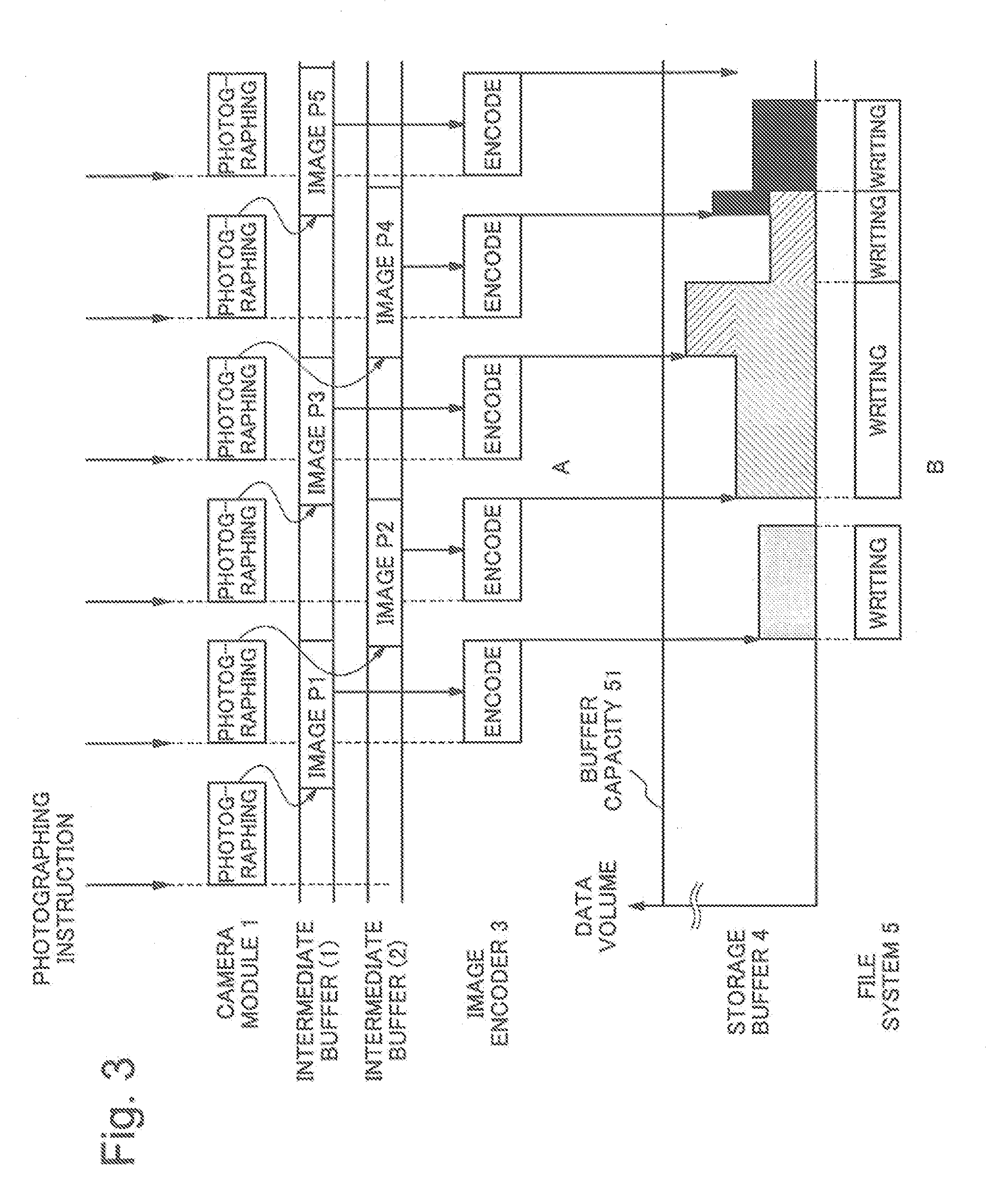

Imaging device, imaging method, and program

InactiveUS20100289917A1Stable continuous operationTelevision system detailsColor television detailsComputer visionImaging data

Owner:NTT DOCOMO INC

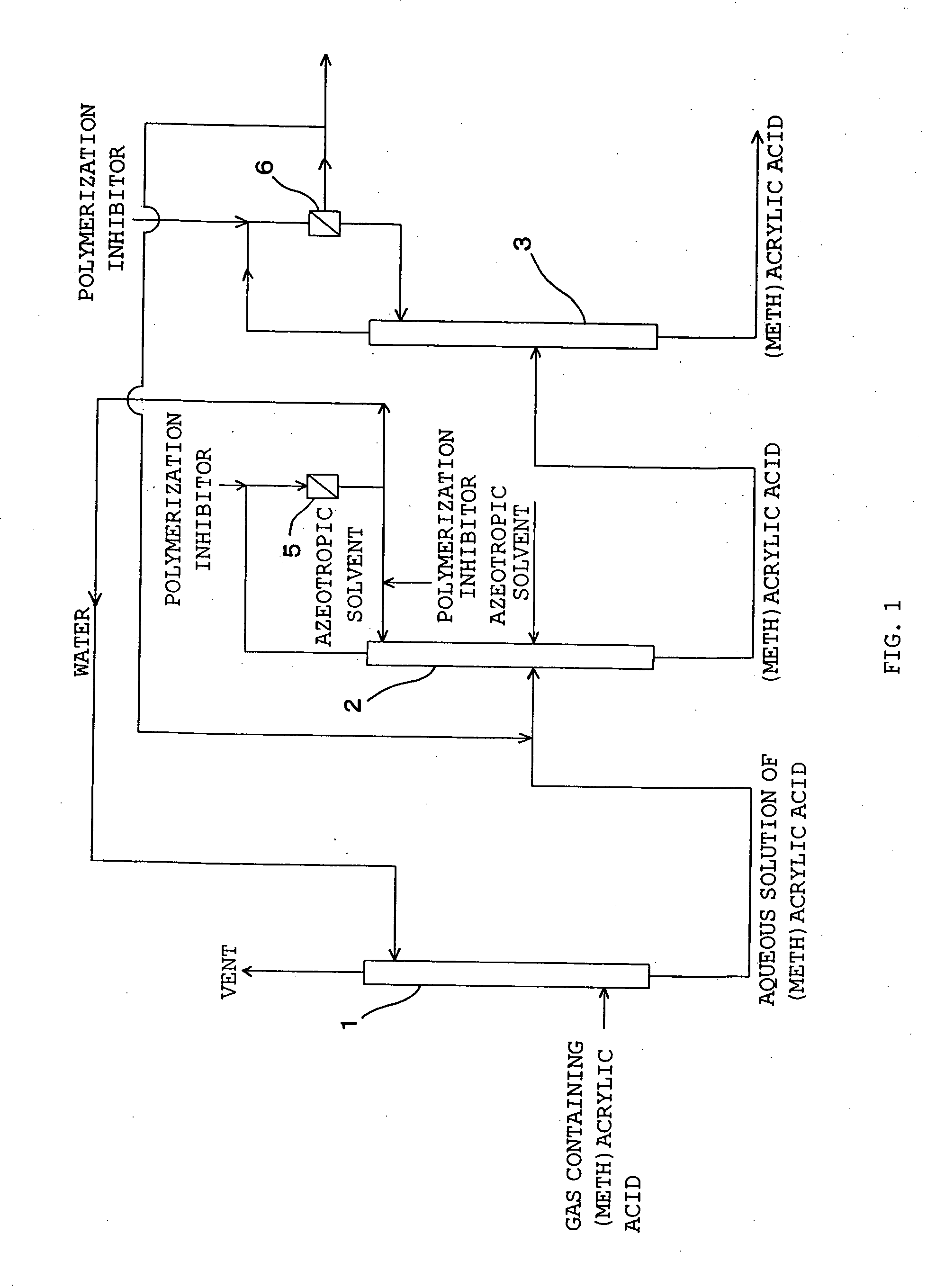

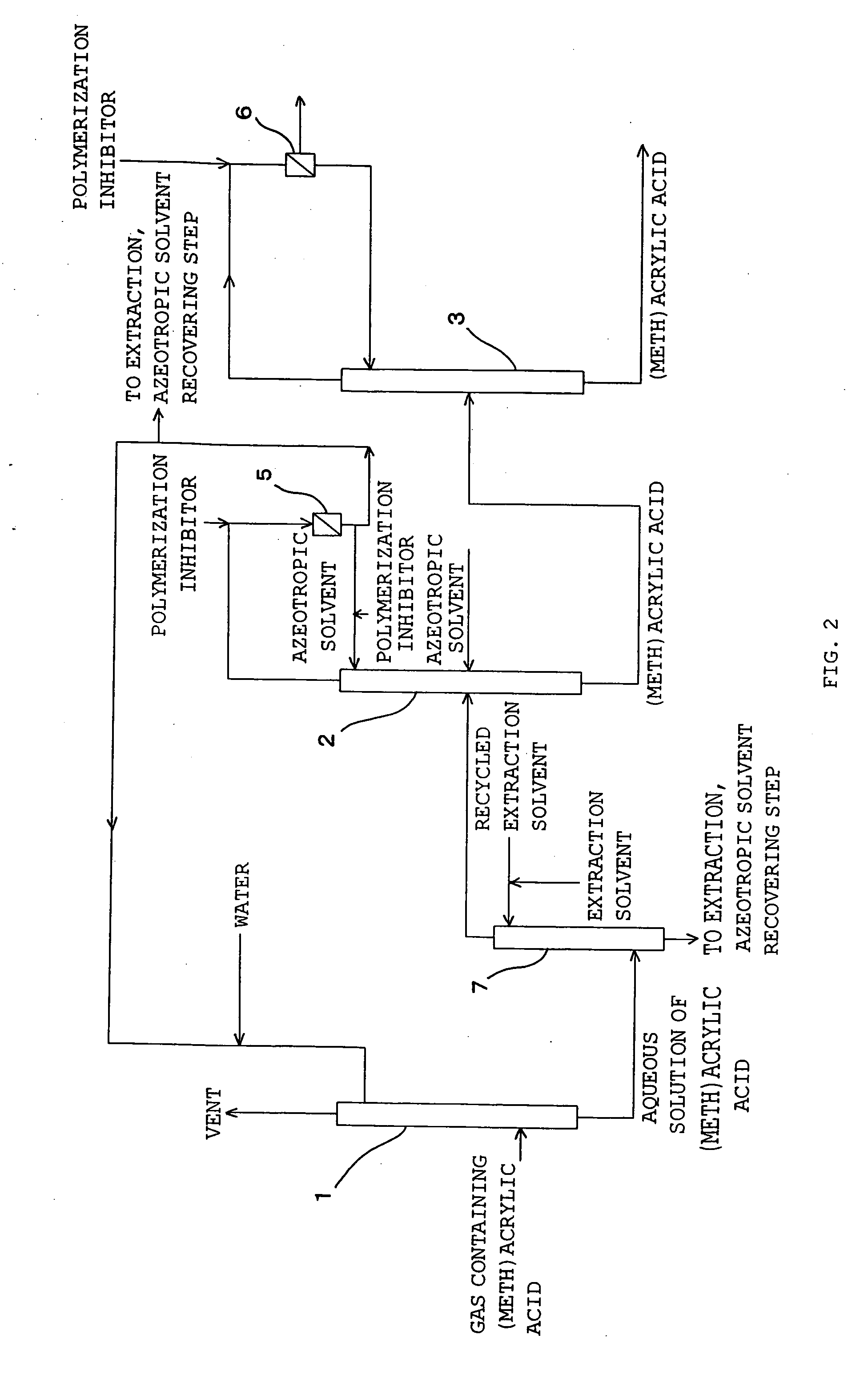

Method for producing (meth)acrylic acid

InactiveUS20070055079A1Avoid it happening againStable continuous operationOrganic compound preparationCarboxylic compound separation/purificationPolymer scienceMeth-

The present invention provides a method for suppressing an undesirable polymerization reaction of (meth)acrylic acid in a purification step for producing (meth)acrylic acid and for avoiding troubles due to clogging of devices or the like, to thereby attain a stable continuous operation. The present invention provides a method for producing (meth)acrylic acid comprising: distilling a water-containing liquid of (meth)acrylic acid containing (meth)acrylic acid and water by using a distillation column in the presence of an azeotropic solvent boiling together with at least water to remove water from the water-containing liquid of (meth)acrylic acid through azeotropy with the azeotropic solvent, in which the water-containing liquid of (meth)acrylic acid is distilled in the presence of the azeotropic solvent after distillation by the azeotropic solvent is carried out in the distillation column.

Owner:MITSUBISHI CHEM CORP

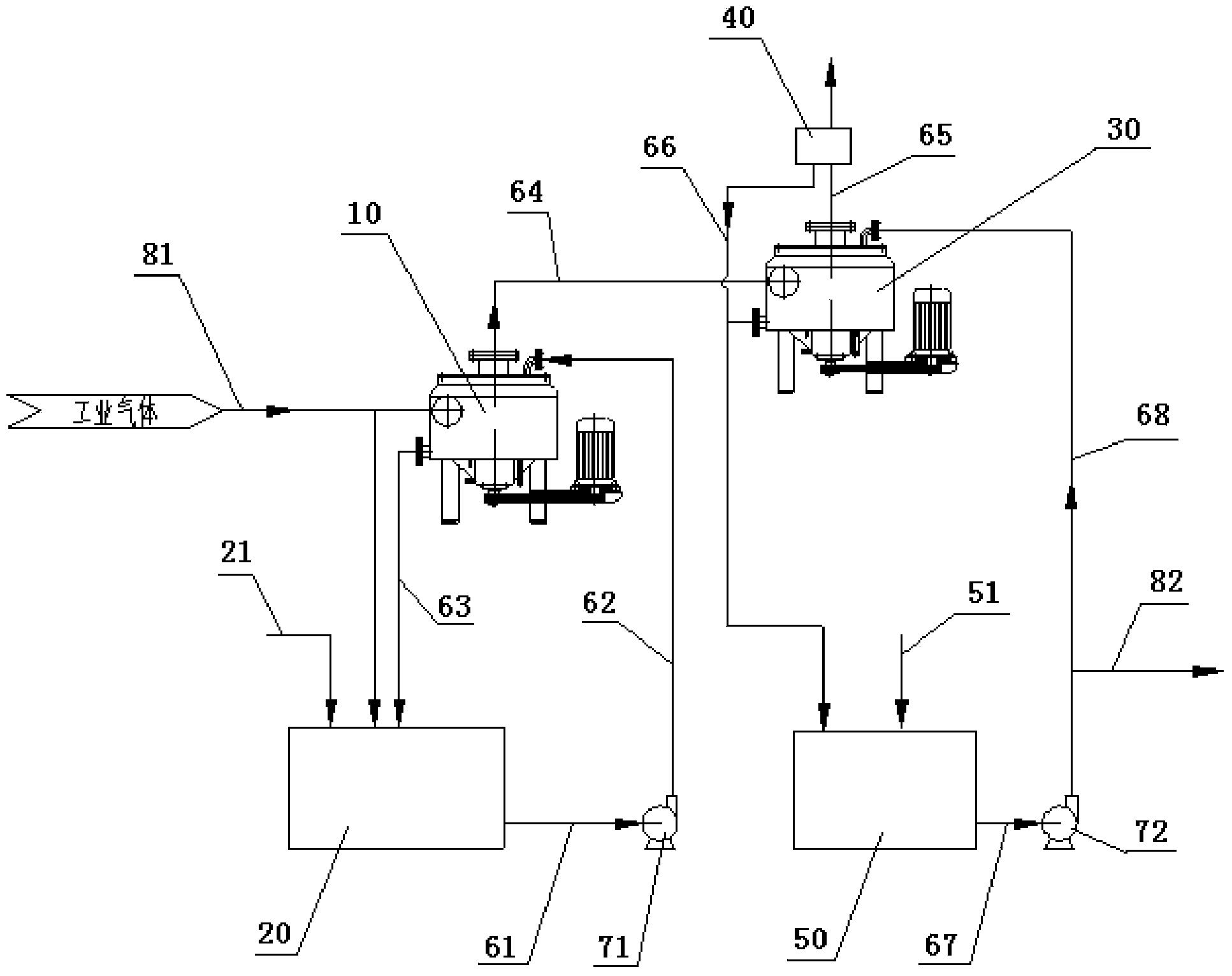

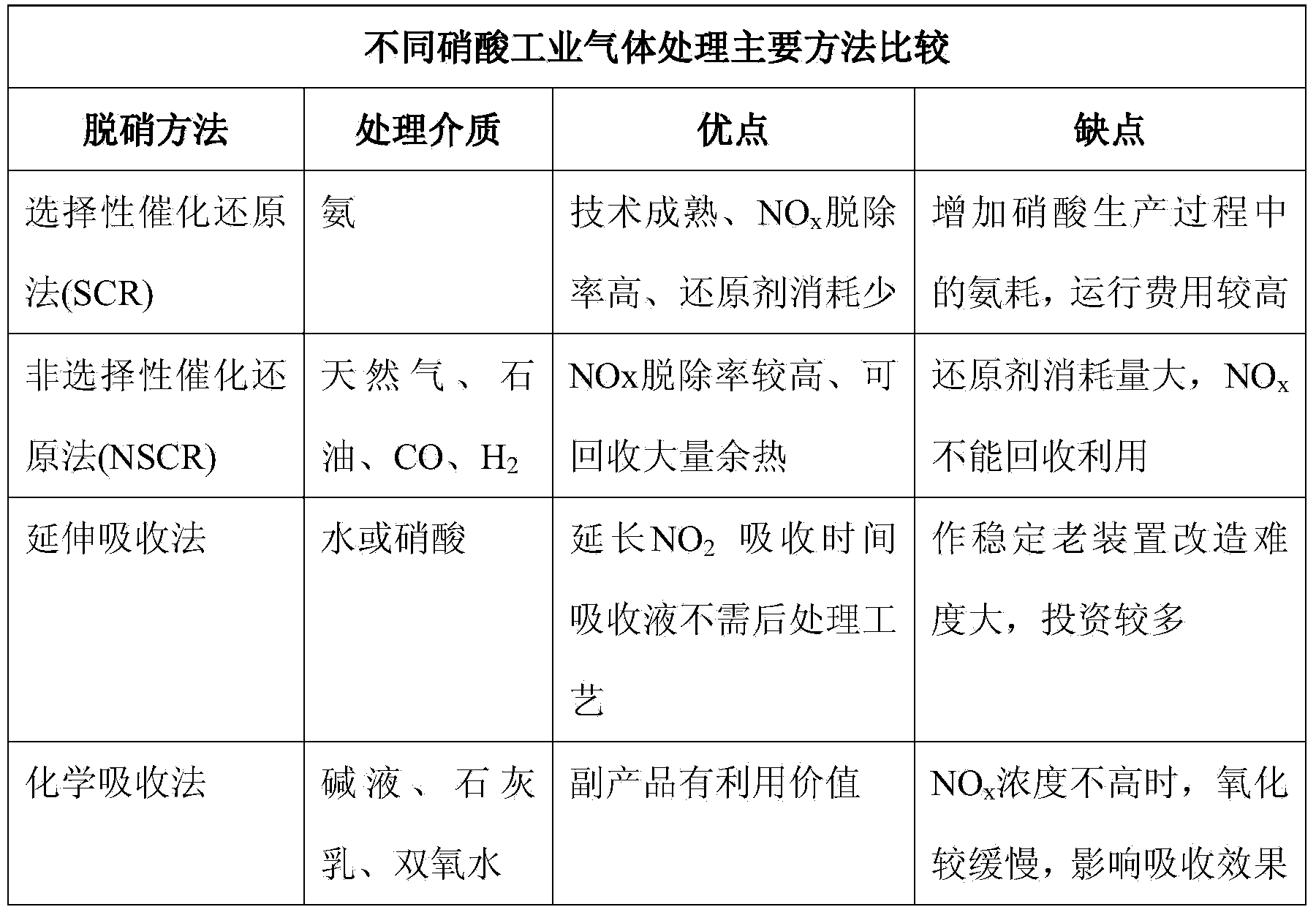

Device and process for removing NOx by hyper-gravity with high efficiency

InactiveCN103521055ASimple processStable continuous operationDispersed particle separationCirculating pumpContinuous operation

The invention discloses a device for removing NOx by hyper-gravity with high efficiency. The device comprises a hyper-gravity gas conditioner, a nitric acid circulating tank, a hyper-gravity lye absorber, a demister and a lye tank, wherein the nitric acid circulating tank is connected to a first circulating pump through a first pipe, and the first circulating pump is connected and communicated with the hyper-gravity gas conditioner through a second pipe; the hyper-gravity gas conditioner is connected to the nitric acid circulating tank through a third pipe; the hyper-gravity gas conditioner is externally connected with an pipe for conveying industrial exhaust which contains nitric acid gas or NOx; the hyper-gravity gas conditioner is connected to the hyper-gravity lye absorber through a fourth pipe; the hyper-gravity lye absorber is connected to the demister through a fifth pipe; the demister is connected to the lye tank through a sixth pipe; the lye tank is connected to a second circulating pump through a seventh pipe; a liquid outlet pipe is arranged on an eighth pipe. The device for removing NOx by hyper-gravity with high efficiency has the beneficial effects that the process flow is simple, the NOx removing efficiency can reach over 93%, continuous operation is stable, and the cost is low.

Owner:BEIJING UNIV OF CHEM TECH +1

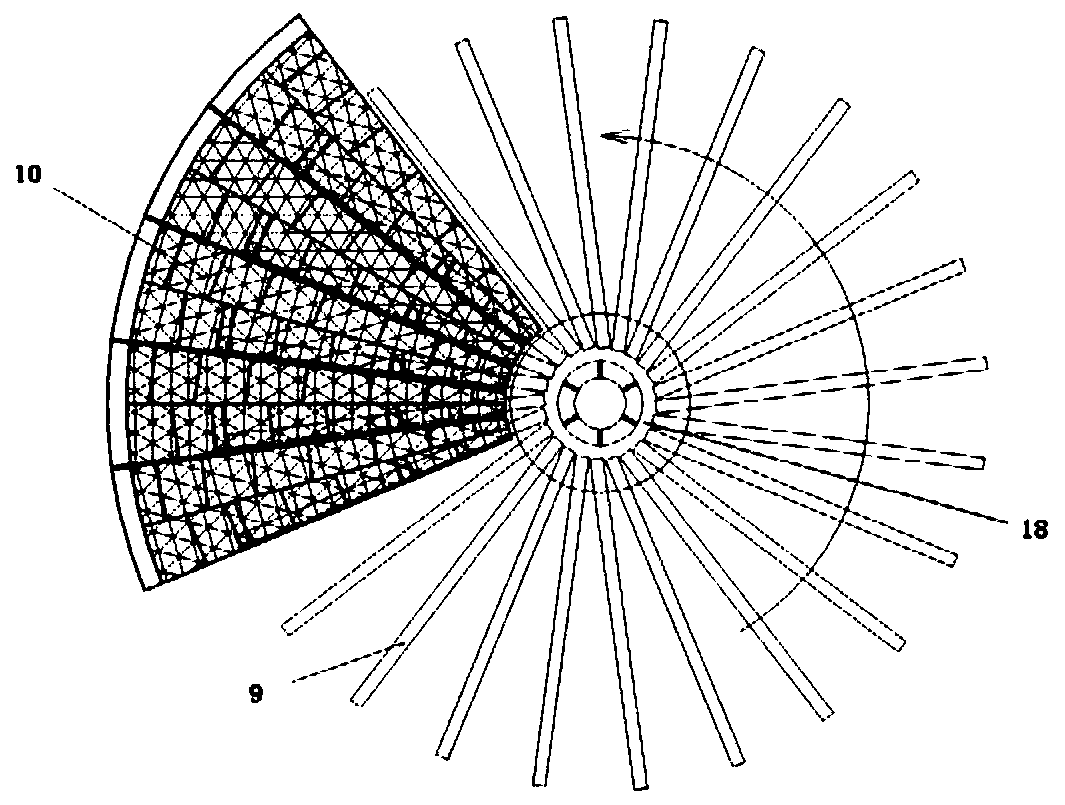

Turning plate material tray for material transfer

PendingCN111006498AGuaranteed continuous operationReduce frictionDrying chambers/containersDrying solid materialsRotational axisEngineering

The invention relates to a turning plate material tray for material transfer. The turning plate material tray includes turning plates distributed radially with a rotating shaft as a center, each turning plate is in a fan shape, the turning plates turn over around supporting rods so as to ensure that wet materials evenly fall into a lower layer material tray from an upper layer material tray, and aguide rail is provided with a gap with a cross section at one end and a curved surface at one end. When a low-temperature material dryer is started, the material trays of each layer are driven to rotate synchronously through the rotating shaft; the turning plates of the upper layer material tray turn downwards by taking the supporting rods as shafts under the action of gravity when rotate throughthe gap of the guide rail, and the actions of overturning, climbing and climbing horizontally are completed in turn. The wet materials on the turning plates further fall onto the lower layer materialtray, so that the transfer of the wet materials on the turning plates from the upper layer material tray to the lower layer material tray is realized.

Owner:北京水木益华环保科技有限公司

Radial cross-flow moving bed reactor for adsorbing and removing hydrogen sulfide at variable temperature

ActiveCN103768892AAchieve removalUniform feedingDispersed particle separationHigh concentrationEngineering

The invention discloses a radial cross-flow moving bed reactor for adsorbing and removing hydrogen sulfide at variable temperature. The reactor comprises a material discharging section, a reaction section and a material discharging section in sequence from top to bottom; due to arrangement of a material discharging structure of the material discharging section, uniform material discharging is guaranteed; due to the arrangement of a gas homogenization baffle at the reaction section, uniform distribution of fed gas in the axial direction and the radial direction is guaranteed, and gas inlet pressure drop is reduced; due to arrangement of an annular material discharging pipe and a funnel material discharging structure at the material discharging section, uniform material discharging is guaranteed, and the phenomenon that the downward moving speed of particles in the central region is higher than that of particles on the wall is avoided. The radial cross-flow moving bed reactor can be used for removing a large amount of hydrogen-sulfide-containing gas with high concentration and has the advantages of uniform material discharging, stable continuous running, low equipment investment and low running cost.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

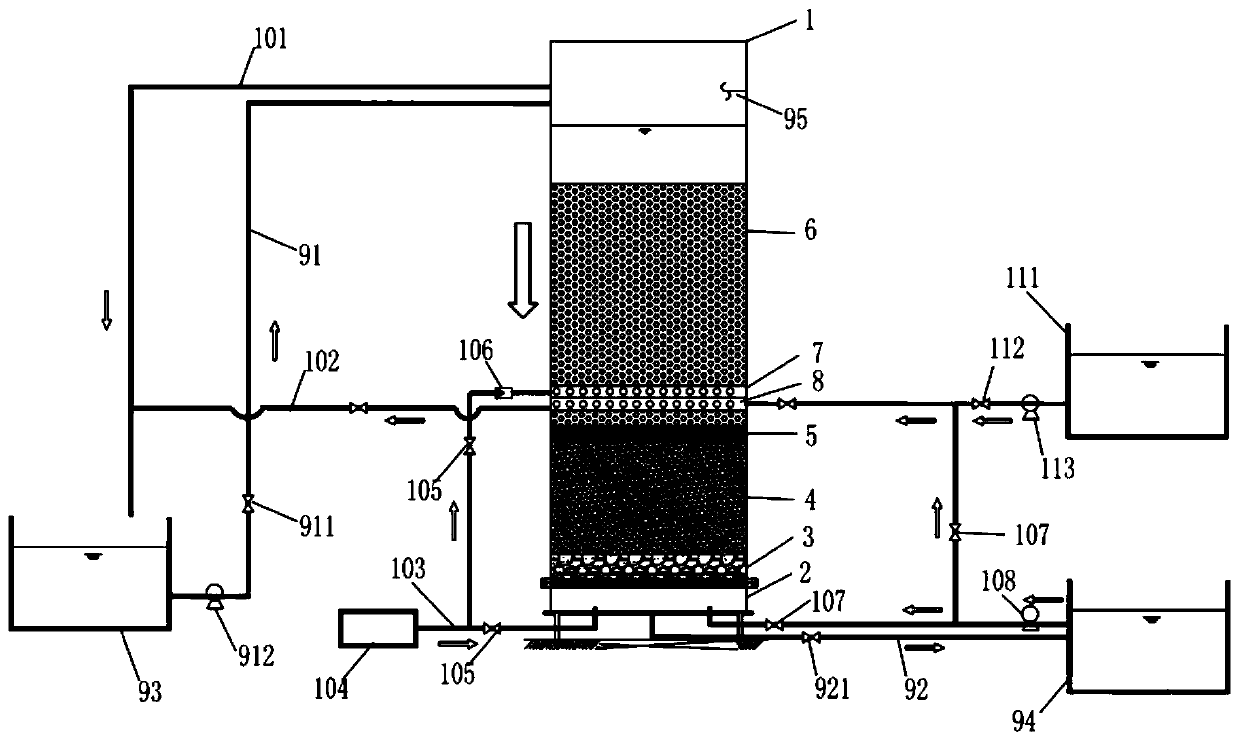

Efficient bio-degradation filter reactor and method for treating black odorous water bodies through efficient bio-degradation filter reactor

ActiveCN109704511AEnhanced denitrification and denitrificationWide range of actionWater treatment parameter controlTreatment using aerobic processesSpecific gravitySewage treatment

The invention discloses an efficient bio-degradation filter reactor and a method for treating black odorous water bodies through the efficient bio-degradation filter reactor, and belongs to the technical field of sewage treatment. The efficient bio-degradation filter reactor comprises a reactor column, wherein a bioreaction zone and a deep filtration zone are arranged inside the reactor column from top to bottom, an isolation layer composed of a flaky material is arranged at a boundary between the bioreaction zone and the deep filtration zone, and light suspension filler with a particle size of 2-4 mm is arranged in the bioreaction zone; and large-specific-gravity filler with a particle size of 1.0-2.0 mm is arranged in the deep filtration zone, and the specific gravity of the filler in the deep filtration zone is 2.5-3 times that of the filler in the bioreaction zone. Biodegradation of organic matter, denitrification, phosphorus removal and removal of fine suspended solids are integrated into one by the reactor, and the reactor is applied to treatment of black odorous water bodies, so that the surface water bodies of a V class and an inferior V class are gradually improved into water bodies of a IV class or above, and the problem of pollution of the black odorous water bodies is solved fundamentally.

Owner:HUNAN HENGKAI ENVIRONMENT TECH INVESTMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com