Turning plate material tray for material transfer

A technology of turning plate and feeding tray, which is applied in the direction of drying solid materials, dryers, lighting and heating equipment, etc. It can solve the problems of wet materials staying on the feeding tray, poor drying effect, and increased equipment complexity, etc., to achieve Ensure continuous operation, reduce friction and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

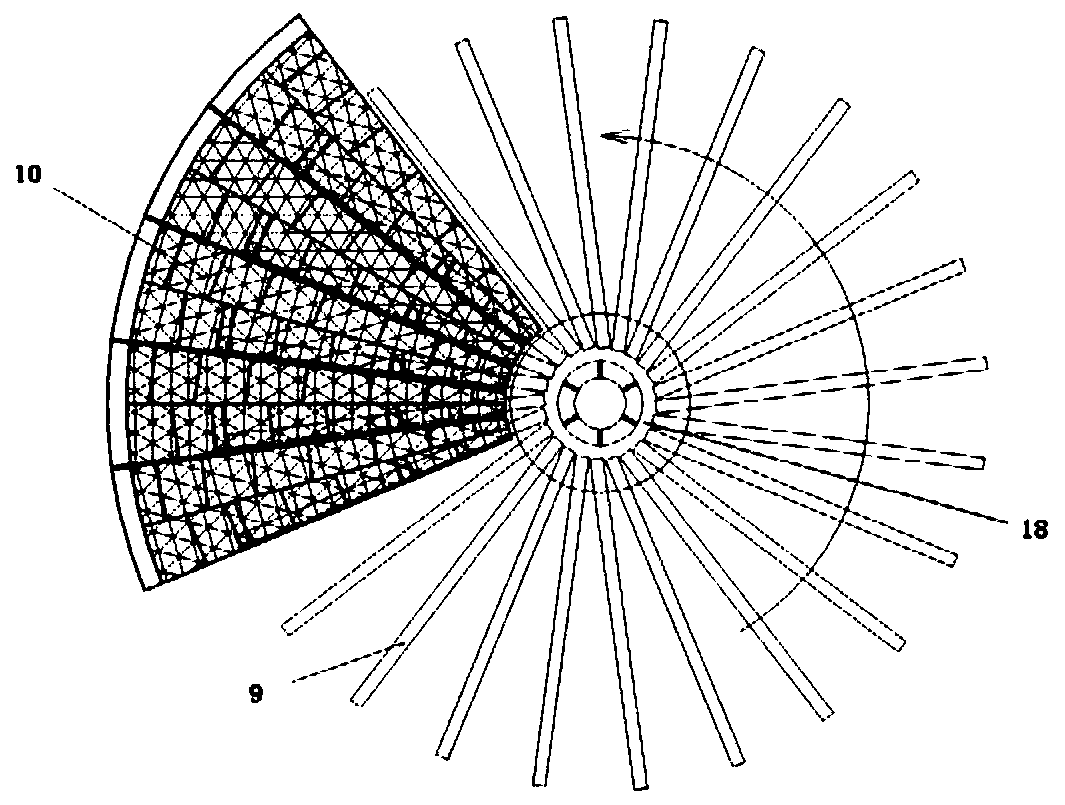

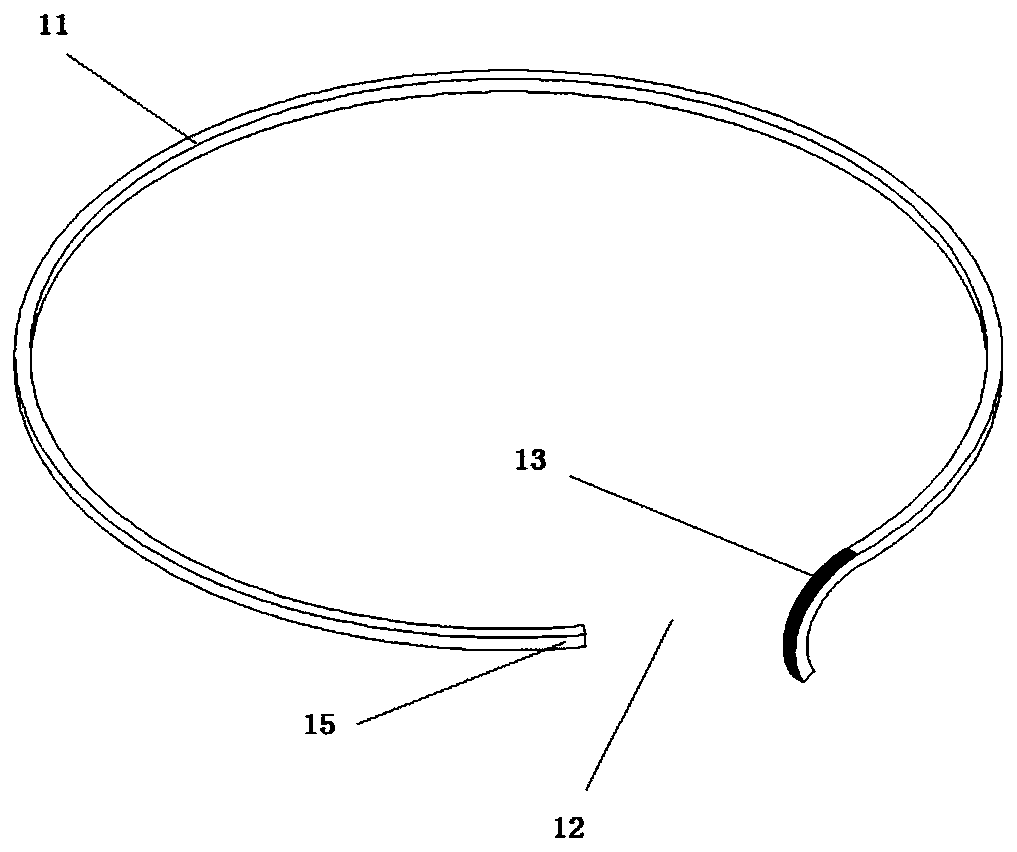

[0031] In order to solve the problem of the wet material being turned inside and outside on the tray and the transfer between the upper and lower trays, the present invention designs the tray as a fan-shaped flap assembly, and the flaps perform flipping, climbing, and leveling actions one by one , in this process, the material on the turning plate falls to the lower tray under the action of gravity, and the transfer of wet material is completed without any tools.

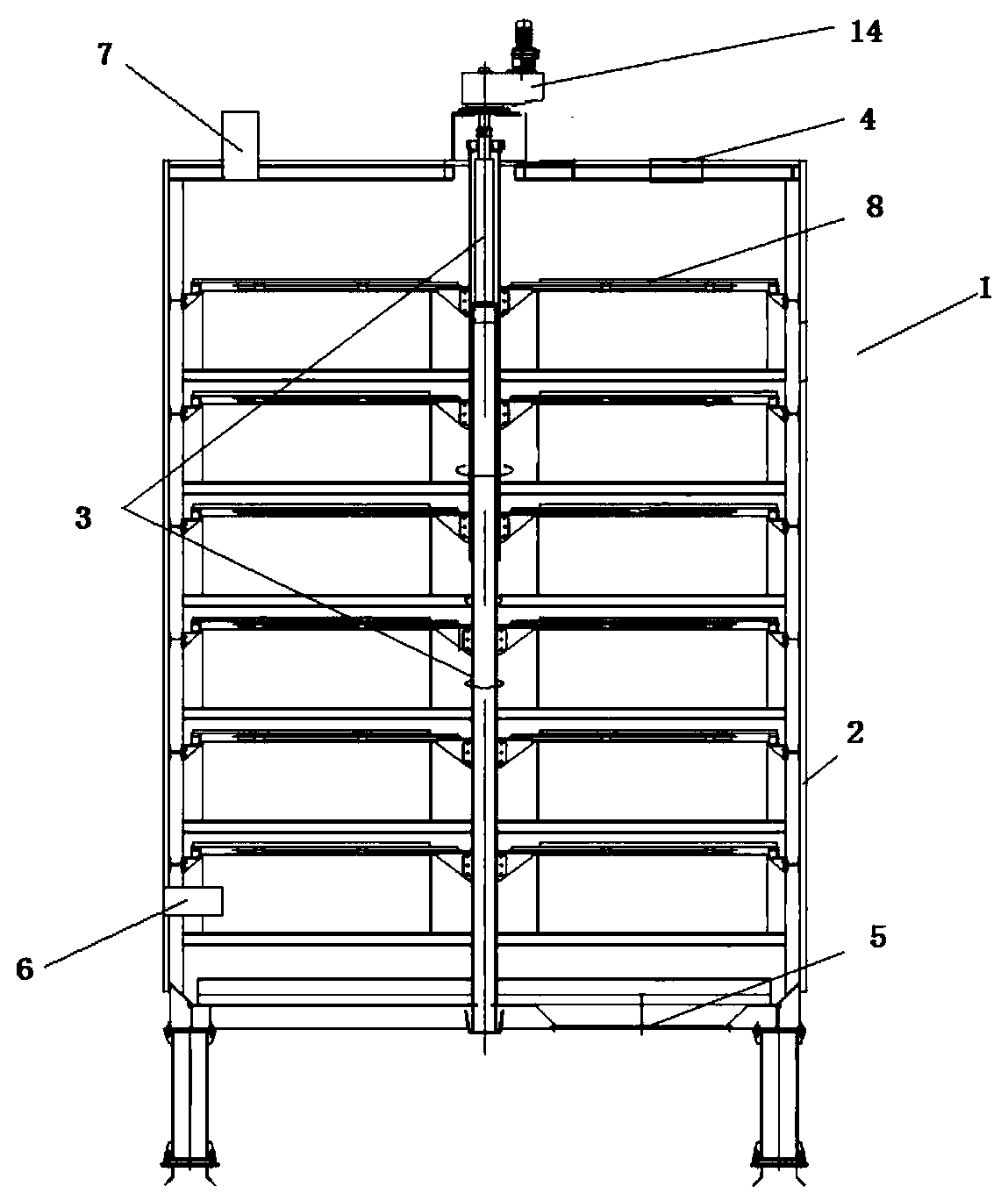

[0032] Such as figure 1 As shown, the low temperature material dryer includes a drying chamber 1, the hot air inlet 6 at the bottom of the drying chamber 1 is connected to the air outlet of the heat pump, and the cold air outlet 7 at the top of the drying chamber 1 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com